We3107 v.110413 save this manual you will need this manual for safety instructions, operating procedures, and warranty. Put it and the original sales invoice in a safe, dry place for future reference. Conservez ce guide vous aurez besoin de ce guide pour les instructions de sécurité, les procédures ...

2 catalogue general safety rules technical specification know your welder installation operation troubleshooting diagram & parts list warranty.

3 general safety rules warning: read and understand all instructions. Failure to follow all instructions listed below may result in serious injury. Caution: do not allow persons to operate or assemble this wave 200kd until they have read this manual and have developed a thorough understanding of how...

4 -do not drape cables over or around your body. -wear a full coverage helmet with appropriate shade (see ansi z87.1 safety standard) and safety glasses while welding. -wear proper gloves and protective clothing to prevent your skin from being exposed to hot metals, uv and ir rays. -do not overuse o...

5 shade 10 lens; for above 160 amps, use a shade 12. Refer to the ansi standard z87.1 for more information. -cover all bare skin areas exposed to the arc with protective clothing and shoes. Flame-retardant cloth or leather shirts, coats, pants or coveralls are available for protection. -use screens ...

6 shielding gas cylinders can explode high pressure cylinders can explode if damaged, so treat them carefully. -never expose cylinders to high heat, sparks, open flames, mechanical shocks or arcs. -do not touch cylinder with mig gun. -do not weld on the cylinder -always secure cylinder upright to a ...

7 technical specification term unit wave 200kd rated input voltage v 220 power frequency hz 50/60 rated input capacity kva 7.9 rated input current a 36 output no load voltage v 65 rated working voltage v 18 dc argon welding current a 5~ 200 ac argon welding current a 10~ 200 stick welding current a ...

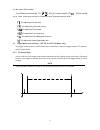

8 welding regulations parameter table (only for reference) mode material type designe d joint work thicknes s (mm) wire dia Φ (mm) welding current (a) polarity argon flow (dm 3 /mi n) tungste n stick dia Φ (mm) angle top dia Φ (mm) vertical joint 1.6~3.0 50~90 1.0 12~20° 0.12~0.25 v groove > 3.0~6.0...

9 1.3. Ac/dc transfer knob use this knob to choose the ac or dc, when ac indicator light, means the machine is under ac mode. When dc indicator light, means the machine is under dc mode. 1.4. Pulse switch use this knob to choose whether you need the pulse, when the indicator light, means it is under...

10 when the input voltage is below or over the specified voltage, the machine will cut off the power to protect itself until the input voltage is available. Installation 1. Power requirement - ac single phase 220v, 60 hz with a 50 amp circuit breaker is required. Do not operate this unit if the actu...

11 5. Input connection method exposure to a welding arc is extremely harmful to the eyes and skin! Prolonged exposure to the welding arc can cause blindness and burns. Never strike an arc or begin welding until you are adequately protected. Wear flame-proof welding gloves, a heavy long sleeved shirt...

12 2. Tig: 2.1 dc tig welding set the【welding mode knob】to “ ”,and【ac/dc transfer knob】to dc“ ”,would enter into dc tig welding mode. In this mode to adjust by “parameter knob” ”parameter positive knob”: 【 】to adjust the pre-flow time 【 ic 】to adjust the welding current; 【 】to adjust the stopping ga...

13 2.2 dc pulse tig welding set 【welding mode knob】to “tig ”,【ac/dc transfer knob】to “dc ” , 【pulse switch】 set on “pulse” would enter into the by “parameter knob””parameter positive knob”: 【 】 to adjust the pre-flow time; 【 】 to adjust the pulse peak current; 【 】 to adjust the pulse width; 【 】 to a...

14 2.3.2 4t latch mode this mode of welding is mainly used for long welding runs to reduce operator fatigue. In this mode the operator can press and release the torch trigger and the output will remain active. To deactivate the power source, the trigger switch must again be depressed and realized, t...

15 2.5 ac pulse tig welding set 【welding mode knob】to “tig ” and 【ac/dc transfer knob】to “ac ”, 【pulse switch】set on “pulse” would enter into ac pulse tig welding mode. Then to choose by “parameter knob””parameter positive knob”: 【 】 to adjust the pre-flow time; 【 】 to adjust the pulse peak current;...

16 based on different welding position, there are different welding joint, see following images for more information. 3.3 ground clamp connection clear any dirt, rust, scale, oil or paint on the ground clamp. Make certain you have a good solid ground connection. A poor connection at the ground clamp...

17 3.5 selecting the proper electrode there is no golden rule that determine the exact rod or heat setting required for every situation. The type and thickness of metal and the position of the work piece determine the electrode type and the amount of heat needed in the welding process. Heavier and t...

18 3.7.1 holding the electrode the best way to grip the electrode holder is the way that feels most comfortable to you. Position the electrode to the work piece when striking the initial arc it may be necessary to hold the electrode perpendicular to the work piece. Once the arc is started the angle ...

19 the weave beadused when you want to deposit metal over a wider space than would be possible with a stringer bead. It is made by weaving from side to side while moving with the electrode. It is best to hesitate momentarily at each side before weaving back the other way. 3.7.4 welding position flat...

20 3.7.6 finish the bead as the coating on the outside of the electrode burns off, it forms an envelope of protective gases around the weld. This prevents air from reaching the molten metal and creating an undesirable chemical reaction. The burning coating, however, forms slag. The slag formation ap...

21 tungsten electrode current ranges guide for selecting filler wire diameter tungsten electrode types aluminium welding material.

22 welding rate tig welding is generally regarded as a specialised process that requires operator competency. While many of the principles outlined in the previous arc welding section are applicable a comprehensive outline of the tig welding process is outside the scope of this operating manual. Tro...

23 thermal relay broken replace the thermal relay over/lack voltage more than 15% become normal after voltage ok relevant potentiometer broken replace the potentiometer main pc board broken replace the pc board 5 panel knob not adjustable cable broken/fallen off find the disconnected wire and connec...

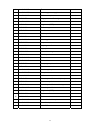

24 diagram & parts list no code number description qty 1 2.05.08.115 handle 1 2 1.1.01.01.0742 enclosure 1 3 1.1.10.34.0030 remote control absorption module 1 4 1.1.05.11.0062 secondary inverter arc plate 1 5 2.05.17.028 tension disc 2 6 2.04.30.103 cable holder 1 7 1.1.11.34.0046 power line 1 8 2.0...

25 12 1.1.10.34.0029 fan 1 13 1.1.05.01.0547 switching power supply board 1 14 1.1.05.10.0038 pulse run-on plate 1 15 2.07.37.553 single phase rectifier bridge 2 16 1.1.05.11.0064 rectifier inverter board 1 17 2.07.33.996 single tube (igbt) 4 18 2.05.05.173 radiator support 4 19 2.07.43.962 rectifie...