Magnum CARIMIG 202LCD Manual

WE3107 v.110413

SAVE THIS MANUAL

You will need this manual for safety instructions, operating procedures, and warranty.

Put it and the original sales invoice in a safe, dry place for future reference.

CONSERVEZ CE GUIDE

Vous aurez besoin de ce guide pour les instructions de sécurité, les procédures d’utilisation et la garantie.

Conservez-le dans un endroit sûr et sec pour référence future.

QUESTIONS? 1-800-567-8979

Model

:

Our Customer Service staff are ready to provide assistance.

If a part is damaged or missing, replacement parts can be

shipped from our facility.

For help with assembly, or for additional product

information, call our North American toll-free number:

1-800-567-8979

Notre personnel de service à la clientèle sera prêt à

fournir assistance. Si une pièce est endommagée ou

manquante, des remplacements seront expédiés de notre

usine.

Pour de l’aide avec l’assemblage, ou pour des

informations additionnelles sur le produit, appeller notre

numéro sans frais nord-américain : 1-800-567-8979

CARIMIG 202LCD

Multi-Process DC LCD Welder

Summary of CARIMIG 202LCD

Page 1

We3107 v.110413 save this manual you will need this manual for safety instructions, operating procedures, and warranty. Put it and the original sales invoice in a safe, dry place for future reference. Conservez ce guide vous aurez besoin de ce guide pour les instructions de sécurité, les procédures ...

Page 2: General Safety Instruction

Please read and save these instructions. Read through this owner’s manual carefully before using product. Protect yourself and others by observing all safety information, warnings, and cautions. Failure to comply with instructions could result in personal injury and/or damage to product or property....

Page 3

General safety instruction 2 -wear proper gloves and protective clothing to prevent your skin from being exposed to hot metals, uv and ir rays. -do not overuse or overheat your welder. Allow proper cooling time between duty cycles. -keep hands and fingers away from moving parts and stay away from th...

Page 4

General safety instruction 3 uv and ir arc rays the welding arc produces ultraviolet (uv) and infrared (ir) rays that can cause injury to your eyes and skin. Do not look at the welding arc without proper eye protection. -always use a helmet that covers your full face from the neck to top of head and...

Page 5

General safety instruction 4 sparks/flying debris welding creates hot sparks that can cause injury. Chipping slag off welds creates flying debris. -wear protective apparel at all times: ansi-approved safety glasses or shield, welder’s hat and ear plugs to keep sparks out of ears and hair. Electromag...

Page 6: Mig Welder

Please read and save these instructions. Read through this owner’s manual carefully before using product. Protect yourself and others by observing all safety information, warnings, and cautions. Failure to comply with instructions could result in personal injury and/or damage to product or property....

Page 7

Operating instructions and parts manual mig/mma welder 2 1.3 after unpacking unit, inspect carefully for any damage that may have occurred during transit. Check for loose, missing, or damaged parts. Shipping damage claim must be filed with carrier. Operating instructions and parts manual specificati...

Page 8: Removing From Carton

Operating instructions and parts manual mig/mma welder 3 removing from carton 1.1 remove cartons, bags or styrofoam containing the welder and accessories. 1.2 check the contents with the packing list below. Z factory standard: en60974-1 z optional accessories: protective mask、tip、welding wire know y...

Page 9

Operating instructions and parts manual mig/mma welder 4 z input power cord the power cord connects the welder to the 120v/230 volt power supply. 14 amp receptacle to supply power to the welder. Z torch polarity change cable to change the polarity of gun for kinds of core wire welding. Z namepalte o...

Page 10

Operating instructions and parts manual mig/mma welder 5 z interface description 1. Multi-functions selection: total 9 functions, 8 welding functions and 1 setting. Adjusting multi-function knob for selecting, press for confirming 2. Output setup: shows output connection under different welding mode...

Page 11

Operating instructions and parts manual mig/mma welder 6 4. Material thickness: adjusting multi-function knob to select different material thickness, press for confirming 5. Welding display:shows all selected parameters. A. Under mig welding, user can set wire feeding speed and voltage. Adjusting mu...

Page 12

Operating instructions and parts manual mig/mma welder 7 c. Under stick welding, user can set current, arc force parameter and hot start. 6. Setting interface: it shows language setting, units setting, light setting, information and recover setting. 7. Alarm interface:it shows the machine is overloa...

Page 13: Installation

Operating instructions and parts manual mig/mma welder 8 installation outside connection of the machine 1. Power requirement ac single phase 230v or 120v , 50/60hz fused with a 15 amp time delayed fuse or circuit breaker is required. •high voltage danger from power source! Consult a qualified electr...

Page 14

Operating instructions and parts manual mig/mma welder 9 drop they produce. This drop in voltage can affect the performance of the welder. If you need to use an extension cord it must be a #12 gauge cord at the smallest. -do not use an extension cord over 25 ft. In length. 3. Setting up the work pie...

Page 15

Operating instructions and parts manual mig/mma welder 10 4. Ground clamp connection clear any dirt, rust, scale, oil or paint on the ground clamp. Make certain you have a good solid ground connection. A poor connection at the ground clamp will waste power and heat. Make sure the ground clamp touche...

Page 16

Operating instructions and parts manual mig/mma welder 11 -do not touch cylinder with mig gun. -do not weld on the cylinder. -always secure cylinder upright to a cart or stationary object. -keep cylinders away from welding or electrical circuits. -use the proper regulators, gas hose and fittings for...

Page 17

Operating instructions and parts manual mig/mma welder 12 6.2.The gas hose, regulator and gas cylinder connection attach one end of the gas hose to the gas solenoid valve (gas inlet) located on the back panel of the welder. Attach the other end to the gas regulator which is attached to the shielding...

Page 18

Operating instructions and parts manual mig/mma welder 13 7 installation of wire spool 7.1 open the turning plate of the machine, rotate the adjusting nut on the wire shaft anti- clockwise to remove it from the wire spool screw, and then take down the wire spool block seat; 7.2 let the inner hole of...

Page 19

Operating instructions and parts manual mig/mma welder 14 8 installation of wire feeder and connection of welding stick 8.1 while installing the wire spool, check previously that wire feeding roller in the wire feeder is suitable for the contact tip in the torch and wire diameter 8.2 after the confi...

Page 20: Operation

Operating instructions and parts manual mig/mma welder 15 9.4 after the installation of wire roller, screw the cover clockwise tightly. Make sure the screw thread connection is correct, to avoid damaging of the screw thread due to the connection deviation. Remark: he spec marked on the front of the ...

Page 21

Operating instructions and parts manual mig/mma welder 16 3.1. Angle a can be varied, but in most cases the optimum angle will be 60 degrees, the point at which the torch handle is parallel to the work piece. If angle a is increased, penetration will increase. If angle a is decreased, penetration wi...

Page 22

Operating instructions and parts manual mig/mma welder 17 5.4. With your free hand, turn the wire speed dial to maximum and continue to hold onto the knob. 5.5. Lower your welding helmet and pull the trigger on the torch to start an arc, then begin to drag the torch toward you while simultaneously t...

Page 23

Operating instructions and parts manual mig/mma welder 18 the stringer bead is formed by traveling with the torch in a straight line while keeping the wire and nozzle centered over the weld joint (see following figure) the weave bead is used when you want to deposit metal over a wider space than wou...

Page 24

Operating instructions and parts manual mig/mma welder 19 puddle control and allow slower rates of travel speed to achieve deeper penetration. When vertical welding, angle b (see holding the torch) is usually always kept at zero, but angle a will generally range from 45 to 60 degrees to provide bett...

Page 25

Operating instructions and parts manual mig/mma welder 20 fillet weld joints. Most fillet weld joints, on metals of moderate to heavy thickness, will require multiple pass welds to produce strong joint. The illustrations in figure 19 show the sequence of laying multiple pass beads into a t fillet jo...

Page 26

Operating instructions and parts manual mig/mma welder 21 6.6 spot welding instructions 1. Select the wire diameter and heat setting recommended above for the method of spot welding you intend to use. 2. Tune in the wire speed as if you were going to make a continuous weld. 3. Hold the nozzle piece ...

Page 27: Operation

Operating instructions and parts manual mig/mma welder 22 a. The bead will be high and irregular b. The arc will be difficult to maintain 3. When the rod is too large a. The arc will burn through light metals b. The bead will undercut the work c. The bead will be flat and porous d. Rod may be freeze...

Page 28

Operating instructions and parts manual mig/mma welder 23 2.2 striking the arc exposure to a welding arc is extremely harmful to the eyes and skin. •never strike an arc or begin welding until you have adequate protection. • wear flameproof welding gloves, heavy long-sleeved shirt, cuffless trousers,...

Page 29

Operating instructions and parts manual mig/mma welder 24 2.3 types of weld bead the following paragraphs discuss the most commonly used arc welding beads. The stringer bead formed by traveling with the electrode in a straight line while keeping it centered over the weld joint. The weave bead used w...

Page 30

Operating instructions and parts manual mig/mma welder 25 the horizontal positionis is performed very much the same as the flat weld except that the angle is different such that the electrode, and therefore the arc force, is directed more toward the metal above the weld joint. This more direct angle...

Page 31

Operating instructions and parts manual mig/mma welder 26 a solid weld bead requires that the electrode be moved slowly and steadily along the weld seam. Moving the electrode rapidly or erratically will prevent proper fusion or create a lumpy, uneven bead. To prevent electric shock, do not perform a...

Page 32

Operating instructions and parts manual mig/mma welder 27 striking the arc method following step: a.Turns on the welding torch built-in air valve approaches the striking the arc spot the spray nozzle to cause the tungstic electrode and the work piece is separated 2~3mm b.Slowly lifts the welding tor...

Page 33: Trouble Shooting Chart

Operating instructions and parts manual mig/mma welder 28 trouble shooting chart no breakdown analysis solutions voltage is too high (≥15%) voltage is too low (≤15%) switch off power source; check the main supply; restart welder when power recovers to normal state. Bad power ventilation lead to over...

Page 34

Operating instructions and parts manual mig/mma welder 29 too large contact tip makes the current unsteady change the proper contact tip or roller too thin power cable makes the power astaticism change the power cable too low input voltage enhance the input voltage 4 arc is not stable and splash is ...

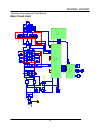

Page 35: Main Circuit Chart

Operating instructions and parts manual mig/mma welder 30 main circuit chart 1 2 1 2 sw 1 30a 250 v a c ea r t h ac 1 ac 2 1 1 5v /2 30 v a c c8 m px/ m k p x2 1 05 k 2 75 vac p= 22 .5 ym 1 471k d2 0 ac 1 ac 2 c4 d1 1 m7 r17 pt c m z 32 4 7r g c e t1 g c e t4 6 7 4 5 1 2 zb y q 1 7: 3: 3 ea r t h + ...

Page 36: Spare Part List

Operating instructions and parts manual mig/mma welder 31 spare part list repair parts list serial number code definition quantity 1 2.05.08.115 holder 1 2 2.05.17.012 hinge 2 3 1.1.01.01.0890 case 1 4 1.1.01.05.3233 riser 1 5 1.2.02.01.6569 backboard 1 6 2.03.05.275 power line 1 7 2.04.30.102 fixed...

Page 37

Operating instructions and parts manual mig/mma welder 32 16 1.1.01.04.1537 baseboard 1 17 2.05.05.519 front plastic board 1 18 2.07.57.960 rapid socket 2 19 2.07.54.019 aerial socket 1 20 1.2.07.02.3975 umpolung cable 1 21 2.07.11.021 potentiometer knob 2 22 1.1.05.07.0268 panel support plate 1 23 ...