- DL manuals

- Magnum

- Lawn and Garden Equipment

- 246185

- Repair Manual

Magnum 246185 Repair Manual

Graco Inc. P.O. Box 1441 Minneapolis, MN 55440-1441

www.graco.com

Copyright 2003

Graco Inc. is registered to I.S. EN ISO 9001

309797P

Repair

Interior Texture Sprayers

TexFinish™

U.S. patent D526,045

For Water-Based Materials Only

Models: 246185, 246186, 249175, 249176

55 psi (3.79 bar) Maximum Fluid Working Pressure

Related Manuals

Read warnings and instructions.

309584

309796

ti3157b

US

C

Conforms to ANSI/UL

standard 1450

Summary of 246185

Page 1

Graco inc. P.O. Box 1441 minneapolis, mn 55440-1441 www.Graco.Com copyright 2003 graco inc. Is registered to i.S. En iso 9001 309797p repair interior texture sprayers texfinish™ u.S. Patent d526,045 for water-based materials only models: 246185, 246186, 249175, 249176 55 psi (3.79 bar) maximum fluid...

Page 2

2 309797p warnings fire and explosion hazard improper grounding, poor ventilation, open flames or sparks can cause a hazardous condition and result in fire or explosion and serious injury. • the system is for use with water-based materials only. Only use fluids compatible with the equipment. Refer t...

Page 3

309797p 3 electric shock hazard to reduce the risk of electric shock: • be sure sprayer is adequately grounded through electrical outlet, page 5. • use only 3-wire, extension cords. • make sure ground prongs are intact on sprayer and extension cords. • do not operate with cover removed. • turn off s...

Page 4: Component Identification

Component identification 4 309797p component identification wlf cc g l a b aa y m p k e d f w j t r u s bb dd n ti3157b h item component item component a air hose outlet p nozzle storage b material hose outlet r hose plug d hopper gun/spray gun selector switch s gun plug e on/off switch t material t...

Page 5: Preparation

Preparation 309797p 5 preparation pressure relief to reduce risk of injury, follow this procedure whenever you see this symbol throughout this manual, also, perform this procedure whenever you: • stop spraying. • check or repair any part of this system. • install or clean spray nozzle. 1. Turn power...

Page 6: Rotoflex™ Pump

Rotoflex™ pump 6 309797p rotoflex™ pump use rotoflex pump kit 234156. Disassembly 1. Relieve pressure, page 5. 2. Unplug sprayer from outlet. 3. Remove shroud (6 bolts). 4. Remove hopper by loosening bottom fitting and then lift- ing hopper straight up, off unit. 5. Remove material hose. 6. Loosen b...

Page 7

Rotoflex™ pump 309797p 7 reassembly reinstall rotoflex pump hose on plate. 1. Kink hose as shown, making sure dots located on hose fitting face each other. 2. Slide hose onto plate as shown below, mak- ing sure plate slides into slot between hex fitting on end of hose. 3. Align dots located on hose ...

Page 8: Compressor Repair

Compressor repair 8 309797p compressor repair use compressor repair kit, 234211. Disassembly 1. Relieve pressure, page 5. 2. Unplug sprayer. 3. Remove shroud (6 bolts). 4. Remove green ground wire and black, and white wires to compressor. 5. Loosen fittings (a and b) and remove air line. 6. Using a ...

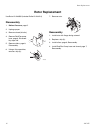

Page 9: Roller Replacement

Roller replacement 309797p 9 roller replacement use roller repair kit 234214. Disassembly 1. Relieve pressure, page 5. 2. Unplug sprayer from outlet 3. Remove shroud (6 bolts). 4. Remove rotoflex pump, page 6. 5. Using a crow bar as a wedge to keep rollers from moving, loosen shoulder bolt. 6. Remov...

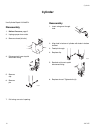

Page 10: Cylinder

Cylinder 10 309797p cylinder use cylinder repair kit 246574. Disassembly 1. Relieve pressure, page 5. 2. Unplug sprayer from outlet. 3. Remove shroud (6 bolts). 4. Disconnect air hose at quick disconnect fitting. 5. Remove clip. 6. Remove pin. 7. Pull swing arm out of opening. Reassembly 1. Insert s...

Page 11: Capacitor Replacement

Capacitor replacement 309797p 11 capacitor replacement use capacitor replacement kit 246683. Disassembly 1. Relieve pressure, page 5. 2. Unplug sprayer. 3. Remove shroud, (6 bolts). 4. Capacitors can hold a charge. To pre- vent electric shock, use a flat bladed screw driver as a con- ductive device ...

Page 12: Motor Repair

Motor repair 12 309797p motor repair use motor repair kit 246572. Disassembly 1. Relieve pressure, page 5. 2. Unplug sprayer from outlet. 3. Remove shroud (6 bolts). 4. Remove rotoflex pump hose; page 6. 5. Remove air cylinder; page 10. 6. Cut wire tie (a). 7. Remove yellow wire (b). 8. Remove groun...

Page 13

Motor repair 309797p 13 4. Using one hand to support motor, slide rod (f) through motor bracket. 5. Replace c-clip (e). For steps 6-9 refer to illustration below step 9. 6. Reattach blue wire to switch (d). 7. Replace ground nut (c). 8. Reattach yellow wire (b). 9. Secure all wires together with wir...

Page 14: Cooler Repair

Cooler repair 14 309797p cooler repair use cooler repair kit 246578. Disassembly 1. Relieve pressure, page 5. 2. Unplug sprayer. 3. Remove shroud (6 bolts). 4. Loosen nuts (a and b). 5. Disconnect air hose at fitting. 6. Carefully drill out rivets. 7. Pull cooler out of hous- ing. Reassembly 1. Inst...

Page 15: Relief Valve Replacement

Relief valve replacement 309797p 15 relief valve replacement use air relief valve kit 246580. Disassembly 1. Relieve pressure, page 5. 2. Unplug sprayer. 3. Remove shroud (6 bolts). 4. Remove screw on top of unit. 5. Remove air lines. 6. Pull air manifold down through inside of housing. 7. Disconnec...

Page 16: Rotor Replacement

Rotor replacement 16 309797p rotor replacement use rotor kit 246585 (includes roller kit 234214) disassembly 1. Relieve pressure, page 5. 2. Unplug sprayer. 3. Remove shroud (6 bolts). 4. Remove rotoflex pump hose, page 6, disassem- bly, steps 4-8. 5. Remove rollers, page 9, disassembly. 6. Using a ...

Page 17: Troubleshooting

Troubleshooting 309797p 17 troubleshooting pressure relief, page 5 problem cause solution sprayer won’t run power switch not on turn switch on. No power at wall outlet check outlet by plugging in another appliance. If appliance does not work, try another outlet. Wrong size generator use a 3500 watt ...

Page 18

Troubleshooting 18 309797p speed of application too slow material too thick thin material. Nozzle too small change nozzles to a larger size. See operation manual, recommended nozzle selection chart, page 10. Too much air being used. Partially close gun air valve to reduce air flow. Plugged or dirty ...

Page 19: Wiring Diagram

Wiring diagram 309797p 19 wiring diagram air diagram electrolytic capacitor black black blue yellow ground green green black black white white black green ti3120a power switch selector switch air compressor power cord motor air compressor air cylinder air cooler air manifold ti3179a.

Page 20: Parts

Parts 20 309797p parts e d wlh f f d 3djh 81.

Page 21

309797p 21 replacement danger and warning labels, tags and cards are available at no cost . Ref no. Part no. Description qty 3 117563 switch, selector 1 4 117693 switch, on/off 1 6 15a903 plate, hose 1 9 15c087 plate, frame, top 1 10 15b873 support, front, frame 1 11 246580 kit, manifold, air, inclu...

Page 22

22 309797p wlf 3djh.

Page 23

309797p 23 * when repairing elbow, order both part numbers for 80 ref no. Part no. Description qty 1 234214 kit, roller 1 5 15b858 leg, frame 1 8 246585 kit, pulley, includes 1, 2, 41 1 12 15b439 shaft, pivot, motor tray 1 13 15b530 rod, axle 1 14 15b861 handle, 1 15 15b543 rack, hose 1 16 15b857 fr...

Page 24

24 309797p.

Page 25: Technical Data

Technical data 309797p 25 technical data * measured while spraying at 1 m. ** measured per iso-3744 main unit power requirements. . . . . . . . . . . . . . . . . . . . . . 120 vac, 60 hz, 15a, 1 phase maximum fluid working pressure . . . . . . . . . . . . . . . . . . . 55 psi, (3.8 bar) maximum air ...

Page 26: Limited Warranty

Limited warranty 26 309797p limited warranty graco warrants to the original purchased (other than for purposes of resale or rental) all equipment manufactured by graco and bearing its name to be free from defects in material and workmanship if operated in accordance with graco’s printed recommendati...