- DL manuals

- Magnetrol

- Switch

- T20

- Installation And Operating Manual

Magnetrol T20 Installation And Operating Manual

Summary of T20

Page 1

Installation and operating manual liquid level switches top mounting t20 and t21.

Page 2

44-604 top mounting liquid level switches read this manual before installing this manual provides information on the top mounting liquid level switch. It is important that all instructions are read carefully and followed in sequence. Detailed instructions are included in the installation section of ...

Page 3: Top Mounting

Table of contents 1.0 introduction 1.1 principle of operation...........................................4 2.0 installation 2.1 unpacking.............................................................4 2.2 critical alarm function ..........................................5 2.3 mounting ...................

Page 4

4 44-604 top mounting liquid level switches 1 pivot return spring process liquid rising level 6 5 4 3 2 figure 1 process liquid falling level figure 2 1.0 introduction t20 and t21 level switches are float operated units designed for top mounting to a tank or vessel by means of threaded or flanged pi...

Page 5

5 44-604 top mounting liquid level switches 2.2 critical alarm function it is recommended that for critical alarm functions, an additional level switch be installed as a high–high or low– low level alarm for maximum protection. 2.3 mounting caution: operation of all buoyancy type level devices shoul...

Page 6

6 44-604 top mounting liquid level switches internal circuit (right) switch 1 2 3 load load close on high level common close on low level line 4 5 6 internal circuit (left) switch load load close on high level common close on low level line set screw screw screw figure 3 housing set screws figure 4 ...

Page 7

7 44-604 top mounting liquid level switches 6. Dress wiring to ensure no interference or contact with the switch actuation arm, or replacement of switch housing cover. Note: observe all applicable electrical codes and proper wiring procedures. Prevent moisture seepage into the enclosure by installin...

Page 8

8 44-604 top mounting liquid level switches 3.0 switch differential adjustment the standard differential of the single float model t20 may be field adjusted. Adjustment may be necessary if a wider differential needs to be set to overcome switch chatter caused by the process. The differential, or the...

Page 9

9 44-604 top mounting liquid level switches 7. With switch housing and enclosing tube removed, jam nuts and attraction sleeve are accessible. Measure position of upper jam nuts from stem end; then loosen and remove upper jam nuts, guide washer, and attraction sleeve. 8. Loosen and adjust lower jam n...

Page 10

10 44-604 top mounting liquid level switches 4.0 preventive maintenance periodic inspections are a necessary means to keep your level control in good working order. This control is a safe- ty device to protect the valuable equipment it serves. Therefore, a systematic program of “preventive mainte- n...

Page 11

11 44-604 top mounting liquid level switches 5. On units with pneumatic switches, air (or gas) lines sub- jected to vibration, may eventually crack or become loose at connections causing leakage. Check lines and connec- tions carefully and repair or replace, if necessary. Note: as a matter of good p...

Page 12

12 44-604 top mounting liquid level switches 5.0 reference information 5.1 troubleshooting usually the first indication of improper operation is failure of the controlled equipment to function, (i.E.: pump will not start (or stop), signal lamps fail to light, etc.) when these symptoms occur, whether...

Page 13

13 44-604 top mounting liquid level switches 5.1.2 check complete unit 1. Reconnect power supply and carefully actuate switch mechanism manually (using a non-conductive tool) to determine whether controlled equipment will operate. Caution: with electrical power on, care should be taken to avoid cont...

Page 14

14 44-604 top mounting liquid level switches 5.2 agency approvals 6. Check float to be certain it is buoyant in the liquid (tank or vessel must have adequate liquid level). If float is deter- mined to be filled with liquid, or it is collapsed, it must be replaced immediately. Do not attempt to repai...

Page 15

15 44-604 top mounting liquid level switches 5.3 specifications 5.3.1 physical inches (mm) b 7.94* (201) a 2.44 (61) 1" npt distance to actuating level (4" min. Actuating level 6.25* (158) housing ➀ a b conduit connections type 4x/7/9, 5.93 3.87 1" npt dual entry group b (151) (98) nema 1 ➁ 4.70 5.0...

Page 16

16 44-604 top mounting liquid level switches 5.4 replacement parts 1 5 9 3 6 12 11 7 8 10 2 4 item description 1 housing cover 2 housing base 3 switch mechanism 4 attraction sleeve 5 jam nuts 6 guide washer(s) 7 float stem 8 float 9 adaptor bushing/guide tube assembly 10 enclosing tube gasket 11 enc...

Page 17

17 44-604 top mounting liquid level switches 5.4.1.1 model t20 5.4.1.3 switch and housing reference 125 lb cast iron 150 lb forged steel 300 lb forged steel 150 lb forged 304 150 lb forged 316 4" flange z04-5840-001 z04-5840-011 z04-5840-016 004-5840-021 004-5840-026 5" flange z04-5840-002 z04-5840-...

Page 18

18 44-604 top mounting liquid level switches 5.4 replacement parts 1 5 4 12 3 6 14 13 7 8 15 16 2 17 9 10 11 5.4.2 model t21 parts identification item description 1 housing cover 2 housing base 3 switch mechanism 4 upper attraction sleeve 5 jam nuts 6 guide washer(s) 7 upper stem assembly 8 lower fl...

Page 19

19 44-604 top mounting liquid level switches 5.4.2.1 model t21 series type bulletin# dry contact b, c, d 42-683 hermetically sealed f 42-683 hermetically sealed hs 42-694 bleed type pneumatic j 42-685 non-bleed type pneumatic k 42-486 high temperature snap r, 8, 9 42-799 5.4.2.3 switch and housing r...

Page 20

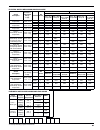

20 44-604 top mounting liquid level switches model no. Set points tank connection float and trim sleeve t20-1 1—single float carbon steel 300 series ss 400 series ss t20-4 316 ss 316 ss 316 ss liquid float size specific 3.00 x 5.00 4.00 4.50 gravity (76 x 127) (102) (114) 1.00 39 (991) 48 (1219) 48 ...

Page 21

Maximum maximum switch supply process bleed orifice nema 1 description pressure temperature diameter 100 psig .063 jde (7 bar) 400° f (1.6 mm) series j 60 psig (204° c) .094 jee bleed type (4 bar) (2.4 mm) 100 psig 700° f .055 jfe (7 bar) (371° c) (1.4 mm) series k 100 psig — koe non-bleed (7 bar) 4...

Page 22

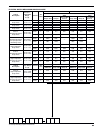

22 44-604 top mounting liquid level switches model number code and materials of construction model no. Set points tank connection float and trim sleeve t21-1 2—tandem float carbon steel 300 series ss 400 series ss t21-4 316 ss 316 ss 316 ss important: actuating level(s), in either the rising or fall...

Page 23

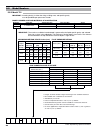

23 44-604 top mounting liquid level switches electric switch mechanism and enclosure switch description process ➃ temperature range °f (°c) contacts set points t21-1 models t21-4 models type 4x/7/9 aluminum enclosure ➄≈ class i, div 1 groups c&d class i, div 1 group b atex ex ii 2 g eex d iic t6 cla...

Page 24

Bulletin: 44-604.17 effective: january 2015 supersedes: may 2010 service policy owners of magnetrol may request the return of a con- trol or any part of a control for complete rebuilding or replacement. They will be rebuilt or replaced promptly. Controls returned under our service policy must be ret...