- DL manuals

- Magiglo

- Indoor Fireplace

- TRIBUTE PD-08-002

- User, Installation & Servicing Instructions

Magiglo TRIBUTE PD-08-002 User, Installation & Servicing Instructions

TRIBUTE

Balanced Flue Convector

Model Number; PD-08-002

Fuel Effect Options:

Coal Effect

Gas Options:

NG

Control Options:

Manual Control

Remote Control

Total Control

For use on Natural Gas (G20) at a supply pressure of 20mbar in GB and IE.

Users,

Installation & Servicing

Instructions

MUST BE LEFT WITH THE USER

Summary of TRIBUTE PD-08-002

Page 1

Tribute balanced flue convector model number; pd-08-002 fuel effect options: coal effect gas options: ng control options: manual control remote control total control for use on natural gas (g20) at a supply pressure of 20mbar in gb and ie. Users, installation & servicing instructions must be left wi...

Page 2

Manufacturer contact details: burley appliances ltd lands’ end way oakham rutland le15 6rb tel: +44 (0)1572 725570 fax: +44 (0)1572 724390 general e-mail: info@magiglo.Co.Uk web site: www.Magiglo.Co.Uk technical support: direct dial on (01572) 725570 or email: technical@magiglo.Co.Uk burley magiglo ...

Page 3: Contents

Contents 1. General information .......................................................................................... 1 2. User instructions ................................................................................................ 3 2.1. Location of pilot burner ............................

Page 4

4. Servicing instructions ..................................................................................... 33 4.1. General requirements ................................................................................ 33 4.1.1. Cleaning the fuel effect, fire-bed and combustion chamber .............

Page 5: 1. G

Page 1 1. G eneral i nformation introduction 1. This appliance is suitable for installation in gb and ie and should be installed in accordance with the rules in force. In gb, the installation must be carried out by a gas safe registered installer. It must be carried out in accordance with the releva...

Page 6

Page 2 ventilation requirements 1. This appliance does not require any ventilation in the room where it is fitted. It is a balanced flue appliance whereby the air for combustion is drawn in from the outside and the products of combustion are evacuated to the outside through a concentric flue duct sy...

Page 7: 2. U

Page 3 2. U ser i nstructions 2.1. Location of pilot burner the pilot assembly is located at the centre of the appliance in front of the main burner. The pilot can be viewed by looking downwards through the hole in the front ceramic between the second and third coals from the right hand side (see fi...

Page 8: 2.2. Lighting Procedure

Page 4 2.2. Lighting procedure your fire will be fitted with one of the following different types of gas control valves. Identify the control system on your fire as shown and follow the appropriate operating instructions in the appropriate section. Control valve operation control type + manual = man...

Page 9: Manual Control

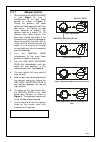

Page 5 2.2.1. Manual control 1. Whilst pushing the ignition knob in (see figure 3), turn it anticlockwise to the pilot flame position as shown in figure 4. During this process, the spark ignition will have operated and lit the pilot flame. On lighting the pilot flame continue to depress the ignition...

Page 10

Page 6 2.2.2. Lighting procedure (remote control) 1. Press the bottom button on the remote handset until clicking is heard on the valve, and the gas rate adjustment knob is at the off position. 2. With gas available at the valve press the ignition knob in and turn it anticlockwise to the pilot flame...

Page 11

Page 7 2.2.3. Lighting procedure (total control) 1. Ensure that gas is available at the valve and the on/off switch in the on position (–). (see figure 9) 2. Simultaneously press and hold the (red circle) and (large flame) buttons until a short acoustic signal confirms the start sequence has begun, ...

Page 12: Handset

Page 8 2.3. Battery replacement (remote control) 2.3.1. Handset 1. On the reverse of the handset remove the battery cover by pressing down at the top of the cover and sliding down. 2. Remove and unclip the old battery and replace with a new pp3 9v battery. 3. Replace the cover. - figure 11 press her...

Page 13: 2.4. Fitting The Trim

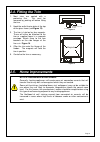

Page 9 2.4. Fitting the trim 1. Most trims are coated with a protective film. This must be removed by peeling off before fitting the trim. 2. Hook the outlet fascia plate at the top of the glass frame (see figure 13). 3. The trim is held on by four magnets. These will either be attached to the trim ...

Page 14: Painted Metal Surfaces

Page 10 2.6. Cleaning and care instructions 2.6.1. Painted metal surfaces these surfaces should be dusted regularly and any marks removed with a soft damp cloth. This should be done only when the appliance is cold. 2.6.2. Brass or chrome surfaces these surfaces should be cleaned with a proprietary n...

Page 15: 3. I

Page 11 3. I nstallation i nstructions before installation, ensure that the local distribution conditions (identification of the type of gas and pressure) and the adjustment of the appliance are compatible) 3.1. General safety requirements before commencing installation, ensure that the intended ins...

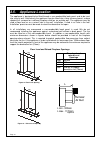

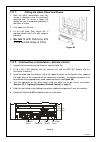

Page 16: 3.3. Flue Options

Page 12 3.3. Flue options ducts 440 x 100 dia. 141 45 230 (upto 1000 long available) 520 figure 16 the horizontal length is measured from the rear of the appliance outer flange to the external face of an external wall..

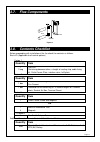

Page 17: 3.4. Technical Data

Page 13 3.4. Technical data natural gas (g20) nominal maximum heat input (hot) 4.0 kw (gross) nominal minimum heat input (hot) 2.3 kw (gross) setting pressures (cold) max 7.0 ±0.5 mbar setting pressures (cold) min 2.0 + 0.2 mbar gas rate 0.36 m3/h injector size multiport 7 x 0.77mm ø gas inlet conne...

Page 18: 3.5. Appliance Location

Page 14 3.5. Appliance location the appliance is designed to be fitted through a non-combustible back panel and to be inset into a cavity wall. Alternatively the appliance may be fitted into a false chimney breast, a deep rebated fire surround or a defunct fireplace sited on an outside wall. The app...

Page 19

Page 15 3.5.1. Mantels & combustible shelves 1. Shelves or mantels made from combustible materials should not be placed closer than 300mm above the appliance. Light coloured and resin mantels may discolour in time. The temperature rating of the surround should be checked before use. We recommend a f...

Page 20

Page 16 3.6. Flue terminal location the minimum acceptable dimensions from the flue terminal to obstructions and ventilating openings are shown in table 3 and figure 20. Dimension terminal position value mm a directly below an opening, air brick, opening windows, etc. 300 b above an opening, air bri...

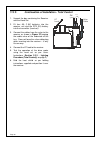

Page 21: 3.7. Flue Components

Page 17 3.7. Flue components wall plate terminal / air duct ducts figure 21 3.8. Contents checklist before proceeding with installation of the fire check the contents as follows: basic kit (applicable to all control options) carton 1 quantity item 1 gas fire 1 bag containing documentation, a length ...

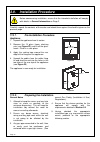

Page 22: Pre-Installation Procedure

Page 18 3.9. Installation procedure before commencing installation, ensure that the intended installation will comply with details in general information on page 1. Carefully unpack the contents of the carton and check them against the checklist given on the previous page. 3.9.1. Pre-installation pr...

Page 23: On The Inside Wall:

Page 19 3.9.2. Installation procedure for recessed installation on the inside wall: 1. Measure the height of the hearth (in the case of a raised installation ascertain the height of the top surface of the hearth) and mark a horizontal line on the wall at the same height. 2. Above the hearth level dr...

Page 24

Page 20 l back panel/ surround 200mm min terminal/ air duct base lintel figure 25 11. Important! Thefire cement supplied must be applied around each of the duct spigots on the rear of the appliance to guarantee a seal. Do not use silicone based sealants anywhere around the firebox. 12. Push the two ...

Page 25

Page 21 14. Slide each of the tensioning screws all the way onto the cable and through the hole in the bracket. 15. Whilst holding the cable tensioning screw in the bracket, pull the cable taught and without releasing the tension tighten the thumb screw firmly. To further tighten the cables, screw t...

Page 26: On The Outside Wall

Page 22 on the outside wall 1. Unscrew the outer cover and terminal from the wall plate. 2. Engage the duct spigots with the two ducts from the rear of the appliance. The duct spigot on the outside of the wall plate should be uppermost. 3. Mark the four fixing positions onto the wall and remove the ...

Page 27: On The Inside Wall:

Page 23 3.9.3. Surface mounted firebox preparation on the inside wall: 1. Measure the height of the hearth (in the case of a raised installation ascertain the height of the top surface of the hearth) and mark a horizontal line on the wall at the same height. 2. Mark a vertical line on the wall on th...

Page 28

Page 24 l surround/ false chimney breast 200mm min terminal/ air duct base figure 32 11. Apply the fire cement supplied around each of the duct spigots on the rear of the appliance. 12. Push the two lengths of duct previously cut on to the duct spigots. Make sure the ducts are pushed fully home up t...

Page 29: On The Outside Wall:

Page 25 on the outside wall: 1. Unscrew the outer cover and terminal from the snorkel wall plate. 2. Engage the duct spigots with the two ducts from the rear of the appliance. The duct spigot on the outside of the wall plate should be uppermost. 3. Mark the four fixing positions onto the wall and re...

Page 30: The Gas Supply

Page 26 3.9.4. The gas supply 1. The gas supply can be fed into the firebox from the left hand rear. Care should be taken to sleeve the pipe when passing through masonry. 2. Make an appropriate slit in the rubber grommet and feed the gas supply pipe through it. Seal gas inlet slot with the grommet. ...

Page 31: Fuel Effect Layouts

Page 27 3.9.5. Fuel effect layouts due to the nature of this appliance, the fuel effect layout should only be carried out by a gas safe registered installer in gb or a competent person (engineer) in ie and other ec countries. Rcf advice: this product may use components (fuel effects & ceramic backs)...

Page 32: Coal Effect Layout

Page 28 3.9.6. Coal effect layout the fire is supplied with a set of ceramic fuel set as follows: qty front ceramic 1 rear ceramic 1 moulded matrix 1 proceed with the layout as follows: 1. Position the rear burner ceramic in position behind the rear burner flange, as shown in figure 34. 2. Place the...

Page 33

Page 29 3.9.7. Fitting the glass panel and frame 1. Refit the glass panel/frame and fully secure in position using the previously removed nuts. To ensure a good seal tighten the nuts in a diagonal sequence a few turns at a time 2. Fully tighten all the nuts. 3. Fit the infill plate (see figure 48). ...

Page 34

Page 30 3.9.9. Continuation of installation - total control 1. Unpack the box containing the receiver and the hand set. 2. Fit four aa (1.5v) batteries into the receiver unit and the pp3 (9v) battery into the transmitter (hand set). 3. Connect the cables from the valve to the receiver as shown in fi...

Page 35: Commissioning

Page 31 3.9.10. Commissioning 1. Turn on the gas supply to the fire and purge the gas line. Check all the gas joints for gas soundness. 2. Connect a pressure gauge to the pressure test point on the isolating valve. 3. Ignite the pilot in accordance with the user instructions. 4. Set the controls to ...

Page 36: Fitting The Trim

Page 32 3.9.11. Fitting the trim if the appliance is installed at floor level a three sided trim will be supplied with the appliance. Follow instructions in users section to fit the trim 3.9.12. Instructing the user the installer must hand over these instructions to the user and explain how to opera...

Page 37: 4. S

Page 33 4. S ervicing i nstructions 4.1. General requirements all repairs and servicing must be carried out by a qualified registered gas installer (e.G. Member of gas safe register in gb) in accordance with the current gas safety (installation and use) regulations and these instructions. Before any...

Page 38: Chamber

Page 34 4.1.1. Cleaning the fuel effect, fire-bed and combustion chamber 1. Remove the infill plate and the glass door panel and place it in a safe place. 2. Carefully remove all the fuel bed ceramics from the fire. Lift out the front and rear ceramics. Any debris/dust or soot can be brushed off usi...

Page 39: 4.2. Replacing Parts

Page 35 4.2. Replacing parts for any spare parts that are required, please contact either your supplier or the manufacturer directly. You will need the model name i.E. Model number, the gas type, the type of control and serial number. Only approved parts should be used. Isolate the gas supply at the...

Page 40: Control)

Page 36 4.2.3. Control valve replacement (manual control /remote control) referring to figure 39 and figure 40: 1. Remove the glass door panel and the ceramic fuel bed components. 2. Remove the main burner after removing the securing screws and lifting up the right hand side of the burner (see figur...

Page 41

Page 37 4.2.4. Control valve replacement (total control) 1. Pull out the receiver from under the fire and remove the batteries. 2. Carefully pull out the valve cable (see figure 41). 3. Disconnect the sw cable (with yellow sleeve) from the receiver (see figure 41). 4. Remove the glass door panel, th...

Page 42

Page 38 4.2.5. Motor replacement (remote control model) the gas rate adjusting motor is replaceable in situ. 1. Remove the batteries from the receiver unit to prevent the risk of short circuit. 2. Remove the two motor connection tags from the valve. 3. Remove the valve cover securing screw. 4. Uncli...

Page 43

Page 39 4.2.6. Replacing the receiver (total control) 1. Pull out the receiver from under the fire and remove the batteries. 2. Gently pull out the ht lead and the valve cable from the receiver (see figure 41). 3. Unscrew and remove the sw and tc connections. 4. Refit in reverse order. (the valve ca...

Page 44: Troubleshooting

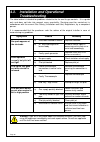

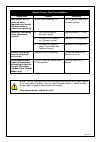

Page 40 4.3. Installation and operational troubleshooting the table below is intended for problems related to the fire and its gas controls. It is a guide only and does not take into account every eventuality. Servicing must be carried out in accordance with the current gas safety (installation and ...

Page 45: Symptom

Page 41 remote control, total control models symptom cause remedy main burner will not come on when required even though the drive motor is heard to be operating ignition knob incorrectly set set the ignition knob at the 9 o’clock position. Motor not functioning when buttons are pressed a) flat hand...

Page 46

Mf476.1 this page is intentionally blank.

Page 47

Page 43 this page is intentionally blank.

Page 48

Mf476.1 burley magiglo fires are protected by uk patents 2193802, 2240620 and 2256920 other patents pending magiglo is a registered trademark of burley appliances ltd. Burley appliances ltd, lands’ end way, oakham, rutland, le15 6rb tel: 01572 725570 fax: 01572 724390 www.Magiglo.Co.Uk email: info@m...