Summary of MPG 5600

Page 1

Portable generator mpg 6000 operating/parts manual.

Page 2: Magnum Products Llc

2 introduction this manual provides information and procedures to safely operate and maintain the portable generator. For your own safety and protection from physical injury, carefully read, understand, and observe the safety instructions described in this manual. The information contained in this m...

Page 3

Table of contents 3 page introduction .............................................................................................................................. 2 table of contents ......................................................................................................................

Page 4

4 note: notes contain additional information important to a procedure and will be found within the regular text body of this manual. Operating safety before using the generator be sure you read and understand all of the instructions! This equipment was designed for specific applications; do not modi...

Page 5

5 engine safety internal combustion engines present special hazards during operation and fueling! Failure to follow the safety guidelines described below could result in severe injury or death. Read and follow all safety warnings described in the engine operator's manual. A copy of this manual was s...

Page 6

Unit id tag 215 power drive • berlin, wi 54923 1-800-926-9768 model serial number mpg 6600 000000 120/240 120/240 55.0/27.5 50.0/25.0 kg lbs. Amb. Temp. Rpm hz phase kw v a continuous maximum kw v a 1 Ø 6 refer to the location illustrated at right to find the unit id tag. Important information, such...

Page 7

7 read this manual carefully before attempting to use this generator. The potential for property damage, personal injury or death exists if this equipment is misused or installed incorrectly. Read all of the manuals included with this unit. Each manual details specific information regarding items su...

Page 8

Fuel tank cap fuel level gauge fuel shut off valve (under tank) recoil starter control panel engine starting battery battery tray (optional) engine exhaust wheel kit (optional) handle - wheel kit (optional) central lifting eye air filter housing engine choke (under tank) component locations 8.

Page 9: Mpg 6000

Control panel components a. Engine start switch: this switch must be in the on position to start the engine. To stop the engine, place switch in off position. B. Auto idle switch: when this switch is engaged, the engine speed will return to idle whenever the generator is not under load. C. Engine st...

Page 10

Ground source location grounding the generator prevention of overload exceeding wattage capacity can result in damage to the generator and to the connected electrical devices. Adhere to the following to prevent exceeding wattage capacities: • calculate the total wattage of all electrical devices to ...

Page 11

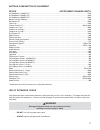

Wattage consumption of equipment device approximate running watts air conditioner (12,000 btu)** ........................................................................................................................... 1700 air conditioner (24,000 btu)** ..............................................

Page 12

Adding engine oil 1. Place the generator on a firm, level surface. 2. Remove the oil fill cap/dipstick. Clean the area around the oil fill cap and wipe the dipstick clean. 3. Insert the dipstick in oil filler neck. Do not thread into filler neck. Remove the dipstick, and check the oil level. 3. If o...

Page 13

Starting the engine 1. Unplug all electrical loads from the unit’s receptacles before starting the engine. 2. Make sure the generator is on a firm, level surface, away from any overhangs, open windows, vents or doors. 3. Check the fuel and engine oil levels. 4. Turn the main circuit breaker off. 5. ...

Page 14

Stopping the engine 2. Turn the idle control switch off. 3. Switch the main circuit breaker to the off position. 3. Let the unit run for 3-5 minutes with no load to allow stabilization of the internal temperatures of the engine and generator. 4. Turn the unit off. 5. Close the fuel shut-off valve. 1...

Page 15

A large central lifting eye is located on the top of the generator and the eye is connected to the frame of the unit. Attach a sling or hook directly to the lifting eye only if the devices are in good condition and the equipment being used to raise the unit has sufficient capacity. Approximate weigh...

Page 16

Unit decals note: all safety and operating decals shown above are located on decal sheet 26332, unless otherwise noted. 16 ground fault sensing module warning test before each use see instructions reset reset p o w e r f a u l t gfci testing instructions test before each use! Normal operating state ...

Page 17

To frame item no. Part no. Qty description 1 26213 1 panel, control - rear housing 2 24986r 1 panel, control 3 65888 2 receptacle, 120v/20a duplex-black 4 65878 1 module, auto idle 5 65487 1 receptacle, 120v/30a twist (l5-30r) 6 65488 1 receptacle, 240v/30a twist (l14-30r) 7 65886 1 module, gfi sens...

Page 18

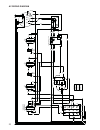

18 1 18 3 2 21 4 5 6 7 6 8 22 19 34 33 38 37 9 10 11 13 36 13 35 14 13 10 12 34 33 15 16 17 31 32 19 20 20 23 22 19 34 34 30 29 30 22 28 26 27 41 40 39 43 9 25 24 frame and fuel tank assembly 42.

Page 19

19 item no. Part no. Qty description 1 26123 1 valve, fuel tank 2 26122 1 gauge, fuel tank 3 28495 1 cap, fuel tank 4 28494 1 tank, fuel 5 60393 4 screw, .250-20x1.000 hx hd 6 60243 9 washer, flat .250 uss 7 24916b 1 weldment, frame 8 60144 4 nut, .250-20 nylock 9 60690 2 screw, .375-16x1.000 hx hd ...

Page 20

To muffler to frame to frame to frame 1 2 13 1 2 3 4 5 10 2 9 1 2 7 6 3 3 39 11 15 16 14 12 17 18 19 8 24 26 25 18 19 19 24 17 23 20 22 21 17 27 19 18 18 30 29 28 31 32 33 34 35 36 37 33 38 40 40 41 engine and generator assembly 20 42.

Page 21

21 item no. Part no. Qty description 1 60028 8 screw, .312-18x1.000 hx hd 2 60271 10 washer, split lock .312 3 61147 8 nut, .312-18 u-clip g5 zy long type 4 24922r 1 muffler guard front 5 24954 1 muffler 6 60119 2 washer, .312 flat .875/.070 7 60020 2 nut, m8-1.25 ser flg g8.8 lock 8 60358 2 nut, .3...

Page 22

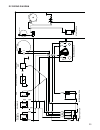

22 ac wiring diagram 1 2 3 4 (y) (r) (b) (g) see dc print wht/blk blk com n/o 13 24 line load orn 4 2 3 commons 120 onl y 120/240 x g w y g y w w x x 8 6 7 12 10 11 16 14 15 w x x 20a grn/yel wht wht wht blk yel wht red blk blu red blk blu wht red red blk blk blk blk blk blk blk blu blu grn rd/wt rd...

Page 23

Dc wiring diagram 23 on/off switch idle/run switch idle/run module grn red blu orn idle/run solenoid shutdown solenoid coil oil level switch oil aler t unit + - charge coil rectifier st ar t switch st ar ter genera to r bl/wt blk/wht grn red wht gry gry wht wht 1 2 3 4 1 2 orn blk/wht blu b+ c+ wht ...

Page 24

Rev: org part no: 28922 02.04.09.