- DL manuals

- Magnetrol

- Switch

- B60

- Installation And Operating Manual

Magnetrol B60 Installation And Operating Manual

Summary of B60

Page 1

Float actuated liquid level switches flanged external cage installation and operating manual.

Page 2

Read this manual before installing this manual provides information on the flanged external cage liquid level switches. It is important that all instructions are read carefully and followed in sequence. Detailed instructions are included in the installation section of this manual. Conventions used i...

Page 3: Flanged External Cage

46-605 flanged external cage float actuated liquid level switches table of contents 1.0 installation 1.1 unpacking................................................................ 4 1.2 critical alarm function............................................ 4 1.3 piping......................................

Page 4

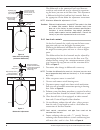

4 46-605 flanged external cage float actuated liquid level switches optional drain valve shutoff valve (if used) conduit outlet switch actuating level lreference marks shutoff valve (if used) typical piping arrangement 1.0 installation caution: if equipment is used in a manner not specified by manu-...

Page 5

46-605 flanged external cage float actuated liquid level switches 5 1.4 mounting caution: this instrument is intended for use in installation category ii , pollution degree 2 locations. Adjust piping as required to bring control to a vertical position. Magnetrol ® controls must be mounted within 3° ...

Page 6

6 46-605 flanged external cage float actuated liquid level switches internal circuit (right) switch 1 2 3 load load line 4 5 6 internal circuit (left) switch load load close on high level close on high level common common close on low level close on low level line figure 2 terminal connections dpdt ...

Page 7

46-605 flanged external cage float actuated liquid level switches 7 2.0 reference information 2.1 description flanged external cage liquid level switches are completely self-contained units designed for side mounting to a vessel or tank with threaded or flanged pipe connections. 2.2 theory of operat...

Page 8

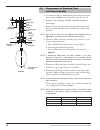

8 46-605 flanged external cage float actuated liquid level switches the differential, or the amount of level travel between switch-on and switch-off, may be adjusted by reposition- ing the lower jam nuts on the float stem. This adjustment is different for high level and low level controls. Refer to ...

Page 9

46-605 flanged external cage float actuated liquid level switches 9 7. Lift enclosing tube, switch, and base off float chamber. Jam nuts and attraction sleeve are now accessible. 8. Measure the distance “d” from the top edge of the upper jam nuts to the top of the float stem. Refer to figure 7 . Rec...

Page 10

10 46-605 flanged external cage float actuated liquid level switches 2.5 replacement of standard float and stem assembly 1. Disconnect wiring or medium lines from control and per- form system shutdown. See troubleshooting, section 3.0. 2. Remove switch housing assembly from float chamber at head fla...

Page 11

46-605 flanged external cage float actuated liquid level switches 11 3.0 troubleshooting usually the first indication of improper operation is failure of the controlled equipment to function, i.E., pump will not start (or stop); signal lamps fail to light, etc. When these symptoms occur, whether at ...

Page 12

12 46-605 flanged external cage float actuated liquid level switches 3.2 check sensing unit 1. Reconnect power supply. Carefully actuate the switch mechanism manually (use a non-conductive tool on electri- cal switch mechanisms) to determine whether controlled equipment will operate. Caution: with e...

Page 13

46-605 flanged external cage float actuated liquid level switches 13 11. Check float to be certain it is buoyant in the liquid (float chamber or vessel must have adequate liquid level). If float is determined to be filled with liquid, or it is collapsed, it must be replaced immediately. Caution: do ...

Page 14

14 46-605 flanged external cage float actuated liquid level switches screw at point of contact between screw and lever.Such wear can cause false switch actuating levels. See switch mechanism bulletin supplied with control should switch adjustment or replacement become necessary. 2. Do not operate yo...

Page 15

46-605 flanged external cage float actuated liquid level switches 15 5.0 specifications 5.1 agency approvals agency approved model area classification fm all with an electric switch mechanism and a housing non-hazardous type 4x listed as type 4x all with an electric switch mechanism and a housing cl...

Page 16

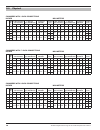

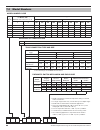

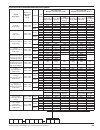

16 46-605 flanged external cage float actuated liquid level switches 5.2 physical chambers with 1-inch connections inches millimeters chambers with 2-inch connections inches millimeters chambers with 1 1 ⁄ 2 -inch connections inches millimeters min. Sp. Gr. 1" npt threaded & socket weld 1" flanged u...

Page 17

46-605 flanged external cage float actuated liquid level switches 17 c hl ll d d plugged a b 10.12 (257) 8.46 (215) c hl ll d d plugged a b 5.93 (151) 10.12 (257) 3.78 (96) 8.46 (215) side/bottom flanged threaded and socket weld c hl ll d d plugged a b 5.93 (151) 10.12 (257) 3.78 (96) 8.46 (215) sid...

Page 18

18 46-605 flanged external cage float actuated liquid level switches 6.1.1 parts identification 6 1 3 2 9 15 14 4 8 5 7 12 10 11 17 16 13 6.1.3 model c29 housing cover refer to section 6.1.2 housing base refer to section 6.1.2 switch mechanism refer to section 6.1.2 enclosing tube kit: includes item...

Page 19

46-605 flanged external cage float actuated liquid level switches 19 6.1.4 models d30, j30 and l30 housing cover refer to section 6.1.2 housing base refer to section 6.1.2 switch mechanism refer to section 6.1.2 enclosing tube kit ➀ ➁ 089-5915-001 089-5933-011 includes items 4 and 5 enclosing tube g...

Page 20

20 46-605 flanged external cage float actuated liquid level switches 6.2.1 parts identification series type bulletin # dry contact b, c, d 42-683 hermetically sealed f 42-683 hermetically sealed hs 42-694 bleed type pneumatic j 42-685 non-bleed type pneumatic k 42-686 high temperature 8, 9, r 42-799...

Page 21

46-605 flanged external cage float actuated liquid level switches 21 6.2.3 model c29 tdm housing kit: includes items 1 and 2 refer to section 6.2.2 switch mechanism refer to section 6.2.2 enclosing tube kit: includes items 4 and 5 89-5909-002 enclosing tube gasket 12-1204-001 head flange kit: includ...

Page 22

22 46-605 flanged external cage float actuated liquid level switches maximum maximum bleed models with supply process orifice material of construction switch pressure temperature diameter code 1 code 2 description psig bar ° f ° c inches mm nema 1 nema 1 series j 100 7 +400 +204 .063 1.6 jdg jde ble...

Page 23

46-605 flanged external cage float actuated liquid level switches 23 electric switch mechanism and enclosure switch description process ➄ temperature range °f (°c) contacts set points all models with material of construction code 1 all models with material of construction code 2 type 4x/7/9 aluminum...

Page 24

Bulletin: 46-605.20 effective: february 2017 supersedes: january 2015 705 enterprise street • aurora, illinois 60504-8149 • 630-969-4000 • fax 630-969-9489 info@magnetrol.Com • www.Magnetrol.Com copyright © 2017 magnetrol international, incorporated service policy owners of magnetrol may request the...