- DL manuals

- Magnetek

- Controller

- HPV 900 Series 2

- Technical Manual

Magnetek HPV 900 Series 2 Technical Manual

Summary of HPV 900 Series 2

Page 1

Hpv 900 series 2 ac/pm elevator drive technical manual includes quick start guides drive firmware: 97sa4810-010220.41 tm7333 rev 21 © 2017 magnetek elevator.

Page 2

Warranty standard products manufactured by the company are warranted to be free from defects in workmanship and material for a period of one year from the date of shipment, and any products which are defective in workmanship or material will be r epaired or replaced, at the company’s option, at no c...

Page 3

Important grounding considerations it is very important to make proper ground connections to the drive. The drive has a common ground bus terminal connection. All grounds need to land at this common point including building, motor, transformer, and filter grounds. This will limit the impedance betwe...

Page 5

I closed-loop quick start-up guide note: this quick start-up guide just outlines the general parameters that should be changed / verified when a drive is installed with information that are readily available. The drive will not run if only these parameters are set. Because different controller manuf...

Page 6

Ii electrical considerations if possible, insulate both the encoder case and shaft from the motor. use twisted pair cable with shield tied to chassis ground at drive end use limited slew rate differential line drivers. do not allow capacitors from internal encoder electronics to case. do n...

Page 7

Iii parameter description default units suggested adjustment inertia system inertia 2.00 sec determines the system inertia in terms of the time it takes the elevator to accelerate to contract speed. If the car is light, the value will be smaller than the default and vice versa if the car is heavy. E...

Page 8

Iv motor a5 parameter description default units suggested adjustment motor id motor identification none used to initialize the drive. Display will change to block capital letters when initialized. Enter either 4 or 6 pole motor. Rated mtr power rated motor output power 0 hp set to motor hp/kw rating...

Page 9

V open-loop quick start-up guide note: this quick start-up guide just outlines the general parameters that should be changed / verified when a drive is installed with information that are readily available. The drive will not run if only these parameters are set. Because different controller manufac...

Page 10

Vi hoistway parameter set-up 4) enter / verify the hoistway parameters: contract car spd (a1) parameter should be the elevator contract speed in m/s. contract mtr spd (a1) parameter should be set to a rpm that will make the elevator travel at desired car speed (measured with hand tachometer) not...

Page 11

Vii parameter description default units suggested adjustment torq boost gain torque boost responsiveness 0.00 none enter / verify that it is set at default until the open-loop performance adjustments on page 167 dictates a different number table 4 ol: important parameters in a1 menu to set/check whe...

Page 12

Viii basics u9 parameter description default choices suggested adjustment drive mode drive operation closed loop open loop closed loop pm adjust to open-loop so drive can run motor without an encoder table 7 ol: important parameter in u9 menu to set/check when setting up a drive in open-loop.

Page 13: Pm Quick Start-Up Guide

Ix pm quick start-up guide note: this quick start-up guide just outlines the general parameters that should be changed / verified when a drive is installed with information that are readily available. The drive will not run if only these parameters are set. Because different controller manufacturers...

Page 14

X encoder hpv900 s2 endat termination cable color 46s04327- 1100 previous versions black heidenhain ziehl green encoder cable torin encoder cable on site color a/ a- tb2-65 yellow/black red & blue yellow brown a a+ tb2-66 green/black grey & pink green green b/ b- tb2-67 red/black red red yellow b b+...

Page 15

Xi if given rated excitation frequency and the rated motor speed, use the following calculation: poles of # speed motor rated frequency excitation motor 60 2 3) select the pm default motor for the motor id (a5) parameter. Enter / verify the following from the motor’s nameplate: motor hp or kw rati...

Page 16

Xii scroll to u10 menu – rotor alignment and change the parameter alignment from disabled to enabled scroll to a5 menu and to the parameter encoder ang ofst press enter and manually enter the ‘known’ offset value – the motor should then be able to run – attempt this on test controls. If the roto...

Page 17

Xiii also in the u10 alignment menu ensure the parameter alignment method is set to hf inject or auto align next change the parameter begin alignment to on run the drive is now ready for alignment, so simply press and hold the run, run up, or run down buttons. You should see the run led on the d...

Page 18

Xiv key drive parameters drive menu a1 parameter description default units suggested adjustment contract car spd elevator contract speed 400.0 fpm adjust to speed the installation is rated to run at. 0.0 m/s contract mtr spd motor speed at elevator contract speed 1130.0 rpm adjust this value to ensu...

Page 19

Xv parameter description default units suggested adjustment iq reg intg gain integral gain for the current regulator torque generation 1.00 none enter / verify that it should be set to default. Table 3 pm: important parameters in a4 menu to set/check when setting up a drive in pm mode motor a5 param...

Page 20

Xvi autotune sel u12 parameter description default choices suggested adjustment autotune select allow autotune to run disable disable on run yes adjust to pm so drive can run a pm motor. Table 8 pm: important parameter in u12 menu to set/check when setting up a drive in pm mode.

Page 21: Table Of Contents

Table of contents hpv 900 series 2 drive ratings ........................................................................................................... 1 introduction ...................................................................................................................................

Page 22

Safe-off .................................................................................................................................... 159 brake monitoring ........................................................................................................................... 162 testpoint...

Page 23

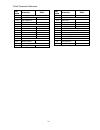

1 hpv 900 series 2 drive ratings table 1: hpv 900 series 2 drive ratings note: all ratings at 60/50hz and bases on a geared elevator appilcation 1. Na refers to drives sold in north america and ratings are based off of 460vac input. Eu refers to drives sold in europe and are based off of 400vac inpu...

Page 24

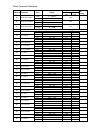

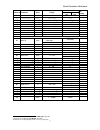

Quick parameter reference 2 submenu parameter units range default site setting english (u3) metric (u3) a1 drive a1 submenu – for details, see drive a1 submenu on page 40. A1 contract car spd fpm 0.0 – 1500.0 400.0 - m/s 0.000 – 8.000 - 0.000 a1 contract mtr spd rpm 0.0 – 3000.0 1130.0 i, iii 0.0 13...

Page 25

Quick parameter reference 3 submenu parameter units range default site setting english (u3) metric (u3) a1 i,ii spd dev time i,ii sec i,ii 0.00 – 9.99 i,ii 0.50 i,ii 5.00 i,ii a1 ii spd dev alm lvl ii % ii 0.00 – 99.9 ii 10.0 ii a1 ii spd dev flt lvl ii % ii 0.00 – .99.9 ii 25.0 ii a1 up to spd. Lev...

Page 26

Quick parameter reference 4 submenu parameter units range default site setting english (u3) metric (u3) a1 ntsd threshold 1 ft/ min 0 – 1500.0 0.0 m/ sec 0 – 7.600 a1 ntsd threshold 2 ft/ min 0 – 1500.0 0.0 m/ sec 0 – 7.600 a1 ntsd threshold 3 ft/ min 0 – 1500.0 0.0 m/ sec 0 – 7.600 a2 s-curves a2 s...

Page 27

Quick parameter reference 5 submenu parameter units range default site setting english (u3) metric (u3) a2 accel jerk in 4 ft/s 3 0.0 – 29.9 0.0 - m/s 3 0.00 – 9.99 - 0.00 a2 accel jerk out 4 ft/s 3 0.0 – 29.9 0.0 - m/s 3 0.00 – 9.99 - 0.00 a2 decel jerk in 4 ft/s 3 0.0 – 29.9 0.0 - m/s 3 0.00 – 9.9...

Page 28

Quick parameter reference 6 submenu parameter units range default site setting english (u3) metric (u3) a3 ii v2 ii ft/min -3000.0 – +3000.0 0.0 - m/sec -16.000 – +16.000 - 0.000 a3 ii v3 ii ft/min -3000.0 – +3000.0 0.0 - m/sec -16.000 – +16.000 - 0.000 a3 ii v4 ii ft/min -3000.0 – +3000.0 0.0 - m/s...

Page 29

Quick parameter reference 7 submenu parameter units range default site setting english (u3) metric (u3) a4 iii dist lp off freq iii hz iii 0.0 – 99.9 iii 60.0 iii a4 iii ilimit integ gn iii none iii 0.00 – 9.99 iii 1.00 iii a4 iii hunt prev gain iii none iii 0.00 – 4.00 iii 1.00 iii a4 iii hunt prev...

Page 30

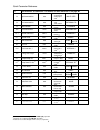

Quick parameter reference 8 c1 user switches c1 submenu – for details, see user switches c1 on page 80. C1 spd command src none multi-step ser mult step analog input serial multi-step c1 run command src none external tb serial serial+extern external tb c1 motor rotation none forward reverse forward ...

Page 31

Quick parameter reference 9 c1 user switches c1 submenu continued… c1 serial mode none none mode 1 mode 2 mode 3 dcp4 dcp3 mode 2 test none c1 ser2 flt mode none immediate run remove rescue immediate c1 drv fast disable none disable enable disable c1 i,ii speed reg type i,ii none i,ii ...

Page 32

Quick parameter reference 10 c1 drive enable src none external tb serial serial+extern external tb c1 rec travel dir none none geared gearless none c1 phase loss check none high sens. Low sens. Disabled high sens. C1 overload select % 250 200 250 c1 ntsd mode none external 1 threshold 2 thresholds ...

Page 33

Quick parameter reference 11 c2 logic inputs c2 submenu – for details, see logic inputs c2 on page 100. C2 logic input 1 contact cfirm drive enable extrn fault 1 extrn fault 2 extrn fault 3 extrn/flt 4 fault reset low gain sel mains dip mech brk hold mech brk pick 1 mech brk ...

Page 34

Quick parameter reference 12 c4 analog outputs c4 submenu – for details, see analog outputs c4 on page 106. C4 analog output 1 abs pos bin aux torq cmd bus voltage current out d-current ref drv overload flux current flux output flux ref flux voltage frequency out mtr overload...

Page 35

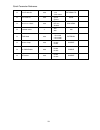

Quick parameter reference 13 sub menu parameter units d1 elevator data d1 submenu d1 speed command ft/min or m/s d1 speed reference ft/min or m/s d1 speed feedback ft/min or m/s d1 analog spd cmd volts d1 encoder speed rpm d1 i,ii speed error i,ii ft/min or m/s i,ii d1 i,ii est inertia i,ii seconds ...

Page 36

Quick parameter reference 14 sub menu parameter units u10 ii rotor align u10 submenu ii u10 ii alignment ii u10 ii begin alignment ii u10 ii alignment method ii u11 time u11 submenu u11 year u11 month u11 day u11 hour u11 minute u11 second u12 ii autotune u12 submenu ii u12 ii autotune select ii u13...

Page 37: Introduction

Introduction 15 introduction drive specifications ratings north american horse power ratings - 230 volt ac input: 7.5, 10, 15, 20, 25, 30, and 40 hp - 460 volt ac input: 5, 7.5, 10, 15, 20, 25, 30, 40, 50, 60, and 75 hp european horse power ratings - 400 volt ac input: 5, 5.5, 7.5, 10, 15, 20, 2...

Page 38

Introduction 16 digital outputs two (2) programmable form-c relays relay 1&2: 2a at 30vdc / 250vac resistive (inductive load) update rate: 2 msec. minimum recommended load 100ma, 5vdc four (4) programmable opto-isolated open-collectors voltage: 50 volts dc (max.) capacity: 100 ma updat...

Page 39

General start-up 17 general start-up procedure the following is a recommended start-up procedure: 1. The hpv 900 series 2 is thoroughly tested at the factory. Verify the drive has been installed without shipping and installation damage. 2. Review the hpv 900 series 2 technical manual, shipped with t...

Page 40

General start-up 18 pre-power check caution: to prevent damage to the drive. The following checks must be performed before applying the input power. inspect all equipment for signs of damage, loose connections, or other defects. ensure the three-phase line voltage is within 10% of the nominal i...

Page 41: Terminals

Terminals 19 terminals remember when servicing the hpv900 series 2: hazardous voltages may exist in the drive circuits even with drive circuit breaker in off position. Important: use extreme caution: do not touch any circuit board, the drive, or motor electrical connections without making sure that ...

Page 42

Terminals 20 remember when servicing the hpv900 series 2: hazardous voltages may exist in the drive circuits even with drive circuit breaker in off position. Important: use extreme caution: do not touch any circuit board, the drive, or motor electrical connections without making sure that the unit i...

Page 43

Terminals 21 remember when servicing the hpv900 series 2: hazardous voltages may exist in the drive circuits even with drive circuit breaker in off position. Important: use extreme caution: do not touch any circuit board, the drive, or motor electrical connections without making sure that the unit i...

Page 44

Terminals 22 remember when servicing the hpv900 series 2: hazardous voltages may exist in the drive circuits even with drive circuit breaker in off position. Important: use extreme caution: do not touch any circuit board, the drive, or motor electrical connections without making sure that the unit i...

Page 45

Terminals 23 remember when servicing the hpv900 series 2: hazardous voltages may exist in the drive circuits even with drive circuit breaker in off position. Important: use extreme caution: do not touch any circuit board, the drive, or motor electrical connections without making sure that the unit i...

Page 46

Interconnections 24 remember when servicing the hpv900 series 2: hazardous voltages may exist in the drive circuits even with drive circuit breaker in off position. Important: use extreme caution: do not touch any circuit board, the drive, or motor electrical connections without making sure that the...

Page 47: Interconnections

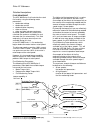

Interconnections 25 interconnections 13 14 15 16 12 tb2 tb1 tb1 6 7 8 9 10 11 24 25 26 21 22 23 logic input 1 logic input 2 logic input 3 logic input 4 logic input 5 logic input 6 logic input 7 logic input 8 logic input 9 +24vdc isolated logic input common +24vdc iso. Common commcommoncommon logic o...

Page 48

Interconnections 26 logic inputs the hpv 900 series 2’s nine programmable logic inputs are opto-isolated. The inputs become “true” by closing contacts or switches between the logic input terminal and voltage source common (or voltage source). The voltage supply for the logic inputs is 24vdc. The cho...

Page 49

Interconnections 27 figure 11 shows the connection for using the external voltage supply. And in this case the voltage source common is positive side of the external voltage supply. Figure 11: logic inputs sourcing operation (low true - external supply) figure 12 shows the connection for using the e...

Page 50

Interconnections 28 logic outputs the hpv 900 series 2’s four programmable logic outputs are opto-isolated, open collector. The outputs are normally open and can withstand an applied maximum voltage of 50vdc. When the output becomes “true”, the output closes and is capable of sinking up to 150ma bet...

Page 51

Interconnections 29 serial connections the hpv900 series 2 supports serial data communication between the control system and the drive using both rs-422 & rs-485 interfaces and support multiple serial protocols detailed on page 84. The serial terminations should be as detailed in table 5. Db9 to fly...

Page 52

Interconnections 30 encoder the hpv 900 series 2 can be configured for an incremental two-channel quadrature encoder. The drive’s encoder circuitry incorporates resolution multiplication and complimentary outputs. It is recommended that a diferential line driver encoder of type 7272 is used. Push-pu...

Page 53

Interconnections 31 terminal description incremental encoder connections hpv900 series 2 hpv900 hpv600 option card a tb1-1 tb1-21 tb2-63 /a tb1-2 tb1-20 tb2-62 b tb1-3 tb1-23 tb2-65 /b tb1-4 tb1-22 tb2-64 z tb1-19 n/a n/a /z tb1-20 n/a n/a encoder +5 /+12vdc tb1-17 tb1-25 tb1-24 tb2-67 tb2-66 encode...

Page 54

Interconnections 32 heidenhain 309778-xx cable. Maximum length of the encoder cable (including a pigtail cable, if applicable) is 15 meters (50’). For cables longer than 15 meters (50’) the sense wires should be connected and jp1 and/or jp2 on the endat board should be set to the 2-3 position. Note:...

Page 55

Interconnections 33 analog inputs the hpv 900 series 2 has two non- programmable differential analog input channels. analog input channel 1 is reserved for the speed command (if used). analog input channel 2 is reserved for the pre-torque command (if used). The analog input channels are bipolar ...

Page 56

Interconnections 34 analog outputs the hpv 900 series 2 has two programmable differential analog output channels. The two analog output channels were designed for diagnostic help. For more information on programming the analog output channels, see analog outputs c4 submenu on page 106. The analog ou...

Page 57

Interconnections 35 figure 27: main circuit block diagram (230vac 1-20hp cube) figure 28: main circuit block diagram (230vac 25-60hp).

Page 58

Interconnections 36 figure 29: main circuit block diagram (460vac 1-20hp) figure 30: main circuit block diagram (460vac 25-75hp).

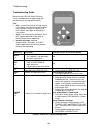

Page 59: Parameters

Parameters 37 parameters parameter introduction this section describes the parameter menu structure; how to navigate this menu structure via the hpv 900 series 2 digital operator; and a detailed description of each parameter. Parameters are grouped under six major menus: adjust a0 configure c0 ...

Page 60

Parameters 38 figure 33: operator navigation ready run user fault torque limit sub menu data entry 8:55 may 20 a0 adjust a1 drive 8:55 may 20 d0 display d1 elevator data ready run user torque limit sub menu data entry fault a1 8:57 contract car spd 0400.0 ft/min min 0.0 max 1500.0 ready run user fau...

Page 61

Parameters 39 a1 8:55 contract car spd 0400.0 ft/min ready run user fault torque limit sub menu data entry 8:55 may 20 a0 adjust a1 drive ready run user fault torque limit sub menu data entry a1 8:57 contract car spd 0400.0 ft/min min 0.0 max 1500.0 ready run user fault torque limit sub menu data en...

Page 62: Adjust A0 Menu

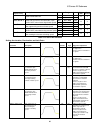

Drive a1 submenu 40 adjust a0 menu drive a1 submenu note: when hidden item appears with the parameter description, it indicates that its appearance in the list is controlled by the hidden items setting. See details on page 119. Note: when run lock out appears with the parameter description, the para...

Page 63

Drive a1 submenu 41 parameter [ alphanumeric] description units range default hidden item run lockout english (u3) metric (u3) regen torq limit [a108] (regenerating current limit) this parameter sets the maximum amount of regenerative torque the drive will see during regeneration. This parameter may...

Page 64

Drive a1 submenu 42 parameter [ alphanumeric] description units range default hidden item run lockout english (u3) metric (u3) contact flt time [a115] (contact fault time ) when external logic outputs are used to control the closing of the motor contactor, this parameter sets the amount of time dela...

Page 65

Drive a1 submenu 43 parameter [ alphanumeric] description units range default hidden item run lockout english (u3) metric (u3) ab off delay i,ii [a123] (auto brake off delay i,ii ) this parameter determines the time after zero speed is reached (level determined by the ab zero spd lev (a1) parameter)...

Page 66

Drive a1 submenu 44 parameter [ alphanumeric] description units range default hidden item run lockout english (u3) metric (u3) dc stop freq iii [a127] (dc injection stopping frequency ii ) the frequency at which dc injection begins to occur when the drive is decelerating to a stop. If ramp to stop i...

Page 67

Drive a1 submenu 45 parameter [ alphanumeric] description units range default hidden item run lockout english (u3) metric (u3) stall fault time iii [a134] (stall fault time iii ) this parameter sets the time that the drive can be at or above the stall test lvl(a1), before the drive declares an stall...

Page 68

Drive a1 submenu 46 parameter [ alphanumeric] description units range default hidden item run lockout english (u3) metric (u3) torq boost time iii [a137] (torque boost time constant iii ) this parameter is the torque boost filter time constant. Adjusted for torque compensation response and stability...

Page 69

Drive a1 submenu 47 parameter [ alphanumeric] description units range default hidden item run lockout english (u3) metric (u3) spd dev alm lvl ii [a141] (speed deviation alarm level ii ) this parameter sets the level at which a speed deviation alarm will be declared. For more information, see spd de...

Page 70

Drive a1 submenu 48 parameter [ alphanumeric] description units range default hidden item run lockout english (u3) metric (u3) run delay timer i,ii [a149] (run delay timer i,ii ) allows the user to delay the drive’s recognition of the run signal. Sec i,ii 0.00 – 0.99 i,ii 0.00 i,ii y i,ii y i,ii tac...

Page 71

Drive a1 submenu 49 parameter [ alphanumeric] description units range default hidden item run lockout english (u3) metric (u3) spd command mult [a154] (speed command multiplier) this parameter scales the analog speed command. Uses software drive signal mult command spd bias command spd voltage input...

Page 72

Drive a1 submenu 50 parameter [ alphanumeric] description units range default hidden item run lockout english (u3) metric (u3) ana 1 out offset [a161] (digital to analog #1 output offset) offset for scaling analog output channel #1. Voltage output channel analog gain out ana offset out ana creates s...

Page 73

Drive a1 submenu 51 parameter [ alphanumeric] description units range default hidden item run lockout english (u3) metric (u3) ser2 flt tol [a168] (serial mode 2 fault tolerance) used only with custom serial protocol (mode 2) when in serial mode 2, this parameter defines the maximum time that may el...

Page 74

Drive a1 submenu 52 parameter [ alphanumeric] description units range default hidden item run lockout english (u3) metric (u3) arb timeout i,ii [a179] (anti-rollback timeout i,ii ) time from when the drive is turned on and arb stops looking for motion. Typical value are arb advance + arb decay + 0.2...

Page 75

Drive a1 submenu 53 parameter [ alphanumeric] description units range default hidden item run lockout english (u3) metric (u3) ntsd target spd [a187] (normal terminal stopping device target speed) maximum speed at which drive will run when ntsd is active. Ft/min 0.0 – 50.0 0.0 n y m/s 0.000 – 0.250 ...

Page 76

Drive a1 submenu 54 detailed descriptions flux weakening i the hpv 900 series 2 will calculate the rated flux level by using the following motor parameters: rated motor voltage rated motor current rated excitation frequency stator resistance stator and rotor leakage reactances as motor spe...

Page 77

Drive a1 submenu 55 gain chng level i,ii (gain change level) note: this parameter is only accessible and usable when the drive is set for closed loop operation. When the gain control is set to internal, the drive will control the high/low gain switch. This parameter sets the speed reference level, w...

Page 78

Drive a1 submenu 56 ramped stop time i,ii (ramped stop time) this parameter is only used by the torque ramp down stop function and sets the time to ramp torque from rated torque to zero. After the elevator lands and the brake is applied, the torque ramp down function allows the torque to ramp down a...

Page 79

Drive a1 submenu 57 figure 34: speed deviation example for closed loop (u9) figure 35: speed deviation example for pm (u9) notch filter frq i,ii (notch filter center frequency) this parameter determines the notch filter center frequency. Notch filter although originally created for gearless applicat...

Page 80

Drive a1 submenu 58 anti-rollback anti-rollback is an independent function meant to calculate the amount of torque necessary to hold the car when load weighing is not available. See below for help in adjusting and setting up arb for a hpv900 s2 drive. Please note: arb should be a final adjustment. A...

Page 81

Drive a1 submenu 59 to set up arb3: 1. Verify that the pre torque src (c1) is set to none so it does not affect the arb function. 2. Arb3 is enabled by setting arb select (c1) to arb3. 3. After enabling the function in arb select (c1 submenu), in most cases arb3 will work well with all related a1 su...

Page 82

Drive a1 submenu 60 mspd delay 1-4 (multi-step speed delay) these four parameters determine the recognition time delay for a multi-step speed commands defined by mlt-spd to dly1-4 (c1) parameters. When setting up an elevator, slow-down and stop switches are set at fixed locations in the shaft. Once ...

Page 83

S-curves a2 submenu 61 s-curves a2 submenu detailed descriptions the hpv 900 series 2 speed command is passed through an internal s-curve in order to produce the speed reference. In general, the s-curve function takes an arbitrary speed command and generates a speed reference subject to the conditio...

Page 84

S-curves a2 submenu 62 parameter [alphanumeric] description units range default hidden item run lockout accel rate 0 acceleration rate ft/s 2 0.00 – 7.99 3.00 n y [a201] m/s 2 0.000 – 3.999 0.800 decel rate 0 deceleration rate ft/s 2 0.00 – 7.99 3.00 n y [a202] m/s 2 0.000 – 3.999 0.800 accel jerk i...

Page 85

S-curves a2 submenu 63 parameter [alphanumeric] description units range default hidden item run lockout decel rate 4 ntsd deceleration rate ft/s 2 0.00 – 7.99 5.00 n y [a226] m/s 2 0.000 – 3.999 0.800 accel jerk in 4 ntsd rate of increase of acceleration, up to accel rate, when increasing elevator s...

Page 86

Multistep ref a3 submenu 64 multistep ref a3 submenu detailed descriptions (non dcp operation) the multi-step speed reference function is one possible way for the drive to accept speed command. To use this function, the user can enter up to fifteen speed commands (cmd1 – cmd15) and assign four logic...

Page 87

Multistep ref a3 submenu 65 parameter [alphanumeric] description units range default hidden item run lockout speed command 1 i [a301] multi-step speed command #1 ft/min -3000.0 – +3000.0 0.0 n y m/sec -16.000 – +16.000 0.000 speed command 2 i [a302] multi-step speed command #2 ft/min -3000.0 – +3000...

Page 88

Multistep ref a3 submenu 66 parameter [alphanumeric] description units range default hidden item run lockout i v1 ii [a318] speed reference 1 ft/min -3000.0 – +3000.0 0.0 n y m/sec -16.000 – +16.000 0.000 v2 ii [a319] speed reference 2 ft/min -3000.0 – +3000.0 0.0 n y m/sec -16.000 – +16.000 0.000 v...

Page 89

Power convert a4 submenu 67 power convert a4 submenu note: when hidden item appears above a parameter description, it indicates that its appearance in the list is controlled by the hidden items setting. See details on page 119. Note: when run lock out appears above a parameter description, the param...

Page 90

Power convert a4 submenu 68 parameter [alphanumeric] description units range default hidden item run lockout english (u3) metric (u3) id reg prop gain [a407] (current regulator proportional gain for flux generation) the proportional gain for the current regulator flux generation. This parameter is m...

Page 91

Power convert a4 submenu 69 parameter [alphanumeric] description units range default hidden item run lockout english (u3) metric (u3) id ref threshld ii [a426] for magnetek personnel – this parameter is used to manually set non-zero current reference for flux production. This needs to be zero for no...

Page 92

Power convert a4 submenu 70 parameter [alphanumeric] description units range default hidden item run lockout english (u3) metric (u3) id dist loop fc iii [a416] (corner frequency on distortion loop for flux current iii ) this parameter is the high-pass corner frequency on the distortion loop regulat...

Page 93

Power convert a4 submenu 71 parameter [alphanumeric] description units range default hidden item run lockout english (u3) metric (u3) hunt prev gain iii [a421] (hunt prevent gain iii ) determines the response to changes in torque (torque slew rate gain). Increasing the gain slows drive torque respon...

Page 94

Power convert a4 submenu 72 parameter [alphanumeric] description units range default hidden item run lockout english (u3) metric (u3) load sense time [a431] (load sense time) this is the duration that the drive spends in the recommended travel direction mode to figure out the direction that will req...

Page 95

Power convert a4 submenu 73 flux weakening ii at voltage limits flux weakening parameters the following hpv 900 s2 pm parameters affect flux weakening: flux weakening slew (flux weaken rate (a4)) flux weakening level (flux weaken lev (a4)) permanent magnets are used to generate a constant flux l...

Page 96

Motor a5 submenu 74 motor a5 submenu this sub-menu contains parameters, which are programmed with information about the motor being controlled by the drive. Important the parameters in this sub-menu defined the motor model, which is very important for proper operation. Ensure that the data is accura...

Page 97

Motor a5 submenu 75 parameter [ alphanumeric] description units range default hidden item run lockout english (u3) metric (u3) rated mtr pwr [a502] (rated motor power) this parameter sets the rated power in horsepower (hp) or kilowatts (kw) of the motor. Note: value should be obtained from the motor...

Page 98

Motor a5 submenu 76 parameter [ alphanumeric] description units range default hidden item run lockout english (u3) metric (u3) stator leakage x i, iii [a509] (stator leakage reactance i, iii ) this parameter sets the stator reactance leakage, as a percent of the base impedance, which appears in the ...

Page 99

Motor a5 submenu 77 parameter [ alphanumeric] description units range default hidden item run lockout english (u3) metric (u3) motor mid freq iii [a514] (v/hz pattern middle frequency iii ) this parameter sets middle frequency used to define the v/hz pattern. Note: a setup flt #9 will occur if the b...

Page 100

Motor a5 submenu 78 parameter [ alphanumeric] description units range default hidden item run lockout english (u3) metric (u3) ol align scale ii [a525] (open-loop alignment scale ii ) the drive automatically calculates the torque constant. This value can scale the calculated torque constant to provi...

Page 101

Motor a5 submenu 79 motor overload curve 110% 130% 150% 170% 190% 210% 230% 250% 10 100 1000 10,000 current (percentage of rated motor current) default motor overload trip time (seconds) curve #1 olvd start level = 110% curve #1 olvd time out = 60 sec curve #2 olvd time out = 40 sec curve #2 olvd st...

Page 102: Configure C0 Menu

User switches c1 submenu 80 configure c0 menu user switches c1 submenu parameter [alphanumeric] description choices default hidden item run lockout english (u3) metric (u3) spd command src [c101] (speed command source) this parameter designates the source of the drive’s speed command. The four possi...

Page 103

User switches c1 submenu 81 parameter [alphanumeric] description choices default hidden item run lockout english (u3) metric (u3) encoder select ii [c104] (encoder selection ii ) hpv900 s2 pm drives can run either with an incremental encoder or with an heidenhain endat encoder. This parameter sets t...

Page 104

User switches c1 submenu 82 parameter [alphanumeric] description choices default hidden item run lockout english (u3) metric (u3) i-reg inner loop ii [c110] (current regulator inner loop ii ) this switch is used to disable/enable the current regulator inner loop function. It is used to enhance the c...

Page 105

User switches c1 submenu 83 parameter [alphanumeric] description choices default hidden item run lockout english (u3) metric (u3) brake pick src [c116] (brake pick source) if the brake pick src (c1) is set to internal, the hpv 900 series 2 will attempt to pick (lift) the brake when magnetizing curre...

Page 106

User switches c1 submenu 84 parameter [alphanumeric] description choices default hidden item run lockout english (u3) metric (u3) auto stop [c120] (auto stop function enable) the auto stop function determines how the drive logic will respond to a zero or non-zero speed command. If speed command src ...

Page 107

User switches c1 submenu 85 parameter [alphanumeric] description choices default hidden item run lockout english (u3) metric (u3) ser2 flt mode [c124] (serial mode 2 fault mode) used only with serial protocol (mode 2) this parameter defines the reaction to a serial communications fault while in seri...

Page 108

User switches c1 submenu 86 parameter [alphanumeric] description choices default hidden item run lockout english (u3) metric (u3) brake hold src [c127] (brake hold source) if set to internal, the drive will command the mechanical brake to hold mode until confirmation of brake picked exists. intern...

Page 109

User switches c1 submenu 87 parameter [alphanumeric] description choices default hidden item run lockout english (u3) metric (u3) fault reset src [c131] (fault reset source) this parameter determines the source of the drive’s external fault reset from one of the following sources: an external fault ...

Page 110

User switches c1 submenu 88 parameter [alphanumeric] description choices default hidden item run lockout english (u3) metric (u3) pretorque latch i,ii [c134] (pre-torque latch i,ii ) this parameter determines if the pre- torque signal is latched. Note: if pretorque source has been set to none, the s...

Page 111

User switches c1 submenu 89 parameter [alphanumeric] description choices default hidden item run lockout english (u3) metric (u3) dir confirm [c136] (direction confirm) when enabled, the function allows confirmation of the polarity of the initial analog speed command via the run up or run down logic...

Page 112

User switches c1 submenu 90 parameter [alphanumeric] description choices default hidden item run lockout english (u3) metric (u3) mlt-spd to dly 1 [c138] (multi-step speed command delay x) this parameter assigns multi-step speed command to recognition delay timer x as defined by the mspd delay x (a1...

Page 113

User switches c1 submenu 91 parameter [alphanumeric] description choices default hidden item run lockout english (u3) metric (u3) endat out mult ii [c145] (endat output multiplier ii ) this parameter is the encoder ppr multiplier that sets the pulse rate of the differential quadrature buffered outpu...

Page 114

User switches c1 submenu 92 parameter [alphanumeric] description choices default hidden item run lockout english (u3) metric (u3) fan pwm enable [c152] this parameter allows the user to enable and disable soft starting on the fans. enable [1] disable [0] enable n y ppt select [c153] (pulse pre-t...

Page 115

User switches c1 submenu 93 detailed descriptions fast flux i (fast flux enable) this parameter addresses the method the hpv 900 series 2 uses to build up flux in the motor. Enabling the fast flux function can decrease the motor fluxing time significantly. By decreasing the motor’s flux time, the st...

Page 116

User switches c1 submenu 94 drive senses the motor is above a defined speed level. The defined speed level is determined by the gain change level parameter. An example of internal high / low gain control is shown below. High / low gain example i ,ii ramped stop sel i,ii (ramp stop select) this param...

Page 117

User switches c1 submenu 95 s-curve abort this parameter, s-curve abort (c1), addresses how the hpv 900 series 2’s s- curve speed reference generator handles a reduction in the speed command before the s- curve generator has reached its target speed. Note: the default for the s-curve abort (c1) para...

Page 118

User switches c1 submenu 96 auto stop (auto stop function enable) the auto stop function determines how the drive logic will respond to a zero or non-zero speed command. The function will work with a multistep/serial/analog speed command. When speed command src (c1) is set to analog, the auto stop f...

Page 119

User switches c1 submenu 97 the inner loop crossover parameter (inner loop xover(a1)) should not need to be changed. But if the number is changed, it must satisfy the following formula: multiplier reduce gain response crossover loop inner pi speed regulator when the proportional plus integral (pi) s...

Page 120

User switches c1 submenu 98 recommended travel direction (recommended travel direction) the recommended travel direction feature is designed to allow the drive the ability to determine the lightest loaded travel direction, and communicate this information to the car controller. The car controller ca...

Page 121

User switches c1 submenu 99 mains dip enable (mains dip enable) when enabled, the function will reduce the speed (by the percentage defined by the mains dip speed parameter) when the drive goes into ‘low voltage’ mode. ‘low voltage’ mode is defined as when the drive declares a uv alarm, which is def...

Page 122

Logic inputs c2 submenu 100 logic inputs c2 submenu note: the user can assign particular functions to each input terminal. Only one function per terminal is allowed and multiple terminals cannot have the same function. When a function is assigned to an input terminal, it is removed from the list of ...

Page 123

Logic inputs c2 submenu 101 choices… choice descriptions… mech brake pick2 [12] (mechanical brake pick) auxiliary contacts from mechanical brake switch 2. Asserted when brake is picked (lifted). Nc ctct cfirm [13] (normally closed contact confirm) opening of the auxiliary contacts confirming closure...

Page 124

Logic inputs c2 submenu 102 choices… choice descriptions… run [21] (run) if drive is enabled through the drive enable logic input, this function will start drive operation. Run down [22] (run down) if drive is enabled through the drive enable logic input, this function will start drive operation wit...

Page 125

Logic outputs c3 submenu 103 logic outputs c3 submenu logic output x (logic outputs 1-4) this parameter defines the function of the logic outputs. Note: the current setting of each parameter is displayed in all caps; all other choices in the list are displayed in lower case. Relay coil x (relay logi...

Page 126

Logic outputs c3 submenu 104 choices… choice descriptions… drv overload [17] (drive overload) the output is true when the drive has exceeded the drive overload curve. Encoder flt [18] (encoder fault) the output is true when the drive is declaring an encoder fault ext fan en [19] (external fan indica...

Page 127

Logic outputs c3 submenu 105 choices… choice descriptions… regen trq lim [44] (regeneration torque limit) the output is true when the torque limit has been reached while the drive is in the regenerative mode. The regenerative mode is defined as when the motor is returning energy to the drive. When t...

Page 128

Analog outputs c4 submenu 106 analog outputs c4 submenu analog output 1 (analog outputs 1) default: speed ref this parameter defines the function of the analog output #1. Note: the current setting of each parameter is displayed in all caps; all other choices in the list are displayed in lower case. ...

Page 129

Analog outputs c4 submenu 107 choices… choice descriptions… d/a units… spd rg tq cmd [19] (speed regulator torque command) torque command from speed regulator. % base torque speed command [20] (speed command) speed command before s-curve % rated speed speed error [21] (speed error) speed reference m...

Page 130: Display D0 Menu

Display d0 menu 108 display d0 menu elevator data d1 submenu parameter [alphanumeric] description units hidden item speed command [d101] (speed command) - monitors the speed command before the speed reference generator (input to the s-curve). This command comes from multi-step references, speed comm...

Page 131

Display d0 menu 109 d1 8:55 rx logic in 00-0000 ready run user fault torque limit sub menu data entry bit 0 bit 5 parameter [alphanumeric] description units hidden item logic inputs [d109] (logic inputs status) - this display shows the condition of the logic inputs. (1=true 0=false) 1=true 0=false n...

Page 132

Display d0 menu 110 d1 8:55 start logic 000-0000-0000-0000 ready run user fault torque limit sub menu data entry bit 0 bit 14 parameter [alphanumeric] description units hidden item start logic i,ii [d111] (start logic status i,ii ) - this display shows the condition of certain starting logic bits. (...

Page 133

Display d0 menu 111 d1 8:55 rx com status 000-0000-0000-0000 ready run user fault torque limit sub menu data entry bit 0 bit 15 parameter [alphanumeric] description units hidden item start logic i,ii (continued) bit name description/reason 8 spd_reg_rel_bit bit is true when the speed regulator is re...

Page 134

Display d0 menu 112 d1 8:55 dcp command 0000-0000 ready run user fault torque limit sub menu data entry bit 0 bit 7 parameter [alphanumeric] description units hidden item pre-torque ref i,ii [d114] (pre-torque reference i,ii ) - monitors the pre torque reference, coming from either analog channel #2...

Page 135

Display d0 menu 113 parameter [alphanumeric] description units hidden item dcp status [d121] (dcp status monitoring) - used for monitoring signals given by the drive serially to the control system when using dcp bit name description/reason s0 drive controller ready s1 travel active s2 advance warnin...

Page 136

Display d0 menu 114 power data d2 submenu parameter [alphanumeric] description units hidden item dc bus voltage [d201] (dc bus voltage) measured voltage of the dc bus. Volts n motor current [d202] (rms motor current output) monitors the rms motor output current. Amps n motor voltage [d203] (motor vo...

Page 137

Display d0 menu 115 parameter [alphanumeric] description units hidden item base impedance [d221] (base impedance) displays the drive calculated base impedance, which is based on the rated mtr pwr and the rated mtr volts parameters. This value is used to calculate the per unit values of the system im...

Page 138: Utility U0 Menu

Utility u0 menu 116 utility u0 menu u0 parameter [alphanumeric] description default choices hidden item run lockout u1 password for more information, see password on page 119. Enter password [u101] allows the user to enter in a password 12345 0 – 65535 n n new password [u102] used to change the pass...

Page 139

Utility u0 menu 117 u0 parameter [alphanumeric] description default choices hidden item run lockout u9 basics for more information, see basics on page 122 drive mode [u901] selects open-loop, closed-loop, or permanent magnet drive operation closed loop closed loop [1] open loop [2] pm [3] n y u10 ro...

Page 140

Utility u0 menu 118 u0 parameter [alphanumeric] description default choices hidden item run lockout operator to drive xfer [u1302] allows a user the ability to recall parameters from the operator disable enable [1] disable [0] n n u14 power meter for more information see power meter on page124 motor...

Page 141

Utility u0 menu 119 detailed description password (password function) the following three different screens are used by the password function: enter password new password password lockout password function the password function allows the user to select a six-digit number for a password. The p...

Page 142

Utility u0 menu 120 overspeed test (overspeed test function) the speed command is normally limited by overspeed level parameter (overspeed level(a1)), which is set as a percentage of the contract speed (100% to 150%). But in order to allow overspeed tests during elevator inspections, a means is prov...

Page 143

Utility u0 menu 121 restore dflts (restore parameter defaults) two different functions are included in this sub-menu. Restore drive defaults this function resets all parameters to their default values except the parameters in the motor a5 sub-menu and utiliity u menus. The following shows how to res...

Page 144

Utility u0 menu 122 cube id screen displays the cube identification number of the drive. Model cube size id# hpv900-4008-2e1-01 1 4008 hpv900-4012-2e1-01 2 4012 hpv900-4016-2e1-01 2 4016 hpv900-4021-2e1-01 3 4021 hpv900-4027-2e1-01 3 4027 hpv900-4034-2e1-01 4 4034 hpv900-4041-2e1-01 4 4041 hpv900-40...

Page 145

Utility u0 menu 123 time (time setting function) the clock located at the top of the operator under the user led, will set after the second parameter has been enter. For the year, enter the last two digits corresponding to the current year. This will update and continue to be stored in the u11 subme...

Page 146

Utility u0 menu 124 autotune sel ii (autotune selection) the autotune feature allows for the drive to automatically measure the stator resist (a5), d axis inductance (a5), and q axis inductance(a5). The procedure itself may be found in the appendix on page ix. Upload/dl (upload/download parameters) ...

Page 147: Fault F0 Menu

Fault f0 menu 125 ready run user fault torque limit fault f0 menu f0 parameter [alphanumeric] description hidden item run lockout f1 active faults [f101] contains a list of the active faults n n f2 fault history [f201] contains a list of up to the last sixteen faults with time stamps n n f3 sorted h...

Page 148

Fault f0 menu 126 sorted history the sorted history displays all faults and the number of times they have occurred since that last fault history clearing. The faults are listed by occurrence. The most numerous occurrences will appear at the top of the list. Press the enter key to enter the sorted hi...

Page 149

Fault f0 menu 127 press the enter key. The submenu led will turn on, using the down arrow key, scroll until the following displays on digital operator: press the enter key, then use the down arrow to get the following display: press the enter key. The drive will reset the active fault list and displ...

Page 150: Maintenance

Maintenance 128 maintenance maintenance overview preventive maintenance is primarily a matter of routine inspection and cleaning. The most important maintenance factors are the following: is their sufficient airflow to cool the drive? Has vibration loosened any connections? The hpv 900 series 2 need...

Page 151: Troubleshooting

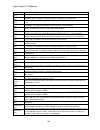

Troubleshooting 129 troubleshooting faults and alarms the hpv 900 series 2 reports two classes of warnings; these are identified as faults and alarms. Faults and fault annunciation a fault is a severe failure that will stop a drive if it has been running and prevent the drive from starting as long a...

Page 152

Troubleshooting 130 troubleshooting guide below lists the hpv 900 series 2’s faults, alarms, and operator messages along with possible causes and corrective actions. Note: fault - a severe failure that will stop a drive if it has been running and prevent the drive from starting as long as it is pr...

Page 153

Troubleshooting 131 the following table lists the hpv 900 series 2’s faults and alarms along with possible causes and corrective actions. Note: fault - a severe failure that will stop a drive if it has been running and prevent the drive from starting as long as it is present. All faults require so...

Page 154

Troubleshooting 132 name description possible causes & corrective action brk open flt [f64] the drive saw movement during either the rotor align (u10) or the auto-tune (u12) elevator brake is not set verify the elevator brake is clamped and no visual movement occurred check parameter settings ch...

Page 155

Troubleshooting 133 name description possible causes & corrective action contactor flt [f03] the command to close the contactor and the contactor feedback do not match before the time specified by the contact flt time parameter. Check parameter settings and contactor check contact flt time(a1) par...

Page 156

Troubleshooting 134 name description possible causes & corrective action db voltage (fault) [f53] or db voltage (alarm) [f83] dynamic braking igbt is still on ten seconds after the drive stops running too high of braking resistor value check for no braking resistor possible brake igbt failure ...

Page 157

Troubleshooting 135 name description possible causes & corrective action drive ovrload [f08] the drive has exceeded the drive overload curve. Excessive field weakening decrease flux wkn factor (a1) parameter decrease both mtr torque limit (a1) and regen torq limit (a1) parameters watch for the...

Page 158

Troubleshooting 136 name description possible causes & corrective action encdr crc err (fault) [f60] encdr crc warn (alarm) [f87] alarm and fault: absolute encoder checksum error is detected. The alarm is posted if the crc error does not affect drive operation. If the error persists, the alarm is co...

Page 159

Troubleshooting 137 name description possible causes & corrective action encoder flt [f09] the drive is in a run condition and the encoder is: not functioning or not connected. Or phasing is not proper with the motor. Encoder should match motor phasing usually drive’s “hit torque limit” alarm messag...

Page 160

Troubleshooting 138 name description possible causes & corrective action extrn fault 3 [f13] user defined external logic fault input check parameter settings and external fault signal wiring check the correct logic input is configured for the correct tb1 terminal and set to extrn fault 3 (c2) ch...

Page 161

Troubleshooting 139 name description possible causes & corrective action max flt retries (alarm) [f89] the drive has reached the maximum allowable automatic drive resets. Check parameter setting check that fault reset src (c1) is set correctly check that the flt reset / hour (a1) and flt reset d...

Page 162

Troubleshooting 140 name description possible causes & corrective action motor ovrload fault [f48] or motor ovrload alarm [f74] the motor had exceeded the user defined motor overload curve. Note: fault or alarm setting dependant on setting of motor ovrld sel (c1) parameter. Verify overload curve par...

Page 163

Troubleshooting 141 name description possible causes & corrective action mtr data flt [f19] this fault is declared if any motor nameplate data information in the a5 submenu is 0. Check parameter settings: check rated mtr power (a5) check rated mtr volts (a5) check rated excit freq (a5) check...

Page 164

Troubleshooting 142 name description possible causes & corrective action overcurr flt [f20] the phase current exceeded 300% of rated current. Encoder problem check encoder coupling: align or replace encoder failure (replace encoder) motor problem possible motor lead short check for motor fai...

Page 165

Troubleshooting 143 name description possible causes & corrective action overvolt flt [f42] the dc bus voltage of the drive exceeded: 850 volts for a 460v class drive 425 volts for a 230v class drive. Too high of braking resistor value check for no braking resistor possible brake igbt failure ...

Page 166

Troubleshooting 144 name description possible causes & corrective action safe-off open [f66] the drive has received a run command, but the “safe-off” input is open. if the “safe-off” input is open and the drive is in the ready state, but has a run command active, then “safe-off open” will be decla...

Page 167

Troubleshooting 145 name description possible causes & corrective action setup fault 4 [f24] this fault is declared if the contract motor speed (in rpm) and encoder pulses/revolution do not satisfy: 000 , 000 , 18 000 , 300 pulses encoder speed motor contract check parameters settings: check encod...

Page 168

Troubleshooting 146 name description possible causes & corrective action setup fault 10 [f30] this fault is declared when a run is issued and the input l-l volts (a4) is set to 000.00 check parameters settings: check input l-l volts (a4) verify setting of input l-l volts matches measure ac input...

Page 169

Troubleshooting 147 name description possible causes & corrective action spd dev flt (pm) [f63] & spd dev alm [f76] the speed feedback is failing to properly track the speed reference. Encoder cable not properly grounded verify encoder cable is properly grounded using the shield clamp provided on ...

Page 170

Troubleshooting 148 name description possible causes & corrective action srl timeout (fault) [f45] srl timeout (alarm) [f81] the drive is being operated by serial communications and one of the following has occurred: communication time-out – if the serial run bit is set and the drive does not rece...

Page 171

Troubleshooting 149 name description possible causes & corrective action undervolt flt [f47] this fault is generated during a run condition if the dc bus voltage falls below the level that is specified by uv fault level (a4). Fault is declared when: ) 4 ( * 2 * ) 4 ( a volts l l input a level fault ...

Page 172

Troubleshooting 150 name description possible causes & corrective action z marker lost [f62] this fault is declared when the drive expects to see a signal from the z channel of the encoder within a window but it doesn’t during an open- loop alignment. Phasing problem – incremental pm swap two enco...

Page 173: Appendix

Appendix – drive overload 151 appendix drive overload curve when the drive is running an output frequency of less than or equal to 3 hertz, the drive will use an adjusted overload curve. See the graph below for current vs. Time. 1 10 100 1000 60% 80% 100% 120% 140% 160% 180% 200% 220% 240% 260% 280%...

Page 174: Appendix

Appendix – adaptive tune 152 appendix closed loop adaptive tune the adaptive tune automatically calculates, under certain operating conditions, the percentage no load current and the rated rpm (slip frequency). The hpv 900 series 2 software uses these two adaptive tune calculated values to obtain th...

Page 175

Appendix – adaptive tune 153 figure 38: motor parameters entered from motor nameplate description parameter 4 pole dflt 6 pole dflt percentage no load current % no load curr 35.0 % 45.0 % stator leakage reactance stator leakage x 9.0 % 7.5 % rotor leakage reactance rotor leakage x 9.0 % 7.5 % stator...

Page 176

Appendix – adaptive tune 154 note: if you are having problems getting the motor torque under 15% the cause may be: no compensation chains if the elevator system has no compensation chains, achieving balanced condition may be difficult. In that case, the motor torque should be between 15% for as m...

Page 177

Appendix – adaptive tune 155 if the est no load curr is 2% smaller than the % no load curr then, increase the flux sat slope 2 by 10%. Note: if the est no load curr and % no load curr are within 2% of each other, then continue on to tuning the rated motor rpm. continue iterating flux sat slope 2...

Page 178: Appendix

Appendix – dcp 4 setup and calibration 156 appendix dcp 4 setup and calibration the commissioning and setup of the hpv900s2 in dcp 4 mode is relatively simple, all that is required is the calibration of the drive to ensure the actual elevator speed exactly matches our commanded speed – this is essen...

Page 179: Appendix

Appendix – normal terminal stopping device 157 appendix ntsd normal terminal stopping device functional overview: the drive can be configured to perform a pre- programmed ntsd slowdown by several different methods as outlined below. External: the car controller or other elevator controls provide all...

Page 180

Appendix – normal terminal stopping device 158 mode c1: 2 thresholds ntsd input 1 ntsd input 2 result 1 1 normal operation 1 0 if speed feedback is greater than ntsd threshold 2, decel using s- curve 4 and clamp the speed command to be no greater than ntsd target speed. 0 0 if speed feedback is grea...

Page 181: Appendix

Appendix – safe-off 159 appendix safe-off safe-off functional overview to summarize the feature, the safe-off function is yet another way to positively disable the drive so it cannot cause a motor runaway. It uses a switch to change terminal tb1- 26 from “logic input 9” to a base enable (be) functio...

Page 182

Appendix – safe-off 160 the safe off feature is enabled by setting the switch in the center of the control card from i9 (input 9) to be (base enable) as per figure 1. This allows the igbts to be enabled when logic input 9 is closed (logic high), and disabled when logic input 9 is open (logic low). F...

Page 183

Appendix – safe-off 161 (enabled or disabled). Used to determine if the drive has been correctly set for the “safe off” function, and provide similar feedback to that of a contactor auxiliary. Can be configured to any free output. This output will be high when the drive’s igbts are disabled by the s...

Page 184: Appendix

Appendix – safe-off 162 appendix brake monitoring to summarize the feature, the brake monitoring feature in the drive is used to monitor up to two brake pick switches, and determine that their operation is as expected. 1. The drive can monitor up to two brake switches with logic inputs and a logic o...

Page 185

Appendix – safe-off 163 logic input 8 † (c2) mech brk pick 2 input for a normally open brake switch. The drive monitors this input, and if it doesn’t switch as expected after a change in brake pick/autob rake output, it will declare ‘brake pick fault 2’ brake pick flt ena (c1) enable this parameter ...

Page 186: Appendix

Appendix – testpoints 164 appendix testpoints (control board) figure 39: main board testpoints t9 common t13 +15vdc t10 -15vdc t12 +5vdc t11 +24vdc t1 motor current (u phase) t3 motor current (w phase) t2 motor current (v phase) t4 dc bus voltage scaling: 3v=300v(230v class) 3v=600v(460v class) the ...

Page 187: Appendix

Appendix – testpoints 165 appendix testpoints (endat option card part number 46s04327-1030 through 46s04327-1010 - power supplies) figure 40: endat option card part number 46s04327-1030 power supply testpoints tp13 analog common tp15 analog common tp28 -15vdc tp21 +15vdc tp16 +5vdc tp17 +3.3vdc tp22...

Page 188: Appendix

Appendix – testpoints 166 appendix testpoints (endat option card part number 46s04327-1030 through 46s04327-1010 - other) figure 41: endat option card other testpoints tp13 analog common tp15 analog common tp20 common tp23 common tp3 endir tp4 edatao tp5 eclk tp9 a_d_m tp11 b_d_m tp1 aenc tp2 benc t...

Page 189: Appendix

Appendix – testpoints 167 appendix testpoints (endat option card part number 46s04327-1100 - power supplies) figure 42: endat optional card part number 46s04327-1100 power supply testponts tp25 5v iso tp26 common iso tp24 7.5v iso tp41 24v iso tp29 24v common iso tp16 5v tp20 common tp17 3.3v tp19 1...

Page 190: Appendix

Appendix – testpoints 168 appendix testpoints (endat option card part number 46s04327-1100 - other) figure 43 endat optional card part number 46s04327-1100 other testpoints tp8 /d2a_ld jm2* power sense enable tp7 p_sp_mo led1** status tp30 calib tp14 analog output 2 tp15 analog common tp13 analog co...

Page 191: Appendix

Appendix – testpoints 169 appendix testpoints (termag board) figure 44: termag board testpoints tpao1 analog output 1 tpagnd analog common tpao2 analog output 2 tpg iso common tpz encoder z sig tpb encoder b sig tpa encoder a sig sw1* filter switches sw3* encoder config sw2* power supply grounding s...

Page 192: Appendix

Appendix – ce guidelines 170 appendix ce guidelines below are guidelines for ce compliance. Standards en 12015 electromagnetic compatibility emission en 12016 electromagnetic compatibility immunity recommended line filter a line filter must be connected between the main power supply and input three ...

Page 193

Appendix – ce guidelines 171 wiring external to the enclosure to help comply, the treatment of cables is the most important countermeasure. The grounding and the treatment of gaps in the external connection sections between the control panel and the machine are also important. It is recommended that...

Page 194: Appendix

Appendix – dimensions, mounting holes, & weights 172 appendix dimensions, mounting holes, & weights figure 45: frame 1 dimensions, mounting holes, and weight.

Page 195

Appendix – dimensions, mounting holes, & weights 173 figure 46: frame 2 dimensions, mounting holes, and weight.

Page 196

Appendix – dimensions, mounting holes, & weights 174 figure 47: frame 3 dimensions, mounting holes, and weight.

Page 197

Appendix – dimensions, mounting holes, & weights 175 figure 48: frame 3.5 dimensions, mounting holes, and weight.

Page 198

Appendix – dimensions, mounting holes, & weights 176 figure 49: frame 4 dimensions, mounting holes, and weight.

Page 199

Appendix – dimensions, mounting holes, & weights 177 figure 50: frame 5 dimensions, mounting holes, and weight.

Page 200: Appendix

Appendix – dynamic braking resistor selection 178 appendix dynamic braking resistor selection drive model power dissipation kw (worm gear) resistor value range (worm gear) power dissipation kw (planetary gear) resistor value range (planetary gear) hpv900-4008-2e1-01 0.8 162 - 53 1.7 77 - 53 h...

Page 201: Appendix

Appendix – dynamic braking resistor fusing selection 179 appendix dynamic braking resistor fusing selection all fuses should be rated for 800vdc drive model fuse type (bussmann pn) fuse size (in amps) hpv900-4008-2e1-01 fws-10a20f 10a hpv900-4012-2e1-01 fws-15a20f 15a hpv900-4016-2e1-01 fwj-20a14f 2...

Page 202: Appendix

Appendix – ac input fuse selection 180 appendix ac input fusing selection drive model recommendation 1 recommendation 2 fuse mfg fuse model no. Fuse rating (amps/volts) fuse mfg fuse model no. Fuse rating (amps/volts) hpv900-4008-2e1-01 ferraz a60q25-2 25a/600v ferraz a70qs25-14f 25a/690v hpv900-401...

Page 203: Appendix

Appendix – open-loop adjustments 181 appendix open-loop performance adjustments stalling attempting to lift load if the motor stalls as it attempts to lift the load, then until resolved, try the following (in order): 1. Increase the torque boost gain parameter 2. Adjust the motor stator resistance p...

Page 204

Appendix – open-loop performance 182 rollback or bump at start if rollback is observed or a bump is felt at the start, then until resolved, try the following (in order): 1. Verify mechanical brake timing 2. Increase dc injection start level note: if no performance change is observed after any one st...

Page 205

Appendix – open-loop adjustments 183 (see stalling attempting to lift load); spotting or stalling going into leveling ; or overshooting floor only with regen load). Increase dc injection start level increase the dc start level (a1) parameter by increments of 5% and observe performance. Measuring t...

Page 206

Appendix – open-loop performance 184 leveling times different up vs. Down if the elevator exhibits significantly different leveling speeds/times up vs. Down then until resolved, try the following (in order) 1. Verify the slip compensation parameters 2. Complete motor rpm adjustment procedure verify ...

Page 207

Appendix – open-loop adjustments 185 secondly, decrease decel rate via decel rate x (a2) parameter and observe performance overshooting floor if the car is overshooting the floor then until resolved, try the following (in order): o verify mechanical brake timing o decrease leveling speed o increas...

Page 208

Appendix – open-loop performance 186 measure the resistance between the two motor terminals in ohms (stator resistance) with the motor nameplate values entered in the a5 menu, use the base impedance (d2) value (in ohms) to calculate the stator resist (a5) parameter (as a percentage of base impedan...

Page 209: Appendix

Appendix – selection and mounting of encoder 187 appendix selecting and mounting of encoder encoder specification the hpv 900 series 2 has connections for an incremental two-channel quadrature encoder. For better noise immunity, the hpv 900 series 2 provides… an isolated power supply, which separa...

Page 210

Appendix – selection and mounting of encoder 188 direct motor mounting use direct motor mounting without couplings, in order to avoid eccentricities and to provide for zero backlash. Figure 51: direct motor mount direct mounted encoders do not have shafts and are mounted directly onto the motor shaf...

Page 211

Appendix – selection and mounting of encoder 189 it is preferred that a solid shaft extension is specified from the motor manufacturer for a length recommended by the encoder manufacturer. Although it is not the preferred method, installations that employ a screwed on sub shaft adapter should: - use...

Page 212

Appendix – selection and mounting of encoder 190 differential / single-ended encoder configurations drives with termag boards 46s04284-1020 can be configured to run with either a differential or single-ended encoder with the setting of the sw3 dip switches. Below are examples of how the termag can b...

Page 213

Appendix – selection and mounting of encoder 191 figure 60: encoder with a capacitor (common to ground) figure 61: encoder with no capacitor (common to ground) exceeding operating specification do not exceed the operating specification of the encoder/drive, in order to prevent the encoder from provi...

Page 214: Appendix

Appendix – suggested wire sizes 192 appendix suggested wire sizes drive model input power (r,s,t) and output power (u,v,w), ground terminals wire size range awg (mm 2 ) 90 c (194f) / 105c (221f) torque spec lbin (nm) wire size range awg (mm 2 ) torque spec lbin (nm) hpv900-2025-2e1-01 8 (8.4...

Page 215: Appendix

Appendix – input / output rating 193 appendix input / output rating drive model input output voltage v current a short circuit withstand rating voltage v current a hpv900-2025-2e1-01 200-240 27.7 10ka 0-input voltage 25 hpv900-2031-2e1-01 200-240 34.4 10ka 0-input voltage 31 hpv900-2041-2e1-01 200-2...

Page 216: Appendix

Appendix – single phase ratings 194 appendix single phase ratings the hpv900 series 2 drives may be run with a single phase vac input. However, in order to run the drive single phased, the drive must be derated by 60%. See table 31 below for the single phased ratings. Rated input voltage continuous ...

Page 217: Appendix

Appendix – carrier frequency rating 195 appendix carrier frequency ratings (250% overload) the hpv900 series 2 drives may be run with a high pwm switching frequency. The default drive ratings are based off of 10khz setting. The drive will be derated according to the table below if the setting for pw...

Page 218: Appendix

Appendix – carrier frequency rating 196 appendix carrier frequency ratings (250% overload) the hpv900 series 2 drives may be run with a high pwm switching frequency. The default drive ratings are based off of 10khz setting. The drive will be derated according to the table below if the setting for pw...

Page 219: Appendix

Appendix – power dissipation 197 appendix watts loss 460v power loss 230v power loss hpv900-4008-2e1-01 132 watts hpv900-2025-2e1-01 229 watts hpv900-4012-2e1-01 275 watts hpv900-2031-2e1-01 294 watts hpv900-4016-2e1-01 314 watts hpv900-2041-2e1-01 378 watts hpv900-4021-2e1-01 360 watts hpv900-2052-...

Page 220: Appendix

Appendix – relay specifications 198 appendix relay specifications relay 1 & 2 contact data load resistive load (p.F. = 1) n.O. Contact n.C. Contact rated load 5a at 277vac 10a at 125vac 5a at 30vdc 3a at 277vac 3a at 30vdc carry current 10a 3a max. Operating voltage 277vac, 30vdc max. Operating curr...

Page 221: Appendix

Appendix – replacement parts 199 appendix replacement parts part number description detailed description hpv9-ctl0020-01 fru,hpv900 series 2,ctl pcb, std sfw includes the control pcb with standard software hpv9-endat-01 fru,hpv900 series 2, endat option card and hardware includes endat option card a...

Page 222

Appendix – replacement parts 200 hpv9s2-reflash fru,hpv900s2, reflash kit includes cable, reflash board, instructions for software uploads, and usb flash drive 46s03543-0020 cable,usb a to mini b cable for parameter and software uploads 46s04413-hp02 asm,h9s2,sftr update kit includes tech manual, so...

Page 223: Index

201 index a ab off delay parameter, closed loop..................... 43 ab zero spd lev parameter, closed loop .............. 42 abs ref offset parameter ..................................... 52 ac input fusing values ....................................... 180 accel jerk in parameter .................

Page 224

202 drive info submenu............................................. 121 drive overload display ........................................ 114 drive ovrload fault ............................................. 135 drive specifications ......................................... 15 –16 drive temp alarm ......

Page 225

203 logic inputs c2 submenu ........................... 100 –102 logic inputs display ............................................. 109 logic output connections ..................................... 28 logic outputs c3 submenu ............................ 102 –5 logic outputs display ..................

Page 226

204 relay output connections .................................... 28 remote keypad .................................................... 16 response parameter, closed loop ......................... 40 restore defaults submenu ................................. 121 rotor align submenu ....................

Page 227

205 z z marker lost ............................................... 150 zero speed level parameter ................................ 47 zero speed logic output ...................................... 105 zero speed time parameter ................................. 47.

Page 230: Hpv 900 Series 2

Hpv 900 series 2 data subject to change without notice. Hpv 900 s2 and series 2 is a trademark of magnetek, inc. Magnetek elevator products n50 w13775 overview dr menomonee falls, wisconsin 53051 (800) 236-1705, (262) 252-6999, fax (262) 790-4142 http://www.Elevatordrives.Com magnetek elevator produ...