Magnetrol Kotron II Series 801 Instruction manual - Series 801

7

UNIT CONFIGURATION

GENERAL CONFIGURATION INSTRUCTIONS

The Kotron

II Series 801 capacitance transmitter contains a

microprocessor-based operator interface which allows for

easy configuration of level, flow or volume control applica-

tions. These features are built into the transmitter and are

entered via a keypad located on the front of the unit.

This operator interface and the instructions for the Unit

Configuration are broken down into six main groups of

menus, as follows:

MEASURED VALUES

To view measured values

SYSTEM CONFIG

First time configuration (Essential

programming

information

for

measurements)

I/O CONFIG

Configure input/output functions

ADVANCED

CONFIGURATION

Values

that

affect

the

units

performance

DIAGNOSTICS

Test functions

LAPTOP

Download data log to Lap Top

computer. (With optional Data

Logger only)

Passwords

The Series 801 transmitter has two types of passwords that

can be used to protect configuration parameters. They are

as follows:

GENERAL PASSWORD – The General Password is

used for the I/O Config portion of the Menu Structure

(except for probe lo/probe hi). Any time a change is made to

parameters in this menu, ie. 4–20 mA, relays, etc., the Series

801 will prompt the operator to enter a password. This pass-

word can be any one to six character numeric combination

that is easy for the operator to remember.

SUPERVISORY PASSWORD – The Supervisory Pass-

word is used for the System Config and the Calibration

portion of the Menu Structure (and probe lo/probe hi). This

password is used to protect values that can affect the per-

formance and/or accuracy of the device.

NOTE: Although the Supervisory Password is normally used

in the System Config and the Calibration menus, this pass-

word can also be used in any portion of the menus. The

Supervisory Password overrides the General Password.

The Passwords can be changed at any time via the

Calibration mode.

If an invalid password is entered into the 801, the display will

read PASSWORD INVALID. By pressing the DEL key three

times, the unit will return to the normal run mode and con-

tinue to operate with the previous programmed parameters.

Please enter the programmed password below for future

reference.

Password

CAUTION:

The Series 801 is shipped from the

factory with the password 0801. If the pro-

grammed password is misplaced or forgotten,

please consult the factory for assistance.

GENERAL CONFIGURATION INSTRUCTIONS cont.

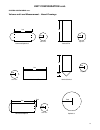

Operator keypad

All Unit Configuration instructions in this manual will show

the local transmitter display exactly as it will appear to the

operator on the Series 801.

The operator interface to the 801 is via a keypad consisting

of the following keys:

–

For numeric entry of parameters

For decimal numeric entries

To exit any programming area and re-

turn to the measurement mode

For storing new parameter values into

memory. Also used to exit the para-

meter entry mode, if pressed prior

to entering numeric parameter values

To

sequentially

access

other

para-

meter procedures. In addition, para-

meters may be skipped over without

affecting their stored values

To change the display scrolling speed

when entering text

All values for Parameter Entry procedures follow the trans

action flow below:

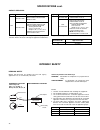

FIRST LEVEL PROGRAMMING MENUS

Series 801

Measured Values

System Configuration

I/O Configuration

Advanced Configuration

Diagnostics

Laptop

>>>QUIT<<<

DEL

2ND

ENT

.

9

0