- DL manuals

- Magnum

- Lawn and Garden Equipment

- X5

- Repair Manual

Magnum X5 Repair Manual

Magnum X5

Magnum X7

(16J750)

(16J751)

ti17678a

- For Portable Spray Applications Architectural Paints and Coatings -

- Not for use in explosive atmospheres -

Models:

Magnum X5 (16J750) - Series A

Maximum Working Pressure: 207 bar, 21 MPa (3000 PSI)

Includes:

•

0.91 lpm (0.24 gpm) stand-mount sprayer

•

SG2 gun - Manual 312830

•

0.635 cm (1/4 in) x 7.5 m (25 ft) hose

Magnum X7 (16J751) - Series A

Maximum Working Pressure: 207 bar, 21 MPa (3000 PSI)

Includes:

•

1.17 lpm (0.31 gpm) cart-mount sprayer

•

SG3 gun - Manual 312830

•

0.635 cm (1/4 in.) x 15 m (50 ft) hose

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

Repair

Magnum X5 and X7 Airless Sprayers

3A1943B

EN

Use water based or mineral-spirit type material only.

Do not use materials having flash points lower than

70°F (21°C). For more information about your mate-

rial request MSDS from distributor or retailer.

Summary of X5

Page 1

Magnum x5 magnum x7 (16j750) (16j751) ti17678a - for portable spray applications architectural paints and coatings - - not for use in explosive atmospheres - models: magnum x5 (16j750) - series a maximum working pressure: 207 bar, 21 mpa (3000 psi) includes: • 0.91 lpm (0.24 gpm) stand-mount sprayer...

Page 2: Specifications

Specifications 2 3a1943b specifications this equipment is not intended for use with flammable or combustible materials used in places such as cabinet shops or other “factory”, or fixed locations. If you intend to use this equipment in this type of application, you must comply with nfpa 33 and osha r...

Page 3: Warnings

Warnings 3a1943b 3 warnings the following warnings are for the setup, use, grounding, maintenance and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risks. Refer back to these warnings. Additional, product-spe...

Page 4: Warning

Warnings 4 3a1943b fire and explosion hazard flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent fire and explosion: • do not spray flammable or combustible materials near an open flame or sources of ignition such as cigarettes, motors, and electrica...

Page 5: Warning

Warnings 3a1943b 5 toxic fluid or fumes hazard toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or swallowed. • read msdss to know the specific hazards of the fluids you are using. • store hazardous fluid in approved containers, and dispose of it a...

Page 6: Grounding Instructions

Grounding instructions 6 3a1943b grounding instructions sprayer must be grounded. Grounding reduces the risk of static and electric shock by providing an escape wire for electrical current due to static build up or in the event of a short circuit. 1. This sprayer requires 220-240 vac, 50/60 hz 10a c...

Page 7

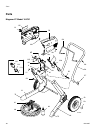

Component identification (16j750) 3a1943b 7 component identification (16j750) b j a h l g k d c p m s r q ti17679a t v z a electric motor (inside enclosure) b power switch c pressure control knob d pump fluid outlet fitting g suction tube h prime tube (with diffuser) j prime/spray valve control k fl...

Page 8

Component identification (16j751) 8 3a1943b component identification (16j751) b j a h l g k d c p m u s r q ti17680a t v w z x a electric motor (inside enclosure) b power switch c pressure control knob d pump fluid outlet fitting g suction tube h prime tube (with diffuser) j prime/spray valve contro...

Page 9: General Repair Information

General repair information 3a1943b 9 general repair information trigger lock always engage the trigger lock when you stop spraying to prevent the gun from being triggered accidentally by hand or if dropped or bumped. Pressure relief procedure follow this pressure relief procedure whenever you stop s...

Page 10

General repair information 10 3a1943b • keep all screws, nuts, washers, gaskets, and electri- cal fittings removed during repair procedures. These parts usually are not provided with replacement kits. • test repairs after problems are corrected. • if sprayer does not operate properly, review repair ...

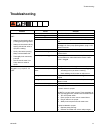

Page 11: Troubleshooting

Troubleshooting 3a1943b 11 troubleshooting problem cause solution pump will not prime hint: • attempt to free check balls by pushing pump priming button. • attempt to free check balls by tapping side of inlet valve as sprayer is stroking. • strain paint before spraying. Keep sand and debris out. • t...

Page 12

Troubleshooting 12 3a1943b problem cause solution pump cycles but pressure does not build up. Pump not primed. Prime pump. Inlet screen clogged. Clean debris off inlet screen suction tube not immersed. Reposition suction tube in bottom of paint pail. Paint pail empty. Refill paint pail and reprime s...

Page 13

Troubleshooting 3a1943b 13 problem cause solution sprayed paint runs down wall or sags. Going on too thick. Move gun faster. Use tip with smaller hole size. Use tip with wider fan. Move gun away from surface. Sprayed paint is not covering. Going on too thin. Move gun slower. Use tip with larger hole...

Page 14

Troubleshooting 14 3a1943b basic electrical problems. Motor overheated. Allow motor to cool for 45 minutes. Retry. Electrical outlet is damaged. Reset building circuit breaker or replace fuse. Try another outlet. Check electric supply with volt meter. Meter must read 220 to 240v ac. If voltage is to...

Page 15

Troubleshooting 3a1943b 15 sprayer wiring problems note: remove enclosure mounting screws and pull enclosure away from drive housing. Take care not to pull on leads from electrical cord and power switch. Sprayer electrical cord damaged. Unplug sprayer electrical cord. Disconnect black electrical cor...

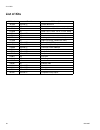

Page 16: List of Kits

List of kits 16 3a1943b list of kits kit number models kit description 16g223 x5 and x7 control board kit 16k624 x5 and x7 enclosure 247339 x5 hose 1/4 in. X 25 ft, 1/4 in. X 1/4 in. Fitting 247340 x7 hose 1/4 in. X 50 ft, 1/4 in. X 1/4 in. Fitting 257566 x5 and x7 strainer inlet 16e839 x5 stand 257...

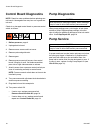

Page 17: Motor Diagnostics

Motor diagnostics 3a1943b 17 motor diagnostics check for electrical continuity in motor armature, windings and brush as follows: rotate motor and inspect bearings and shaft for proper fit. There should be no clearance. Inspect gear train for wear or binding. Check armature and field winding for disc...

Page 18: Control Board Diagnostics

Control board diagnostics 18 3a1943b control board diagnostics note: check for motor problems before replacing con- trol board. A damaged motor may burn out a good con- trol card. Check for a damaged control board or pressure control switch as follows: 1. Relieve pressure, page 9. 2. Unplug electric...

Page 19: Notes

Notes 3a1943b 19 notes.

Page 20: Parts

Parts 20 3a1943b parts magnum x5 model 16j750 5 9 72 72c 72 a 72 b 1 1 a 1 b 1d 1c 1e 2 74 4 55 7 8 3 1 16 17 3 0 1 8 1f 7 3 3 6 3 7 67 66 38 66 70 1 72 72c 72 a 72 b ti17725a.

Page 21: Parts List

Parts 3a1943b 21 parts list magnum x5 model 16j750 ref. Part description qty. 1 16g227 pump, assembly, magnum, 240v (includes 1a, 1b, 1c, 1d, 1e, 1f, 72) 1 1a 235014 dump valve 1 1b 24e578 base, valve 1 1c 111600 pin, grooved 1 1d 187625 handle, valve, drain 1 1e 16f292 valve, outlet 1 1f 16f621 mod...

Page 22: Parts

Parts 22 3a1943b parts magnum x5 model 16j750 41 40 46 6 4 10 11 11 12 56 57 19 50 51 52 52 53 22a 10 102 39 115 121 122 123 125 22b 57 ti17681a 75.

Page 23: Parts List

Parts 3a1943b 23 parts list magnum x5 model 16j750 ref. Part description qty. 4 112689 screw, button hd 2 6 16d684 frame 1 10 16k624 enclosure, sprayer (blue) 1 11 115477 screw, mach, torx pan hd 6 12 118899 switch, rocker, spdt 1 19 16e839 base, assembly 1 22a 16j789 cord set, 2m, australia 1 22b 1...

Page 24: Parts

Parts 24 3a1943b parts magnum x7 model 16j751 1 101 74 1 72 72c 72 a 72 b 9 2 5 4 6 3 7 8 3 1 16 17 1 b 1d 1c 3 0 101 1 8 1f 1 a 1e 6 8 66 67 66 38 3 7 3 6 70 7 3 72 72c 72 a 72 b ti17724a.

Page 25: Parts List

Parts 3a1943b 25 parts list magnum x7 model 16j751 ref. Part description qty. 1 16g227 pump, assembly, magnum, 240v (includes 1a, 1b, 1c, 1d, 1e, 1f, 72) 1 1a 235014 dump valve 1 1b 24e578 base, valve 1 1c 111600 pin, grooved 1 1d 187625 handle, valve, drain 1 1e 16f292 valve, outlet 1 1f 16f621 mod...

Page 26: Parts

Parts 26 3a1943b parts magnum x7 model 16j751 39 10 20 55 51 22b 10 46 121 122 123 59 56 57 52 53 60 61 11 6 4 125 65 64 58 12 115 54 21 102 22a 11 65 40 41 ti17682a 75 75.

Page 27: Parts List

Parts 3a1943b 27 parts list magnum x7 model 16j751 ref. Part description qty. 4 112689 screw, button hd 2 6 16d685 frame 1 10 16k624 enclosure, sprayer (blue) 1 11 115477 screw, mach, torx pan hd 6 12 118899 switch, rocker, spdt 1 20 257569 leg, left 1 21 257568 leg, right 1 22a 16j789 cord set, 2m,...

Page 28: Wiring Diagram

Wiring diagram 28 3a1943b wiring diagram magnum x5 16j750 magnum x7 16j751 ti17683a power cord green wire on/off switch power cord brown wire black motor lead black motor lead wiring diagram power cord blue wire 9 ref.

Page 29: Technical Data

Technical data 3a1943b 29 technical data *measured while spraying water-based paint - specific gravity 1.36 through a 517 tip at 207 bar, 21 mpa (3000 psi) per iso 9614-2. Actual sound levels may vary with length of extension used. X5 x7 maximum fluid working pressure - sprayer 207 bar, 21 mpa (3000...

Page 30: Graco Standard Warranty

All written and visual data contained in this document reflects the latest product information available at the time of publication. Graco reserves the right to make changes at any time without notice. For patent information, see www.Graco.Com/patents. Original instructions. This manual contains eng...