- DL manuals

- Magnetek

- Controller

- 2001-G+M

- Instruction Manual

Magnetek 2001-G+M Instruction Manual

Summary of 2001-G+M

Page 1

Adjustable frequency crane controls advanced instruction manual software #14513 march 2014 part number: 144-25085 r5 © copyright 2014 magnetek.

Page 3

Impulse•g+ mini advanced instruction manual - march 2014 ©2014 magnetek all rights reserved. This notice applies to all copyrighted materials included with this product, including, but not limited to, this manual and software embodied within the product. This manual is intended for the sole use of t...

Page 4

Impulse•g+ mini advanced instruction manual - march 2014 danger, warning, caution, and note statements danger, warning, caution, and note statements are used throughout this manual to emphasize important and critical information. You must read these statements to help ensure safety and to prevent pr...

Page 5: Contents:

Impulse•g+ mini advanced instruction manual— march 2014 contents: product warranty information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Ii-iii chapter1: introduction introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 6

Impulse•g+ mini advanced instruction manual— march 2014 chapter 5: programming features application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3 preset reference . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 7

Impulse•g+ mini advanced instruction manual— march 2014 option parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-47 pulse generated (pg) control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 8: Chapter 6: Troubleshooting

Impulse•g+ mini advanced instruction manual— march 2014 chapter 6: troubleshooting troubleshooting the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3 maintenance and inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 9: Introduction

C h a p t e r 1 introduction.

Page 10

Impulse•g+ mini advanced instruction manual - march 2014 1-2 this page intentionally left blank..

Page 11

Impulse•g+ mini advanced instruction manual - march 2014 1-3 wa r n i n g read and understand this manual before installing, operating, or servicing this drive. All warnings, cautions, and instructions must be followed. All activity must be performed by qualified personnel. The drive must be install...

Page 12: Introduction

Impulse•g+ mini advanced instruction manual - march 2014 1-4 introduction the impulse•g+ mini drive is the next generation of magnetek, inc. Drives, providing compact and economical crane control. The drive maintains a similar footprint size and feature set of previous generation drives, while offer...

Page 13

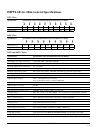

Impulse•g+ mini advanced instruction manual - march 2014 1-5 impulse•g+ mini general specifications 230v class 460v class 230v and 460v classes specification specification values and information for each 230v-class model 2 001 2 003 2 005 2 008 201 1 2 017 2 025 2 033 2 047 2 060 rated current (a) 1...

Page 14

Impulse•g+ mini advanced instruction manual - march 2014 1-6 ac reactor specifications reactors, both as input (line) and output (load) devices, protect adjustable frequency drives, motors, and other load devices against excessive voltage and current. The following guidelines may help determine inpu...

Page 15

Impulse•g+ mini advanced instruction manual - march 2014 1-7 460v class impulse•g+ mini external resistor specifications if magnetek resistors are not used, this table should be used to determine the minimum resistance values. Model number 460 v part number maximum amps of reactor 4001-g+m rea460-1 ...

Page 16

Impulse•g+ mini advanced instruction manual - march 2014 1-8 this page intentionally left blank..

Page 17: Installation

C h a p t e r 2 installation.

Page 18

Impulse•g+ mini advanced instruction manual - march 2014 2-2 this page intentionally left blank..

Page 19

Impulse•g+ mini advanced instruction manual - march 2014 2-3 assessing the system requirements it is important to know how you are going to use the drive before you start installation and wiring. You will need to know your requirements for the following components: • motion (traverse or hoist) • mot...

Page 20

Impulse•g+ mini advanced instruction manual - march 2014 2-4 impulse•g+ mini system components and external devices optional drive components • 120 vac interface card (part number g+m-if-120vac) • 48 vac interface card (part number g+m-if-48vac) • 24 vac interface card (part number g+m-if-24vac) • p...

Page 21: Long Time Storage

Impulse•g+ mini advanced instruction manual - march 2014 2-5 long time storage powering up the drives every six months is quite beneficial. Over longer periods of time without power, the drives’ electrolytic dc bus capacitors require reformation, especially if stored in an area of high temperatures....

Page 22

Impulse•g+ mini advanced instruction manual - march 2014 2-6 abnormal signs within the inverter. While increasing the variac’s output voltage, the current will momentarily increase as current is necessary to charge the capacitors. • once 30 to 60 minutes elapse, remove power and package the drive fo...

Page 23

Impulse•g+ mini advanced instruction manual - march 2014 2-7 impulse•g+ mini dimensions/heat loss - open chassis* voltage model w h d w1 h1 d wt. Lbs. Total heat loss (w)** dimensions in inches 230v 2001-g+m 2.68 5.04 2.99 2.20 4.65 m4 1.3 14.7 2003-g+m 2.68 5.04 4.25 2.20 4.65 m4 2.0 24.0 2005-g+m ...

Page 24: Installing The Drive

Impulse•g+ mini advanced instruction manual - march 2014 2-8 installing the drive the following two figures show the minimum clearances when mounting the drive in standard or side-by-side installations. Figure 2-2: standard installation installing the drive (side-by-side) figure 2-3: side-by-side in...

Page 25: Wiring

C h a p t e r 3 wiring.

Page 26

Impulse•g+ mini advanced instruction manual - march 2014 3-2 this page intentionally left blank..

Page 27

Impulse•g+ mini advanced instruction manual - march 2014 3-3 impulse•g+ mini wiring practices • connect the incoming three-phase ac source to terminals r/l1, s/l2, t/l3. • connect the motor leads to terminals u/t1, v/t2, w/t3. • ensure the drive-to-motor wiring distance is less than 150 ft unless ap...

Page 28

Impulse•g+ mini advanced instruction manual - march 2014 3-4 • when using more than one transformer for the drive's power, properly phase each transformer. • to reverse the direction of rotation, interchange any two motor leads (u/t1, v/t2 or w/t3; changing r/l1, s/l2 or t/l3 will not affect the sha...

Page 29

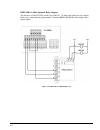

Impulse•g+ mini advanced instruction manual - march 2014 3-5 impulse•g+ mini typical connection diagram figure 3-1: impulse•g+ mini typical connection diagram.

Page 30

Impulse•g+ mini advanced instruction manual - march 2014 3-6 terminal description type terminal name function (signal level) ma in cir cu it r/l1, s/l2, t/l3 ac power supply input ac power supply input u/t1, v/t2, w/t3 inverter output inverter output b1, b2 braking resistor connection braking resist...

Page 31: Safe Disable Function

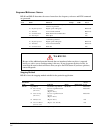

Impulse•g+ mini advanced instruction manual - march 2014 3-7 safe disable function the safe disable function can be utilized to perform a safe stop according to the en60204-1, stop category 0 (uncontrolled stop by power removal). It is designed to meet the requirements of the en954-1, safety categor...

Page 32

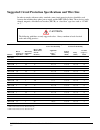

Impulse•g+ mini advanced instruction manual - march 2014 3-8 suggested circuit protection specifications and wire size in order to comply with most safety standards, some circuit protective devices should be used between the incoming three-phase power supply and the impulse•g+ mini. These devices ca...

Page 33

Impulse•g+ mini advanced instruction manual - march 2014 3-9 grounding 1. Connect terminal to the common panel ground. Use ground wiring as specified in “suggested circuit protection specifications and wire size” on page 3-8, and keep the length as short as possible. • ground resistance: 230v class;...

Page 34

Impulse•g+ mini advanced instruction manual - march 2014 3-10 wiring the control circuit control circuit terminals the impulse•g+ mini is shipped with a 120v interface card, allowing direct connection of 120v user input devices. The interface card connects to drive terminals s1-s7 and sc. The user i...

Page 35

Impulse•g+ mini advanced instruction manual - march 2014 3-11 control board dip switches there are three switch settings on the controller board that are used for controller input (s1 - s7) polarity, analog input signal control method, and rs485 termination. The figure below shows the location of th...

Page 36

Impulse•g+ mini advanced instruction manual - march 2014 3-12 impulse•g+ mini optional relay outputs the interface card p3s2-out2 provides two 240 vac, 1.5 amp rated solid-state relay outputs. Each relay is independently programmable. Constants h02.02 and h02.03 will configure these digital outputs....

Page 37

Impulse•g+ mini advanced instruction manual - march 2014 3-13 impulse•g+ mini power terminal arrangement figure 3-7: impulse•g+ mini power terminal arrangement 230v arrangement 460v arrangement 2001-g+m 1 4001-g+m 2 2003-g+m 1 4002-g+m 2 2005-g+m 1 4003-g+m 2 2008-g+m 2 4004-g+m 2 2011-g+m 2 4009-g+...

Page 38

Impulse•g+ mini advanced instruction manual - march 2014 3-14 this page intentionally left blank..

Page 39: Getting Started

C h a p t e r 4 getting started.

Page 40

Impulse•g+ mini advanced instruction manual – march 2014 4-2 this page intentionally left blank..

Page 41: Overview

Impulse•g+ mini advanced instruction manual – march 2014 4-3 overview with its easy-to-use keypad and x-press programming™ feature, the impulse•g+ mini makes it easy to get up and running right away. This chapter explains how to navigate through the drive’s menus along with the function and meaning ...

Page 42: Using The Keypad

Impulse•g+ mini advanced instruction manual – march 2014 4-4 using the keypad all functions of the drive are accessed using the keypad. The operator can enter information using the keypad to configure the drive for their application. This information will be stored in the drive’s memory. Keypad func...

Page 43

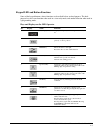

Impulse•g+ mini advanced instruction manual – march 2014 4-5 keypad led and button functions some of the keypad buttons, whose functions are described below, are dual-purpose. The dual- purpose keys have one function when used in a view-only mode, and another function when used in a programming mode...

Page 44

Impulse•g+ mini advanced instruction manual – march 2014 4-6 lo/re led and run led indications function leds no. Led lit flashing flashing quickly off 10 during run. During deceleration to stop. When a run command is input and frequency reference is 0. During deceleration at a fast- stop. During sto...

Page 45

Impulse•g+ mini advanced instruction manual – march 2014 4-7 quick start guide information basic programming of the drive consists of entering motor parameters, choosing a motion, and selecting a speed reference. After applying power to the drive, the display will show the output frequency of 0.00. ...

Page 46

Impulse•g+ mini advanced instruction manual – march 2014 4-8 use the following table to select the desired motor for your application: use the , , and keys to change the value. Press to save your changes. The display will temporarily show , then a01.03. Setting speed reference: press the key to navi...

Page 47

Impulse•g+ mini advanced instruction manual – march 2014 4-9 setting motor full load amps: locate the nameplate on your motor to find the full load amps (fla), and the motor rpm. Press the key once to move the cursor to the left most spot. Use the and keys to navigate to the “e” menu. The display sh...

Page 48

Impulse•g+ mini advanced instruction manual – march 2014 4-10 parameters the parameters are organized by function group, that determine how the drive functions. These parameters are programmed in the drive’s software as measurable values or options—both of which will be referred to in this manual as...

Page 49

Impulse•g+ mini advanced instruction manual – march 2014 4-11 parameter modes all parameters are organized under four modes: operation mode drive operation is enabled. Drive status led lights. Programming mode parameter access levels, control method, motion, speed control mode, and passwords are sel...

Page 50

Impulse•g+ mini advanced instruction manual – march 2014 4-12 impulse•g+ mini structure of parameters group function monitor u1 monitor u2 fault trace u3 fault history u4 maintenance u6 motor initialize a1 initialization parameters a2 user-defined parameters application b1 preset references b2 refer...

Page 51

Impulse•g+ mini advanced instruction manual – march 2014 4-13 initialization set-up parameter access level (a01.01) this parameter controls the level of access for all the parameters in the drive. Using this parameter controls the “masking” of parameters according to the access level selected. There...

Page 52

Impulse•g+ mini advanced instruction manual – march 2014 4-14 select motion (a01.03) set this parameter to match the motion of application. See tables 4.1 and 4.2 (x-press programming) for details. Speed reference (a01.04) this parameter will automatically define the input terminals for the selectio...

Page 53

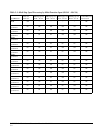

Impulse•g+ mini advanced instruction manual – march 2014 4-15 parameters changed by x-press programming table 4-1: traverse (a01.03= 00) a01.04 description c01.01 d09.01 d09.02 d09.03 e01.03 h01.01 h01.02 h01.03 h01.04 h01.05 h01.06 h01.07 h02.01 h02.02 h02.03 h03.01 n02.05 quick stop s-curve accel ...

Page 54

Impulse•g+ mini advanced instruction manual – march 2014 4-16 parameters changed by x-press programming table 4-2: standard hoist (a01.03 = 01) a01.04 description c01.01 d09.01 d09.02 d09.03 e01.03 h01.01 h01.02 h01.03 h01.04 h01.05 h01.06 h01.07 h02.01 h02.02 h02.03 h03.01 n02.05 quick stop s-curve...

Page 55

Impulse•g+ mini advanced instruction manual – march 2014 4-17 parameters changed by x-press programming table 4-3: braketronic (a01.03 = 04) a01.04 description c01.01 d09.01 d09.02 d09.03 e01.03 h01.01 h01.02 h01.03 h01.04 h01.05 h01.06 h01.07 h02.01 h02.02 h02.03 h03.01 n02.05 quick stop s-curve ac...

Page 56

Impulse•g+ mini advanced instruction manual – march 2014 4-18 initialize parameters (a01.05) use this parameter to reset the drive to user-specified initial values or clear an ope04 fault. User initialize (a01.05 = 1110) once the drive is configured and the system is running, set parameter o02.03 = ...

Page 57

Impulse•g+ mini advanced instruction manual – march 2014 4-19 to clear a parameter stored in the a02.Xx, change the value to “----”. Change the access level to user program (a01.01 = 0000). Password entry 2 (a01.08) used to access oem specific crane and hoist functions..

Page 58: Auto-Tuning

Impulse•g+ mini advanced instruction manual – march 2014 4-20 auto-tuning the impulse•g+ mini can adapt to all motors manufactured world wide with its automatic tuning function. The drive asks the user for minimal motor information, and then guides them through a quick, simple tuning process. Ideall...

Page 59: Using Auto-Tuning

Impulse•g+ mini advanced instruction manual – march 2014 4-21 using auto-tuning with the keypad, use the up or down arrow keys to show the auto-tuning menu . Press the enter key and scroll through the tuning parameters using the up arrow key and enter each of the required parameter settings. Press t...

Page 60

Impulse•g+ mini advanced instruction manual – march 2014 4-22 this page intentionally left blank..

Page 61: Programming Features

C h a p t e r 5 programming features.

Page 62

Impulse•g+ mini advanced instruction manual – march 2014 5-2 this page intentionally left blank..

Page 63: Application

Impulse•g+ mini advanced instruction manual – march 2014 5-3 application the application parameters control the acceleration and deceleration characteristics, as well as any preset frequencies the system will require for operation. Application parameters included in this section are listed below: • ...

Page 64

Impulse•g+ mini advanced instruction manual – march 2014 5-4 table 5-1: multi-step speed processing by multi-function input (b01.01 ~ b01.16) speed reference forward/reverse h01.01 = 80 h01.02 = 81 multi-step speed 2 h01.01 ~ .06 = 00 multi-step speed 3 h01.01 ~ .06 = 01 multi-step speed 4 h01.01 ~ ...

Page 65

Impulse•g+ mini advanced instruction manual – march 2014 5-5 reference limits these parameters will limit the frequency range as a percentage of maximum output frequency (e01.04). An alternate upper limit frequency can be used during operation when a multi-function input (mfi) is set to 59 (alt f-re...

Page 66

Impulse•g+ mini advanced instruction manual – march 2014 5-6 sequence/reference source b03.01 and b03.02 determine the source from where the frequency reference and run command are generated. Stopping method b03.03 selects the stopping method suitable for the particular application. Parameter code n...

Page 67

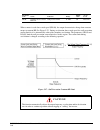

Impulse•g+ mini advanced instruction manual – march 2014 5-7 decel to stop (b03.03 = 00) upon removal of the fwd or rev run command, the motor decelerates at a rate determined by the time set in deceleration time 1 (b05.02) and dc injection braking is applied after the dc injection start frequency, ...

Page 68

Impulse•g+ mini advanced instruction manual – march 2014 5-8 coast to stop (b03.03 = 01) upon removal of the fwd or rev run command, the motor starts to coast and the electric brake sets. Figure 5-4: b03.03 = 01 (coast to stop) without dc injection figure 5-5: b03.03 = 01 (coast to stop) with dc inj...

Page 69

Impulse•g+ mini advanced instruction manual – march 2014 5-9 dc injection braking (b03.03 = 02) figure 5-6: b03.03 = 02 (dc injection at stop) without dc injection at start figure 5-7: b03.03 = 02 (dc injection at stop) with dc injection at start.

Page 70

Impulse•g+ mini advanced instruction manual – march 2014 5-10 decel with timer (b03.03 = 04) figure 5-8: b03.03 = 04 (decel with timer) without dc injection.

Page 71

Impulse•g+ mini advanced instruction manual – march 2014 5-11 figure 5-9: b03.03 = 04 (decel with timer) with dc injection, where c12.02 > d01.04 figure 5-10: b03.03 = 04 (decel with timer) without dc injection, where d01.04 > c12.02.

Page 72

Impulse•g+ mini advanced instruction manual – march 2014 5-12 fast stop (h01.Xx = 40 or 42) figure 5-11: h01.Xx = 40 or 42 (fast stop) without dc injection figure 5-12: h01.Xx = 40 or 42 (fast stop) with dc injection motor rotation change this parameter allows you to change the motor direction witho...

Page 73

Impulse•g+ mini advanced instruction manual – march 2014 5-13 loc/rem run select if the run reference/speed reference are switched between serial mode and drive terminal mode, b03.07 determines action after the switch. Parameter code name function range initial value access level b03.07 loc/rem run ...

Page 74

Impulse•g+ mini advanced instruction manual – march 2014 5-14 acceleration/deceleration acceleration time sets the time necessary for the output frequency to accelerate from 0hz to maximum output frequency (e01.04). Deceleration time sets the time necessary for the output frequency to decelerate fro...

Page 75

Impulse•g+ mini advanced instruction manual – march 2014 5-15 note: assume the constant b03.03 is set to “00” (decel to stop). Figure 5-13: normal accel/decel time and multiple accel/decel changeover jump frequencies this function allows the “jumping” of critical frequencies so that the motor can op...

Page 76: Special Functions

Impulse•g+ mini advanced instruction manual – march 2014 5-16 special functions the special function parameters are special crane and hoist specific functions used to control how the system will operate. These include quick stop™ and reverse plug simulation™. Listed below are the special function pa...

Page 77

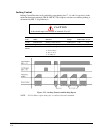

Impulse•g+ mini advanced instruction manual – march 2014 5-17 quick stop the quick stop function provides an automatic alternate deceleration at stop command. Note: the quick stop deceleration time differs from the normal deceleration time and is applied only when the run command is removed. Figure ...

Page 78

Impulse•g+ mini advanced instruction manual – march 2014 5-18 reverse plug simulation™ the reverse plug simulation provides an automatic alternate deceleration time/acceleration time at a change direction command before the brake sets. The deceleration time and the acceleration time are set independ...

Page 79

Impulse•g+ mini advanced instruction manual – march 2014 5-19 micro-positioning control™ micro-positioning control function can provide a reduced speed range operation for precise positioning. Enabled by a multi-function input, it multiplies the normal speed reference by the micro-speed gain. Two mi...

Page 80

Impulse•g+ mini advanced instruction manual – march 2014 5-20 travel limits this function can automatically slow and stop a crane or hoist when it reaches the end of the travel limits. Two types of limit inputs (slow and stop) are available in both travel directions. Inputs can be programmed through...

Page 81

Impulse•g+ mini advanced instruction manual – march 2014 5-21 phantom stop the phantom stop feature is designed to stop the drive operation using the stopping method selected in c03.09 when a phantom fault input (h01.01–h01.07 = 5f or 63) is active. The drive will indicate a phantom fault has occurr...

Page 82

Impulse•g+ mini advanced instruction manual – march 2014 5-22 load check ii™ the load check ii function is a load-limiting feature which ensures the programmed load limit of the hoist is not exceeded. It prevents the lifting (and potential stall) of a load that is overweight. When the impulse•g+ min...

Page 83

Impulse•g+ mini advanced instruction manual – march 2014 5-23 4. With load check disabled, lift the rated load a foot or two off the ground. 5. Set c05.01 equal to 09. 6. Press and hold the hoist (up) command button on the pendant or radio for full speed operation (60 hz). Note: the load check set u...

Page 84

Impulse•g+ mini advanced instruction manual – march 2014 5-24 c05.03 lc setting time sets the time to hold the output frequency allowing the output current/torque to stabilize. 0.00–2.55 sec 0.15 adv c05.04 lc testing time sets the time (after the lc setting time) for comparing output current/torque...

Page 85

Impulse•g+ mini advanced instruction manual – march 2014 5-25 swift-lift™ swift-lift provides additional productivity by allowing a hoist to quickly move into position by increasing speeds under light or no load conditions. Swift-lift will enable the motor to over-speed by calculating the maximum sa...

Page 86

Impulse•g+ mini advanced instruction manual – march 2014 5-26 configuring the swift-lift function: using multi-step 2, 3, 5 (a01.04 = 00, 01, or 02): if the system is using multi-step as the speed control method, use the following instructions to set up swift-lift. 1. Set v/f selection (e01.03) = 0f...

Page 87

Impulse•g+ mini advanced instruction manual – march 2014 5-27 running speed reference (see step 3). A. For example: if the maximum normal running speed is at 60 hz, set c06.06 to 58 or 59 hz as the swift-lift enabling speed. Using uni-polar analog (a01.04 = 05): if the system is using uni-polar anal...

Page 88

Impulse•g+ mini advanced instruction manual – march 2014 5-28 figure 5-17: swift lift timing diagram.

Page 89

Impulse•g+ mini advanced instruction manual – march 2014 5-29 torque limit (open loop vector only) impulse•g+ mini dynamically controls the torque output of the motor at all times when the control method is set to open loop vector (a01.02 = 02). The torque limit function limits the amount of motor t...

Page 90

Impulse•g+ mini advanced instruction manual – march 2014 5-30 brake delay timers this function is used in trolley or bridge applications. It can reduce the mechanical brake wear when the operator tries to position a load. This function is available only in traverse mode and the constant b03.03 must ...

Page 91

Impulse•g+ mini advanced instruction manual – march 2014 5-31 maintenance timer the maintenance timer feature will set an output after a pre-determined period of time (hours) to alert an operator to perform or take some action, i.E. Grease the bearings. To use this feature, program the number of hou...

Page 92

Impulse•g+ mini advanced instruction manual – march 2014 5-32 inching control inching control function can be enabled by programming data 17, 18, and 19 respectively to the multi-function input terminals (h01.01–h01.07). The frequency reference used during inching is determined by b01.17 (jog refere...

Page 93: Tuning

Impulse•g+ mini advanced instruction manual – march 2014 5-33 tuning these parameters help tune the motor for your application, which include torque compensation and s-curve characteristics for smoother transition during machine acceleration and deceleration. Below are the parameters included in thi...

Page 94

Impulse•g+ mini advanced instruction manual – march 2014 5-34 parameter code name function range initial value access level d01.08 magnetic flux compensation sets the magnetic flux compensation as a percentage of the no load current value (e02.03). 0000–1000 0000 adv d01.15 mechanical weakening dete...

Page 95

Impulse•g+ mini advanced instruction manual – march 2014 5-35 automatic slip compensation as the load becomes larger, the motor speed is reduced and the motor slip increases. The slip compensation function keeps the motor speed constant under varying load conditions. D02.01 sets the slip compensatio...

Page 96

Impulse•g+ mini advanced instruction manual – march 2014 5-36 when more torque is needed, increase the torque compensation gain in one-tenth (0.1) increments. Increase the setting when the wiring distance between the inverter and the motor is 100ft. Or longer. If the motor generates excessive vibrat...

Page 97

Impulse•g+ mini advanced instruction manual – march 2014 5-37 dwell function the dwell function is used to temporarily hold the output frequency at a set reference for a set time. This function can be used when driving a motor with a heavy starting load. This pause in acceleration reduces traditiona...

Page 98

Impulse•g+ mini advanced instruction manual – march 2014 5-38 s-curve acceleration/deceleration an s-curve pattern is used to reduce shock and provide smooth transitions during machine acceleration and deceleration. S-curve characteristic time is the time from the output frequency to the set accel/d...

Page 99

Impulse•g+ mini advanced instruction manual – march 2014 5-39 figure 5-23: s-curve characteristics–fwd/rev operation carrier frequency parameter code name function range initial value access level d10.01 ct/vt selection constant torque/variable torque selection 00, 01 00 adv 00 heavy duty 01 normal ...

Page 100

Impulse•g+ mini advanced instruction manual – march 2014 5-40 hunting prevention occasionally, in an application, resonance between the internal control system and the mechanical system causes current instability. This is called hunting, and may cause a crane to vibrate at a lower speed (up to 30 hz...

Page 101: Motor Parameters

Impulse•g+ mini advanced instruction manual – march 2014 5-41 motor parameters motor data such as full load amps and v/f patterns are selected with the following parameters. These parameters include the ability to select and set up custom v/f patterns for the type of motor used. • e1 v/f pattern • e...

Page 102

Impulse•g+ mini advanced instruction manual – march 2014 5-42 table 5-4:v/f parameters table 5-3: inverter voltage e1-01 setting overvoltage trip braking transistor trip reset on off 230 150-255 400v 380v 380v 375v 460 400 800v 760v 760v 750v 460 720v 680v 660v 650v parameter code name function ran...

Page 103

Impulse•g+ mini advanced instruction manual – march 2014 5-43 table 5-5: voltage/frequency pattern options for 230 v class table 5-6: voltage/frequency pattern options for 460 v class e01.04 e01.05 e01.06 e01.07 e01.08 e01.09 e01.10 e01.11 e01.12 e01.13 e01.03 hz v hz hz v hz v hz v v 00 (4) 60.0 23...

Page 104

Impulse•g+ mini advanced instruction manual – march 2014 5-44 motor set-up e2 constants define motor parameters. Normally, the default settings for e2 constants are determined by kva selection (o02.04). In open loop vector control the e2 constants will be set automatically during auto-tuning. If the...

Page 105: Option Parameters

Impulse•g+ mini advanced instruction manual – march 2014 5-45 option parameters • f1 pulse generated option set up pulse generated (pg) control the following option parameters are used to set and control the action for the pulse generated (pg) input and output, including overspeed detection. These p...

Page 106: Terminal Parameters

Impulse•g+ mini advanced instruction manual – march 2014 5-46 terminal parameters there are both digital and analog inputs and outputs that can be programmed for customized operation and sequencing. These include input and output terminal selection along with serial communication. Listed below are t...

Page 107

Impulse•g+ mini advanced instruction manual – march 2014 5-47 09 lower limit 2 n.O. Lower limit - stop; normally open. Ll2 - blinking 5-20 basic/adv 0a upper limit 1 n.C. Upper limit - slow down; normally closed. Ul1 - blinking 5-20 basic/adv 0b upper limit 2 n.C. Upper limit - stop; normally closed...

Page 108

Impulse•g+ mini advanced instruction manual – march 2014 5-48 20 thru 2f external fault desired setting is possible. Input mode: n.O./n.C., detection mode: always/ during run (see external fault response selection table 5-7) 5-53 basic/adv 30 program lockout program lockout closed: parameters enable...

Page 109

Impulse•g+ mini advanced instruction manual – march 2014 5-49 59 alternate upper frequency alternate reference upper limit frequency 5-5 basic/adv 5a maintenance reset reset maintenance timer (c12.05 - c12.06, u01.52) 5-33 adv 5b be6 up speed limit limit fref to c08.17 (be6 up speed limit) -- adv 5f...

Page 110

Impulse•g+ mini advanced instruction manual – march 2014 5-50 external fault response selection it is sometimes desirable to have at least one external fault input to the drive. To properly program a multi-function input (h01.01 to h01.07) for this purpose an external fault response must be selected...

Page 111

Impulse•g+ mini advanced instruction manual – march 2014 5-51 digital outputs the impulse•g+ mini has three multi-function control outputs (one relay, two open collector) for indicating various conditions. The following table lists the function selections for the multi-function contact outputs and i...

Page 112

Impulse•g+ mini advanced instruction manual – march 2014 5-52 015 freq detect 3 closed when output frequency l04.03 5-72 adv 016 freq detect 4. Closed when output frequency l04.03 5-72 adv 017 trq det 1 n.C. Open when torque > l06.02 for longer than l06.03 time 5-75 basic/adv 018 trq det 2 n.O. Clos...

Page 113

Impulse•g+ mini advanced instruction manual – march 2014 5-53 03f klixon closed when mfdi 56 or 57 is on - motor is overheating 5-21 adv 040 ~ ff fault annunciate closed on specific faults -- adv 101 inverse zero speed open when the output frequency is below b02.02 or d01.01 -- basic/adv 102 inverse...

Page 114

Impulse•g+ mini advanced instruction manual – march 2014 5-54 11b inverse reverse direction open when running rev/ down -- adv 11c inverse swift-lift active open when swift lift is active 5-26 adv 11d inverse baseblock n.C. Closed during baseblock 2 -- adv 120 inverse auto-reset open when auto-reset...

Page 115

Impulse•g+ mini advanced instruction manual – march 2014 5-55 analog inputs the impulse•g+ mini has two analog inputs (two multi-function and one reference) for the external input of numerous references and limits. Parameter code name function range initial value access level h03.01 terminal a1 sign...

Page 116

Impulse•g+ mini advanced instruction manual – march 2014 5-56 parameter code name function range initial value access level h03.09 terminal a2 signal select selects the signal level for terminal a2 00–03 02 basic/adv 00 0vdc ~ 10vdc (switch s2 must be in the “v” position) basic/adv 02 4 to 20ma (swi...

Page 117

Impulse•g+ mini advanced instruction manual – march 2014 5-57 analog outputs the impulse•g+mini has two analog outputs for the external monitoring of drive conditions. Parameter code name function range initial value access level h04.01 terminal am select assigns one of the following functions for a...

Page 118

Impulse•g+ mini advanced instruction manual – march 2014 5-58 serial communication set-up the impulse•g+ mini uses terminals r + /r - , s + /s - to communicate modbus rtu (rs-485/422) protocol. Parameter code name function range initial value access level h05.01 serial comm address serial communicat...

Page 119

Impulse•g+ mini advanced instruction manual – march 2014 5-59 note: after changing any h05.Xx parameter, power to the inverter must be cycled for the changes to take effect. Note: after initial communication, if the inverter does not detect communication for h05.09 time, a communication fault will o...

Page 120

Impulse•g+ mini advanced instruction manual – march 2014 5-60 pulse inputs parameter code name function range initial value access level h06.01 pulse input selection sets the function of the pulse input terminal (rp) 00, 03 00 adv 00 frequency reference 03 encoder feedback h06.02 pulse input scaling...

Page 121: Protection Parameters

Impulse•g+ mini advanced instruction manual – march 2014 5-61 protection parameters the impulse•g+ mini has the ability to protect both the drive’s hardware and motor by allowing various means to detect and take corrective action when a condition occurs. These include motor overload detection, torqu...

Page 122

Impulse•g+ mini advanced instruction manual – march 2014 5-62 parameter code name function range initial value access level l01.01 motor overload fault select enable/disable motor overload detection. 00–03 03 basic/adv 00 disabled disables the motor thermal overload protection 01 standard fan cooled...

Page 123

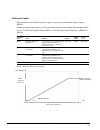

Impulse•g+ mini advanced instruction manual – march 2014 5-63 figure 5-25: motor protection operation time power loss ride thru parameter code name function range initial value access level l02.01 power-loss selection enables/disables the power loss ride thru function 00–02 00 adv 00 disable disable...

Page 124

Impulse•g+ mini advanced instruction manual – march 2014 5-64 stall prevention table 5-8: stall prevention accel selection parameter code name function range initial value access level l03.01 stall prevention accel select enable/disable stall prevention during acceleration. 00–02 01 basic/adv 00 dis...

Page 125

Impulse•g+ mini advanced instruction manual – march 2014 5-65 the stall prevention/current limit level during acceleration is set as a percentage of inverter rated current. Setting l03.01 = 00 disables current limit during acceleration. During acceleration, if the output current exceeds this current...

Page 126

Impulse•g+ mini advanced instruction manual – march 2014 5-66 when a motor is used above rated speed (e01.06), the output characteristics change from constant torque to constant hp (see figure 5-27). During acceleration above rated speed, the stall prevention current limit level is automatically red...

Page 127

Impulse•g+ mini advanced instruction manual – march 2014 5-67 sets a function to prevent stalling during an overload condition while running at constant speed. Table 5-9:stall prevention run selection parameter code name function range initial value access level l03.05 stall prevention run select en...

Page 128

Impulse•g+ mini advanced instruction manual – march 2014 5-68 the stall prevention/current limit level during running is set as a percentage of inverter rated current. A setting of l03.05 = 00 disables current limit during running. During speed agree, if the output current exceeds this current limit...

Page 129

Impulse•g+ mini advanced instruction manual – march 2014 5-69 parameter code name function range initial value access level l03.17 overvoltage suppression and stall prevention sets the desired value for the dc bus voltage during overvoltage suppression and stall prevention during deceleration. Enabl...

Page 130

Impulse•g+ mini advanced instruction manual – march 2014 5-70 reference detection the impulse•g+ mini utilizes three different functions for detecting output frequency: • when frequency agree is enabled using the multi-function contact outputs (h02.Xx = “002” or “013”), the contact closes whenever t...

Page 131

Impulse•g+ mini advanced instruction manual – march 2014 5-71 parameter code name function range initial value access level l04.07 speed agree detection sets the detection level during baseblock 00, 01 00 adv 00 no detection during baseblock 01 detection always enabled.

Page 132

Impulse•g+ mini advanced instruction manual – march 2014 5-72 torque detection the overtorque detection circuit activates when the motor load causes the motor current to exceed the overtorque detection level (l06.02). When an overtorque condition is detected, alarm signals will be shown on the keypa...

Page 133

Impulse•g+ mini advanced instruction manual – march 2014 5-73 overtorque detection 2 functions the same as overtorque/undertorque detection 1 (l06.01), except that “ot2/ut2” is displayed on the digital operator instead. This function is used when two types of detection are output to the multi-functi...

Page 134

Impulse•g+ mini advanced instruction manual – march 2014 5-74 parameter code name function range initial value access level l06.05 torque detection 2 level torque detection 2 level 0–300% 150 adv l06.06 torque detection 2 time torque detection 2 time 0.0–10.0 sec 0.1 adv l06.08 mechanical weakening ...

Page 135

Impulse•g+ mini advanced instruction manual – march 2014 5-75 hardware protection the impulse•g+ mini comes equipped with a number of built-in functions designed to protect the inverter and its components from damage. Parameter code name function range initial value access level l08.02 oh pre-alarm ...

Page 136

Impulse•g+ mini advanced instruction manual – march 2014 5-76 l08.18 soft cla sel enables/disables the software current limit function. Limits output frequency when current exceeds 110% of rated. 00–01 01 adv 00 disabled 01 enabled l08.19 overheat pre-alarm frequency reduction rate 0.1–0.9% 0.8 adv ...

Page 137

Impulse•g+ mini advanced instruction manual – march 2014 5-77 automatic reset when a fault occurs during operation, the impulse•g+ mini can be programmed to automatically reset the fault and restart operation. Parameter code name function range initial value access level l09.01 auto reset select act...

Page 138

Impulse•g+ mini advanced instruction manual – march 2014 5-78 example: enable auto-reset for uv2 and ce faults. 1. Place a “1” above uv2 and ce faults. 2. Convert binary to hexadecimal using table 5-16 for each digit. 3. Program l09.04 to 0003 to enable uv2 and uv1 from table 5-12. 4. Program l09.05...

Page 139

Impulse•g+ mini advanced instruction manual – march 2014 5-79 table 5-16: binary to hexadecimal conversion table 5-14: uv2 example l09.04 binary hex binary number hexadecimal number digit 4 0000 0 0000 0 digit 3 0000 0 0001 1 digit 2 0000 0 0010 2 digit 1 0011 3 0011 3 0100 4 0101 5 table 5-15: ce e...

Page 140: Motor Tuning

Impulse•g+ mini advanced instruction manual – march 2014 5-80 motor tuning • n2 automatic frequency regulator tuning (olv only) • n6 online tuning automatic frequency regulator tuning (olv only) the automatic frequency regulator (afr) is used to achieve stability when a load is suddenly applied or r...

Page 141

Impulse•g+ mini advanced instruction manual – march 2014 5-81 table 5-17: olv stabilization table note: if the motor is hunting, increase the value of n02.05 per the table to stabilize the load. . Control method (a01.02) setting olv stabilization level (n02.05) setting (hex) torq. Comp time (d03.02)...

Page 142

Impulse•g+ mini advanced instruction manual – march 2014 5-82 online tuning parameter code name function range initial value level access n06.01 line-to-line motor tuning selection line-to-line motor tuning 00–01 01 adv 00 disabled 01 enabled.

Page 143: Operator Parameters

Impulse•g+ mini advanced instruction manual – march 2014 5-83 operator parameters the keypad parameters give the ability to show a variety of information such as frequency reference, motor current, input and output terminal status, along with fault trace information. Information displayed can be cus...

Page 144

Impulse•g+ mini advanced instruction manual – march 2014 5-84 164 lc zone 165 lc margin 401 cumulative operation time 403 cooling fan operation time 404 cooling fan maintenance 405 capacitor maintenance 406 soft charge bypass relay maintenance 407 igbt maintenance 408 heatsink temperature 410 kwh; l...

Page 145

Impulse•g+ mini advanced instruction manual – march 2014 5-85 keypad key selection o01.02 power-on monitor selects the monitor to be displayed on the digital operator immediately after the power supply is turned on. 01–05 03 adv 01 frequency reference (u01.01) 02 forward/reverse 03 output frequency ...

Page 146

Impulse•g+ mini advanced instruction manual – march 2014 5-86 clear history 63 2a0006 2005-g+m 64 -- not used 65 2a0010 2008-g+m 66 2a0012 2011-g+m 67 2a0018 not used 68 2a0020 2017-g+m 69 -- not used 6a 2a0030 2025-g+m 6b 2a0040 2033-g+m 6c -- not used 6d 2a0056 2047-g+m 6e 2a0069 2060-g+m 91 4a000...

Page 147

Impulse•g+ mini advanced instruction manual – march 2014 5-87 o03.02 elapsed time selection selects how the elapsed time is accumulated 00, 01 01 adv 00 power on time 01 running time o03.03 fan on time -- 0000–9999hr 0000 adv o03.05 capacitor maintenance time -- 000–150% 000 adv o03.07 inrush preven...

Page 148

Impulse•g+ mini advanced instruction manual – march 2014 5-88 monitor parameters monitor parameter code name function units access level u01.01 frequency reference frequency reference hz basic/adv u01.02 output frequency inverter output frequency hz basic/adv u01.03 output current inverter output cu...

Page 149

Impulse•g+ mini advanced instruction manual – march 2014 5-89 u01.12 inverter control status operation status -- basic/adv u01.13 elapsed time cumulative operation time at drive. Defined by o03.02. Hours basic/adv u01.14 flash id flash rom software id number -- basic/adv u01.15 terminal a1 level ext...

Page 150

Impulse•g+ mini advanced instruction manual – march 2014 5-90 fault trace fault history parameter code name function units access level u02.01 current fault displays the most recent fault detected before being reset -- basic/adv u02.02 last fault displays the most recent fault after being reset (sam...

Page 151

Impulse•g+ mini advanced instruction manual – march 2014 5-91 maintenance u03.20 elapsed time 10 elapsed time of tenth most recent fault -- adv u03.21 accumulated operations displays the number of fwd and rev commands -- adv u03.22 u03.21 rollovers increments when u03.21 reaches 65535. U03.21 is set...

Page 152

Impulse•g+ mini advanced instruction manual – march 2014 5-92 u06.03 asr input % adv u06.04 asr output % adv u06.05 output voltage reference (vq) v adv u06.06 output voltage reference (vd) v adv u06.07 acr (q) output % adv u06.08 acr (d) output % adv u06.20 frequency reference bias (up/down2) % adv ...

Page 153: Troubleshooting

Troubleshooting impulse•g+ mini c h a p t e r 6.

Page 154

Impulse•g+mini advanced instruction manual – march 2014 6-2 this page intentionally left blank..

Page 155: Troubleshooting The Drive

Impulse•g+mini advanced instruction manual – march 2014 6-3 troubleshooting the drive in this troubleshooting section, “check” means investigating whether an item is functioning and in an acceptable physical condition, and then taking corrective action (adjusting, fixing, replacing, etc.) as necessa...

Page 156

Impulse•g+mini advanced instruction manual – march 2014 6-4 drive faults, alarms and indicators motor rotates, but at minimum speed only. 1. Check wiring of speed inputs and verify inputs (u01.10). 2. Verify speed reference setting (a01.04). 3. Verify reference and run source settings are correct (b...

Page 157

Impulse•g+mini advanced instruction manual – march 2014 6-5 cpf02 a/d conversion error. An a/d conversion error occurred. 1. Cycle power to the drive. 2. Ensure that the control board terminals and wiring are shielded from electrical noise. 3. Check resistance of potentiometer. 4. Replace the drive....

Page 158

Impulse•g+mini advanced instruction manual – march 2014 6-6 dne drive not ready user is trying to give a run command while a fwd or rev is present at power up. 1. Check input terminals. 2. Check h01.01 to h01.07 programming. Ef (flashing) external fault both forward/up and reverse/down commands are ...

Page 159

Impulse•g+mini advanced instruction manual – march 2014 6-7 lf output phase loss an open phase occurred at the inverter output. 1. Check for broken wires in output cable. 2. Check for open winding in the motor. 3. Check for loose terminals. Ll1 (flashing) lower limit 1 err lower limit 1—slow down in...

Page 160

Impulse•g+mini advanced instruction manual – march 2014 6-8 ope03 terminal multi-function input setting fault. Set values other than “f” and “ff” are duplicated. 1. Check the settings for h01.01 to h01.07, verify that the same input is not used twice. Ope04 terminal parameters do not match. The driv...

Page 161

Impulse•g+mini advanced instruction manual – march 2014 6-9 ul2 upper limit 2 err upper limit 2—stop indicator. Upper limit 2—stop switch status is changed. 1. May not require corrective action. 2. Check the position of the limit switch. 3. Check the condition of the limit switch. 4. Check the condi...

Page 162

Impulse•g+mini advanced instruction manual – march 2014 6-10 fault display and corrective actions at auto-tuning the following are fault displays and corrective actions at auto-tuning. If any of the following faults are found, the digital operator displays that fault’s contents; the motor coasts to ...

Page 163: Power Section Check

Impulse•g+mini advanced instruction manual – march 2014 6-11 power section check power off checks to perform a power section check, remove the drives main and control wiring from the terminal strips. Obtain reading as specified in the table on the next page, and ensure that the reading falls within ...

Page 164

Impulse•g+mini advanced instruction manual – march 2014 6-12 braking circuit test equipment - analog ohmmeter set to r x 1 scale or digital multimeter set to the diode check. Figure 6-1: braking circuit step no. Ohmmeter positive lead ohmmeter negative lead expected reading (analog meter) expected r...

Page 165: Impulse•g+ Mini Advanced

Impulse•g+ mini advanced parameter listing a p p e n d i x a.

Page 166

Impulse•g+ mini advanced instruction manual – march 2014 a-2 this page intentionally left blank..

Page 167

Impulse•g+ mini advanced instruction manual – march 2014 a-3 impulse•g+ mini parameter listing parameter parameter name default range units reference page a01.01 access level 0000: user 0001: basic 0002: advanced 0001 0000~0001 -- 4-13 a01.02 control method 00: v/f 02: olv 00 00, 02 -- 4-13 a01.03 m...

Page 168

Impulse•g+ mini advanced instruction manual – march 2014 a-4 b01.18 reference priority 00: digital reference only 01: analog reference only 02: higher reference select 00* 00–02 -- 5-3 b02.01 frequency reference upper limit 100.0 0.0–110.0 % 5-5 b02.02 frequency reference lower limit 0.0 0.0–110.0 %...

Page 169

Impulse•g+ mini advanced instruction manual – march 2014 a-5 b05.09 accel/decel units 00: unit of 0.01 seconds 01: unit of 0.1 seconds 01 00–01 -- 5-14 b05.10 accel/decel switch frequency 120.0 0.0–150.0 hz 5-14 b05.11 switch frequency compare 00: lower switch frequency 01: upper switch frequency 01...

Page 170

Impulse•g+ mini advanced instruction manual – march 2014 a-6 c03.11 klixon action 00: decel to stop 01: lower only 00 00–01 -- 5-21 c05.01 load check 00: disable 01: enable load check 03: enable load check continuous 09: load check set up 00 00, 01, 03, 09 -- 5-23 c05.02 lc alarm action 00: alarm on...

Page 171

Impulse•g+ mini advanced instruction manual – march 2014 a-7 c06.04 swift-lift forward torque 50 0–100 % 5-25 c06.05 swift-lift reverse torque 30 0–100 % 5-25 c06.06 swift-lift enabling speed 59.00 0.00–150.00 hz 5-25 c06.07 swift-lift delay time 2.0 0.0–25.5 sec 5-25 c06.08 swift-lift acceleration ...

Page 172

Impulse•g+ mini advanced instruction manual – march 2014 a-8 d02.06 magnetic flux characteristic 00: slip include 01: slip exclude 00 00–01 -- 5-35 d03.01 torque compensation gain 1.00 0.00–2.50 -- 5-36 d03.02 torque compensation time 200**** 0–60000 ms 5-36 d03.03 forward torque compensation @ star...

Page 173

Impulse•g+ mini advanced instruction manual – march 2014 a-9 e01.05 max voltage ** 0.0–255.0 0.0–510.0 v 5-42 e01.06 base frequency ** 0.00–150.00 hz 5-42 e01.07 mid frequency a ** 0.00–150.00 hz 5-42 e01.08 mid voltage a ** 0.0–255.0 0.0–510.0 v 5-42 e01.09 min frequency ** 0.00~150.00 hz 5-42 e01....

Page 174

Impulse•g+ mini advanced instruction manual – march 2014 a-10 f01.09 overspeed detection time 0.0 0.0–2.0 sec 5-45 f01.10 excessive speed detection level 10 00–50 % 5-45 f01.11 excessive speed detection time 0.3 0.0–10.0 sec 5-45 f01.14 pgo detection time 0.5 0.0–10.0 sec 5-45 parameter parameter na...

Page 175

Impulse•g+ mini advanced instruction manual – march 2014 a-11 h01.01 input terminal 1 select (see reference page for further details) 00: multi-step reference 2 01: multi-step reference 3 02: multi-step reference 4 03: multi-step reference 5 04: speed hold 2 05: accel command 06: upper limit 1 n.O. ...

Page 176

Impulse•g+ mini advanced instruction manual – march 2014 a-12 h01.03 terminal 3 select (see reference page for further details) 00* 00–81 -- 5-46 h01.04 terminal 4 select (see reference page for further details) 01* 00–81 -- 5-46 h01.05 terminal 5 select (see reference page for further details) 0f* ...

Page 177

Impulse•g+ mini advanced instruction manual – march 2014 a-13 h02.01 output contact (mc-mb-ma) select 000: brake release 001: zero speed 002: fref. Fout agree 1 003: fref/set agree 1 004: frequency detect 1 005: frequency detect 2 006: inverter ready 007: dc bus undervolt 008: base block n.O. 009: o...

Page 178

Impulse•g+ mini advanced instruction manual – march 2014 a-14 114: (inverse) freq set 2 115: (inverse) frequency detect 3 117: (inverse) torque detect 1 n.C. 118: (inverse) torque detect 2 n.O. 119: (inverse) torque detect 2 n.C. 11a: (inverse) forward direction 11b: (inverse) reverse direction 11c:...

Page 179

Impulse•g+ mini advanced instruction manual – march 2014 a-15 h03.10 terminal a2 select 00: frequency bias 01: frequency gain 02: aux speed reference 1 03: aux speed reference 2 04: output voltage bias 07: ot/ut detection level 0f: not used 10: forward torque limit 11: reverse torque limit 12: regen...

Page 180

Impulse•g+ mini advanced instruction manual – march 2014 a-16 h05.07 rts control select 00: disable 01: enable 01 00–01 -- 5-58 h05.09 communication - error detection time 2.0 0.0–10.0 sec 5-58 h05.10 output voltage reference 00: 0.1v 01: 1v 00 00–01 -- 5-58 h05.11 communcation enter function select...

Page 181

Impulse•g+ mini advanced instruction manual – march 2014 a-17 l02.01 power-loss selection 00: disable 01: enabled 02: cpu power active 00 00–02 -- 5-63 l02.02 power-loss ride thru time 0.1 (varies) 0.0–25.5 sec 5-63 l02.03 power-loss base block time 01. (varies) 0.1–5.0 sec 5-63 l02.04 power-loss v/...

Page 182

Impulse•g+ mini advanced instruction manual – march 2014 a-18 l06.01 torque detection 1 level select 00: disabled 01: overtorque @ speed agree (alarm) 02: overtorque @ run (alarm) 03: overtorque @ speed agree (fault) 04: overtorque @ run (fault) 05: undertorque @ speed agree (alarm) 06: undertorque ...

Page 183

Impulse•g+ mini advanced instruction manual – march 2014 a-19 l08.06 input phase loss detection level (increasing l08.06 from default value may cause dc bus capacitor failure) 5.0 0.0–5.0 % 5-75 l08.07 output phase loss selection 00: disabled 01: enabled 01 00, 01 -- 5-75 l08.08 output phase loss de...

Page 184

Impulse•g+ mini advanced instruction manual – march 2014 a-20 o01.01 user montior selection 104: control method 105: motor speed - olv only 106: output voltage 107: dc bus voltage 108: output power 109: torque reference - olv only 110: input terminal status 111: output terminal status 112: operation...

Page 185

Impulse•g+ mini advanced instruction manual – march 2014 a-21 o01.02 power-on monitor 01: frequency reference (u01.01) 02: forward/reverse 03: output frequency (u01.02) 04: output current (u01.03) 05: user monitor (o01.01) 03 01–05 -- 5-85 o01.03 display sealing 00: 0.01 hz 01: 0.01% 02: r/min 03: u...

Page 186

Impulse•g+ mini advanced instruction manual – march 2014 a-22 o02.05 operator m.O.P 00: disabled 01: enabled 00 00, 01 -- 5-86 o02.07 motor direction at power-up 00: forward 01: reverse 00 00, 01 -- 5-86 o03.01 elapsed time setting 0000 0000–9999 hr 5-86 o03.02 elapsed time selection 00: power on ti...

Page 187

Impulse•g+ mini advanced instruction manual – march 2014 a-23 u01.11 output terminal status -- -- -- 5-88 u01.12 inverter control status -- -- -- 5-89 u01.13 elapsed time -- -- hours 5-89 u01.14 flash id -- -- -- 5-89 u01.15 terminal a1 level -- -- % 5-89 u01.16 terminal a2 level -- -- % 5-89 u01.20...

Page 188

Impulse•g+ mini advanced instruction manual – march 2014 a-24 u03.09 fault message 9 -- -- -- 5-90 u03.10 fault message 10 -- -- -- 5-90 u03.11 elapsed time 1 -- -- hours 5-90 u03.12 elapsed time 2 -- -- hours 5-90 u03.13 elapsed time 3 -- -- hours 5-90 u03.14 elapsed time 4 -- -- hours 5-90 u03.15 ...

Page 189

Impulse•g+ mini advanced instruction manual – march 2014 a-25 u06.05 output voltage reference (vq) -- -- v 5-92 u06.06 output voltage reference (vd) -- -- v 5-92 u06.07 acr (q) output -- -- % 5-92 u06.08 acr (d) output -- -- % 5-92 u06.20 frequency reference bias (up/down2) -- -- % 5-92 u06.21 offse...

Page 190

Impulse•g+ mini advanced instruction manual – march 2014 a-26 this page intentionally left blank..