- DL manuals

- Magtrol

- Controller

- DSP6001

- User manual

Magtrol DSP6001 User manual

Summary of DSP6001

Page 1

Model dsp6001 high speed programmable dynamometer controller user’s manual via paolo uccello 4 - 20148 milano tel +39 02 48 009 757 fax +39 02 48 002 070 info@dspmindustria.It www.Dspmindustria.It.

Page 2

1st edition, revision j – march 2010 while every precaution has been exercised in the compilation of this document to ensure the accuracy of its contents, magtrol, inc. Assumes no responsibility for errors or omissions. Additionally, no liability is assumed for any damages that may result from the u...

Page 3

I 1. Make sure that all magtrol dynamometers and electronic products are earth-grounded, to ensure personal safety and proper operation. 2. Check line voltage before operating the dsp6001. 3. Make sure that dynamometers and motors under test are equipped with appropriate safety guards. Safety precau...

Page 4

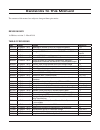

Ii the contents of this manual are subject to change without prior notice. Revision date 1st edition, revision j – march 2010 table of revisions revisions to this manual date edition change section(s) 03/01/10 1st edition - rev. J added 60 bit encoder to chart for torque transducers 3.3.1 04/16/09 1...

Page 5

Iii table of contents safety precautions ......................................................................................................................... I revisions to this manual .................................................................................................................

Page 6

Iv magtrol model dsp6001 dynamometer controller table of contents 3.3 speed encoder setup ......................................................................................................................................... 36 3.3.1 bit configurations ...............................................

Page 7

V magtrol model dsp6001 dynamometer controller table of contents 6.6 water flow alarm ............................................................................................................................................. 57 6.6.1 instructions for water flow alarm setup ..........................

Page 8

Vi magtrol model dsp6001 dynamometer controller table of contents 9.3.2 tsc1 offset and gain .................................................................................................................................... 77 9.3.3 tsc2 offset and gain ...............................................

Page 9

Vii magtrol model dsp6001 dynamometer controller table of contents table of figures 2. Controls figure 2–1 front panel ..............................................................................................................................................8 figure 2–2 secondary function menu .....

Page 10

Viii magtrol model dsp6001 dynamometer controller table of contents figure 5–4 high initial p setting for torque control .............................................................................................44 figure 5–5 initial i setting for torque control ......................................

Page 11

Ix preface purpose of this manual this manual contains all the information required for the installation and general use of the model dsp6001 dynamometer controller. To ensure proper use of the instrument, please read this manual thoroughly before operating it. Keep the manual in a safe place for qu...

Page 12

X magtrol model dsp6001 dynamometer controller preface chapter 10: troubleshooting - solutions to common problems encountered during setup and testing. Appendix a: labview™ programming examples - magtrol’s comprehensive motor-test software programs, made specifically to compliment the dsp6001 dynamo...

Page 13

1 general informa tion calibration certificate 1. Introduction 1.2 new features of the dsp6001 magtrol’s new model dsp6001 dynamometer controller is an upgraded version of the dsp6000, providing superior motor testing capabilities by using state-of-the-art digital signal processing technology. Desig...

Page 14

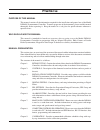

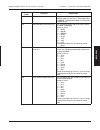

2 magtrol model dsp6001 dynamometer controller chapter 1 – introduction general informa tion 1.3 data sheet dsp6001 data sheet dsp6001 high-speed programmable dynamometer controller 1 www.Magtrol.Com magtrol features • two channels:enabletheunittosupportupto twotestinginstrumentswithindependentortan...

Page 15

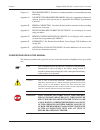

3 magtrol model dsp6001 dynamometer controller chapter 1 – introduction general informa tion 2 dsp6001 magtrol specifications front panel rear panel set desired power units (w, kw or hp) set desired torque units (oz.In., oz.Ft., lb.In., lb.Ft., g.Cm, kg.Cm, nmm, ncm, nm) ready for rack mounting disp...

Page 16

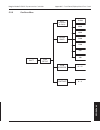

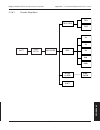

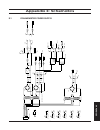

4 magtrol model dsp6001 dynamometer controller chapter 1 – introduction general informa tion 3 dsp6001 magtrol system configurations motor under test optional: ±10 volts tsc2 only 14-pin connector pin 13 = com pin 14 = signal auxiliary input dynamometer / tsc1 aux / tsc2 supply 2 supply 1 rs-232c gp...

Page 17

5 magtrol model dsp6001 dynamometer controller chapter 1 – introduction general informa tion 4 dsp6001 magtrol system configurations dynamometer / tsc1 aux / tsc2 supply 2 supply 1 rs-232c gpib/ieee–488 brake accessory torque–speed output ctrl out brake fuse caution: double pole fusing 75va 50/60hz ...

Page 18

6 magtrol model dsp6001 dynamometer controller chapter 1 – introduction general informa tion 5 dsp6001 magtrol dynamometer / tsc1 aux / tsc2 supply 2 supply 1 rs-232c gpib/ieee–488 brake accessory torque–speed output ctrl out brake fuse caution: double pole fusing 75va 50/60hz earth ground fuse (5×2...

Page 19

7 magtrol model dsp6001 dynamometer controller chapter 1 – introduction general informa tion dsp6001 due to the continual development of our products, we reserve the right to modify specifications without forewarning. Www.Magtrol.Com magtrol inc 70 gardenville parkway buffalo, new york 14224 usa pho...

Page 20

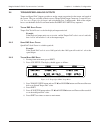

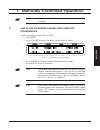

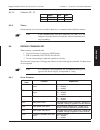

8 general informa tion 2. Controls 2.1 front panel the front panel provides a power switch, nine control buttons, a decrease/increase dial, and vacuum fluorescent display (vfd). Model dsp6001 dynamometer controller power power brake status set point set point p i d torque speed status decrease incre...

Page 21

9 magtrol model dsp6001 dynamometer controller chapter 2 – controls general informa tion 2. Press any control button to enable the function shown in blue letters above the button. 3. Press the shift button again to exit the secondary function and return to main menu. Note: if the brake status is on,...

Page 22

10 magtrol model dsp6001 dynamometer controller chapter 2 – controls general informa tion 2.2.3.2 double-function buttons button to use function power units press shift and release; then press this button. Sets desired unit of power. Press up or down button to see options. Press shift to enable ...

Page 23

11 magtrol model dsp6001 dynamometer controller chapter 2 – controls general informa tion 2.3.1 c ontrast s ettings the dsp6001 is shipped with the contrast setting at zero (lowest) in order to prolong display life. If it is necessary to increase the contrast for improved readability, execute the fo...

Page 24

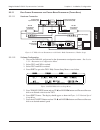

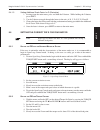

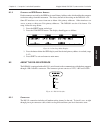

12 magtrol model dsp6001 dynamometer controller chapter 2 – controls general informa tion 2.4 rear panel the rear panel provides connectors and receptacles for connecting to appropriate equipment. Dynamometer / tsc1 aux / tsc2 supply 2 supply 1 rs-232c gpib/ieee–488 brake accessory torque–speed outp...

Page 25

13 magtrol model dsp6001 dynamometer controller chapter 2 – controls general informa tion dynamometer/ tsc1 connect dynamometer signal cable here. 14. Torque signal 13. Torque common 12. D.P. B 11. Index 10. Tach. A 9. D.P. A 8. +5.0 vdc com 7. +5.0 vdc 6. -24 vdc 5. -24 vdc com 4. +24 vdc com 3. +2...

Page 26

14 magtrol model dsp6001 dynamometer controller chapter 2 – controls general informa tion supply 2 connect wb/pb des supply for tsc2. 3. Clutch 8. W flow_2 11. Stand-by channel 2 1. Shield (earth) 2. Electrical alarm channel 2 4. Primary supply contr. Channel 2 5. Supply +24 vdc 6. +5.0 vdc com 7. C...

Page 27

15 setup 3. Installation/configuration note: before installing the dsp6001, you should become familiar with the front and rear panels, as outlined in chapter 2–controls. 3.1 powering up the dsp6001 warning! To reduce the risk of electric shock, make sure the dsp6001 is earth grounded before starting...

Page 28

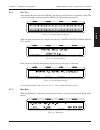

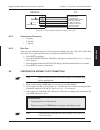

16 magtrol model dsp6001 dynamometer controller chapter 3 – installation/configuration setup 3.1.2 s elf -t est after turning the power on to the dsp6001, the display panel will show all segments of the vfd (series of rectangles), indicating that the dsp6001 is downloading the program. Power brake s...

Page 29

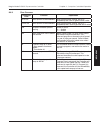

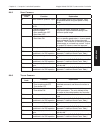

17 magtrol model dsp6001 dynamometer controller chapter 3 – installation/configuration setup 3.2 testing instrumentation setup the dsp6001 has the ability to support a combination of up to two testing instruments with independent or tandem configurations. Typically used combinations include: tsc1 ts...

Page 30

18 magtrol model dsp6001 dynamometer controller chapter 3 – installation/configuration setup 3.2.1 d ynamometer c onfiguration m enu to reach the dynamometer configuration menu: 1. Turn on dsp6001 power. See section 3.1 – powering up the dsp6001. 2. Press shift. The word “shift” will appear in the d...

Page 31

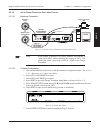

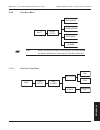

19 magtrol model dsp6001 dynamometer controller chapter 3 – installation/configuration setup 3.2.2 h ysteresis d ynamometer s etup 3.2.2.1 hardware connection dynamometer / tsc1 aux / tsc2 supply 2 supply 1 rs-232c gpib/ieee–488 brake accessory torque–speed output ctrl out brake fuse caution: double...

Page 32

20 magtrol model dsp6001 dynamometer controller chapter 3 – installation/configuration setup 3.2.3 h ysteresis d ynamometer with t orque t ransducer s etup 3.2.3.1 hardware connection motor under test dynamometer / tsc1 aux / tsc2 supply 2 supply 1 rs-232c gpib/ieee–488 brake accessory torque–speed ...

Page 33

21 magtrol model dsp6001 dynamometer controller chapter 3 – installation/configuration setup 3.2.3.2 software configuration 1. Turn on the dsp6001 and proceed to the dynamometer configuration menu. See section 3.2.1 – dynamometer configuration menu . 2. Select tsc1 until hd is reached. 3. Select tsc...

Page 34

22 magtrol model dsp6001 dynamometer controller chapter 3 – installation/configuration setup 3.2.4 h ysteresis d ynamometer with a uxiliary i nstrumentation s etup 3.2.4.1 hardware connection motor under test dynamometer / tsc1 aux / tsc2 supply 2 supply 1 rs-232c gpib/ieee–488 brake accessory torqu...

Page 35

23 magtrol model dsp6001 dynamometer controller chapter 3 – installation/configuration setup 3.2.4.2 software configuration 1. Turn on the dsp6001 and proceed to the dynamometer configuration menu. See section 3.2.1 – dynamometer configuration menu . 2. Select tsc1 until hd is reached. 3. Select tsc...

Page 36

24 magtrol model dsp6001 dynamometer controller chapter 3 – installation/configuration setup 3.2.5 h ysteresis d ynamometer with e ddy -c urrent or p owder b rake s etup 3.2.5.1 hardware connection dynamometer / tsc1 aux / tsc2 supply 2 supply 1 rs-232c gpib/ieee–488 brake accessory torque–speed out...

Page 37

25 magtrol model dsp6001 dynamometer controller chapter 3 – installation/configuration setup 3.2.5.2 software configuration 1. Turn on the dsp6001 and proceed to the dynamometer configuration menu. See section 3.2.1 – dynamometer configuration menu . 2. Select tsc1 until hd is reached. 3. Select tsc...

Page 38

26 magtrol model dsp6001 dynamometer controller chapter 3 – installation/configuration setup 3.2.6 e ddy -c urrent or p owder b rake d ynamometer s etup 3.2.6.1 hardware connection dynamometer / tsc1 aux / tsc2 supply 2 supply 1 rs-232c gpib/ieee–488 brake accessory torque–speed output ctrl out brak...

Page 39

27 magtrol model dsp6001 dynamometer controller chapter 3 – installation/configuration setup 3.2.7 e ddy -c urrent or p owder b rake d ynamometer with t orque t ransducer s etup 3.2.7.1 hardware connection dynamometer / tsc1 aux / tsc2 supply 2 supply 1 rs-232c gpib/ieee–488 brake accessory torque–s...

Page 40

28 magtrol model dsp6001 dynamometer controller chapter 3 – installation/configuration setup 3.2.8 e ddy -c urrent or p owder b rake d ynamometer with a uxiliary i nstrumentation s etup 3.2.8.1 hardware connection dynamometer / tsc1 aux / tsc2 supply 2 supply 1 rs-232c gpib/ieee–488 brake accessory ...

Page 41

29 magtrol model dsp6001 dynamometer controller chapter 3 – installation/configuration setup 3.2.9 t wo e ddy -c urrent /p owder b rake d ynamometers (i ndependent s etup ) 3.2.9.1 hardware connection dynamometer / tsc1 aux / tsc2 supply 2 supply 1 rs-232c gpib/ieee–488 brake accessory torque–speed ...

Page 42

30 magtrol model dsp6001 dynamometer controller chapter 3 – installation/configuration setup 3.2.9.2 software configuration 1. Turn on the dsp6001 and proceed to the dynamometer configuration menu. See section 3.2.1 – dynamometer configuration menu . 2. Select tsc1 until wb or pb is reached. 3. Sele...

Page 43

31 magtrol model dsp6001 dynamometer controller chapter 3 – installation/configuration setup 3.2.10 t wo e ddy -c urrent /p owder b rake d ynamometers (t andem s etup ) 3.2.10.1 hardware connection dynamometer / tsc1 aux / tsc2 supply 2 supply 1 rs-232c gpib/ieee–488 brake accessory torque–speed out...

Page 44

32 magtrol model dsp6001 dynamometer controller chapter 3 – installation/configuration setup 3.2.10.2 software configuration 1. Turn on the dsp6001 and proceed to the dynamometer configuration menu. See section 3.2.1 – dynamometer configuration menu . 2. Select tsc1 until wb or pb is reached. 3. Sel...

Page 45

33 magtrol model dsp6001 dynamometer controller chapter 3 – installation/configuration setup 3.2.11 e ddy -c urrent d ynamometer with p owder b rake d ynamometer (t andem s etup ) 3.2.11.1 hardware connection dynamometer / tsc1 aux / tsc2 supply 2 supply 1 rs-232c gpib/ieee–488 brake accessory torqu...

Page 46

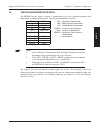

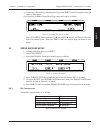

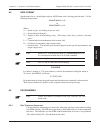

34 magtrol model dsp6001 dynamometer controller chapter 3 – installation/configuration setup 8. Press shift 2 times to get to the tsc2 powder brake setup menu as shown below. Power brake status set point set point p i d torque speed status figure 3–29 tsc2 powder brake setup menu 9. Press torque uni...

Page 47

35 magtrol model dsp6001 dynamometer controller chapter 3 – installation/configuration setup 3.2.12 i n -l ine t orque t ransducer c ross l oop f unction 3.2.12.1 hardware connection dynamometer / tsc1 aux / tsc2 supply 2 supply 1 rs-232c gpib/ieee–488 brake accessory torque–speed output ctrl out br...

Page 48

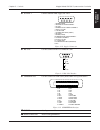

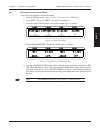

36 magtrol model dsp6001 dynamometer controller chapter 3 – installation/configuration setup 8.A. If choosing a hysteresis or powder brake type, press shift 2 times to complete setup and return to main menu. 8.B. If choosing an eddy-current brake type, menu will appear as follows: power brake status...

Page 49

37 magtrol model dsp6001 dynamometer controller chapter 3 – installation/configuration setup 3.4 torque/speed analog outputs torque and speed dac outputs provide an analog output proportional to the torque and speed of the system. They are available on the accessory torque-speed output connector (as...

Page 50

38 setup 4. Digital filters the digital filters of the dsp6001 are used to remove undesired noise from the tsc inputs. This noise could be conducted from an undesired measured signal such as mechanical vibration or other electrical sources. 4.1 filter parameters the input to the a/d converter intern...

Page 51

39 magtrol model dsp6001 dynamometer controller chapter 4 – digital filters setup 4.2 filter setup note: filter setup should take place after hardware installation and software configuration of the chosen testing instruments has been completed. See chapter 3 – installation/configuration . There are ...

Page 52

40 setup 5. Pid settings 5.1 about the pid loop the dsp6001 has pid adjustment capability for both the speed and torque modes to provide the best system response. The pid loop comprises the following three variables: p = proportional gain i = integral d = derivative other important variables include...

Page 53

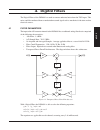

41 magtrol model dsp6001 dynamometer controller chapter 5 – pid settings setup 5.3 how the pid loop works the following diagram demonstrates the correlation between the variables in the pid loop. Derivative proportional integral set point reading - e(t) yd(t) yp(t) yi(t) yt(t) ys(t) + + scale a/d po...

Page 54

42 magtrol model dsp6001 dynamometer controller chapter 5 – pid settings setup 5.3.3 e quations where skp, ski and skd are system coefficients… yd(t) = (e(t) - e(t-3) + 3 * (e(t-1) - e(t-2))) * (10/skd) * d% yp(t) = (e(t) + yd(t)) * (10/skp) * p% yi(t) = yi(t-1) + (e(t) + yd(t)) * (10/ski) * i% yt(t...

Page 55

43 magtrol model dsp6001 dynamometer controller chapter 5 – pid settings setup 5.4.1.3 setting additional scale factor for d (derivative) 1. Starting from the main menu, press and hold the d button. While holding the d button, press shift. 2. Use the d button to toggle through the letters in the uni...

Page 56

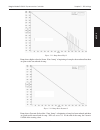

44 magtrol model dsp6001 dynamometer controller chapter 5 – pid settings setup figure 5–3 initial p setting for torque control at 25% figure 5–4 high initial p setting for torque control 6. Turn the brake off. 7. Increase the i term to 10%. 8. Turn the brake on and observe response, then turn the br...

Page 57

45 magtrol model dsp6001 dynamometer controller chapter 5 – pid settings setup a. If the response was too slow, increase the i term in 1-5% increments and repeat #8. B. If the response was too fast, decrease the i term in 1-5% increments and repeat #8. Figure 5–5 initial i setting for torque control...

Page 58

46 magtrol model dsp6001 dynamometer controller chapter 5 – pid settings setup 5.5.3 s etting the pid for s peed c ontrol 1. With the motor and brake off, set the desired speed set point by pressing the speed set button and using the up and down buttons and decrease/increase dial. 2. Set the p, ...

Page 59

47 magtrol model dsp6001 dynamometer controller chapter 5 – pid settings setup figure 5–8 initial i setting for speed control c. If there is too much over shoot, increase the d term in 1% increments and repeat #8. For each incremental increase of the d term, reduce the p term by a proportional amoun...

Page 60

48 magtrol model dsp6001 dynamometer controller chapter 5 – pid settings setup 5.5.4 s etting the pid for r amp d own it is nearly impossible to select a pid value that optimizes the control loop over a wide range of speed. With magtrol’s experience in motor test, their engineers have developed a dy...

Page 61

49 magtrol model dsp6001 dynamometer controller chapter 5 – pid settings setup figure 5–11 ramp down high i ramp shows higher value for i term. Note “bump” at beginning of ramp has been reduced but there are poor results toward end of ramp. Figure 5–12 ramp down dynamic i ramp shows dynamic scale ef...

Page 62

50 setup • opera tion 6. Alar m system 6.1 general information new to the dsp6001 is a built-in alarm system, designed to caution the user when problems occur. An automatic electrical and temperature alarm is programmed into the unit to protect against electrical overloads and overheating equipment ...

Page 63

51 magtrol model dsp6001 dynamometer controller chapter 6 – alarm system setup • opera tion the relay contacts are made accessible on the accessory torque/speed output rear panel connector. See figure 2–6. Common n.O. N.C. 24vdc contactor coil ac mains motor under test figure 6–3 typical application...

Page 64

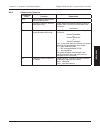

52 magtrol model dsp6001 dynamometer controller chapter 6 – alarm system setup • opera tion 6.1.3 a larm p riority while in an alarm condition, a higher priority alarm will be acknowledged, while lower priority alarms are ignored. The priority order is as follows. Priority alarm availability hystere...

Page 65

53 magtrol model dsp6001 dynamometer controller chapter 6 – alarm system setup • opera tion 6.2.2 p ower a larm a ction when the power exceeds that of the maximum power setting, the message -ol- will appear and blink in the power section of the display accompanied by an audible beeping sound (as ind...

Page 66

54 magtrol model dsp6001 dynamometer controller chapter 6 – alarm system setup • opera tion 6.3.2 m aximum s peed a larm a ction a. If speed is greater than the maximum speed setting but less than 120%, -ol- will flash on the display where the speed reading was (as indicated in figure 6–8) and will ...

Page 67

55 magtrol model dsp6001 dynamometer controller chapter 6 – alarm system setup • opera tion power brake status set point set point p i d torque speed status figure 6–10 torque alarm setup menu 5. Press aux setup button and use up and down buttons and decrease/increase dial to set desired maximum...

Page 68

56 magtrol model dsp6001 dynamometer controller chapter 6 – alarm system setup • opera tion 6.5 air flow alarm • usedtoindicatealackofairflowfromablowerorairline • onlyforusewithhysteresisdynamometers • monitoredonlywhenthebrakeison • defaultissetin“off”mode 6.5.1 i nstructions for a ir f low a larm...

Page 69

57 magtrol model dsp6001 dynamometer controller chapter 6 – alarm system setup • opera tion 6.6 water flow alarm • usedtoindicatelackofwaterflow • onlyforusewitheddy-currentorpowderbrakedynamometers • defaultissetin“off”mode • monitoredonlywhenthebrakeis“on” 6.6.1 i nstructions for w ater f low a la...

Page 70

58 magtrol model dsp6001 dynamometer controller chapter 6 – alarm system setup • opera tion 6.7 external alarm • usedtoshutdownsystembasedonadditionaluserinput • defaultissetin“off”mode 6.7.1 i nstructions for e xternal a larm s etup 1. Starting from main menu, press shift. 2. Press dyno setup butto...

Page 71

59 magtrol model dsp6001 dynamometer controller chapter 6 – alarm system setup • opera tion 6.8 temperature alarm • toalertuserwhendynamometergetstoohotandthermalswitchopens • onlyavailableforusewithwborpbdynamometers • default-alwaysactive 6.8.1 i nstructions for t emperature a larm s etup no setup...

Page 72

60 magtrol model dsp6001 dynamometer controller chapter 6 – alarm system setup • opera tion 6.9 electrical alarm • usedtoprotectthedessupply • monitorselectricalinput(mains)andcircuitryofthedes • onlyavailableforusewithwborpbdynamometers • default-alwaysactive 6.9.1 i nstructions for e lectrical a l...

Page 73

61 opera tion 7. Manually controlled operation note: using the dsp6001 without a computer will limit its testing capabilities. 7.1 how to choose desired channel when using two dynamometers to select the desired channel (tsc1 or tsc2): 1. Press shift. 2. Press aux setup button. The display should app...

Page 74

62 magtrol model dsp6001 dynamometer controller chapter 7 – manually controlled operation opera tion 7.2 how to set desired power units to select the desired power units (w, kw or hp): 1. Press shift. 2. Press power units button. The display should appear as follows: power brake status set point set...

Page 75

63 magtrol model dsp6001 dynamometer controller chapter 7 – manually controlled operation opera tion note: if the response is too slow or oscillatory, adjust the values for p, i and d. (for more detailed instruction, refer to chapter 5– pid settings .) c aution : d o not exceed the capabilities of t...

Page 76

64 magtrol model dsp6001 dynamometer controller chapter 7 – manually controlled operation opera tion 4. Press the shift button to exit the max speed function. 5. Press the speed set button. 6. Use up and down buttons and the decrease/increase dial to set a speed equal to the max. Speed. Note: pi...

Page 77

65 opera tion 8. Computer controlled operation the dsp6001 can be used with a computer to control a dynamometer and to transmit data from the motor testing device directly to the computer. Using the dsp6001 with a computer enables the unit to perform at its full capacity. 8.1 about the gpib interfac...

Page 78

66 magtrol model dsp6001 dynamometer controller chapter 8 – computer controlled operation opera tion 8.1.2 c hanging the gpib p rimary a ddress each instrument serviced by the gpib has its own primary address code, which enables the computer to obtain readings from the instrument. The factory defaul...

Page 79

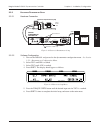

67 magtrol model dsp6001 dynamometer controller chapter 8 – computer controlled operation opera tion note: if the desired results did not occur, please see chapter 10 – troubleshooting . Digital ground 4. 2. 3. 6. 1. 5. 7. 8. 9. Dsp6001 pc 5. Gnd (signal ground) 1. Dcd (data carrier detect) 6. Dsr (...

Page 80

68 magtrol model dsp6001 dynamometer controller chapter 8 – computer controlled operation opera tion 8.4 data format speed-torque data is a fixed-length string in ascii format with a floating point decimal. Use the following string format: sdddddtdddd.R(cr)(lf) or sdddddtdddd.L(cr)(lf) where… s = sp...

Page 81

69 magtrol model dsp6001 dynamometer controller chapter 8 – computer controlled operation opera tion 8.5.1.2 codes for cr - lf basic hex dec cr = chr$(13) 0d 13 lf = chr$(10) 0a 10 8.5.2 t imeout set the timeout for at least one second if asked to set a communication fault delay timeout. Note: if th...

Page 82

70 magtrol model dsp6001 dynamometer controller chapter 8 – computer controlled operation opera tion 8.6.2 c ommunication c ommands command code function explanation *idn? Returns magtrol identification and software revision. Oa prompts to return to auxiliary input data string. Output auxiliary prom...

Page 83

71 magtrol model dsp6001 dynamometer controller chapter 8 – computer controlled operation opera tion 8.6.3 r amp c ommands command code function explanation dilxx.Xx sets dynamic scale coefficient. When using dynamic scaling, xx.Xx is multiplied by the i term to give the end i value. Dplxx.Xx sets d...

Page 84

72 magtrol model dsp6001 dynamometer controller chapter 8 – computer controlled operation opera tion 8.6.4 s etup c ommands command code function explanation af1# sets the analog filter for tsc1. Values for # are: 0 = off 1 = 10 hz 2 = 25 hz 3 = 50 hz 4 = 3 hz af2# sets the analog filter for tsc2. V...

Page 85

73 magtrol model dsp6001 dynamometer controller chapter 8 – computer controlled operation opera tion command code function explanation ua# sets auxiliary input scaling to #. This command sets the scaling factor for the auxiliary input to # units/volt. The range is 0.0 to 10000.0. Programmed value # ...

Page 86

74 magtrol model dsp6001 dynamometer controller chapter 8 – computer controlled operation opera tion 8.6.5 s peed c ommands command code function explanation f# sets maximum speed to # rpm. Sets a speed range for the controller. Must be specified before using the speed or ramp mode. G# sets maximum ...

Page 87

75 magtrol model dsp6001 dynamometer controller chapter 8 – computer controlled operation opera tion 8.6.7 m iscellaneous c ommand command code function explanation dir# selects/deselects the quadrature input circuitry. User has access to up/down counter via oh1 command. The displayed rpm is sent to...

Page 88

76 maintenance 9. Calibration 9.1 closed-box calibration the dsp6001 features closed-box calibration. The advantage of closed-box calibration is that the user does not have to disassemble the case or make mechanical adjustments. 9.2 calibration schedule calibrate the dsp6001: • afteranyrepairsareper...

Page 89

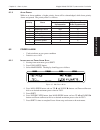

77 magtrol model dsp6001 dynamometer controller chapter 9 – calibration maintenance power brake status set point set point p i d torque speed status figure 9–1 calibration display analog inputs note: to exit calibrate mode without making any changes, press the shift button 8 times. 9.3.2 tsc1 o ffse...

Page 90

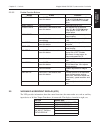

78 magtrol model dsp6001 dynamometer controller chapter 9 – calibration maintenance 9.3.3 tsc2 o ffset and g ain 1. Connect the external voltage reference common to pin 13 of the tsc2 input connector. 2. Connect the external voltage reference high to pin 14 of the tsc2 input connector. 11. N/c 10. T...

Page 91

79 magtrol model dsp6001 dynamometer controller chapter 9 – calibration maintenance 15. N/c 14. Current set point (analog 0v) 13. +5.0 vdc com 12. Supply +24 vdc 11. Stand-by channel 1 10. Temperature alarm channel 1 9. Shield (earth) 8. W flow_1 7. Current set point (signal) 6. +5.0 vdc com 5. Supp...

Page 92

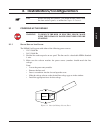

80 magtrol model dsp6001 dynamometer controller chapter 9 – calibration maintenance 8. Connect volt meter to pin 3 (negative) and pin 1 (positive) of accessory torque- speed output. 7 6 3 1 5 4 2 8 8. +5.0 vdc com 7. External alarm input 6. Alarm relay (common) 5. Alarm relay (normally closed) 4. Al...

Page 93

81 magtrol model dsp6001 dynamometer controller chapter 9 – calibration maintenance 9.3.6 d ecimal p oint c heck 1. Connect a 0.5 vdc source to pins 14 (torque signal) and 13 (torque common) of the 14-pin tsc1 connector. For reference, see figure 9–2 tsc1 input connector. 2. Verify that the torque d...

Page 94

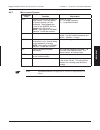

82 maintenance 10. Troubleshooting if you require additional assistance, please contact magtrol customer service at 1-716-668-5555. Problem reason solution display indicates i/o error. Command does not match the unit’s programmed set of instructions. Use correct command and format. Speed command sen...

Page 95

83 appendices appendix a: labview programming examples 0 [0..1] 1 [0..1] magtrol offers a comprehensive motor testing software program to satisfy most of your programming needs. To order your software, call magtrol sales at 1-716-668-5555. A.1 simple read.

Page 96

84 magtrol model dsp6001 dynamometer controller appendix a: labview programming examples appendices 0 [0..2] 1 [0..2] 1 [0..2] 2 [0..2] a.2 torque stabilized.

Page 97

85 magtrol model dsp6001 dynamometer controller appendix a: labview programming examples appendices a.3 speed stabilized 0 [0..2] 1 [0..2] 2 [0..2] 2 [0..2].

Page 98

86 appendices appendix b: inertia correction b.1 inertial effect on motor test data a major advantage of the dsp6001 is its ability to obtain full motor performance data (free run to locked rotor) by continuous load application with an absorption dynamometer. Data acquisition is fast, resulting in m...

Page 99

87 magtrol model dsp6001 dynamometer controller appendix b: inertia correction appendices b.2.1 k ey c onditions • select appropriate value. The test point selection of 78% is typical for an induction motor. Use a value in the linear portion of the motor curve where there is a substantial torque cha...

Page 100

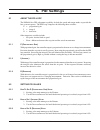

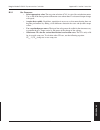

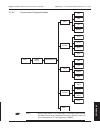

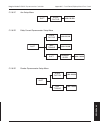

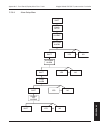

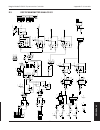

88 appendices appendix c: front panel/display menu flow charts model dsp6001 dynamometer controller power power brake status set point set point p i d torque speed status decrease increase up d i p dyno setup shift com setup aux setup speed set max speed torque set torque units brake on/off power un...

Page 101

89 magtrol model dsp6001 dynamometer controller appendix c: front panel/display menu flow charts appendices c.2 secondary key functions c.2.1 p ower u nits m enu power units shift w hp kw c.2.2 t orque u nits m enu torque units shift n.M n.Cm n.Mm kg.Cm g.Cm lb.Ft. Lb.In. Oz.Ft. Oz.In..

Page 102

90 magtrol model dsp6001 dynamometer controller appendix c: front panel/display menu flow charts appendices c.2.4 a ux s etup m enu aux setup shift close loop on speed dac torque dac 0.000–99,000 units/v tsc1 tsc2 0.000–99,999 rpm/v display on off (if aux or tm2xx on tsc2 ) (if other) c.2.3 m ax s p...

Page 103

91 magtrol model dsp6001 dynamometer controller appendix c: front panel/display menu flow charts appendices c.2.5 c om s etup m enu com setup shift rs-232 baud bite (if tm 2xx on tsc2) gpib address contrast 19,200 9600 4800 2400 1200 600 300 0 – 15 0 – 3.

Page 104

92 magtrol model dsp6001 dynamometer controller appendix c: front panel/display menu flow charts appendices c.2.6.1 maxpower setup menu shift dyno setup max power tsc1/tsc2 max power tsc1 tsc2 0.000–99,999 kw c.2.6 d yno s etup m enu note: refer to the flow charts on the following pages for a more d...

Page 105

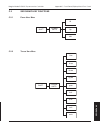

93 magtrol model dsp6001 dynamometer controller appendix c: front panel/display menu flow charts appendices c.2.6.2 dynamometer configuration menu note: refer to flow charts c.2.6.2a through c.2.6.2h for a more detailed breakdown based on test instrument selection. All flow charts will be a continua...

Page 106

94 magtrol model dsp6001 dynamometer controller appendix c: front panel/display menu flow charts appendices c.2.6.2a hysteresis dynamometer setup menu input units shift n.M n.Cm n.Mm kg.Cm g.Cm max torque 0.000– 10,000 lb.Ft. Lb.In. Oz.Ft. Oz.In. Shift scale factor max torque 0.000–10,000 0.000–99,9...

Page 107

95 magtrol model dsp6001 dynamometer controller appendix c: front panel/display menu flow charts appendices c.2.6.2c aux setup menu shift scale factor 0.000–99,999 c.2.6.2d eddy-current dynamometer setup menu shift scale factor max torque 0.000–10,000 shift nominal speed 0.000–10,000 0.000–99,999 c....

Page 108

96 magtrol model dsp6001 dynamometer controller appendix c: front panel/display menu flow charts appendices c.2.6.2f eddy-current dynamometer with eddy-current dynamometer (tandem setup) shift tsc1 scale factor max torque 0.000– 10,000 shift nominal speed 0.000– 10,000 0.000– 99,999 shift tsc2 scale...

Page 109

97 magtrol model dsp6001 dynamometer controller appendix c: front panel/display menu flow charts appendices c.2.6.2g powder brake dynamometer with powder brake dynamometer (tandem setup) shift tsc1 scale factor max torque 0.000–10,000 0.000–99,999 shift tsc2 scale factor max torque 0.000–10,000 0.00...

Page 110

98 magtrol model dsp6001 dynamometer controller appendix c: front panel/display menu flow charts appendices c.2.6.2h eddy-current dynamometer with powder brake dynamometer (tandem setup) shift tsc1 scale factor max torque 0.000– 10,000 shift nominal speed 0.000– 99,999 0.000– 99,999 shift tsc2 scale...

Page 111

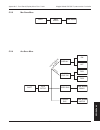

99 magtrol model dsp6001 dynamometer controller appendix c: front panel/display menu flow charts appendices c.2.6.3 encoder setup menu encoders dyno setup shift tsc1/tsc2 bits shift speed alarm tsc1 tsc2 20 30 6000 600 60 0.000 – 99,999.

Page 112

100 magtrol model dsp6001 dynamometer controller appendix c: front panel/display menu flow charts appendices c.2.6.4 alarm setup menu air flow alarm alarms dyno setup shift yes no shift or external alarm water flow alarm yes no shift or yes no shift or enable all alarms yes no shift or.

Page 113

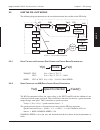

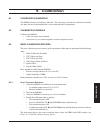

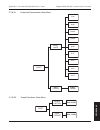

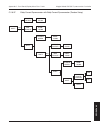

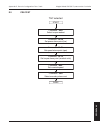

101 appendices appendix d: remote configuration flow charts d.1 advanced configuration command - all0 turn off all alarms while configuring unit command - din1# select what instrument is on tsc1 command - tsf1# set the scale factor for tsc1 command - r reset unit to known state command - sfc# enable...

Page 114

102 magtrol model dsp6001 dynamometer controller appendix d: remote configuration flow charts appendices d.2 pre-test start command - ur# select torque readout command - als# set speed alarm point (rpm) command - alp# set power alarm point (kw) command - alt# set torque alarm point (readout units) c...

Page 115

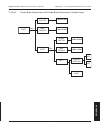

103 magtrol model dsp6001 dynamometer controller appendix d: remote configuration flow charts appendices d.3 ramp command - f set max speed (calculation purposes) start command - pu# or pd# command to ramp up or down & at what rate command - pr terminate ramp test command - s# set start or stop spee...

Page 116

104 magtrol model dsp6001 dynamometer controller appendix d: remote configuration flow charts appendices d.4 speed start command - n# set speed point command - n reset speed point command - nps# select p multiplier command - nis# select i multiplier command - nds# select d multiplier command - np# s...

Page 117

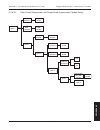

105 magtrol model dsp6001 dynamometer controller appendix d: remote configuration flow charts appendices d.5 torque start command - q# set speed point command - qps# select p multiplier command - qis# select i multiplier command - qds# select d multiplier command - qp# select p term command - qi# se...

Page 118

106 magtrol model dsp6001 dynamometer controller appendix d: remote configuration flow charts appendices d.6 miscellaneous command - dir# selects quadrature input or single frequency command - oh1 returns quadrature counter values command - ioxx.Xx applies offset to output dac on channel 1 command -...

Page 119

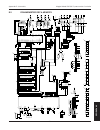

107 appendices appendix e: schematics e.1 dynamometer power supply a_gnd a_+5vd l7 1uh l8 1uh tp12 tp18 0.1uf c131 +5vd +5va 1uh l3 1uh l2 tp1 1uf c3 +5vd tp2 agnd $g_dgnd $g_dpw r +12v -12v 10uf c44 10uf c41 tp16 +12v -12v 0.1uf c45 0.1uf c40 tp15 agnd agnd l1 c4 1uh a_com +25v -25v ou t 3 1uh l4 1...

Page 120

108 magtrol model dsp6001 dynamometer controller appendix e: schematics appendices e.2 dynamometer dsp & memory psc_ 1 20 0 r7 4 3 4 c100 +25v 1 3 4 5 6 7 8 9 10 2 j10 11 12 mh1 1 2 r4 4 330 ps2702- 1 u2 0 13 14 15 16 17 18 19 20 21 22 23 24 mh2 ieee488 stby_ 1 r76 20 0 r75 clutch stby_ 2 20 0 r77 2...

Page 121

109 magtrol model dsp6001 dynamometer controller appendix e: schematics appendices e.3 dsp dynamometer analog i/o j6 1 2 1 fuse f1 header_sip2 a1 a2 a3 a4 a5 j1 2 a7 a8 a9 a1 0 a1 1 a1 2 a1 3 a1 4 a6 b1 b2 b3 b4 b5 b6 b7 b8 b9 b1 0 b1 1 b1 2 b1 3 b1 4 a1 5 agnd psc_ 1 psc_ 2 stby_ 2 stby_ 1 +25v +25...

Page 122

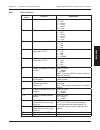

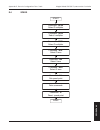

110 appendixappendices appendix f: additional scale factor table the additional scale factor table is the same as the m-test defaults file, which contains default values for all parameters used in the testing of magtrol dynamometers and torque transducers. The m-test defaults file is subject to chan...

Page 123

111 index a accessory torque-speed output 12,37,80 additional scale factor 42,110 advanced configuration 101 air flow alarm 56 alarm commands 69 operation 51 priority 52 relay 50 alarms air flow 56 electrical 60 external 58 maximum speed 53 maximum torque 54 power 52 temperature 59 alarm system 50 a...

Page 124

112 magtrol model dsp6001 dynamometer controller index gpib 65 integral 40,42 l labview programming examples 83 line voltage 15 m maximum speed alarm 53 maximum torque alarm 54 maxpower setup menu 92 max speed menu 90 memory 108 menus 88 alarm setup 100 aux setup 21,90 com setup 91 dynamometer confi...

Page 125

113 magtrol model dsp6001 dynamometer controller index testing instrumentation setup 17 timeout 69 torque configuration 105 torque commands 74 torque control 62 pid settings 43 torque dac scale factor 37 torque stabilized 84 torque transducer setup 20,27,35,94 torque transducer setup 94 torque units...

Page 126

Testing, measurement and control of torque-speed-power • load-force-weight • tension • displacement via paolo uccello 4 - 20148 milano tel +39 02 48 009 757 fax +39 02 48 002 070 info@dspmindustria.It www.Dspmindustria.It.