- DL manuals

- Magtrol

- Controller

- 6200

- User Manual

Magtrol 6200 User Manual

Summary of 6200

Page 1

Model 6200 open loop dynamometer controller user’s manual via paolo uccello 4 - 20148 milano tel +39 02 48 009 757 fax +39 02 48 002 070 info@dspmindustria.It www.Dspmindustria.It.

Page 2

1st edition rev. A – march 2014 while every precaution has been exercised in the compilation of this document to ensure the accuracy of its contents, magtrol, inc. Assumes no responsibility for errors or omissions. Additionally, no liability is assumed for any damages that may result from the use of...

Page 3: Safety Precautions

Iii 1. Make sure that all magtrol dynamometers and electronic products are earth-grounded, to ensure personal safety and proper operation. 2. Check line voltage before operating the 6200. 3. Make sure that dynamometers and motors under test are equipped with appropriate safety guards. Safety precaut...

Page 4: Revisions to This Manual

Iv the contents of this manual are subject to change without prior notice. Revision date 1st edition rev. A – march 2014 table of revisions revisions to this manual date edition change section(s) 03/03/14 1st edition - rev. A torque offset and gain procedure updated. 6.3.2 03/03/14 1st edition - rev...

Page 5: Table of Contents

V table of contents safety precautions ....................................................................................................................... Iii revisions to this manual ..............................................................................................................Iv...

Page 6

Vi magtrol model 6200 open loop dynamometer controller table of contents 5.1.1 installing the gpib (ieee-488) connector cable ......................................................................................... 14 5.1.2 changing the gpib primary address ............................................

Page 7

Vii magtrol model 6200 open loop dynamometer controller table of contents table of figures 2. Controls ....................................................................................................................................... 12 figure 2–1 front panel ......................................

Page 8: Preface

Vii purpose of this manual this manual contains all the information required for the installation and general use of the model 6200 open loop dynamometer controller. To ensure proper use of the instrument, please read this manual thoroughly before operating it. Keep the manual in a safe place for qu...

Page 9

Viii magtrol model 6200 open loop dynamometer controller preface appendix c: schematics - for encoder/switch board, power supply, dsp & memory and analog i/o. Conventions used in this manual the following symbols and type styles may be used in this manual to highlight certain parts of the text: note...

Page 10: 1. Introduction

9 general informa tion calibration certificate 1. Introduction 1.2 features of the 6200 • highquality,easytoreaddisplay-vacuumfluorescentreadoutwith0.36”(9.1mm)highdigits. • high-speeddataacquisition-120torqueandspeedreadingspersecondviaieee(gpib)bus. • pass/failtesting-upperandlowerlimitsareprogram...

Page 11

10 magtrol model 6200 open loop dynamometer controller chapter 1 – introduction general informa tion 1.3 data sheet 6200 data sheet model 6200 open-loop dynamometer controller www.Magtrol.Com magtrol features • open-loopdynamometercontrol • built-inpass/failmotortestingcapability • interfaces:rs-232...

Page 12

11 magtrol model 6200 open loop dynamometer controller chapter 1 – introduction general informa tion 6200 due to the continual development of our products, we reserve the right to modify specifications without forewarning. Www.Magtrol.Com magtrol inc 70 gardenville parkway buffalo, new york 14224 us...

Page 13: 2. Controls

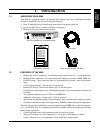

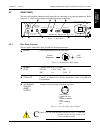

12 general informa tion 2.1 front panel the front panel provides a power switch, nine control buttons, a decrease/increase dial, and vacuum fluorescent display (vfd) model 6200 controller/display up down recall setup shift store clr menu display aux setup torque set torque units brake on/off power u...

Page 14

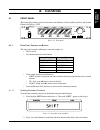

13 magtrol model 6200 open loop dynamometer controller chapter 2 – controls general informa tion power units, torque units, aux setup, clr mem or setup 3. Press the shift button again to exit the secondary function and return to main menu. 2.1.2 h ow to u se f ront p anel c ontrols and b uttons 2.1....

Page 15

14 magtrol model 6200 open loop dynamometer controller chapter 2 – controls general informa tion 2.2 rear panel the rear panel provides connectors and receptacles for connecting to appropriate equipment. Refer to figures 3, 4 and 5 in this chapter for detailed drawings of the brake brake ctrl out dy...

Page 16

15 magtrol model 6200 open loop dynamometer controller chapter 2 – controls general informa tion gpib/ieee-488 use this socket for gpib cable (meets ieee-488 specifications). 24. Signal ground 23. Atn-com 22. Srq-com 21. Ifc-com 20. Ndac-com 19. Nrfd-com 18. Dav-com 17. Ren 16. D8 15. D7 14. D6 13. ...

Page 17

16 magtrol model 6200 open loop dynamometer controller chapter 2 – controls general informa tion 2.3 vacuum fluorescent display (vfd) the vfd provides information about the control functions, the motor under test, and an auxiliary input device (if connected). The displays, from left to right, are: •...

Page 18: 3. Installation

9 setup 3. Installation note: before installing the 6200, you should become familiar with the front and rear panels, as outlined in chapter 2–controls. 3.1 powering up the 6200 warning! To reduce the risk of electric shock, make sure the 6200 is earth grounded before starting! 3.1.1 s etting u nit f...

Page 19

10 magtrol model 6200 open loop dynamometer controller chapter 3 – installation setup 3.1.2 h ardware c onnection do not overload or stall the motor. Prolonged overload can cause the motor to overheat. Note: note: to make sure that the 6200 is operational, a magtrol dynamometer with a test motor ins...

Page 20

11 opera tion 4. Manually controlled operation 4.1 setting desired operating parameters note: see appendix b: front panel/display menu flow charts. 4.1.1 s et p ower d isplay to d esired u nits (w atts , h p or a ux .) 1. Press and release shift. 2. Press power units. 3. Press up or down to scro...

Page 21

12 magtrol model 6200 open loop dynamometer controller chapter 4 – manually controlled operation opera tion 10. Press shift. 11. Press up or down to turn on or off speed pass/fail testing. 12. If on, press shift. 13. Use the up or down buttons and the decrease/increase dial to adjust the hig...

Page 22

13 magtrol model 6200 open loop dynamometer controller chapter 4 – manually controlled operation opera tion 4.3 using internal memory 4.3.1 s toring d ata p oints 1. Press and release store. The vfd will indicate store followed by a number. This indicates the memory location that contains the data. ...

Page 23

14 opera tion 5. Computer controlled operation the 6200 can be used with a personal computer to control a dynamometer and to transmit data from motor testing directly to the computer. 5.1 about the gpib interface magtrol instruments use the gpib (ieee-488 standard) for computer-to-instrument interfa...

Page 24

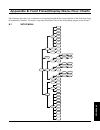

15 magtrol model 6200 open loop dynamometer controller chapter 5 – computer controlled operation opera tion d5 d6 d7 d8 ren dav-com nfrd-com ndac-com ifc-com srq-com atn-com signal ground ieee-488 interface d1 d2 d3 d4 eo1 dav nfrd ndac ifc srq atn shield 1 13 2 14 3 15 4 16 5 17 6 18 7 19 8 20 9 21...

Page 25

16 magtrol model 6200 open loop dynamometer controller chapter 5 – computer controlled operation opera tion desired results: • torque/speed data will be returned note: if the desired results did not occur, please see chapter 7 - troubleshooting. 5.3 programming note: check the manual provided with y...

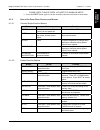

Page 26

17 magtrol model 6200 open loop dynamometer controller chapter 5 – computer controlled operation opera tion command category command code function explanation communications oa prompts to return to auxiliary input data string “output auxiliary” prompt to return the value at the aux input x aux scali...

Page 27

18 magtrol model 6200 open loop dynamometer controller chapter 5 – computer controlled operation opera tion command category command code function explanation setup ui# sets dynamometer torque units to # note: for hp and watts calculations to be correct, the correct dynamometer torque units must be ...

Page 28

19 magtrol model 6200 open loop dynamometer controller chapter 5 – computer controlled operation opera tion . = decimal point. The decimal point location depends on the specific dynamometer and torque range in use. Note: the [cr} and [lf] characters will not display. Example: if a motor is running a...

Page 29

20 magtrol model 6200 open loop dynamometer controller chapter 5 – computer controlled operation opera tion to wire your own serial communications cable, use the following wiring diagram: a cable may also be purchased from your local electronics store. A radio shack #26-152 cable and #26-264 null mo...

Page 30: 6. Calibration

21 maintenance 6. Calibration 6.1 closed-box calibration the 6200 features closed-box calibration. The advantage of closed-box calibration is that the user does not have to disassemble the case or make mechanical adjustments. However, the calibration of the accessory torque output must be done inter...

Page 31

22 magtrol model 6200 open loop dynamometer controller chapter 6 – calibration maintenance 1. Allow the 6200 to stabilize in an environment with: • anambienttemperatureof18°cto25°c. • relativehumiditylessthan80%. 2. Turn on the 6200. 3. Allow the 6200 to warm up for at least 30 minutes. 4. Enable th...

Page 32

23 magtrol model 6200 open loop dynamometer controller chapter 6 – calibration maintenance 6.3.3 a ccessory t orque o ffset and g ain 1. Connect the dmm common to pin 4 of the accessory torque-speed output connector. 2. Connect the dmm high to pin 2 of the accessory torque-speed output connector 3. ...

Page 33

24 magtrol model 6200 open loop dynamometer controller chapter 6 – calibration maintenance 1. Connect the chosen dynamometer to the 6200 using the 14-pin signal cable and the 2-pin brake cable. 2. Attach the calibration beam to the dynamometer shaft. 3. Enter the calibration mode. 4. Press the brake...

Page 34

25 magtrol model 6200 open loop dynamometer controller chapter 6 – calibration maintenance 11. Repeat steps 5 through 10. 12. After completing calibration, press brake on/off button off to remove loading from the dynamometer. 13. Remove the calibration beam from the dynamometer shaft. 14. Proceed wi...

Page 35: 7. Troubleshooting

26 maintenance 7. Troubleshooting if you require additional assistance, please contact magtrol customer service at 1-716-668-5555. Problem reason solution mechanical power reads much higher or lower than expected. Torque units are incorrect. Set torque input units to match the specifications on dyna...

Page 36

27 appendices appendix a: labview programming examples magtrol offers a comprehensive motor testing software program to satisfy most of your programming needs. To order your software, call magtrol sales at 1-716-668-5555. A.1 simple read.

Page 37

28 magtrol model 6200 open loop dynamometer controller appendix a: labview programming examples appendices a.2 current stabilized.

Page 38

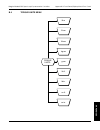

29 appendices appendix b: front panel/display menu flow charts thefollowingflowchartsareareferencefornavigatingthroughthekeysetupfunctionsofthe6200openloop dynamometer controller. For step-by-step setup instructions, refer to the corresponding chapters in this manual. B.1 setup menu i/o: contrast: 0...

Page 39

30 magtrol model 6200 open loop dynamometer controller appendix b: front panel/display menu flow charts appendices b.2 power units menu b.3 aux setup menu hp w aux power units: aux setup: scale: 0 - 10000 units/volt.

Page 40

31 magtrol model 6200 open loop dynamometer controller appendix b: front panel/display menu flow charts appendices b.4 torque units menu oz.In. Oz.Ft. Lb.In. Lb.Ft. G.Cm kg.Cm n.Mm n.Cm n.M torque units:.

Page 41: Appendix C: Schematics

32 appendices appendix c: schematics c.1 encoder/switch board c.2 power supply (rotary encoder) spkr1 (pb0) (pb1) (pb2) (pb3) (pb4) (pb5) (pb6) (pb7) (pb8) (pb9) (pb10) (audio) (+ 5v) (gnd) j1 1 2 3 4 5 6 7 8 9 10 11 12 13 14 r7 r6 r5 r4 r3 r2 r1 r8 r9 r10 r11 c1 22k 22k 22k 22k 22k 22k 22k 22k 22k ...

Page 42

33 magtrol model 6200 open loop dynamometer controller appendix c: schematics appendices c.3 dsp & memory u12 u10 u1 1u 7 i/o 3 i/o 2 i/o 4 a5 13 14 i/o 0 i/o 1 10 9 11 4 3 a2 5 a3 a4 8 a0 a1 6 7 a10 a7 at28c16e-20sc ce i/o 7 a8 a9 oe we i/o 5 a6 i/o 6 16 15 17 21 19 18 20 2 1 23 22 r2 0 22 k r43 22...

Page 43

34 magtrol model 6200 open loop dynamometer controller appendix c: schematics appendices c.4 analog i/o.

Page 44

Testing, measurement and control of torque-speed-power • load-force-weight • tension • displacement via paolo uccello 4 - 20148 milano tel +39 02 48 009 757 fax +39 02 48 002 070 info@dspmindustria.It www.Dspmindustria.It.