- DL manuals

- Magiglo

- Indoor Fireplace

- Elite ET16

- User, Installation & Servicing Instructions

Magiglo Elite ET16 User, Installation & Servicing Instructions

Users,

Installation & Servicing

Instructions

MUST BE LEFT WITH THE USER

ELITE

Models:

ME16T & ME18T

16” & 18” Fires

ET16 & ET18

16” & 18” Fires c/w Thermobox

EV16 & EV18

16” & 18” Victorian Fires

(LPG models prefixed with the letter L)

Fuel Effect Options:

Coal Effect – NG and LPG

Pebble Effect - NG Only

Control Options:

Manual Control

Remote Control (Response-S)

Optimum Control

Trim Switch Control

For use on Natural Gas (G20) at a supply pressure of 20mbar

or Propane (G31) at a supply pressure of 37mbar in GB and IE

(Dependent upon model)

Summary of Elite ET16

Page 1

Users, installation & servicing instructions must be left with the user elite models: me16t & me18t 16” & 18” fires et16 & et18 16” & 18” fires c/w thermobox ev16 & ev18 16” & 18” victorian fires (lpg models prefixed with the letter l) fuel effect options: coal effect – ng and lpg pebble effect - ng...

Page 2

Manufacturer contact details: burley magiglo lands end way oakham, rutland, le15 6rb tel: +44 (0)1572 725570 fax: +44 (0)1572 724390 general e-mail: info@magiglo.Co.Uk web site: www.Magiglo.Co.Uk technical support: direct dial on (01572) 725570 or email: technical@magiglo.Co.Uk magiglo document numb...

Page 3: Contents

Page i contents 1. General information ........................................................................................................... 1 1.1. Important note about ods pilot ................................................................................ 2 1.2. Fire fret dimensions .........

Page 4

Page ii 3.9. Installation procedure (fire) ..................................................................................... 36 3.9.1. Continuation of installation - remote control model ......................................... 36 3.9.2. Continuation of installation - optimum control model .......

Page 5: 1. G

Page 1 1. G eneral i nformation introduction 1. This appliance is suitable for installation in gb and ie and should be installed in accordance with the rules in force. In gb, the installation must be carried out by a corgi registered installer. It must be carried out in accordance with the relevant ...

Page 6

Page 2 makes clear the conditions that must be met to demonstrate that sufficient ventilation is available. 2. Models with heat inputs in excess of 6.9kw require a minimum of 100cm 2 ventilation in the room where the fire is installed when installed in great britain (gb) and in ie, reference should ...

Page 7: 1.2. Fire Fret Dimensions

Page 3 1.2. Fire fret dimensions all models can be used with the burley magiglo range of frets or any other fire fret that falls within the dimensions shown below the fireplace opening must be suitable in size to accommodate the fire being installed. If the appliance is to be used with other firepla...

Page 8

Page 4 this page is left intentionally blank.

Page 9: 2. U

Page 5 2. U ser i nstructions 2.1. Lighting procedure your fire will be fitted with one of the following different types of gas control valves. Identify the control system on your fire as shown and follow the appropriate operating instructions in the appropriate section. Control valve operation cont...

Page 10

Page 6 2.1.1. Lighting procedure (manual bm control) 1. Ensure that the arrow on the control knob is pointing towards the off position as shown in figure 2 . Press in the knob and slowly turn anti-clockwise until a click is heard. The spark should now light the pilot. On first lighting, it may requi...

Page 11

Page 7 2.1.2. Lighting procedure (manual mertik control) 1. Whilst pushing the ignition knob in (see figure 6 ), turn it anticlockwise to the pilot flame position as shown in figure 7 . During this process, the spark ignition will have operated and lit the pilot flame. On lighting the pilot flame co...

Page 12

Page 8 2.1.3. Lighting procedure (remote control) 1. Press the bottom button on the remote handset until clicking is heard on the valve, and the gas rate adjustment knob is at the off position. 2. With gas available at the valve press the ignition knob in and turn it anticlockwise to the pilot flame...

Page 13

Page 9 2.1.4. Lighting procedure (optimum control and trim switch control) 1. Ensure the main burner is off by pressing the button on the trim marked (‘small flame/dot’) until clicking is heard on the valve (see figure 12 / figure 13 ). 2. With the gas available at the valve press in the ignition kn...

Page 14

Page 10 2.2. Battery replacement (remote control) 2.2.1. Handset 1. On the reverse of the handset remove the battery cover by pressing down at the top of the cover and sliding down. 2. Remove and unclip the old battery and replace with a new pp3 9v battery. 3. Replace the cover. Figure 15 – handset ...

Page 15

Page 11 2.3. Battery replacement (optimum control) 1. The battery pack is mounted inside the wall-mounting box behind the wall switch plate. 2. To change the batteries remove the two small screws securing the wall plate using a small screwdriver. 3. Remove the battery pack from the wall box and repl...

Page 16: 2.5. Fuel Effect Layout

Page 12 2.5. Fuel effect layout you fire has been supplied with either coal or pebble effect. Please refer to the relevant section for instructions on how to arrange the imitation fuels. Fuel effect tray type refer to coal effect natural gas & lpg section 0 pebble effect natural gas section 2.5.2 it...

Page 17

Page 13 for clarity, the coal effect layouts start on the next page.

Page 18

Page 14 2.5.1. Coal effect layout this fire is supplied with different sizes of ceramic coal, with the quantity supplied being dependant upon the type of burner: e16 e18 ev16 ev18 small square coals 6 7 6 7 medium square coals 9 10 9 10 random coals 21 24 20 25 half size coals 3 (lpg only) 4 (lpg on...

Page 19

Page 15 medium square coals aeration tubes small square coals half size coals (lpg only) random coals figure 22 – elite 16” victorian medium square coals aeration tubes small square coals half size coals (on lpg burners only) random coals figure 23 – elite 18” victorian.

Page 20

Page 16 2.5.2. Pebble effect layout (natural gas only) the fire is supplied with ceramic pebble sets as follows:- e16 e18 ev16 ev18 large pebbles (a, b & k) 18 22 15 18 medium pebbles (c & d) 3 4 8 10 flat pebbles (h) 4 4 4 4 front pebbles (e) 6 7 6 7 aeration tubes 4 6 4 6 for models me16 and et16 ...

Page 21

Page 17 16” taper first layer second layer front and third layers top layer h h h h large pebbles (a & b) aeration tubes large & medium pebbles (c, d & b) pilot large pebbles (k) front pebbles (e) equally placed flat pebbles (h) large pebbles (a & b) large pebbles (a) figure 24 – elite 16” fire 18” ...

Page 22

Page 18 16” victorian k k k k c d k k k k aeration tubes h pebbles e pebbles k pebbles a&b pebbles c&d pebbles base layer second layer a,b, c,d & f pebbles front and top layer figure 26 – elite 16” victorian 18” victorian k k k k k k k k k k c d aeration tubes h pebbles e pebbles k pebbles a&b pebbl...

Page 23: 2.7. Home Improvements

Page 19 2.7. Home improvements warning: if after installation of this fire any home improvements (e.G. Double glazing, secondary double glazing, draught proofing, fitting extractor fans, laminate flooring etc.) are carried out to the property it is essential to carry out a spillage test on the fire ...

Page 24

Page 20 2.8. Cleaning and care instructions caution: ensure that the appliance is off (including the pilot light) and has completely cooled (off for at least 2 hours) before carrying out any cleaning or maintenance. Rcf advice: this product may use components (coals, pebbles & ceramic backs) contain...

Page 25

Page 21 2.8.2. Cleaning the pilot the oxygen depletion sensing pilot fitted to your burley magiglo fire is a highly reliable safety device which causes the fire to shut down in the unlikely event of a reduction of oxygen in the room where the fire is fitted. After a period of time, it is possible fo...

Page 26

Page 22 2.8.5. Brass or chrome surfaces these surfaces should be cleaned with a proprietary non-abrasive metal cleaner. Remove the trim (if fitted), the fret and the ash-pan cover before cleaning. The trim is held in place by means of four magnets at the rear of the trim. The fret and the ash-pan co...

Page 27: 3. I

Page 23 3. I nstallation i nstructions before installation, ensure that the local distribution conditions (identification of the type of gas and pressure) and the adjustment of the appliance are compatible 3.1. General safety requirements before commencing installation, ensure that the intended inst...

Page 28

Page 24 3.2.2. Installation of burley magiglo elite 16” models (only) into a 125mm (5”) class 2 metal flue system 16” elite thermobox pack incorporating trim switch control should not be installed on a 5” (125mm) flue system due to increased switch temperatures caused by the reduced flue flow. Burle...

Page 29

Page 25 3.2.4. Installation example using existing building opening (16” elite 6.9kw models only) register plate 125mm (5”) flexible liner section through masonry chimney 90 m m mi n figure 32 3.2.5. Installation example using existing milner (clay) fireback (16” elite 6.9kw models only) 125mm (5”) ...

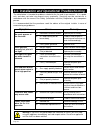

Page 30: 3.3. Technical Data

Page 26 3.3. Technical data natural gas models all 16” models (me16t, et16 and ev16) all 18” models (me18t, et18 and ev18) nominal maximum heat input 6.9 kw (gross) 8.25 kw (gross) setting pressure (cold) 5.6 mbar ±0.2 mbar 7.4 mbar ±0.2 mbar minimum heat input 4.0 kw (gross) 4.0 kw (gross) minimum ...

Page 31: 3.4. Burner Tray Layouts

Page 27 3.4. Burner tray layouts burner board pilot control valve pressure test point silencer chamber grub screw pilot control valve silencer chamber pressure test point grub screw lpg model with bm valve natural gas model with bm valve burner board figure 34 – burner tray layout.

Page 32: 3.5. Appliance Location

Page 28 3.5. Appliance location the fire must be fitted on a flat non-combustible base. In addition a non-combustible hearth or physical barrier with minimum dimensions shown in figures below should be provided in front of the fireplace opening where relevant. However, with hole in the wall fire ins...

Page 33

Page 29 3.5.1. Floor level and raised fireplace openings ow o h od hw hd 50mm figure 35 ow o h od hw hd 50mm figure 36 16” models 18” models oh for use in calculating flue diameter for use in calculating flue diameter ow a minimum of 400mm a minimum of 450mm od a minimum of 200mm when using elite ta...

Page 34

Page 30 3.5.2. Physical barrier any physical barrier should meet the following requirements: 1. Provide at least the equivalent level of warning to the approach of an open fire, to that of a hearth. 2. Define a clear zone where occupants must exercise additional caution. 3. Should be constructed of ...

Page 35

Page 31 figure 42 , figure 43 , figure 44 and figure 45 show examples of how the requirements for the physical barrier may be met. D w figure 42 – example of physical barrier (dimensions as stated in table 2 – protected area) d w figure 43 – example of physical barrier (dimensions as stated in table...

Page 36: 3.6. Ventilation

Page 32 3.6. Ventilation for models with heat inputs not exceeding 6.9kw additional ventilation is not normally required in the room that the fire is fitted. However, if spillage is detected during spillage test additional ventilation may be required. In gb reference should be made to bs 5871:part 3...

Page 37

Page 33 3.8. Installation procedure (thermobox) before commencing installation, ensure that the intended installation will comply with details in general information on page 1 . 3.8.1. Burley magiglo thermobox installation instructions when installing the burley magiglo elite in conjunction with a b...

Page 38

Page 34 6. Adjust the two clamping screws to secure the top of the box into the fireplace opening. 7. Insert the fire into the thermobox and connect the fire to the gas supply via the isolating valve. 8. Secure the fire to the thermobox with the two captive screws (supplied) through the holes in the...

Page 39

Page 35 9. Apply an appropriate seal between the rear of the surround back panel and the thermobox’s front edge. 10. Refer to the section 3.9 for the remainder of the installation. 3.8.6. Alternative ceramic box installation this appliance can be used with the burley magiglo slimline, standard or de...

Page 40

Page 36 3.9. Installation procedure (fire) if applicable, carefully unpack the contents of the carton and check them against the checklist given in section 3.7 . Make sure that the fireplace opening is suitable for the installation of the fire and prepare the fireplace to suit the dimensional requir...

Page 41

Page 37 3.9.2. Continuation of installation - optimum control model 1. Find a suitable position for the wall switch, a maximum of 5 metres of cable is supplied. 2. Fit the wall box into the wall. Cut cross- slots in the rubber grommet and feed the cable through it such that the end with four connect...

Page 42

Page 38 3.9.3. Continuation of installation - trim switch control model 1. Unpack the battery pack and connect to the battery connection on the cable. 2. Fit the connectors on the cable to the drive motor ensuring correct polarity. The cable connectors must be matched to the appropriately sized spad...

Page 43

Page 39 figure 51 figure 52 rubber pad plastic pad figure 53 figure 54 3.9.5. Commissioning 1. Turn on the gas supply to the fire and purge the gas line. Check all the gas joints for gas soundness. 2. Remove the pressure test point screw located as shown in figure 34 and connect a pressure gauge. 3....

Page 44

Page 40 3.9.6. Checking for spillage 1. Close all doors and windows. 2. Turn the fire on to its full rate and leave it burning for 5 minutes. 3. Test for spillage using a smoke match (in a ‘blume tube’) at the top of the appliance, fireplace opening or under the canopy at the centre, with the smoke ...

Page 45: Ervicing

Page 41 4. S ervicing i nstructions 4.1. General requirements all repairs and servicing must be carried out by a qualified registered gas installer (e.G. Member of corgi in gb) in accordance with the current gas safety (installation and use) regulations and these instructions. Before any servicing i...

Page 46: 4.3. Replacing Parts

Page 42 4.3. Replacing parts for any spare parts that are required, please contact either your supplier or the manufacturer directly. You will need the model name i.E. Model number, the gas type, the type of control and serial number. Only approved parts should be used. 4.3.1. Pilot assembly replace...

Page 47

Page 43 4.3.4. Motor replacement (remote control / optimum control models / trim switch models) the gas rate adjusting motor is replaceable in situ. 1. Remove the batteries from the receiver unit to prevent the risk of short circuit. 2. Remove the two motor connection tags from the valve. 3. Remove ...

Page 48

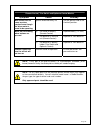

Page 44 4.4. Installation and operational troubleshooting the table below is intended for problems related to the fire and its gas controls. It is a guide only and does not take into account every eventuality. Servicing must be carried out in accordance with the current gas safety (installation and ...

Page 49

Page 45 remote control, trim switch and optimum control models symptom cause remedy main burner will not come on when required even though the drive motor is heard to be operating ignition knob incorrectly set set the ignition knob at the 9 o’clock position. Motor not functioning when buttons are pr...

Page 50

Page 46 this page is left intentionally blank.

Page 51

Page 47 this page is left intentionally blank.

Page 52

Bbmf281.9 burley magiglo fires are protected by uk patents 2193802, 2240620 and 2256920 other patents pending magiglo is a registered trademark of burley appliances ltd burley magiglo, lands end way oakham, rutland, le15 6rb tel: 01572 725570 fax: 01572 724390 www.Magiglo.Co.Uk email: info@magiglo.C...