- DL manuals

- Magnum

- Portable Generator

- MMG100D

- Operating Manual

Magnum MMG100D Operating Manual

Summary of MMG100D

Page 1

Parts manuals available online! Www.M-p-llc.Com power products llc diesel generator 75 mmg75d • mmg100d operating manual.

Page 2: Magnum Power Products Llc

2 introduction this manual provides information and procedures to safely operate and maintain the engine and generator. For your own safety and protection from physical injury, carefully read, understand, and observe the safety instructions described in this manual. The information contained in this...

Page 3

3 table of contents page introduction ............................................................................................................................... 2 safety notes ..........................................................................................................................

Page 4

4 fuel transfer pump option ................................................................................................. 45 viscous fan clutch option .................................................................................................. 46 ac wiring diagram - 3 position voltage sele...

Page 5

This page intentionally left blank 5.

Page 6

6 safety notes this is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all safety messages that follow this symbol to avoid possible injury or death. This manual contains dangers, warnings, cautions, notices and notes which must be followed to prevent the ...

Page 7

7 engine safety internal combustion engines present special hazards during operation and fueling! Failure to follow the safety guidelines described below could result in severe injury or death. Read and follow all safety warnings described in the engine operator's manual. A copy of this manual was s...

Page 8

8 towing safety towing a trailer requires care! Both the trailer and vehicle must be in good condition and securely fastened to each other to reduce the possibility of an accident. Also, some states require that large trailers be registered and licensed. Contact your local department of transportati...

Page 9

9 reporting trailer safety defects if you believe your trailer has a defect which could cause a crash or could cause injury or death, you should immediately inform the national highway traffic safety administration (nhtsa) in addition to notifying magnum power products llc. If nhtsa receives similar...

Page 10

10 safety symbol summary this equipment has been supplied with numerous safety and operating decals. These decals provide important operating instructions and warn of dangers and hazards. Replace any missing or hard-to-read decals and use care when washing or cleaning the unit. Decal placement and p...

Page 11

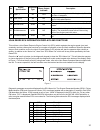

11 specifications - mmg75d read this manual carefully before attempting to use this generator. The potential for property damage, personal injury or death exists if this equipment is misused or installed incorrectly. Read all of the manuals included with this unit. Each manual details specific infor...

Page 12

12 specifications - mmg100d read this manual carefully before attempting to use this generator. The potential for property damage, personal injury or death exists if this equipment is misused or installed incorrectly. Read all of the manuals included with this unit. Each manual details specific info...

Page 13

13 unit dimensions read this manual carefully before attempting to use this generator. The potential for property damage, personal injury or death exists if this equipment is misused or installed incorrectly. Read all of the manuals included with this unit. Each manual details specific information r...

Page 14

14 unit serial number locations refer to the locations illustrated below to find the unit id tag and vin tag on your unit. Important information, such as the unit serial number, model number and vehicle identification number (vin) for your trailer are found on these tags. Record the information from...

Page 15

15 component locations voltage selector switch access handle front hood latch engine exhaust fuel fill oil drain port radiator drain port control panel access emergency stop central lifting eye engine battery access generator access engine access radiator access.

Page 16

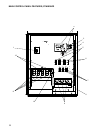

16 main control panel features, standard 2 5 6 7 9 10 11 1 8 4 3 12 auto exhaust filter cleaning limpieza automÁtica de filtro de escape automatische abgasfilterreinigung nettoyage du filtre d’Échappement auto enable einschalten activar activer disable ausschalten desactivar dÉsactiver.

Page 17

17 1. Main circuit breaker: this breaker will disconnect power to the connection lugs (items 10-11). It will not disconnect power to the convenience outlets when the engine is running. 2. Magnum digital controller (mdc): refer to “magnum digital controller (mdc)” on page 18 . 3. Auxilliary light swi...

Page 18

18 magnum digital controller (mdc) the magnum digital controller (mdc) is an enhanced digital generator controller used to start, stop and monitor the operation of the generator and the engine. The controller constantly monitors vital generator and engine functions for a number of pre-programmed ala...

Page 19

19 • “auto ” button: press this button to change from manual starting mode to automatic (remote) starting mode. • “alarm cancel” button: when an alarm is activated, either visually or audibly, press this button to silence or cancel the alarm. • “fault reset” button: press this button to clear the f...

Page 20

20 • oil pressure: displays engine oil pressure. The display registers oil pressure between 0-100 psi (0-689 kpa). Normal operating pressure is between 35-80 psi (241-552 kpa). • engine temp: displays the temperature of the engine’s coolant. If the coolant temperature exceeds the maximum water tempe...

Page 21

21 • “password” screen: the operator may press the “” or “” buttons on the “diagnostics” keypad to move the cursor (>) up or down a list of text. • “history” screen: the operator may press the “” or “” buttons on the “diagnostics” keypad to move the cursor (>) up or down a list of recent alarm o...

Page 22

22 • “dpf inhib” area: this area will display the “disabled regeneration” indicator above the words “dpf inhib” when auto exhaust filter cleaning is disabled. • “alarm” area: this area will display the “yellow alarm” or “red alarm” indicator above the words “alarm” when an alarm condition occurs. Th...

Page 23

23 to adjust the output voltage, check the output voltage on the generator display screen. Look at the “l1n” voltage or the “l12” voltage on the display. The generator nominal output voltage should be within 10% of the voltage rating on the voltage selector switch. To adjust the output voltage, use ...

Page 24

24 to close the front hood: 1. Make sure the skid is free of debris and all personnel are clear of unit. Caution do not attempt to close the hood from the sides of the unit. Proceed to the front of the unit to close the hood. Failure to close the hood correctly could result in personal injury and eq...

Page 25

25 manual starting of the generator 1. Move the control on/off toggle switch to the “control on/i” position. Danger carbon monoxide: using a generator indoors can kill you in minutes! 2. The liquid crystal display (lcd) window will quickly display information, all light emitting diodes (led’s) will ...

Page 26

26 6. The running screen will display. Note: it may take a few seconds for the engine to run smoothly and reach its governed operating speed. The 45 second “v detect” time delay will start to count down. 7. The lcd window will then toggle from the running screen to the generator display screen and t...

Page 27

27 “auto” (remote) starting of the generator the “auto” button is used when the generator is started from a location other than the control panel and by using a transfer switch. “auto” (remote start) is the normal setting when the generator is being used as a standby power supply. Before putting the...

Page 28

28 exhaust filter cleaning operations when enabled, the exhaust filter system goes through an automatic cleaning process known as regeneration. Under normal circumstances, regeneration occurs without interruption of unit operation and with minimal operator involve- ment. In the event there are condi...

Page 29

29 mdc controller information displays, functions, and reset the magnum digital controller (mdc) constantly monitors vital generator and engine functions for a number of operation, alarm and fault conditions. When a fault condition occurs, the engine will shut down automatically and the liquid cryst...

Page 30

30 magnum digital controller (mdc) - list of alarms shutdown and warning fault conditions and the displayed message are described in the following table: no. Events specification protection type information on binary output available description 1 aniniom sd sd yes shutdown alarm configurable on the...

Page 31

31 john deere ecu information displays and functions this unit has a john deere electronic engine control unit (ecu) which regulates the engine speed (rpm) and constantly monitors vital engine functions for a number of operation, alarm and fault conditions. When an operation, alarm or fault conditio...

Page 32

32 *note: the suspect parameter number (spn) is displayed as “fc” on the bottom left of the lcd window. Refer to figure 1. Mdc controller – history the magnum digital controller (mdc) stores a record of each important event into the history file of the controller. The history file seats 117 records....

Page 33

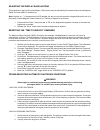

33 adjusting the display backlighting the brightness on the liquid crystal display (lcd) window may be adjusted by the operator whenever the magnum digital controller (mdc) is powered up. Note: anytime an “*” is displayed on the lcd window, the text or set point cannot be changed without the use of ...

Page 34

34 3. If the oil level is good, restart the unit and verify the loss of oil pressure. Shut the engine down immediately if the oil pressure value does not read five (5) psi (34 kpa) within five (5) seconds. 4. Check the oil pressure sender. To identify corrective action, refer to the troubleshooting ...

Page 35

35 generator output connection lugs the generator is equipped with connection lugs behind the lug box door located on the lower portion of the control box. The lugs provide connection points for attachment of external loads to the generator. A large decal on the inside of the connection lug door det...

Page 36

36 voltage selector switch the voltage selector switch is located on a panel attached to the generator behind the door located next to the fuel tank filler. The selector switch is a three position switch that mechanically changes the connections between the generator output leads and the connection ...

Page 37

37 4-position voltage selector switch option the optional four position voltage selector switch is located on a panel attached to the generator behind the door located next to the fuel tank filler. The voltage selector is a four position switch that mechanically changes the connections between the g...

Page 38

38 emergency stop switch the generator is equipped with one emergency stop switch, located on the right rear corner of the unit next to the control door. The switch is clearly labeled “emergency stop ” and is red in color. The switch can be accessed and activated with all doors closed and locked. Ac...

Page 39

39 customer convenience outlets the generator is equipped with five convenience outlets. The large outlets are 240/120vac twist-lock receptacles rated at 50a each. The smaller outlets are 120vac duplex receptacles rated at 20a each with ground fault circuit interrupt (gfci) protection. These recepta...

Page 40

40 transfer switch when the generator is used as a standby power supply, it must be equipped with a transfer switch which isolates it from the utility’s distribution system. A transfer switch is designed to transfer electrical loads from the normal power source (utility) to the emergency power sourc...

Page 41

41 belt tension john deere engines use two types of belt tensioners: manual and automatic. Adjust the belt using the manual tensioner according to the manufacturer’s specifications. The automatic tensioner cannot be adjusted or repaired and is designed to maintain proper tension over the belt’s life...

Page 42

42 • never wash the engine block or fuel tank with a power washer or steam cleaner. Water may enter the cabinet and collect in the generator windings or other electrical parts, causing damage. • if the unit is stored outside, check for water inside the cabinet and generator before each use. If wet, ...

Page 43

43 * replace primary air cleaner when dust valve restriction indicator gauge shows a vacuum of 25 in. H 2 o. ** change the oil and oil filter after the first 100 hours, then every 250 hours. If john deere plus 50 ii engine oil is used, the interval can be increased to every 500 hours. Engine break-i...

Page 44

44 lifting the generator a large central lifting eye is located on the top of the generator. The eye is connected to a central lifting frame inside the unit. Attach a sling or hook directly to the lifting eye only if the devices are in good condition and the equipment being used to raise the unit ha...

Page 45

45 checking generator drive plate torque follow the procedure below to check the torque of the generator drive plate bolts in accordance with the maintenance chart. Refer to “basic maintenance schedule - john deere engine” on page 42 . 1. Disconnect the engine starting battery. 2. Remove the generat...

Page 46

46 viscous fan clutch option the viscous fan clutch option allows the engine cooling fan to engage at lower speeds, and disengage at higher speeds, increasing cooling system efficiency. The cooling fan will engage at full speed when the coolant temperature rises. When the fan is operating at full sp...

Page 47

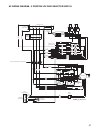

47 ac wiring diagram - 3 position voltage selector switch breaker 240v 50a brn 240v 50a breaker 240v 50a breaker blk blk blk blk brn 5 9 13 6 10 14 7 8 11 12 15 16 t5 blk blk pair blk grn/yel (t7) ct-3 brn/wht l2 l3 shunt l1 ct-2 ct-1 blk grn/yel grn/yel grn/yel pair blk pair blk 1 2 3 4 t4 brn/wht ...

Page 48

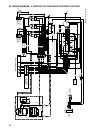

48 ac wiring diagram - 4 position voltage selector switch option brn grn/yel 10ga (t7) ct -3 l2 l3 shunt l1 ct -2 ct -1 breaker grn/yel 14ga grn/yel 10ga grn/yel 10ga (2.5k, 2 w a tt) adjustment vol t age ground t o gen frame l0 mechanical lugs 12vdc (t9) grn/yel 14ga gnd (l0) blk red circuit t o lu...

Page 49

49 ac wiring diagrams for optional equipment circuit breaker cam lock pa n e l gnd l0 l1 l3 l2 6 5 8 7 2 vol t age rela y h1 h3 x2 x4 x1 x3 h2 h4 blk red power rela y blk blk wht wht wht blk buck xformer blk 78 6 5 1 2 34 com no nc e3 e2 e1 yel red blk down cgnd up to t 9 to t 7 bk rd wt droop adjus...

Page 50

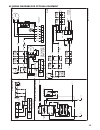

50 dc wiring diagram plug loca tion rpm pin rpm in rpm gnd mag in mag ref d+ plug loca tion power + dc + rela y board d+ lower e st op bi1 7 pin plug (binar y inputs) bo1 c1 +12vdc loca tion control power switch red/blk blk red/blk gen vol t age phase a vol t age phase b vol t a ge phase c vol t age...

Page 51

51 dc wiring diagrams for optional equipment j h deutsch 21 pin conn-2 edison plug 16/3 brn blu yel/grn fa n clutch rela y to cont bo7 bott om pin e st op bi1 6 pin plug (binar y inputs) pin loca tion loca tion plug loca tion remote st ar t bi2 bi3 bi4 bi5 bi6 reconnect door open fuel xfer enable lo...

Page 52

52 wiring block diagram - dedicated 12 lead generators option lo l3 l2 l1 t o control box lo l3 l2 l1 t o control box lo l3 l2 l1 t o control box lo l3 l1 t o control box lo l3 l1 t o control box lo l3 l2 l1 t o control box t o genera t o r 480/277v 3ph high wye 208/120v 3ph low wye 240/120v 3ph hig...

Page 53

53 trailer wiring diagram trailer plug trailer plug gng n bk bk yly l bnb n bnb n wtw t lamp marker amber wt wt wt wt amber marker lamp bk bk wt wt red marker lamp bk bk bk bk lamp marker white wt wt bk bk lamp marker red wt wt stop-turn signal lamp (right) (left) signal lamp stop-turn wt wt bk bk r...

Page 54

54 wiring harness - electric brake option 90286_d_10.31.12 ba tter y breaka w a y switch blu wht b lk wht w ht wht wht brake blu blu brake wht blu blu blu blu wht brake blu blu brake wht wht wht t a ndem axle wht blu brake wht blu blu wht brake blu wht tri-axle single axle.

Page 55

55 service log oil grade and type: ___________________________ brand: ___________________________________ coolant mixture: _____________________________ brand: ___________________________________ __________________________________________________________________________________________ _____________...

Page 56

Rev: b part no: 32668 03.15.13.