- DL manuals

- Magnum Energy

- Inverter

- MS Series

- Owner's Manual

Magnum Energy MS Series Owner's Manual

Summary of MS Series

Page 1

Ms series pure sine wave inverter/charger owner’s manual tm.

Page 2

Page i © 2009 magnum energy inc. Disclaimer of liability since the use of this manual and the conditions or methods of installation, operation, use and maintenance of the ms series inverter/charger is beyond the control of magnum energy inc., this company does not assume responsibility and expressly...

Page 3: Save These Instructions

© 2009 magnum energy inc. Page ii important safety instructions this manual contains important safety instructions that must be followed during the installation and operation of this product. All electrical work must be performed in accordance with local, state and federal electrical codes. Read all...

Page 4: Save These Instructions

Page iii © 2009 magnum energy inc. Important battery safety instructions be very careful when working around batteries, they can produce extremely high currents if short-circuited. Read the battery supplier’s precautions before installing the inverter and batteries. Wear eye protection such as safet...

Page 5: Table of Contents

© 2009 magnum energy inc. Page iv table of contents 1.0 introduction ..................................................................................1 1.1 features and benefi ts ................................................................................. 2 1.2 how an inverter/charger works .....

Page 6: List of Figures

Page v © 2009 magnum energy inc. List of figures figure 1-1, power switch, status led and accessory connection ports .................................................3 figure 1-2, electrical connection points ..............................................................................................

Page 7

Page 1 © 2009 magnum energy inc. Introduction 1.0 introduction congratulations on your purchase of the ms series inverter/charger from magnum energy. The ms series is a “pure” sine wave inverter designed especially for rugged mobile applications, home backup power and stand-alone applications. Power...

Page 8

© 2009 magnum energy inc page 2 introduction 1.1 features and benefi ts the ms series inverter/charger is designed to allow easy access to wiring, circuit breakers, controls and for viewing the led (light emitting diode) status indicator. Its die cast base plate with one piece aluminum cover ensures...

Page 9

Page 3 © 2009 magnum energy inc. Introduction figure 1-1, power switch, status led and accessory connection ports figure 1-2, electrical connection points ac entry/exit connections mounting flange (7) (8) power on/off switch (1) status led (charging/inverting) (2) stacking/accessories port (red labe...

Page 10

© 2009 magnum energy inc page 4 introduction figure 1-3, left side features the left side of the ms series is equipped with the following features (see to fi gure 1-3): (13) exhaust air vent - ventilation openings that allow heated air to be removed by the internal cooling fan. (14) model/serial num...

Page 11

Page 5 © 2009 magnum energy inc. Introduction 1.2 how an inverter/charger works there are two modes of operation associated with this inverter/charger: inverter mode: when the inverter is properly connected to batteries and turned on, the direct current (dc) from the batteries is transformed into a ...

Page 12

© 2009 magnum energy inc page 6 introduction 1.4 appliances and run time the ms series inverter/charger can power a wide range of household appliances including small motors, hair dryers, clocks and other electrical devices. As with any appliance using batteries for power, there is a certain length ...

Page 13

Page 7 © 2009 magnum energy inc. Installation 2.0 installation info: installations should be performed by qualifi ed personnel, such as a licensed or certifi ed electrician. It is the installer’s responsibility to determine which safety codes apply and to ensure that all applicable installation requ...

Page 14

© 2009 magnum energy inc page 8 installation figure 2-1, simplifi ed installation diagram for permanent installations b attery b ank 120/240va c p o wer to in verter on of f on of f on of f on of f on of f on of f on of f on of f 240 va c 120 va c 120 va c d c o vercurrent protection (b reaker or fu...

Page 15

Page 9 © 2009 magnum energy inc. Installation 2.1.3 locating the inverter only install the inverter in a location that meets the following requirements: clean and dry - the inverter should not be installed in an area that allows dust, fumes, insects or rodents to enter or block the inverter’s ventil...

Page 16

© 2009 magnum energy inc page 10 installation 3 0 30 2.2 mounting the inverter the inverter base can reach a temperature up to 90°c (194°f), and it is recommended that it should be mounted on a noncombustible surface*. This surface and the mounting hardware must also be capable of supporting at leas...

Page 17

Page 11 © 2009 magnum energy inc. Installation figure 2-3, ms series dimensions 12 5/8" 12" 4 7/8" 2" 4 7/8" keyhole slots (x4) and mounting holes (x4) accept up to 9/32" screw/ bolt 13 3/4" 8" 6 5/8".

Page 18

© 2009 magnum energy inc page 12 installation 2.3 wiring the inverter - general requirements this section also describes the requirements and recommendations for wiring the ms series inverter/charger. Before wiring the ms series inverter/charger, read all instructions. All wiring should meet all loc...

Page 19

Page 13 © 2009 magnum energy inc. Installation 2.4 dc wiring this section describes the inverter’s required dc wire sizes and the recommended disconnect/ overcurrent protection and how to make the dc connections to the inverter and the battery bank. Refer to fi gure 2-4 when connecting the dc wires....

Page 20

© 2009 magnum energy inc page 14 installation d c ov e rc urre nt p rote c tion (c irc uit b re a k e r or fus e /s witc h ) d c ground b us -ba r d c s hunt battery bank dc circuit breaker box d c n e ga tiv e to d c ground j um pe r d c grounding point [v e hic le c ha s s is , e le c trode c ondu...

Page 21

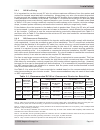

Page 15 © 2009 magnum energy inc. Installation 2.4.1 dc wire sizing it is important to use the correct dc wire to achieve maximum effi ciency from the system and reduce fi re hazards associated with overheating. Always keep your wire runs as short as practical to help prevent low voltage shutdowns a...

Page 22

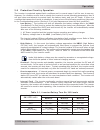

© 2009 magnum energy inc page 16 installation table 2-2, dc wire size for increased distance inverter model minimum recommended dc wire size (one way)* 5 feet or less 5 to 10 feet 10 to 15 feet in conduit in free air in conduit in free air in conduit in free air ms2012 #4/0 awg #2/0 awg #4/0 awg x2 ...

Page 23

Page 17 © 2009 magnum energy inc. Installation 2.4.4 wiring the dc overcurrent protection device a fuse/disconnect or circuit breaker must be provided in the dc positive line between the battery and the inverter to protect the dc wiring system. Mount the fuse block (or circuit breaker assembly) as n...

Page 24

© 2009 magnum energy inc page 18 installation 2.4.6 battery temperature sensor installation and wiring the battery temperature sensor (shown in fi gure 2-7) provides the inverter with precise battery temperature information to automatically adjust the absorb and float charge voltage setpoints this a...

Page 25

Page 19 © 2009 magnum energy inc. Installation 2.4.7 wiring the inverter to the battery bank caution: inverter is not reverse polarity protected, if this happens the inverter will be damaged and will not be covered under warranty. Before connecting the dc wires from the batteries to the inverter, ve...

Page 26

© 2009 magnum energy inc page 20 installation 2.5 ac wiring this section provides information on how to make the ac connections to the inverter using the correct ac wire size and corresponding overcurrent protection. 2.5.1 pre-ac wiring requirements caution: before installing any ac wiring, review t...

Page 27

Page 21 © 2009 magnum energy inc. Installation figure 2-8, ms series inverter/charger - ac wiring figure 2-9, ms series inverter/charger - ac wiring (access panel) ac input strain relief clamp ac access panel ac input circuit breaker (cb3) ac output 2 circuit breaker (cb2) (on -15b, -20b output brea...

Page 28

© 2009 magnum energy inc page 22 installation 2.5.3 recommended gfci (ground fault circuit interruption) breakers some electrical safety codes require the use of gfci’s. In compliance with ul standards, magnum energy has tested the following gfci’s and fi nd that they function properly when connecte...

Page 29

Page 23 © 2009 magnum energy inc. Installation 2.5.5 ac conductor wiring the following steps are basic guidelines for installing and connecting the ac wiring into and out of the inverter, refer to table 2-3 to determine your ac wiring confi gurations before beginning. Warning: before making any ac c...

Page 30

© 2009 magnum energy inc page 24 installation 2.5.5 ac wiring confi gurations the following table provides the different wiring confi gurations for installing and connecting the ac conductors into and out of the inverter (refer to fi gures 2-11 to 2-15 for installation drawings showing these confi g...

Page 31

Page 25 © 2009 magnum energy inc. Installation m ain p an el (u tility /gen erato r in p u t) m s s eries in verter a c t erm in al b lo ck (a c in p u t an d o u tp u t wirin g ) s in g l e in / s in g l e o u t (3 0a) w irin g ac ho t 1 i n (f ro m m a in p a n el ) ac h o t 1 o u t (t o su b pa n...

Page 32

© 2009 magnum energy inc page 26 installation figure 2-12, ac wiring for single in - single out (60 a) confi gurations m ain p an el (u tility /gen erato r in p u t) m s s eries in verter a c t erm in al b lo ck (a c in p u t an d o u tp u t wirin g ) s in g l e in / s in g l e o u t (6 0a) w irin g...

Page 33

Page 27 © 2009 magnum energy inc. Installation figure 2-13, ac wiring for single in - dual out confi gurations m ain p an el (u tility /gen erato r in p u t) m s 2012-15b o r m s 2012-20b in verter a c t erm in al b lo ck (a c in p u t an d o u tp u t wirin g ) s in g l e in / d u a l o u t w irin g...

Page 34

© 2009 magnum energy inc page 28 installation figure 2-14, ac wiring for dual in - single out confi gurations s u b p an el an d ou tlets (in verter l o ad s) 1 2 0 v a c 1 2 0 v a c m ain p an el (u tility /gen erato r in p u t) m s s eries in verter a c t erm in al b lo ck (a c in p u t an d o u t...

Page 35

Page 29 © 2009 magnum energy inc. Installation figure 2-15, ac wiring for dual in - dual out confi gurations 2 4 0 v a c only in s ta ndby m ain p an el (u tility /gen erato r in p u t) m s s eries in verter a c t erm in al b lo ck (a c in p u t an d o u tp u t wirin g ) d u a l in / d u a l o u t w...

Page 36

© 2009 magnum energy inc page 30 installation 2.6 grounding inverters the inverter/charger should always be connected to a permanent, grounded wiring system. An inverter system that is properly grounded will limit the risk of electrical shock, reduce radio frequency noise from the inverter and minim...

Page 37

Page 31 © 2009 magnum energy inc. Installation 2.6.1 sizing the grounding electrode conductors ac side - the size of the ac grounding electrode conductor (gec –ac) depends on the size of the largest ungrounded conductor feeding the ac load center. One #8 awg (8.4 mm 2 ) copper conductor will serve a...

Page 38

© 2009 magnum energy inc page 32 installation method 2 (see fi gure 2-18): when the ac and dc service panels are near each other, then the ac grounding electrode conductor (gec – ac) and dc grounding electrode conductor (gec – dc) can be connected to a single grounding electrode. In this method - si...

Page 39

Page 33 © 2009 magnum energy inc. Installation 2.6.2 system bonding jumper the ms series inverter does not include an internal bond between the grounded conductor (ac neutral/dc negative) and the equipment grounding terminals. This bond [system bonding jumper (sbj)] is usually done in the main distr...

Page 40

© 2009 magnum energy inc page 34 installation 2.6.4 grounding on boats when installing the ms series inverter/charger on a boat, there are several considerations that must be followed when grounding to ensure a safe installation, prevent galvanic corrosion and adhere to abyc (american boat and yacht...

Page 41

Page 35 © 2009 magnum energy inc. Installation 2.6.5 neutral to safety ground bonding the standards for safely wiring residential, commercial, rv/truck and marine installations in the united states require the neutral and safety ground be connected at the ac source; whether it is the utility feed in...

Page 42

© 2009 magnum energy inc page 36 installation 2.6.6 disabling the neutral-to-ground connection all ms series inverter/chargers have the automatic neutral-to-ground switching feature. In some installations/jurisdictions, this feature must be disabled. If you are not sure whether you must disable this...

Page 43

Page 37 © 2009 magnum energy inc. Installation 2.7 inverter notifi cation requirements when an inverter is installed in a building, facility or structure, the nec (national electrical code) requires a label or plaque to be provided. This label/plaque is required to be easily visible and provide info...

Page 44

© 2009 magnum energy inc page 38 installation 2.9 functional test after all electrical connections to the inverter, batteries, ac source, and sub-panel have been completed; follow these steps to test the installation and the inverter operation. Caution: use a multimeter to verify the correct dc volt...

Page 45

Page 39 © 2009 magnum energy inc. Installation 3.0 operation the ms series inverter has two normal operating routines; 1. Inverter mode, which powers your loads using the batteries, and 2. Standby mode, which transfers the incoming ac power (i.E., utility power or a generator) to power your loads an...

Page 46

© 2009 magnum energy inc page 40 operation 3.2 standby mode the ms series features an automatic transfer relay and an internal battery charger when operating in the standby mode. The standby mode begins whenever ac power (utility or generator) is connected to the inverter’s ac input. Once the ac vol...

Page 47

Page 41 © 2009 magnum energy inc. Operation the charge mode provides up to four separate charging stages: bulk charging, absorb charging, float charging and full charge. Bulk charging: this is the initial stage of charging. While bulk charging, the charger supplies the battery with controlled consta...

Page 48

© 2009 magnum energy inc page 42 operation 3.4 transfer time while in the standby mode, the ac input is continually monitored. Whenever ac power falls below the vac dropout voltage (80 vac, default setting), the inverter automatically transfers back to the invert mode with minimum interruption to yo...

Page 49

Page 43 © 2009 magnum energy inc. Operation 3.6 protection circuitry operation the inverter is protected against fault conditions and in normal usage it will be rare to see any. However, if a condition occurs that is outside the inverter’s normal operating parameters, then it will shut down and atte...

Page 50

© 2009 magnum energy inc page 44 operation 3.7 inverter startup on/off switch - the inverter can be turned on and off by lightly pressing and releasing the power on/off switch on the front of the inverter (refer to fi gure 3-5). When the inverter is fi rst connected to the batteries, or when its aut...

Page 51

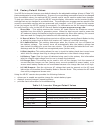

Page 45 © 2009 magnum energy inc. Operation 3.8 factory default values your ms series inverter/charger uses default values for the adjustable settings (shown in table 3-2) that are adequate for most installations. If some of your operating parameters need to be changed from the default values, the o...

Page 52

© 2009 magnum energy inc page 46 maintenance and troubleshooting 4.0 maintenance and troubleshooting the following information is provided to help you keep your ms series inverter/charger in optimum operational condition. 4.1 recommended inverter and battery care the ms series inverter/ charger is d...

Page 53

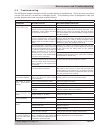

Page 47 © 2009 magnum energy inc. Maintenance and troubleshooting 4.3 troubleshooting the ms series inverter/charger is a fairly simple device to troubleshoot. There are only two active circuits (ac and dc) as well as a charging circuit. The following chart is designed to help you quickly pinpoint t...

Page 54

© 2009 magnum energy inc page 48 maintenance and troubleshooting 1. Press and hold the power on/off pushbutton. 2. Watch the charging/inverting status led, after approximately 15 seconds it should come on and fl ash rapidly to indicate the inverter has reset. The status led will go off after the pus...

Page 55

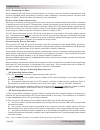

Page 49 © 2009 magnum energy inc. Appendix a - specifi cations ms2012 (-15b, -20b) ms2812 ms4024 inverter specifi cations input battery voltage range 9.0 to 16.8 vdc 9.0 to 16.8 vdc 18.0 to 33.6 vdc absolute maximum dc input 25 vdc 25 vdc 35 vdc ac output voltage accuracy 120 vac ±5% (≤ continuous p...

Page 56

© 2009 magnum energy inc page 50 appendix a - specifi cations 40% 50% 60% 70% 80% 90% 100% 200 400 600 1000 1400 1800 2200 2600 3000 3400 3800 4200 m s2000 / m s 2012 m s 2812 m s 4024 a-2 inverter effi ciency the following curves are plotted to show the ms series effi ciency over the full power ran...

Page 57

Page 51 © 2009 magnum energy inc. Appendix a - specifi cations a-4 optional equipment and accessories the following magnum energy components are available for use with the ms series inverter/charger. Some of these items are required depending upon the intended use of the inverter. A-4.1 automatic ge...

Page 58

© 2009 magnum energy inc page 52 appendix b - battery information appendix b - battery information b-1 battery location periodic maintenance (i.E., checking connections, cleaning, watering) on batteries is required. Locate the batteries in an accessible location to perform this maintenance. Batterie...

Page 59

Page 53 © 2009 magnum energy inc. Appendix b - battery information b-5 battery bank sizing worksheet complete the steps below to determine the battery bank size required to power your ac loads: 1. Determine the daily power needed for each load a) list all ac loads required to run; and b) list the wa...

Page 60

© 2009 magnum energy inc page 54 appendix b - battery information b-6 battery wiring confi gurations the battery bank must be wired to match the inverter’s dc input voltage. In addition, the batteries can be wired to provide additional run time. The various wiring confi gurations are: b-6.1 series w...

Page 61

Page 55 © 2009 magnum energy inc. Appendix b - battery information figure b-4, battery bank wiring examples (12-volt) 12 v d c b attery (100 a h) 12 v d c b attery (100 a h) 12 vo lt b attery b an k (o n e strin g o f o n e 12 -vo lt b attery ) 12 vo lt b attery b an k ( o n e strin g o f tw o 6-vo ...

Page 62

© 2009 magnum energy inc page 56 appendix b - battery information figure b-5, battery bank wiring examples (24-volt) 24 vo lt b attery b an k (o n e strin g o f fo u r 6 -vo lt b atteries w ired in series ) to 24 v d c in verter (to tal cap acity = 200 a h) 6 v d c b attery (200 a h ) ov er - c urre...

Page 63

Page 57 © 2009 magnum energy inc. Appendix c - warranty & service limited warranty magnum energy, inc., warrants the ms series inverter/charger to be free from defects in material and workmanship that result in product failure during normal usage, according to the following terms and conditions: 1. ...

Page 64

Magnum energy, inc. 2211 west casino rd. Everett, wa 98204 phone: 425-353-8833 fax: 425-353-8390 web: www.Magnumenergy.Com ms series owner’s manual (pn: 64-0007 rev a).