- DL manuals

- Magnum

- Lawn and Garden Equipment

- 232735

- Repair And Parts Manual

Magnum 232735 Repair And Parts Manual

309226M

Repair and Parts

Airless Sprayers

US Patent No. 1184US3

- For portable spray applications of architectural paints and coatings -(Specifications, page 3.)

Use water-based or mineral spirit-type material only.

Do not use materials having flash points lower than

70°F (21°C). For information about your material

request MSDS from distributor or retailer.

Important Safety Instructions

Read all warnings and instructions in this manual. Save

these instructions. See page 3 for model and series

information, including dispense rate, recommended hose

length, guns, and maximum working pressure.

ti4309a

ti6878a

ti6877a

ti6879a

M

AGNUM

XR5

M

ODEL

232740

M

AGNUM

dx

M

ODEL

232735

M

AGNUM

XR7

M

ODEL

232745

M

AGNUM

XR9

M

ODEL

232750

Related Manuals - 309225 Operation

EN

Summary of 232735

Page 1

309226m repair and parts airless sprayers us patent no. 1184us3 - for portable spray applications of architectural paints and coatings -(specifications, page 3.) use water-based or mineral spirit-type material only. Do not use materials having flash points lower than 70°f (21°c). For information abo...

Page 2: Contents

2 309226m contents models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 installation ....

Page 3: Models

Models 309226m 3 models specifications this equipment is not intended for use with flammable or combustible materials used in places such as cabinet shops or other “factory”, or fixed locations. If you intend to use this equipment in this type of application, you must comply with nfpa 33 and osha re...

Page 4: Warnings

Warnings 4 309226m warnings the following are general warnings related to the setup, use, grounding, maintenance, and repair of this equipment. Additional, more specific warnings may be found throughout the body of this manual where applicable. Symbols appearing in the body of the manual refer to th...

Page 5

Warnings 309226m 5 equipment misuse hazard misuse can cause death or serious injury. • do not exceed the maximum working pressure or temperature rating of the lowest rated system component. See technical data in all equipment manuals. • use fluids and solvents that are compatible with equipment wett...

Page 6: Installation

Installation 6 309226m installation grounding and electric requirements the sprayer must be grounded. Grounding reduces the risk of static and electric shock by providing an escape wire for the electrical current due to static build up or in the event of a short circuit. The sprayer requires a 120v ...

Page 7: Notes

Installation 309226m 7 notes.

Page 8: Component Identification

Component identification 8 309226m component identification a electric motor (inside enclosures) provides mechanical power to pump. B power switch manually turns on and off electric power to motor (i is on and 0 is off. C pressure control knob manually increases (turn clockwise) and decreases (turn ...

Page 9

Component identification 309226m 9 tia connect cart handles on xr7 and xr9 as follow: 1. Position handle on frame as shown and align bolt holes in handle with bolt holes in frame. 2. Run bolts through holes with heads pointing toward each other, and hand tighten wingnuts. Note: for space-saving conf...

Page 10: Operation

Operation 10 309226m operation pressure relief procedure follow pressure relief procedure when you stop spray- ing and before cleaning, checking, servicing, or trans- porting equipment. Read warnings, page 4. 1. Turn power switch (b) off and unplug power cord. 2. Turn spray- prime/drain valve (j) to...

Page 11: General Repair Information

General repair information 309226m 11 general repair information • keep all screws, nuts, washers, gaskets, and electri- cal fittings removed during repair procedures. These parts usually are not provided with replacement kits. • test repairs after problems are corrected. • if sprayer does not opera...

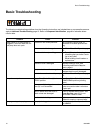

Page 12: Basic Troubleshooting

Basic troubleshooting 12 309226m basic troubleshooting the following troubleshooting guidelines from the operating instructions are included here as a preemptive measure against advanced troubleshooting, page 15. Refer to component identification, page 8 for reference letters used in table. Problem ...

Page 13

Basic troubleshooting 309226m 13 pump cycles but does not build up pressure. Pump is not primed. Prime pump. Inlet screen (l) is clogged or suction tube (g) is not immersed. Clean debris off inlet screen and make sure suction tube is at bottom of paint pail. Paint pail is empty. Refill paint pail. R...

Page 14

Basic troubleshooting 14 309226m motor is hot and runs intermittently. This is not a thermal overload con- dition. Motor automatically shuts off due to excessive heat. Damage can occur if cause is not corrected. Startup hazard after thermal overload, page 6. Vent holes in enclosure are plugged or sp...

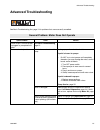

Page 15: Advanced Troubleshooting

Advanced troubleshooting 309226m 15 advanced troubleshooting see basic troubleshooting first, page 12 for problems that are more easily remedied. General problem: motor does not operate specific problem cause solution power switch is on and sprayer is plugged in; pump does not cycle. See basic troub...

Page 16

Advanced troubleshooting 16 309226m basic electrical problems. Motor overheated. Allow motor to cool for 30 minutes. Retry. Electrical outlet is damaged. Reset building circuit breaker or replace fuse. Try another outlet. Check electric supply with volt meter. Meter must read 85 to 130v ac. If volta...

Page 17

Advanced troubleshooting 309226m 17 sprayer wiring problems (cont.) motor thermal overload cutoff switch damaged. Startup hazard after thermal overload, page 6. 1. Unplug sprayer electrical cord. 2. Remove motor harness from control card. 3. Check for continuity between yellow leads or motor harness...

Page 18

Advanced troubleshooting 18 309226m building circuit breaker opens as soon as sprayer is plugged into outlet and sprayer is not turned on. Note: remove enclosure mounting screws and pull enclosure away from drive housing. Take care not to pull on leads from electrical cord and power switch. Sprayer ...

Page 19

Advanced troubleshooting 309226m 19 general problem: low or fluctuating output specific problem cause solution pump cycles, but output is low or surging. See basic troubleshooting, page 12. Worn or obstructed pump valves. Check for worn pump valves as follows: 1. Prime sprayer with paint. 2. Trigger...

Page 20

Advanced troubleshooting 20 309226m control board is damaged. Caution: do not perform control board diagnostics until you have determined the armature is good. A bad motor can burn out a good control board. See control board diagnostics, page 25. If damaged replace control board using control board ...

Page 21

Advanced troubleshooting 309226m 21 general problem: no output specific problem cause solution power switch is on and sprayer is plugged in but pump does not cycle see basic troubleshooting, page 12. Motor runs but pump does not cycle. Gear and/or yoke are damaged (xr models only). Replace gear and ...

Page 22: List of Kits

List of kits 22 309226m list of kits kit number models/series kit description 243230 xr5, series a and b xr7 and xr9, series a 10 mm shaft, gear, yoke, guides (ball bearing equipped cover and motor castings) 245062 xr5, series c, d, e xr7 and xr9, series b and c, d 3/8 in. Shaft gear, yoke, guides (...

Page 23

List of kits 309226m 23 245078 dx pump repair 243090 all xr models pump repair (pump packing module) 243533 all xr models pump replacement (compete pump*) * does not include pressure control switch 244267. Reuse pressure control switch from pump being replaced, or order separately. 196582 dx, series...

Page 24: Motor Diagnostics

Motor diagnostics 24 309226m motor diagnostics check for electrical continuity in motor armature, windings and brush as follows: if motor diagnostics reveal a damaged motor or if motor brushes are shorter than 1/4 in. (6.4 mm) or if the motor shaft cannot turn, replace the motor using motor kit, pag...

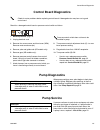

Page 25: Control Board Diagnostics

Control board diagnostics 309226m 25 control board diagnostics check for a damaged control board or pressure control switch as follows: 1. Relieve pressure, page 10. 2. Unplug electrical cord. 3. Remove four cover screws and front cover (xr9). Remove motor enclosure (dx). 4. Remove yoke and guide ro...

Page 26: Parts

Parts 26 309226m parts dx sprayer model 232735 ref no. Part no. Description qty 1 196569 frame, series a, includes two #60 1 15a680 frame. Series b, includes two #60 1 2 243082 strainer 1 3 244035 deflector, barbed 1 4 195400 clip, spring 1 5 196582 tube, suction, series a 1 197608 tube, suction, se...

Page 27: Parts

Parts 309226m 27 parts dx sprayer model 232735 42 44 50 57 59 58 1 56 72 71 70 73 60 12 5 1 56 60 4 61 7 63 51 52 63 23 54 54a 55 62 5 12 2 3 13 4 53 30,32,38 13 64 31 ti5469b.

Page 28: Parts

Parts 28 309226m parts xr5 sprayer model 232740 ▲ replacement danger and warning labels, tags, and cards are available at no cost. Ref. No. Part no. Description qty. 1 195126 pump, housing 1 2 243090 kit, pump repair 1 13 243094 kit, outlet valve (includes #17) 1 17 103338 packing, o-ring 1 18 19594...

Page 29: Parts

Parts 309226m 29 parts xr5 sprayer model 232740 series a, b, c, d 54 58 1 65 76 74 81 72 69 68 67 65 70 52 73 51 62 66 52 61 47 46 13 75 90 36 20 2 19 18 43, 44, 45 88 48 114 114 127 17 25 63 75 59 94 95 137 112 ti5468b 1 apply light coat of lithium-based grease. 1 alternate config. 25 20 71 93 72 4...

Page 30: Parts

Parts 30 309226m parts xr5 sprayer model 232740 series e 1 65 76 74 81 72 69 68 67 65 70 52 73 62 13 75 90 36 20 2 19 18 43, 44, 45 88 127 17 25 75 59 94 95 137 apply light coat of lithium-based grease. 1 alternate config. 25 20 71 93 72 40 66 47 51 54 58 46 52 52 48 114 114 112 148 142 141 140 63 1...

Page 31: Notes

Parts 309226m 31 notes.

Page 32: Parts

Parts 32 309226m parts xr7 sprayer model 232745 ▲ replacement danger and warning labels, tags, and cards are available at no cost. Ref. No. Part no. Description qty. 1 195126 pump, housing 1 2 243090 kit, pump repair 1 13 243094 kit, outlet valve (includes #17) 1 17 103338 packing, o-ring 1 18 19594...

Page 33: Parts

Parts 309226m 33 parts xr7 sprayer model 232745 series a, b, c 63 66 61 62 79 67 68 79 77 76 75 74 80 72 65 72 47 51 73 113 70 1 65 13 54 58 46 71 86 85 20 87 88 89 52 69 36 52 81 43, 44, 45 19 18 52 84 102 48 125 125 25 17 40 150 ti5467b alternate config. 84 20 26 94 88 2 127 95 96 149 126 1 apply ...

Page 34: Parts

Parts 34 309226m parts xr7 sprayer model 232745 series d 63 62 79 67 68 79 77 76 75 74 80 72 65 72 73 113 70 1 65 13 71 86 85 20 87 88 89 69 36 52 81 43, 44, 45 19 18 84 102 25 17 20 26 alternate config. 94 88 2 127 95 96 149 1 apply light coat of lithium-based grease. 1 40 85 66 47 51 54 58 46 52 5...

Page 35: Notes

Parts 309226m 35 notes.

Page 36: Parts

Parts 36 309226m parts xr9 sprayer model 232750 ▲ replacement danger and warning labels, tags, and cards are available at no cost. Ref. No. Part no. Description qty. 1 195126 pump, housing 1 2 243090 kit, pump repair 1 13 243094 kit, outlet valve (includes #17) 1 17 103338 packing, o-ring 1 18 19594...

Page 37: Parts

Parts 309226m 37 parts xr9 sprayer model 232750 series a, b, c 67 68 77 76 75 74 79 72 71 112 69 65 72 73 112 70 71 63 66 61 62 47 51 1 13 54 58 46 86 20 83 87 88 52 36 52 80 40 19 85 52 2 65 78 78 84 48 124 124 101 17 127 43, 44, 45 148 ti5466c alternate config. 85 20 26 94 88 18 25 95 96 147 123 1...

Page 38: Parts

Parts 38 309226m parts xr9 sprayer model 232750 series d 67 68 77 76 75 74 79 72 71 112 69 65 72 73 112 70 71 66 62 47 51 1 13 54 58 46 83 87 88 52 36 52 80 40 19 52 2 65 78 78 48 124 124 101 17 127 94 88 18 25 95 96 147 123 1 apply light coat of lithium-based grease. 1 43, 44, 45 148 86 85 20 84 26...

Page 39: Technical Data

Technical data 309226m 39 technical data m agnum dx m agnum xr5 m agnum xr7 m agnum xr9 working pressure range 0-2800 psi (0-19 mpa, 0 -193 bar) 0-3000 psi (0-21 mpa, 0-207 bar) 0-3000 psi (0-21 mpa, 0-207 bar) 0-3000 psi (0-21 mpa, 0-207 bar) electric motor 6.5 amp (open frame, universal) 5.8 amp (...

Page 40: Graco Standard Warranty

Graco standard warranty 40 309226m graco standard warranty graco warrants all equipment referenced in this document which is manufactured by graco and bearing its name to be free from defects in material and workmanship on the date of sale to the original purchaser for use. With the exception of any...