- DL manuals

- Magnum

- Portable Generator

- MLT 4250

- Operating & Parts Manual

Magnum MLT 4250 Operating & Parts Manual

Summary of MLT 4250

Page 1

Operating/parts manual mlt 4250

Page 2: Magnum Products Llc

2 introduction this manual provides information and procedures to safely operate and maintain the light tower and generator. For your own safety and protection from physical injury, carefully read, understand, and observe the safety instructions described in this manual. The information contained in...

Page 3

Table of contents page introduction ................................................................................................................. 2 table of contents ...................................................................................................... 3 safety notes ...............

Page 4

4 this is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all safety messages that follow this symbol to avoid possible injury or death. This manual contains dangers, warnings, cautions, notices and notes which must be followed to prevent the possibility o...

Page 5

5 internal combustion engines present special hazards during operation and fueling! Failure to follow the safety guidelines described below could result in severe injury or death. Also read and follow all safety warnings described in the engine operator's manual. A copy of this manual was supplied w...

Page 6

6 towing a trailer requires care! Both the trailer and vehicle must be in good condition and securely fas- tened to each other to reduce the possibility of an accident. Also, some states require that large trailers be registered and licensed. Contact your local department of transportation office to...

Page 7

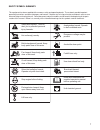

Safety symbol summary this equipment has been supplied with numerous safety and operating decals. These decals provide important operating instructions and warn of dangers and hazards. Replace any missing or hard-to-read decals and use care when washing or cleaning the unit. Decal placement and part...

Page 8

8 specifications read this manual carefully before attempting to use this light tower. The potential for property damage, personal injury or death exists if this equipment is misused or installed incorrectly. Read all of the manuals included with this unit. Each manual details specific information r...

Page 9

9 specifications read this manual carefully before attempting to use this light tower. The potential for property damage, personal injury or death exists if this equipment is misused or installed incorrectly. Read all of the manuals included with this unit. Each manual details specific information r...

Page 10

1 2 3 4 5 6 1. Fuel filler location (under door): use clean diesel fuel only. 2. Radiator access panel: remove this panel for engine coolant service. 3. Control panel location (under door): engine/generator controls and all circuit breakers. 4. Emergency stop switch: for emergency shutdown; stops en...

Page 11

7 10 13 4 2 2 1 3 6 9 12 5 8 11 main control panel components 1. Main circuit breaker (90a): this breaker will disconnect power to the connection lugs. 2. Lug door safety switches: these switches will shut the generator down if the lug door is opened when the generator is running. 3. Generator outpu...

Page 12

Magnum digital controller (mdc) the magnum digital controller (mdc) is an enhanced digital generator controller used to start, stop and monitor the operation of the generator and the engine. The controller constantly monitors vital generator and engine functions for a number of pre-programmed alarm ...

Page 13

• “alarm cancel” button when an alarm is activated, either visually or audibly, press this button to silence or cancel the alarm. • “fault reset” button press this button to clear the fault from the lcd window after the fault has been corrected. Press “fault reset” and “enter” to clear the john deer...

Page 14

Engine monitoring engine information is shown on the liquid crystal display (lcd) window in a toggling manner with the generator information after the first 60 seconds of operation and then every 5 seconds thereafter. The engine display screen will show oil pressure, engine coolant temperature, fuel...

Page 15

The history of alarms or codes of the unit are saved in the digital controller. The most recent alarm or code is the first to be listed, with the time/date of the alarm or code at the bottom of the screen. The controller stores up to 118 codes. When full, the controller will automatically remove the...

Page 16

Magnum digital controller (mdc) information displays, functions and reset the magnum digital controller (mdc) constantly monitors vital generator and engine functions for a number of operation, alarm and fault conditions. When a fault condition occurs, the engine will shut down automatically and the...

Page 17

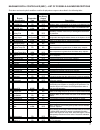

Magnum digital controller (mdc) - list of possible alarms/descriptions shut down and warning fault conditions and the displayed message are described in the following table: no. Events specification protection type information on binary output available description 1 aniniom sd sd yes shutdown alarm...

Page 18

28 vgen unbal sd no the generator voltage is unbalanced more than the value of volt unbal setpoint. 29 wrn ecu alarm wrn no ecu alarm list is not empty. 30 wrn ra15 fail wrn no warning alarm in case of lost connection to igl-ra15 module. 31 wrnservicetime wrn no the period for servicing is set by th...

Page 19

Adjusting the display back lighting the backlighting on the liquid crystal display (lcd) window may be adjusted brighter or darker by the operator whenever the magnum digital controller (mdc) is powered up. 1. Press and hold “enter” and press “ s” or “t” on the diagnostics keypad to increase or decr...

Page 20

Tighten connection lugs with a hex wrench generator output connection lugs the generator is equipped with connection lugs behind a door below the controller face. The lugs provide connection points for attachment of external loads to the generator. A large decal on the inside of the connection lug d...

Page 21

Voltage selector switch the voltage selector switch is located behind the lug door, underneath the engine controller panel. The selector switch is a three position switch that mechanically changes the connections between the generator output leads and the connection lugs. Voltage ranges are selected...

Page 22

Auxiliary outlets the control panel is equipped with six outlets for running acces- sories or tools from the generator. Power is supplied to the outlets any time the engine is running and the main circuit breaker and the auxiliary outlet main circuit breaker are switched in the on “i” position. Shou...

Page 23

Main circuit breaker the main circuit breaker is located on the main control panel. When the breaker is in the off “o” position, power is interrupted between the customer connection lugs and the generator. Once the connections have been made to the connection lugs and the generator has been started ...

Page 24

Incoming utility power white = incoming utility power gray = normal utility power circuit black = emergency generator power circuit utility meter transfer switch main distribution panel (utility power) emergency distribution panel (generator power) power from generator installation of a transfer swi...

Page 25

Light tower set-up 1. For maximum light coverage locate tower at ground level or in a spot higher than the area being illuminated by the lamps. 2. Place the trailer on firm ground that is relatively flat. This will make it easier to level the tower. Block the wheels on the trailer to keep it from mo...

Page 26

I j j k, l, n m o q 1. Remove the mast cradle locking pin from the mast cradle (i). 2. Check both sets of mast cables for excessive wear or damage. Make sure the cables are properly centered in each pulley (j). Check the electrical cord for damage. 3. Make sure the area behind the unit is clear befo...

Page 27

Stop detail v detail w v u s r,t w detail r detail s detail t detail u 1. Set up and level the trailer as described on page 25, and follow steps 1-3 on page 26. 2. Remove the safety pin from the mast lock bar (r). 3. Press the lower winch control toggle switch upward to raise mast into the vertical ...

Page 28

Light tower start up before starting the light tower, carefully read the pre-start check list. Make sure that all of the items are checked before trying to start the light tower. This check list applies for both manual and remote starting. Pre- start check list make sure the control on/off toggle ...

Page 29

4. Press the green “engine start” button. The prestart (preheat) screen will be displayed (if equipped) and a countdown will begin from 20 seconds to 0. 5. The starting screen will be displayed. The engine will crank and start running. 6. The running screen will display. Note: it may take a few seco...

Page 30

10. Once the engine starts it will immediately begin speeding up to a constant 1800 rpm. On units with isochronous engine governing, the engine may hunt or change speeds until operating temperature is reached. After a few minutes of operation, the engine will be warmed up and the lcd window will sho...

Page 31

Shutting down when you have finished using the light tower, proceed with shut down as follows: 1. Remove any loads from the auxiliary outlets. 2. Switch the individual circuit breakers for each light to the off “o” position. 3. Switch the main circuit breaker to the off “o” position. 4. Push the red...

Page 32

32 lowering the tower 1. Shut down the lights and engine. Allow the lights to cool 10-15 minutes before lowering the tower. 2. Turn the upper mast winch handle to collapse the tower to its lowest position. Make sure the electrical cord returns to the storage tube properly. 3. Loosen the mast rotatio...

Page 33

5 2 3 4 1 33 removing the lights for transportation 1. On units equipped with quick disconnect fittings for the lights, disconnect the power cords from the junction box at the top of the mast. Replace the dust caps on the junction box. On other units, remove the junction box cover on the top of the ...

Page 34

Lifting the trailer when lifting the light tower and trailer, attach any slings, chains or hooks directly to the central lifting eye. The lifting eye is located on the mast between the two forklift pockets. 1. Make sure the equipment being used to lift the light tower has sufficient capacity. Note: ...

Page 35

35 engine maintenance note: during the first 50 hours of operation, avoid long periods of no load or sustained maximum load operation. If the light tower is to run for longer than five minutes without a load, shut the engine down. The engine is supplied with engine break-in oil from the factory. Ext...

Page 36

Derating for altitude all light towers are subject to derating for altitude and temperature; this will reduce the available power for operating to tools and accessories connected to the auxiliary outlets. Typical reductions in performance are 2-4% for every 1000 ft. (305 meters) of elevation and 1% ...

Page 37

Troubleshooting the lights mast lights off but ballast indicators on control panel are on: 1. Mast light is too hot. Allow light to cool 10-15 minutes before restarting. 2. Faulty bulb connection. Check that the bulb is tight in the socket. 3. Bulb broken. Check for broken arc tube or outer bulb jac...

Page 38

Warning warnung advertissement advertencia warnung advertissement advertencia warning generateur puet demarrer automatiquement resultant en des accidents de personne. Deconnecter batterie avant tout entretien. Generator can automatically start which can cause serious injury. Disconnect battery befor...

Page 39

Secure mast in transport lock before lifting or towing! Den mast vor dem anheben oder abschleppen in der transporthalterung sichern! Verrouillez solidement le mat pour le transport avant de le hisser ou de le remorquer. Advertencia warnung advertissement fije el mastil en la traba de transporte ante...

Page 40

Located on electric winches mast control mast-steuerung control del mÁstil commande de mt to vertical to horizontal mast telescope mast-teleskop mast telescope tÉlescope de mt telescope up telescope down always keep tension on cables! Slack may cause cable damage and excessive wear! ¡csiempre tensiÓ...

Page 41

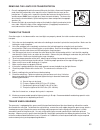

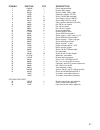

Unit decals 41 item no. Part no. Qty description 1 13136 1 decal set, mlt4250 2 12191 1 decal, label set - mlg25 3 22960 -- decal, breaker 20 amp 4 23203 -- decal, breaker 30 amp 5 23204 -- decal, breaker 50 amp danger gefahr peligro danger lights and equipment outlets main circuit breaker 1 2 3 4 g...

Page 42

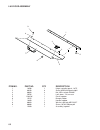

42 33 1 2 31 3 7 8 3 10 4 31 6 5 9 20 32 20 15 20 16 17 18 8 7 26 2 7 8 21 20 17 20 23 24 27 28 29 30 25 22 34 35 19 14 13 12 11 manual winch mast assembly.

Page 43

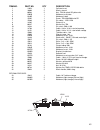

43 item no. Part no. Qty description 1 11954 1 coil cord, mast 2 16600 2 winch, manual 3 60584 2 nut, .750-10 nylock g5 yellow zinc 4 11902b 1 weldment, mast tube 5 11649z 1 weldment, t-bolt 6 15292 1 screw, .750-10x6.500 hx hd ss 7 15380 4 pin, cotter - .125x1.250 8 14262 2 sheave, 3 in. 9 60247 1 ...

Page 44

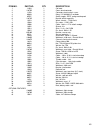

44 43 1 2 3 1 7 4 5 17 18 18 2 3 5 6 41 40 19 39 7 20 19 14 8 10 24 18 28 26 23 39 22 21 25 41 42 38 33 27 8 10 18 18 31 32 34 35 36 37 12 29 15 14 13 12 11 9 10 8 16 30 electric winch mast assembly.

Page 45

45 item no. Part no. Qty description 1 11954 1 coil cord 2 12875b 2 cover, winch contactor 3 11293 2 contactor, electric winch - warn 4 65049 2 relay, 12v 30/40a n.O. W/diode 5 65707 2 switch, toggle - spdt spring weatherproof 6 12872b 2 bracket, winch mounting 7 12874 2 winch, electric - 770 lb. Ho...

Page 46

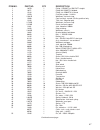

46 frame and components 4 5 6, 69 7 10 11 11 12 13 14, 70 15 18 16 56 57 18 72 19 11 19 11 19 20 21 22 71 23 24 26 25 27 28 29 30 31 32 33 34 35 36 37 38 42 41 40 39 42 43 44 45 45 47 48 49 50 51 46 52 53 55 54 58 59 60 61 62 63 64 65 66 67 67 66 67 66 67 68 1 2 3 8 9 10 11 17.

Page 47

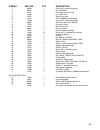

47 item no. Part no. Qty description 1 16270 1 fitting, .375mnpt to .250 fnpt straight 2 16271 1 fitting, 90-.250nptx.188 barb 3 15142 1 fitting, strt-.250nptx.312 barb 4 12259 1 fuel pick up tube - 24.00 in. 5 12361b 1 weldment, fuel tank strap 6 12080 1 cap, fuel tank - vented, 3.5 dia. Grn diesel...

Page 48

48 item no. Part no. Qty description 53 16830 1 coupler - 2.00 ball/2.50 channel 54 23367 1 chain, safety - 7,800 lbs. Rated 55 12420b 1 weldment, removable tongue 56 13300 4 cam, transformer - ballast box (5.5” height) 57 13299 4 transf. & base brkt w/str relief-60hz mh cyl bal optional features: 5...

Page 49

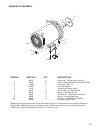

49 generator assembly item no. Part no. Qty description 1 60165 8 screw, m8-1.25x16 std hex g10.9 lb 2 60166 16 washer, m8 flat zb din125 hardened tp200 3 11000 1 plate, drive - sae 7.5 4 11975b 2 plate, gen adapter 5 11524 2 compression mount, engine 6 60275 2 screw, .500-13x1.000 hx hd g5 7 60702 ...

Page 50

50 item no. Part no. Qty description 1 12109 1 box cover, 2-gang plastic 2 66100 4 connector, 2 pos. Wago 3 66101 2 connector, 3 pos. Wago 4 66102 1 connector, 5 pos. Wago 5 60755 2 fitting, .750mnpt x .500fnpt nylon 6 15864 4 strain relief, .500npt water tight 7 12095b 1 bracket, junction box 8 161...

Page 51

51 item no. Part no. Qty description 1 12109 1 box cover, 2-gang plastic 2 66100 4 connector, 2 pos. Wago 3 66101 2 connector, 3 pos. Wago 4 66102 1 connector, 5 pos. Wago 5 60755 2 fitting, .750mnpt x .500fnpt nylon 6 15403 4 connector, quick disconnect (female) 7 15404 4 cap, receptacle w/chain 8 ...

Page 52

Enclosure assembly 4 3 5 6 1 9 8 11 14 7 15 10 13 12 21 19 18 16 17 9 10 5 6 3 22 23 20 18 2 24 52 25 26 27 28.

Page 53

Item no. Part no. Qty description 1 25333w 1 panel, back access 2 12195 1 gasket, radiator access plate 3 11381 2 fender, plastic 4 11507w 1 panel, right side sheetmetal 5 16591w 2 panel, door 6 16598 2 hinge, door 7 10284w 1 panel, roof w/access hole 8 10287w 1 panel, rear 4000 isuzu 9 10220 2 ligh...

Page 54

1 2 8 9 5 4 3 6 7 10 11 13 12 14 15 17 16 18 54 auxiliary outlet panel assembly.

Page 55

Item no. Part no. Qty description 1 65535 1 clamp, 90° 3/4" 2 screw 2 12248b 1 weldment, outlet cover 3 10081 1 hinge, continuous - 11.00 in. 4 11484b 1 cover, breaker 5 14130 2 receptacle, 120v/20a gfci 6 65530 2 block, terminal - 2 pole lug type, 7 pos./pole 7 14137 2 receptacle, 240v/30a twist lo...

Page 56

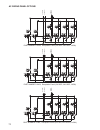

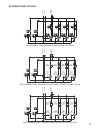

56 auxiliary outlet panel options part number 12399 receptacle panel (2x5-20r, 3xl6-30r, 1x50a) part number 12402 receptacle panel (2x5-20r, 3xl6-20r, 1x50a) part number 12400 receptacle panel (2x5-20r, 3xl14-30r, 1x50a) part number 12401 receptacle panel (2x5-20r, 4xl14-30r).

Page 57

57 item no. Part no. Qty description 1 14130 2 receptacle, 120v 20a gfci 2 14137 - receptacle, 240v 30a twist lock 3 18089 - receptacle, 125/250v 50a twist lock 4 65488 - receptacle, 240v 30a twist lock 5 65849 2 breaker, 20a, 120v, 1 pole, push button 6 65851 2 breaker, 30a 250v 2 pole (ja) screw t...

Page 58

Oval light assembly 33 35 3 4 1 2 6 8 5 7 11 12 10 9 8 13 14 13 21 17 19 16 18 27 8 11 8 20 21 24 25 15 22 7 17 19 16 18 23 26 32 28 31 34 30 36 29 58.

Page 59

Item no. Part no. Qty description 1 60304 1 screw, m5 x 25 pan hd phillips 2 60447 1 nut, m5 nylock 3 13367 1 assembly, aluminum ring 4 13369 1 lens, glass oval 5 13373 1 gasket, lens oval 6 11391 1 bulb, 1000w mh short length 7 13399 2 screw, m4 x 18 pan hd phillips 8 60067 4 washer, #10 flat .435/...

Page 60

Lower radiator hose engine cooling assembly 1 2 3 7 3 12 6 22 4 5 2 1 13 14 15 16 17 8 19 20 9 6 11 18 10 21 6 60 23.

Page 61

Item no. Part no. Qty description 1 60034 12 screw, .375-16x.750 hx ser flg 2 60206 12 washer, split lock .375 3 60386 1 washer, flat .375 4 26305 1 radiator, aluminum 5 11626b 1 weldment, fan shroud 6 15422 4 clamp, hose sae 20 7 11760b 1 panel, fan guard - right 8 60115 8 screw, m6x1.0x12 hx ser f...

Page 62

1 10 4 2 14 9 5 11 3 7 18 21 26 17 27 23 6 24 25 10 5 12 13 4 4 17 18 28 29 engine assembly 15 16 22 20 19 8 32 33 30 31 12 62 38 37 34 35 36.

Page 63

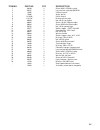

Item no. Part no. Qty description 1 21505 1 assembly, air filter 2 60009 4 screw, m8x1.25x25 hx ser flg 3 12990b 1 bracket, air filter 4 60018 14 screw, m10x1.25x20 hx ser flg 5 60316 2 clamp, hose - sae 32 6 60342 4 nut, m8x1.25 hx gr8.8 ss 7 22320 1 hose, air filter 8 21937 1 element, air filter -...

Page 64

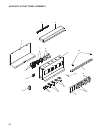

Control panel assembly 64 3 7 2 1 4 6 10 8 9 2 4 6 5 15 24 21 15 20 7 17 22 23 19 18 13 16 12 14 11 25 26 27 28 25 26.

Page 65

Item no. Part no. Qty description 1 60160 3 screw, m8x1.25x30 hx ser flg 2 65287 3 lug, terminal single #6-350 mcm 3 12065 1 channel, glastic 4 12066 2 angle, glastic 5 13126w 1 panel, control 6 11811w 2 bracket, glastic plate 7 60020 7 nut, m8 hx ser flg lock 8 60062 3 screw, 10-32x.750 pan hd phil...

Page 66

Control box assembly 66 7 9 9 28 9 9 7 7 7 7 10 10 10 13 16 18 4 2 1 3 6 12 15 5 5 5 8 11 11 14 17 19 20 23 26 22 25 21 24 27 29 30 33 36 32 35 31 34.

Page 67

Item no. Part no. Qty description 1 12694w 1 panel, top control box 2 65619 1 breaker, 90a, 3 pole 3 65429 1 breaker, 100a, 250v, 2 pole 4 18556 1 regulator, voltage - se 350 5 60355 6 screw, m4x35 pan head phil 6 65442 3 transformer, current - 200:5a 7 60115 25 screw, m6x1.0x12 hx ser flg 8 18081 2...

Page 68

5 6 7 2 4 1 3 9 8 item no. Part no. Qty description 1 18598 1 hinge, controller panel - 18.75 2 60156 8 screw, m5x0.8x16 pan hd phil 3 60038 4 nut, m5 hx nylock din985 4 20762 1 lock, door - 1/4 turn cam 5 12631w 1 panel, lug door 6 15215 1 bumper, rubber 7 18893 1 handle, lug door 8 60043 2 washer,...

Page 69

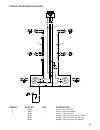

69 trailer lights wiring diagram item no. Part no. Qty description 1 10264 1 harness, left side trailer 2 10261 1 harness, main trailer 4000 3 10265 1 harness, right side trailer - 65465 - adapter, trailer wiring flat 4 to rnd 7 blade - 65464 - adapter, trailer wiring flat 4 to rnd 7 pin - 65463 - a...

Page 70

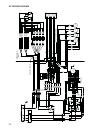

Brn 14ga 240v breaker 240v breaker blk 10ga blk 10ga brn 14ga 59 13 6 10 14 7 8 11 12 15 16 t5 blk 10ga blk 10ga grn/yel 10ga ct -3 l2 l3 shunt l1 ct -2 ct -1 breaker pa ir blk 10ga pa ir blk 10ga pa ir blk 10ga grn/yel 14ga grn/yel 10ga 1 2 3 4 t4 mechanical lugs blk gfci recpt 120v 17 21 25 18 22 ...

Page 71

90215, org 8.07.08 mdc controller 2 pin plug (rpm) rpm in rpm gnd 3 pin analog inputs oil in fuel in wa t e r i n ai1 ai2 ai3 neutral com 4 l1 l2 l3 ct neutral l3 l2 l1 remote st ar t low coolant option open open open bi1 bi2 bi3 b14 bi5 bi6 d b c "option" plug loca tion bott om bott om plug loca ti...

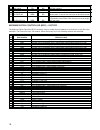

Page 72

72 ac wiring panel options (t o ground) (t o neutral) (t o main breaker) part number 12399; receptacle panel (2x5-20r, 3xl6-30r, 1x50a) (t o ground) (t o neutral) (t o main breaker) part number 12402; receptacle panel (2x5-20r, 3xl6-20r, 1x50a) (t o ground) (t o neutral) (t o main breaker) part numb...

Page 73

73 ac wiring panel options 73 (t o ground) (t o neutral) (t o main breaker) part number 12401; receptacle panel (2x5-20r, 4xl14-30r) part number 13540; receptacle panel (2x5-20r, 1xtt-30r, 1xl6-30r, 2x50a) 240 volt 50 amp twist lock receptacle 240 volt 50 amp twist lock receptacle 240 volt 30 amp tw...

Page 74

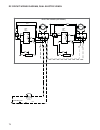

Dc circuit wiring diagram, dual electric winch battery 12v electric winch (optional) brn blk breakers 50 amp circuit brn red brn wht brn wht red red 2 red 1 blk 2 1 red blk red prox. Aux relay 30 87 87a 85 86 prox switch blk blu blk com n/o n/c + - vio blk blu tilt winch extend winch n/c prox switch...

Page 75

Mast junction box wiring diagram 75.

Page 76

Rev: b part no: 13134 11.07.08.