- DL manuals

- Magnetrol

- Measuring Instruments

- E3 Modulevel

- Installation and operating manual

Magnetrol E3 Modulevel Installation and operating manual

Summary of E3 Modulevel

Page 1

Liquid level displacer transmitter installation and operating manual ® e3 modulevel ®.

Page 2

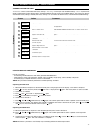

Level liquid level change acts upon the range spring supported displacer causing vertical motion of a core within a linear variable differential transformer (lvdt). The enclosing tube acts as a static isolation barrier between the lvdt and the process media. As core position changes with liquid leve...

Page 3

3 mounting max 1° tolerance use stilling well in case of turbulent medium shut-off valves are recommended always unlock for repositioning or removal of head assembly and always relock, after final positioning calibration vent is recommended transmitter slide the head assembly over the enclosing tube....

Page 4

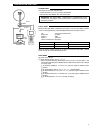

4 wiring caution: power must be switched off before wiring the unit. – + is ® is 0 % 100 % positive supply to (+) terminal negative supply to (-) terminal shield wire to green grounding screw (resistance to ground must be standard shielded twisted pair cable recommended. Use certified flameproof cable...

Page 5

5 display comment units! Cm units cm units! Cm configuration note: when connected to an approved barrier, the intrinsically safe electronics of the e3 modulevel allow to remove the covers with power switched on – even if the area is known to be hazardous 2 line – 8 characters lcd default display cyc...

Page 6

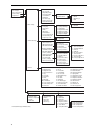

6 = wet calibration procedure - see also pages 12 & 13 menu: step by step procedure – e3 modulevel: level screen action comment ru n m od e co nfi gu ra tio n 1 2 3 4 10 11 12 *status* *level* *%output* *loop* level xx.X %output xx.X% loop xx.Xx ma 6 7 proc sg x.Xxx sg opertemp xxx c 5 lvlunits (sele...

Page 7

7 menu: step by step procedure – e3 modulevel: level screen action comment co nfi gu ra tio n 13 16 17 18 19 21 poll adr xx 14 loop mode (select) trim 4 xxxx 15 trim lvl xx.X trim 20 xxxx loop tst xx.X ma capture 4.00 ma 20 capture 20.00 ma new pass xxx 22 23 language e3 modht ver xx.Xx 24 dispfact (...

Page 8

8 menu: step by step procedure – e3 modulevel: interface = wet calibration procedure. See also pages 12 & 13 screen action comment ru n m od e co nfi gu ra tio n 1 2 3 4 9 10 11 *status* *ifclevel* *%output* *loop* ifclevel xx.X %output xx.X% loop xx.Xx ma 6 opertemp xxx c 5 lvlunits (select) lvl ofs...

Page 9

9 menu: step by step procedure – e3 modulevel: interface screen action comment co nfi gu ra tio n 12 15 16 17 18 20 poll adr xx trim 4 xxxx 14 trim lvl xx.X 13 loop mode (select) trim 20 xxxx loop tst xx.X ma capture 4.00 ma 19 capture 20.00 ma new pass xxx 21 22 language e3 modht ver xx.Xx 23 dispfa...

Page 10

10 menu: step by step procedure – e3 modulevel: density control = wet calibration procedure screen action comment ru n m od e co nfi gu ra tio n 1 2 3 4 8 9 *status* *sg* *%output* *loop* specgrav x.Xx sg %output xx.X% loop xx.Xx ma 5 opertemp xxx c 6 set 4ma xxx.X damping xx sec 7 set 20ma xxx.X fau...

Page 11

11 menu: step by step procedure – e3 modulevel: density control screen action comment co nfi gu ra tio n 10 13 14 15 16 18 poll adr xx trim 4 xxxx 12 trim sg xx.X 11 loop mode (select) trim 20 xxxx loop tst xx.X ma capture 4.00 ma 17 capture 20.00 ma new pass xxx 19 20 language e3 modht ver xx.Xx 21 ...

Page 12

12 wet calibration – guidelines level measurement: 100 % level cannot be reached interface measurement: using the process liquid air/gases air/gases set 4 ma upper liquid interface set 4 ma min 50 mm (2") lower liquid calibrate 4 ma/0 % level bring interface at lowest level press enter = start calib...

Page 13

13 wet calibration – guidelines interface measurement: using water for calibration air/gases set 4 ma water calibrate 4 ma/0 % level immerge displacer for 80 % in water press enter = start calibration. Press up + enter = lock 4 ma value. Air/gases set 20 ma water calibrate 20 ma/100 % level: immerge...

Page 14

14 menu: step by step procedure: advanced configuration screen action comment di ag no st ic s 1 3 4 5 6 7 dispfact select run time xxxx.X h 2 history (current status) history reset meastype (select) 13 weight xx.X kg model (select) springsg (select) 8 9 19 sprgrate x.X sprgmatl 10 templimt xxx c 11...

Page 15

15 menu: advanced calibration - calselct submenu screen action comment di ag no st ic s 1 3 4 5 6 7 lvdt% xx.Xx % drysenr xx.Xx % 2 calib sg xx.Xx sg snrcallo xx.Xx % lvlcallo xx.Xx lu set 4ma xx.Xx lu snrcalhi xx.Xx % 8 9 lvlcalhi xx.Xx lu set 20ma xx.Xx lu 10 escape diagnostic display. Factory set...

Page 16

16 for more details about the use of pactware™ and fdt technology, refer to instruction manual 59-601 pactware™ – configuration and troubleshooting what is fdt, pactware™ and dtm power hart connections 24 v dc pc with hart serial interface • fdt (field device tool) is a new interface code that descri...

Page 17

17 configuration using hart ® important: the digital hart ® communication is superimposed on the 4-20 ma loop and requires a min. Load resistance of 250 Ω and a max load resistance of 450 Ω. + + - - junction control room display power supply current meter r l > 250 Ω connections check hart ® connect...

Page 18

18 configuration using hart ® 1 calibration 2 basic setup 3 advanced setup 4 review 1 pv 2 pv %range 3 pv loop content 4 device setup 5 diagnostics 1 tag 2 long tag 3 descriptor 4 date 5 message 6 poll address 7 loop current mode 8 final asmbly num 9 cfg chng count 1 trim loop current 2 enter passwo...

Page 19

19 maintenance troubleshooting system problems symptom problem solution no loop current. Power supply not turned on. Turn on power. Insufficient source voltage. E3 requires a minimum of 11 vdc at the wiring board. Verify supply voltage. Improperly wired or damaged wiring. Check wiring and connection...

Page 20

20 maintenance information messages the lowest in the hierarchy of diagnostic conditions provides operational factors that are not critical to measurement. Further error infor- mation can be obtained by viewing the status history in the factory menu. Warning messages a warning message identifies the...

Page 21

21 display message description solution secflthi • a/d readings from lvdt secondary windings are above expected range. • bad lvdt wiring connection. • check for missing displacer. • check lvdt winding resistance. Secfltlo* • a/d readings from lvdt secondary windings are below expected range. • bad l...

Page 22

22 caution: bending the enclosing tube will permanently damage the unit. Maintenance removal of ez transmitter head replacing with e3 transmitter head cheking the lvdt winding resistance replacing linear variable differential transformer (lvdt) enter up down e r r o r s p a n z e r o (–) p2 (+) p1 ®...

Page 23

23 replacement parts 2 11 12 6 1 5 e x p e d i t e s h i p p l a n ( e s p ) several parts are available for quick shipment, within max. 1 week after factory receipt of purchase order, through the expedite ship plan (esp). Parts covered by esp service are conveniently grey coded in the selection tab...

Page 24

24 replacement parts caution: field replacement of one of the following parts requires a user calibration of the repaired unit: items 1, 16, 22, 23, 25. 1 x 7 4 2 3 8 9 10 5 6 digit in partn°: partn°: serial n°: x = if there are any deviations from a standard partn° see nameplate, always provide com...

Page 25

25 replacement parts (20) chamber gasket / ring joint note: not applicable if digit 3 = 1, 2 digit 6 digit 3 digit 9 replacement part 3, a 3, 4, 5, 6 1 012-1301-017 2, 3, 8 012-1204-031 4, c 3, 4, 5, 6 1 012-1301-018 2, 3, 8 012-1204-021 5, d, e, k 3, 4, 5, 6 all 012-1204-021 l 3, 5 all 012-1904-002...

Page 26

26 transmitter specifications functional/physical ➀ not applicable for foundation fieldbus™ units. ➁ with aluminium housing only. Does not apply to models with stainless steel housing. Description specification power (at terminals) weatherproof / intrinsically safe: 11 to 28,4 v dc (atex/iec) - 28,6...

Page 27

27 transmitter specifications mechanical specifications performance description specification cage materials carbon steel or 316/316l (1.4401/1.4404) (other materials at request) wetted parts spring inconel ® (other materials at request) displacer 316/316l (1.4401/1.4404) or 316 (1.4401) process con...

Page 28

28 dimensions in mm (inches) d top mounted e31/e32 - j/k/l transmitter head a 407 (16) 22 (0.87) 72 (2.81) 98 (3.86) 70° 159 (6.28) 103 (4.04) 262 (10.32) 206 (8.10) 100 (3.95) 102 (4.02) 102 (4.02) 27 (1.06) Ø 9,5 (0.37) 105 (4.12) 235 (9.25) 167 (6.57) 45° 83 (3.28) 143 (5.63) 295 (11.61) 89 (3.50...

Page 29

29 dimensions in mm (inches) dimension a for all models cage rating sg range 4 th digit 9 th digit dimension a 150 / 300 / 600 lbs pn 16 .. Pn 100 0.23 - 0.54 j/a/m/d 1/2/3 236 (9.29) 0.55 - 1.09 k/b/n/e 186 (7.32) 1.10 - 2.20 l/c/p/f 186 (7.32) 900 / 1500 lbs pn 160 / pn 250 0.55 - 1.09 k/b/n/e 1/2...

Page 30

Model identification 30 a complete measuring system consists of: 1. One order code for a complete e3 modulevel ® transmitter. 2. Options: - adjustable displacer hanger for top mounted units, cable length 2,5 m (8'). Order code 032-3110-004 – required when distance between the top of the displacer an...

Page 31

31 model identification – non steam applications (max 600 lbs) level range specific gravity and process temperature (consult factory for interface applications) process connection for top mounted connection type for external cage models carbon steel models e 3 complete code for e3 modulevel transmit...

Page 32

32 model identification – steam applications (max 600 lbs) 150 °c 200 °c 230 °c 260 °c 370 °c 425 °c max. Temp. / s.G. K b n e n e 0.55 - 1.09 specific gravity level range specific gravity and process temperature (consult factory for interface applications) process connection for top mounted connecti...

Page 33

33 model identification – non steam applications (from 900 lbs to 2500 lbs) e 3 complete order code for e3 modulevel transmitter – non steam applications / high pressure process connection for top mounted connection type specific gravity and process temperature (consult factory for interface applica...

Page 34

34 model identification – steam applications (from 900 lbs to 2500 lbs) e 3 complete code for e3 modulevel transmitter – steam applications / high pressure carbon steel models basic model number e 3 1 top mounted e3 modulevel e 3 3 e3 modulevel with side/bottom cage e 3 5 e3 modulevel with side/side...

Page 35

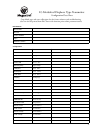

35 ® e3 modulevel displacer type transmitter configuration data sheet copy blank page and store calibration data for future reference and troubleshooting. (data can also be printed from pactware with function print online parameterisation) identification vessel name vessel # process medium tag # elec...

Page 36: Important

W w w .M ag ne tro l.C om benelux heikensstraat 6, 9240 zele, belgië -belgique france tel. +32 (0)52.45.11.11 • fax. +32 (0)52.45.09.93 • e-mail: info@magnetrol.Be deutschland alte ziegelei 2-4, d-51491 overath tel. +49 (0)2204 / 9536-0 • fax. +49 (0)2204 / 9536-53 • e-mail: vertrieb@magnetrol.De in...