- DL manuals

- Magtrol

- Controller

- DSP7000

- User Manual

Magtrol DSP7000 User Manual

Summary of DSP7000

Page 1

Model dsp7000 high speed programmable dynamometer controller user’s manual.

Page 2

2nd edition rev. L – january 2017 while every precaution has been exercised in the compilation of this document to ensure the accuracy of its contents, magtrol, inc. Assumes no responsibility for errors or omissions. Additionally, no liability is assumed for any damages that may result from the use ...

Page 3: Safety Precautions

I 1. Make sure that all magtrol dynamometers and electronic products are earth-grounded, to ensure personal safety and proper operation. 2. Check line voltage before operating the dsp7000. 3. Make sure that dynamometers and motors under test are equipped with appropriate safety guards. Safety precau...

Page 4: Revisions to This Manual

Ii the contents of this manual are subject to change without prior notice. Should revisions be necessary, updates to all magtrol user’s manuals can be found at magtrol’s web site at www.Magtrol.Com/support/manuals.Htm . Please compare the date of this manual with the revision date on the web site, t...

Page 5

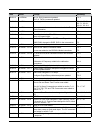

Iii date edition change section(s) 03/09/13 2 nd edition din1,#, din2,# command updated. Tac1,#, tac2,# command updated. 7.4.4 03/09/13 2 nd edition drawing updated 3.2.4.1, 3.2.5.1, 3.2.7.1, 3.2.8.1, 3.2.9.1, 3.2.10.1 03/09/13 2 nd edition note updated with correct section number for the torque fil...

Page 6: Table of Contents

Iv table of contents safety precautions ......................................................................................................................... I revisions to this manual ..................................................................................................................

Page 7

V 3.3 torque filter setup ........................................................................................................................................... 33 3.4 instrumentation setup (speed) ....................................................................................................

Page 8

Vi 5.7 air flow alarm .................................................................................................................................................... 52 5.7.1 instructions for air flow alarm setup .....................................................................................

Page 9

Vii 7.4.4 setup commands ........................................................................................................................................... 78 7.4.5 speed commands ..................................................................................................................

Page 10

Viii appendix b: front panel/display menu flow charts ..................................................... 118 b.1 primary key functions.................................................................................................................................. 118 b.2 secondary key functions ...

Page 11: Table of Figures

Ix table of figures 2. Controls figure 2–1 front panel ............................................................................................................................................10 figure 2–2 secondary function menu ......................................................................

Page 12

X 4. Pid settings figure 4–1 open loop control menu .......................................................................................................................38 figure 4–2 initial p setting for torque control at 25% ..........................................................................

Page 13

Xi 8. Optional equipment figure 8–1 dsp7000 top cover ...............................................................................................................................86 figure 8–2 io card installation .......................................................................................

Page 14: Preface

Xii preface purpose of this manual this manual contains all the information required for the installation and general use of the model dsp7000 dynamometer controller. To ensure proper use of the instrument, please read this manual thoroughly before operating it. Keep the manual in a safe place for q...

Page 15

Xiii magtrol model dsp7000 dynamometer controller preface chapter 10: theory chapter 11: troubleshooting - solutions to common problems encountered during setup and testing. Appendix a: inertia correction - describes the inertial effect on motor test data providing solutions for correction. Appendix...

Page 16: 1. Introduction

1 general informa tion calibration certificate 1. Introduction 1.2 new features of the dsp7000 magtrol’s new model dsp7000 dynamometer controller is an upgraded version of the dsp6001, providing superior motor testing capabilities by using state-of-the-art digital signal processing technology. Desig...

Page 17

2 magtrol model dsp7000 dynamometer controller chapter 1 – introduction general informa tion 1.3 data sheet dsp7000 data sheet dsp7000 series high-speed programmable dynamometer controllers 1 www.Magtrol.Com magtrol features • dsp7001 single channel:lowcostandeasytouse • dsp7002 dual channel:enables...

Page 18

3 magtrol model dsp7000 dynamometer controller chapter 1 – introduction general informa tion 2 dsp7000 magtrol specifications measurement characteristics maximum torque 99,999 units maximum speed 199,999 rpm accuracy speed: 0.01% of reading from 5 rpm to 200,000 rpm torque: 2 volt range ± 0.05% of r...

Page 19

4 magtrol model dsp7000 dynamometer controller chapter 1 – introduction general informa tion 3 dsp7000 magtrol rear panels specifications front panel dsp7001 rear panel for use with any magtrol dynamometer (hysteresis, eddy-current, powder brake), magtrol torque transducer • • connector for model de...

Page 20

5 magtrol model dsp7000 dynamometer controller chapter 1 – introduction general informa tion 4 dsp7000 magtrol system configurations dsp7002 connected to hysteresis dynamometer with in-line torque transducer motor under test tm torque transducer ac mains hysteresis dynamometer (hd) dsp 7002 dynamome...

Page 21

6 magtrol model dsp7000 dynamometer controller chapter 1 – introduction general informa tion 5 dsp7000 magtrol system configurations dsp7002 connected to eddy-current or powder brake dynamometer (wb/pb) with in-line torque transducer tm torque transducer usb pc m-test dsp 7002 dynamometer controller...

Page 22

7 magtrol model dsp7000 dynamometer controller chapter 1 – introduction general informa tion 6 dsp7000 magtrol system configurations dsp7002 connected to eddy-current and powder brake dynamometer (tandem setup) usb pc m-test clutch (ek) dsp 7002 dynamometer controller transformer powder brake dynamo...

Page 23

8 magtrol model dsp7000 dynamometer controller chapter 1 – introduction general informa tion 7 dsp7000 magtrol custom motor test system thedspcanbeincorporatedintoacustomizedmotortestsystem.Thesepcbased,turn-keysystemsarecustomdesigned andbuilttomeetspecificuserrequirements. System configurations he...

Page 24

9 magtrol model dsp7000 dynamometer controller chapter 1 – introduction general informa tion dsp7000 due to the continual development of our products, we reserve the right to modify specifications without forewarning. Www.Magtrol.Com magtrol inc 70 gardenville parkway buffalo, new york 14224 usa pho...

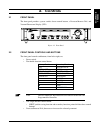

Page 25: 2. Controls

10 general informa tion 2. Controls 2.1 front panel the front panel provides a power switch, eleven control buttons, a decrease/increase dial, and vacuum fluorescent display (vfd). Figure 2–1 front panel 2.2 front panel controls and buttons the front panel controls and buttons, from left to right, a...

Page 26

11 magtrol model dsp7000 dynamometer controller chapter 2 – controls general informa tion 2.2.1 e nabling s econdary f unctions to enable the secondary function of the double-function control buttons: 1. Press the blue shift button and release it. The word “shift” appears in the display: power brake...

Page 27

12 magtrol model dsp7000 dynamometer controller chapter 2 – controls general informa tion 2.2.3 h ow to u se f ront p anel c ontrols and b uttons 2.2.3.1 controls/single-function buttons button to use function power press i to turn power on press o to turn power off. Turns power on or off. Shift pre...

Page 28

13 magtrol model dsp7000 dynamometer controller chapter 2 – controls general informa tion 2.2.3.2 double-function buttons button to use function display both press shift and release; then press this button. Displays both tsc1 and tsc2 measurments. Tsc press this button switches between tsc1 and tsc2...

Page 29

14 magtrol model dsp7000 dynamometer controller chapter 2 – controls general informa tion top row bottom row power brake status (on or off) torque set point (torque) speed set point (speed) user display p i d 2.3.1 c ontrast s ettings the dsp7000 is shipped with the contrast setting at zero (lowest)...

Page 30

15 magtrol model dsp7000 dynamometer controller chapter 2 – controls general informa tion 2.4 rear panel the rear panel provides connectors and receptacles for connecting to appropriate equipment. Figure 2–4 dsp7001 rear panel figure 2–5 dsp7002 rear panel 2.4.1 r ear p anel i nputs and o utputs bra...

Page 31

16 magtrol model dsp7000 dynamometer controller chapter 2 – controls general informa tion tsc1/tsc2 connect torque signal cable here. 1. Flow/clutch 2. Tach. B 3. +24 vdc 4. +24 vdc com 5. -24 vdc com 6. -24 vdc 7. +5.0 vdc 8. +5.0 vdc com 9. D.P. A 10. Tach. A 11. Nc 12. D.P. B 13. Torque common 14...

Page 32

17 magtrol model dsp7000 dynamometer controller chapter 2 – controls general informa tion 2.4.2 o ptional io 1. Io card 1 and io card 2 1. Dac 1 analog torque out or user dac 1 2. Dac 2 analog speed out or user dac 2 3. Ain1+ 4. Ain2+ 5. 5 volts 6. External alarm 7. Di1 8. Di2 9. Dout1 10. Relay1 no...

Page 33

18 magtrol model dsp7000 dynamometer controller chapter 2 – controls general informa tion 2.4.3 o ptional gpib 12. Shield 11. Atn 10. Srq 9. Ifc 8. Ndac 7. Nrfd 6. Dav 5. E01 4. D4 3. D3 2. D2 1. D1 24. Signal ground 23. Atn-com 22. Srq-com 21. Ifc-com 20. Ndac-com 19. Nrfd-com 18. Dav-com 17. Ren 1...

Page 34

19 setup 3. Installation/configuration note: before installing the dsp7000, you should become familiar with the front and rear panels, as outlined in chapter 2–controls. 3.1 powering up the dsp7000 warning! To reduce the risk of electric shock, make sure the dsp7000 is earth grounded before starting...

Page 35

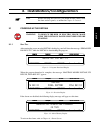

20 magtrol model dsp7000 dynamometer controller chapter 3 – installation/configuration setup 3.1.2 m ain m enu when the dsp7000 is completely powered up and ready for use, the main menu will appear on the display. Power brake status set point set point p i d torque speed user display 0.000 w off 0.0...

Page 36

21 magtrol model dsp7000 dynamometer controller chapter 3 – installation/configuration setup 3.2.1 d ynamometer c onfiguration m enu to reach the dynamometer configuration menu: 1. Turn on dsp7000 power. See section 3.1 – powering up the dsp7000. 2. Press shift. The word “shift” will appear in the d...

Page 37

22 magtrol model dsp7000 dynamometer controller chapter 3 – installation/configuration setup 3.2.2 h ysteresis d ynamometer s etup 3.2.2.1 hardware connection ac mains motor under test hysteresis dynamometer (hd) dsp 7001 dynamometer controller usb pc m-test no connection figure 3–8 hysteresis dynam...

Page 38

23 magtrol model dsp7000 dynamometer controller chapter 3 – installation/configuration setup 3.2.3 h ysteresis d ynamometer with t ransducer s etup 3.2.3.1 hardware connection motor under test tm torque transducer ac mains hysteresis dynamometer (hd) dsp 7002 dynamometer controller no connection usb...

Page 39

24 magtrol model dsp7000 dynamometer controller chapter 3 – installation/configuration setup 3.2.4 h ysteresis d ynamometer with e ddy -c urrent or p owder b rake s etup 3.2.4.1 hardware connection no connection eddy-current (wb) or powder brake (pb) dynamometer ac mains hysteresis dynamometer (hd) ...

Page 40

25 magtrol model dsp7000 dynamometer controller chapter 3 – installation/configuration setup 5.B. If using a powder brake dynamometer, press shift. The display should appear as follows: power brake status set point set point p i d torque speed user display tsc2 max torque x.Xxx figure 3–14 tsc2 powd...

Page 41

26 magtrol model dsp7000 dynamometer controller chapter 3 – installation/configuration setup 4.A if using an eddy current dynamometer, press shift. The display should appear as follows: power brake status set point set point p i d torque speed user display tsc1 max torque nominal speed xxxx xxxx.X f...

Page 42

27 magtrol model dsp7000 dynamometer controller chapter 3 – installation/configuration setup 3.2.6 e ddy -c urrent or p owder b rake d ynamometer with t orque t ransducer s etup 3.2.6.1 hardware connection tm torque transducer usb pc m-test dsp 7002 dynamometer controller excitation torque tsc 401 t...

Page 43

28 magtrol model dsp7000 dynamometer controller chapter 3 – installation/configuration setup 3.2.7 t wo e ddy -c urrent /p owder b rake d ynamometers (i ndependent s etup ) 3.2.7.1 hardware connection eddy-current (wb) or powder brake (pb) dynamometer excitation torque speed tsc 401 torque-speed con...

Page 44

29 magtrol model dsp7000 dynamometer controller chapter 3 – installation/configuration setup 5b. If using a powder brake dynamometer, press shift. The display should appear as shown in figure 3-14 tsc2 powder brake setup menu. Press the torque units button and use and buttons and decrease/increa...

Page 45

30 magtrol model dsp7000 dynamometer controller chapter 3 – installation/configuration setup 3.2.8.2 software configuration 1. Turn on the dsp7000. Set up tsc1 as described in section 3.2.5 eddy-current or powder brake dynamometer setup . Press tsc to swtich to tsc2 setup and proceed to the dynamome...

Page 46

31 magtrol model dsp7000 dynamometer controller chapter 3 – installation/configuration setup 3.2.9 e ddy -c urrent d ynamometer with p owder b rake d ynamometer (t andem s etup ) 3.2.9.1 hardware connection usb pc m-test clutch (ek) dsp 7002 dynamometer controller transformer powder brake dynamomete...

Page 47

32 magtrol model dsp7000 dynamometer controller chapter 3 – installation/configuration setup 14. Select tandem. The display will appear as shown in figure 3-22 tandem configuration menu. 14. Press the scale i button until the menu says “yes”. 15. Press shift once to reach the maximum speed excited m...

Page 48

33 magtrol model dsp7000 dynamometer controller chapter 3 – installation/configuration setup 5. Press scale i to add a filter if desired. 6. Press shift. The display should appear as follows: power brake status set point set point p i d torque speed user display tsc1 max torque xxxx figure 3–26 tsc1...

Page 49

34 magtrol model dsp7000 dynamometer controller chapter 3 – installation/configuration setup figure 3–27 rpm vs ppr chart figure 3–27 provides a reference for allowable maximum rpms when using an encoder with a given ppr. Theses combinations keep the input frequency within the allowable limits for t...

Page 50

35 magtrol model dsp7000 dynamometer controller chapter 3 – installation/configuration setup power brake status set point set point p i d torque speed user display source xxxx ppr xx speed alarm xxxx figure 3–28 encoder menu 5. Press power units button until the desired source selection for the tsc ...

Page 51

36 magtrol model dsp7000 dynamometer controller chapter 3 – installation/configuration setup power brake status set point set point p i d torque speed user display source ai 1 speed alarm xxxx figure 3–30 ai 1 menu 2. Press scale p button and use and buttons and decrease/increase dial to set the...

Page 52: 4. Pid Settings

37 setup 4. Pid settings 4.1 about the pid loop the dsp7000 has pid adjustment capability for both the speed and torque modes to provide the best system response. The pid loop comprises the following three variables: p = proportional gain i = integral d = derivative other important variables include...

Page 53

38 magtrol model dsp7000 dynamometer controller chapter 4 – pid settings setup 4.3 setting the correct pid’s for your motor note: each type of motor will have it’s own optimum pid setting at different load points. 4.3.1 s etting the pid with an u nknown m otor or s ystem if the user is unfamiliar wi...

Page 54

39 magtrol model dsp7000 dynamometer controller chapter 4 – pid settings setup figure 4–2 initial p setting for torque control at 25% figure 4–3 high initial p setting for torque control 6. Turn the brake off. 7. Increase the i term to 10%. 8. Turn the brake on and observe response, then turn the br...

Page 55

40 magtrol model dsp7000 dynamometer controller chapter 4 – pid settings setup a. If the response was too slow, increase the i term in 1-5% increments and repeat #8. B. If the response was too fast, decrease the i term in 1-5% increments and repeat #8. Figure 4–4 initial i setting for torque control...

Page 56

41 magtrol model dsp7000 dynamometer controller chapter 4 – pid settings setup 4.3.3 s etting the pid for s peed c ontrol 1. With the motor and brake off, set the desired speed set point by pressing the speed set button and using the tare and reset tare buttons and decrease/increase dial. 2. Set...

Page 57

42 magtrol model dsp7000 dynamometer controller chapter 4 – pid settings setup figure 4–7 initial i setting for speed control c. If there is too much over shoot, increase the d term in 1% increments and repeat #8. For each incremental increase of the d term, reduce the p term by a proportional amoun...

Page 58

43 magtrol model dsp7000 dynamometer controller chapter 4 – pid settings setup 4.3.4 s etting the pid for r amp d own it is nearly impossible to select a pid value that optimizes the control loop over a wide range of speed. With magtrol’s experience in motor test, their engineers have developed a dy...

Page 59

44 magtrol model dsp7000 dynamometer controller chapter 4 – pid settings setup figure 4–10 ramp down high i ramp shows higher value for i term. Note “bump” at beginning of ramp has been reduced but there are poor results toward end of ramp. Figure 4–11 ramp down dynamic i ramp shows dynamic scale ef...

Page 60: 5. Alar M System

45 setup • opera tion 5. Alar m system 5.1 general information new to the dsp7000 is a built-in alarm system, designed to caution the user when problems occur. An automatic electrical and temperature alarm is programmed into the unit to protect against electrical overloads and overheating equipment ...

Page 61

46 magtrol model dsp7000 dynamometer controller chapter 5 – alarm system setup • opera tion the relay contacts are made accessible on the io card connector. See figure 2–10 i/o interface card 1 and card 2 . Common n.O. N.C. 24vdc contactor coil ac mains motor under test figure 5–3 typical applicatio...

Page 62

47 magtrol model dsp7000 dynamometer controller chapter 5 – alarm system setup • opera tion 5.1.3 a larm p riority while in an alarm condition, a higher priority alarm will be acknowledged, while lower priority alarms are ignored. The priority order is as follows. Priority alarm availability hystere...

Page 63

48 magtrol model dsp7000 dynamometer controller chapter 5 – alarm system setup • opera tion power brake status set point set point p i d torque speed user display -ol- off 0.000 oz.In 0000 0% 0% 0% 0 figure 5–6 power -ol- display b. If power is greater than 120% of the maximum power setting or in co...

Page 64

49 magtrol model dsp7000 dynamometer controller chapter 5 – alarm system setup • opera tion 5. Press torque units button and use and buttons and decrease/increase dial to set desired global power value. 6. Press shift 2 times to complete global power alarm setup and return to the main menu. 5.3....

Page 65

50 magtrol model dsp7000 dynamometer controller chapter 5 – alarm system setup • opera tion 7. To setup maximum speed alarm for tsc2, press tsc to switch to tsc2 setup and follow the instructions above. 5.4.2 m aximum s peed a larm a ction a. If speed is greater than the maximum speed setting but le...

Page 66

51 magtrol model dsp7000 dynamometer controller chapter 5 – alarm system setup • opera tion power brake status set point set point p i d torque speed user display tsc1 max torque xxxx figure 5–13 torque alarm setup menu 6. Press torque units button and use and buttons and decrease/increase dial ...

Page 67

52 magtrol model dsp7000 dynamometer controller chapter 5 – alarm system setup • opera tion 5.6 global torque alarm 5.6.1 i nstructions for g lobal t orque a larm s etup 1. Starting from main menu, press shift. 2. Press setup button. 3. Select tandem. 4. Press scale i button to select “yes” and then...

Page 68

53 magtrol model dsp7000 dynamometer controller chapter 5 – alarm system setup • opera tion power brake status set point set point p i d torque speed user display do you want an air flow alarm? Xxx figure 5–17 air flow alarm setup display 5. Press scale i button to select yes. 6. Press shift 5 times...

Page 69

54 magtrol model dsp7000 dynamometer controller chapter 5 – alarm system setup • opera tion 5.8 water flow alarm • usedtoindicatelackofwaterflow • onlyforusewitheddy-currentorpowderbrakedynamometers • defaultissetin“off”mode • monitoredonlywhenthebrakeis“on” 5.8.1 i nstructions for w ater f low a la...

Page 70

55 magtrol model dsp7000 dynamometer controller chapter 5 – alarm system setup • opera tion 5.9 external alarm (i/o card option) • usedtoshutdownsystembasedonadditionaluserinput • defaultissetin“off”mode 5.9.1 i nstructions for e xternal a larm s etup 1. Starting from main menu, press shift. 2. Pres...

Page 71

56 magtrol model dsp7000 dynamometer controller chapter 5 – alarm system setup • opera tion 5.10 temperature alarm (wb/pb only) • toalertuserwhendynamometergetstoohotandthermalswitchopens • onlyavailableforusewithwborpbdynamometers • default-alwaysactive 5.10.1 i nstructions for t emperature a larm ...

Page 72

57 magtrol model dsp7000 dynamometer controller chapter 5 – alarm system setup • opera tion power brake status set point set point p i d torque speed user display **** electrical alarm tscx **** torque=xxx.Xx xx rpm=x xxxx figure 5–24 electrical alarm message display 5.11.3 t o r eset e lectrical a ...

Page 73

58 opera tion 6. Manually controlled operation note: using the dsp7000 without a computer will limit its testing capabilities. 6.1 how to set desired power units to select the desired power units (w, kw or hp): 1. Press the tsc button to select the desired channel. 2. Press shift. 3. Press power uni...

Page 74

59 magtrol model dsp7000 dynamometer controller chapter 6 – manually controlled operation opera tion note: if the response is too slow or oscillatory, adjust the values for p, i and d. (for more detailed instruction, refer to chapter 4– pid settings .) c aution : d o not exceed the capabilities of t...

Page 75

60 magtrol model dsp7000 dynamometer controller chapter 6 – manually controlled operation opera tion 6.4 how to set speed control note: when using speed control, motors between 0 and 100 rpm cannot be tested unless the dynamometer is equipped with an optional, high resolution speed encoder. 1. Begin...

Page 76

61 magtrol model dsp7000 dynamometer controller chapter 6 – manually controlled operation opera tion note: if the response is too slow or oscillatory, adjust the values for p, i and d. For more detailed instruction, refer to chapter 4 – pid settings . 6.5 how to set open loop control 1. Beginning wi...

Page 77

62 magtrol model dsp7000 dynamometer controller chapter 6 – manually controlled operation opera tion 5. After the preload function has been enabled, and the preload value has been set, the set point the open loop will be initialized to 0.00 % and preload settings is saved to non-volatile memory. 6. ...

Page 78

63 magtrol model dsp7000 dynamometer controller chapter 6 – manually controlled operation opera tion 6.8 how to set the tm/tf invert flag 1. See section 3.2.1 - dynamometer configuration . When the tm/tf torque sensor is chosen, after the max torque screen, the tm/tf torque reading invert flag scree...

Page 79

64 opera tion 7. Computer controlled operation the dsp7000 can be used with a computer to control a dynamometer and to transmit data from the motor testing device directly to the computer. Using the dsp7000 with a computer enables the unit to perform at its full capacity. 7.1 about the usb interface...

Page 80

65 magtrol model dsp7000 dynamometer controller chapter 7 – computer controlled operation opera tion 3. Dsp7000 is a composite device (versions of 7000 prior to ad0 will only offer a single usb interface), meaning that it offers more than one usb interface to your pc. The first device is a communica...

Page 81

66 magtrol model dsp7000 dynamometer controller chapter 7 – computer controlled operation opera tion 5. Select browse my computer for driver software … 6. Select “let me pick from a list of device drivers on my computer ….”. C:\dsp7000 usb driver\windows xp.

Page 82

67 magtrol model dsp7000 dynamometer controller chapter 7 – computer controlled operation opera tion 7. Select ports (com &lpt) and click “next” button. 8. Select have disk….

Page 83

68 magtrol model dsp7000 dynamometer controller chapter 7 – computer controlled operation opera tion 9. Locate the dsp7000vx.Inf on your file system and select it to install. 10. 10. Choose dsp7000 controller and click “next” button..

Page 84

69 magtrol model dsp7000 dynamometer controller chapter 7 – computer controlled operation opera tion 11. Ignore the warning and click yes to continue installation. 12. This successfully installs the virtual com port drivers to your dsp7000..

Page 85

70 magtrol model dsp7000 dynamometer controller chapter 7 – computer controlled operation opera tion 7.1.2 c hecking the dsp7000-t o -pc c onnection for gpib s etup note: make sure that the dsp7000 and its host computer are communicating before acquiring data. 1. Make sure the primary gpib address i...

Page 86

71 magtrol model dsp7000 dynamometer controller chapter 7 – computer controlled operation opera tion 7.2 data format 7.2.1 o utput d ata (od) od (output data) speed-torque data is a fixed-length string in ascii format with a floating point decimal. Use the following string format: sddddddtdddd.R(cr)...

Page 87

72 magtrol model dsp7000 dynamometer controller chapter 7 – computer controlled operation opera tion example if a motor is running at 1725 rpm clockwise, with the dynamometer loading the motor to 22.6 oz.In., the dsp7000 will return: s 1725t22.60r by manipulating the string, the speed-torque and sha...

Page 88

73 magtrol model dsp7000 dynamometer controller chapter 7 – computer controlled operation opera tion number data description data type 22. Quad_cnt_1 quadrature position counter 1 integer 23. Quad_time_1 quadrature position time 1 integer 24. Quad_cnt_2 quadrature position counter 2 integer 25. Quad...

Page 89

74 magtrol model dsp7000 dynamometer controller chapter 7 – computer controlled operation opera tion 7.3.2 t imeout set the timeout for at least one second if asked to set a communication fault delay timeout. Note: if the communication fault delay timeout is too short, or if the computer resets the ...

Page 90

75 magtrol model dsp7000 dynamometer controller chapter 7 – computer controlled operation opera tion 7.4.1 a larm c ommands command code channel 1- command code channel 2 function explanation ala1,# ala2,# enables or disables air flow alarm. Values for # are: 0 = disable 1 = enable alc,# alc,# enabl...

Page 91

76 magtrol model dsp7000 dynamometer controller chapter 7 – computer controlled operation opera tion 7.4.2 c ommunication c ommands command code channel 1 command code channel 2 function explanation *idn? *idn? Returns magtrol identification and software revision. Od1 od2 prompts to return speed- to...

Page 92

77 magtrol model dsp7000 dynamometer controller chapter 7 – computer controlled operation opera tion 7.4.3 r amp c ommands command code channel 1 command code channel 2 function explanation dil1,xx.Xx dil2,xx.Xx sets dynamic scale coefficient. When using dynamic scaling, xx.Xx is multiplied by the i...

Page 93

78 magtrol model dsp7000 dynamometer controller chapter 7 – computer controlled operation opera tion 7.4.4 s etup c ommands command code channel 1 command code channel 2 function explanation af1,# af2,# sets the analog filter for channel 1 or channel 2. Values for # are: 0 = none 1 = 2 hz 2 = 5 hz 3...

Page 94

79 magtrol model dsp7000 dynamometer controller chapter 7 – computer controlled operation opera tion command code channel 1 command code channel 2 function explanation ui1,# ui2,# sets dynamometer torque units to #. Note: for hp and watts calculations to be correct, the correct dynamometer torque un...

Page 95

80 magtrol model dsp7000 dynamometer controller chapter 7 – computer controlled operation opera tion command code channel 1 command code channel 2 function explanation n1 n2 • resets speed point to maximum speed. • sets speed mode off. • sets brake off. Use this command, sent alone, to reset any pre...

Page 96

81 magtrol model dsp7000 dynamometer controller chapter 7 – computer controlled operation opera tion 7.4.6 t orque c ommands command code channel 1 command code channel 2 function explanation q1 q2 • resets torque to 0.0. • turns torque mode off. • turns brake off. This command resets any previous t...

Page 97

82 magtrol model dsp7000 dynamometer controller chapter 7 – computer controlled operation opera tion 7.4.7 m iscellaneous c ommands command code channel 1 command code channel 2 function explanation frz1,# frz2,# freezes the pid loop. Values for # are: 0 = off 1 = freeze pid i1 i2 reset current outp...

Page 98

83 magtrol model dsp7000 dynamometer controller chapter 7 – computer controlled operation opera tion command code channel 1 command code channel 2 function explanation stat read up to 32 bits status flags 0 = dpa1 1 = dpb1 2 = dpa2 3 = dpb2 4 = external alarm 1 5 = dsp7002 6 = io card 1 7 = io card ...

Page 99

84 magtrol model dsp7000 dynamometer controller chapter 7 – computer controlled operation opera tion command code channel 1 command code channel 2 function explanation ob* ob* user can read position counter and position time at a rate of 488 times per second. Timing is accurate to 25 ns. *use cob an...

Page 100: 8. Optional Equipment

85 opera tion 8. Optional equipment 8.1 i/o card 1 and i/o card 2 specifications: i/o analog input: 16 bit convertor +/-10 vdc (0.3 mv resolution) accuracy 0.1% of range (i/o card range is 10 volts. 0.1 % of 10 volts = 0.010 volts or 10 mv) i/o analog output: 16 bit convertor +/-10 vdc (0.3 mv resol...

Page 101

86 magtrol model dsp7000 dynamometer controller chapter 8 – optional equipment opera tion figure 8–1 dsp7000 top cover 2. Remove the two phillips pan head screws from the back panel covering the i/o card 1 slot and remove the panel. 3. Plug i/o card 1 into the female header of main board as shown in...

Page 102

87 magtrol model dsp7000 dynamometer controller chapter 8 – optional equipment opera tion 4. Mount one socket head cap screw onto the main board. Use two philips pan head screws to secure i/o card 1 into the rear panel of the dsp7000. 5. Replace the top cover of the dsp7000 and secure with four phil...

Page 103

88 magtrol model dsp7000 dynamometer controller chapter 8 – optional equipment opera tion pin signal name input/ output level intended use secondary use notes 5 5 volts output + 5 vdc supply external sensor --- * referenced to pin18, 200ma max, internally fused at 500ma 6 external alarm input open o...

Page 104

89 magtrol model dsp7000 dynamometer controller chapter 8 – optional equipment opera tion pin signal name input/ output level intended use secondary use notes 14 dac 1 common n/a bidirectional analog common for torque output --- signal return for pin 1 15 dac 2 common n/a bidirectional analog common...

Page 105

90 magtrol model dsp7000 dynamometer controller chapter 8 – optional equipment opera tion 3. Select i/o. The display should appear as follows: power brake status set point set point p i d torque speed user display filter setup i/o card x channel1 channel2 x hz x hz figure 8–4 filter channel setup me...

Page 106

91 magtrol model dsp7000 dynamometer controller chapter 8 – optional equipment opera tion figure 8–7 alarm contact setup 15. Press scale i button to select yes or no. 16. Press shift. The display should appear as follows: power brake status set point set point p i d torque speed user display io x us...

Page 107

92 magtrol model dsp7000 dynamometer controller chapter 8 – optional equipment opera tion 8.1.4 i/o c ard 1/c ard 2 c ommand s et command code i/o card 1 command code i/o card 2 function explanation io1ai,# io2ai,# read to io card analog input analog channel 1 is available when not assigned as the t...

Page 108

93 magtrol model dsp7000 dynamometer controller chapter 8 – optional equipment opera tion command code i/o card 1 command code i/o card 2 function explanation io1di,# io2di,# read to io card digital input din3 is available if not being used for external alarm read a value of the digital input # 1 = ...

Page 109

94 magtrol model dsp7000 dynamometer controller chapter 8 – optional equipment opera tion figure 8–10 gpib card installation 4. Mount the two standoffs and the two socket head cap screws onto the main board. Use four philips pan head screws to secure the gpib card into the rear panel of the dsp7000....

Page 110

95 magtrol model dsp7000 dynamometer controller chapter 8 – optional equipment opera tion 8.2.3 i nstalling the gpib (ieee-488) c onnector c able c aution : m ake sure both the computer and dsp7000 are turned off before installing the gpib connector cable . 1. Connect one end of a high-quality, doub...

Page 111

96 magtrol model dsp7000 dynamometer controller chapter 8 – optional equipment opera tion 8.3 rs232 interface the dsp7000 is equipped with an rs-232 (serial) interface that communicates with the host computer through a db-9 interface connector. The connector pin-out consists of 2-tx, 3-rx and 5-gnd....

Page 112

97 magtrol model dsp7000 dynamometer controller chapter 8 – optional equipment opera tion figure 8–14 rs-232 card installation 4. Mount the two standoffs and the two socket head cap screws onto the main board. Use four philips pan head screws to secure the rs-232 card into the rear panel of the dsp7...

Page 113

98 magtrol model dsp7000 dynamometer controller chapter 8 – optional equipment opera tion 8.3.3 c ommunication p arameters • noparity • 8databits • 1stopbit • noprotocol 8.3.4 b aud r ate there are eight different baud rates to choose from including 300, 600, 1200, 2400, 4800, 9600, 19200 and 115200...

Page 114

99 magtrol model dsp7000 dynamometer controller chapter 8 – optional equipment opera tion 2. Double click on devices and interfaces in the left column. The submenu will display. 3. Double click on gpib (pci-gpib) in the devices and interfaces submenu. Ensure the primary gpib address is set correctly...

Page 115

100 magtrol model dsp7000 dynamometer controller chapter 8 – optional equipment opera tion figure 8–18 connected instruments window 6. Click the communication with instrument tab, the following screen will show: figure 8–19 communication with instrument window.

Page 116

101 magtrol model dsp7000 dynamometer controller chapter 8 – optional equipment opera tion 7. Click query. The response dsp700x xx xx will display in the string received window. Figure 8–20 query window 8.4.2 rs232 c ommunication c heck note: if you have already installed the tera term application o...

Page 117

102 magtrol model dsp7000 dynamometer controller chapter 8 – optional equipment opera tion 2. Click on the option “i accept the agreement”, then click next. Figure 8–22 tera term licence agreement window 3. Select the default install folder click next. Figure 8–23 tera term destination location wind...

Page 118

103 magtrol model dsp7000 dynamometer controller chapter 8 – optional equipment opera tion 4. Uncheck all boxes except for “tera term & macro” option, then click next. Figure 8–24 tera term select components window 5. Click “yes” to continue to install the application. 6. Select “english”, then clic...

Page 119

104 magtrol model dsp7000 dynamometer controller chapter 8 – optional equipment opera tion 7. Select the start menu folder, then click next. Figure 8–26 tera term start menu folder window 8. Click next. Figure 8–27 tera term additional tasks window 9. Click the finish button..

Page 120

105 magtrol model dsp7000 dynamometer controller chapter 8 – optional equipment opera tion 10. Go to the start menu on your pc desktop. Launch the tera term application. Figure 8–28 tera term window 11. Go to the setup menu. Click on terminal. Configure the selections as follows, and then close this...

Page 121

106 magtrol model dsp7000 dynamometer controller chapter 8 – optional equipment opera tion figure 8–30 serial port setup window 13. Input a command, such as *idn? Plus cr + lf. The response dsp700x xx xx should display. Figure 8–31 tera term window with a command.

Page 122: 9. Calibration

107 maintenance 9. Calibration 9.1 closed-box calibration the dsp7000 features closed-box calibration. The advantage of closed-box calibration is that the user does not have to disassemble the case or make mechanical adjustments. 9.2 calibration schedule calibrate the dsp7000: • afteranyrepairsarepe...

Page 123

108 magtrol model dsp7000 dynamometer controller chapter 9 – calibration maintenance 2. Turn on the dsp7000. 3. Allow the dsp7000 to warm up for at least 30 minutes. 9.3.2 c alibration of a nalog to d igital c onverters 1. A/d offset and gain on any of the 6 analog inputs. • tsc1(lowgainandhighgain)...

Page 124

109 magtrol model dsp7000 dynamometer controller chapter 9 – calibration maintenance 6 = io card 2 channel 1 7 = io card 2 channel 2 6. If the hard ware is not available the unit will respond “not installed.” if the hardware is available the unit will respond “zero to a/d#.” 7. Apply +0.000 vdc and ...

Page 125

110 magtrol model dsp7000 dynamometer controller chapter 9 – calibration maintenance • iocard1channel1=pin14oftheiocard1connector • iocard1channel2=pin15oftheiocard1connector • iocard2channel1=pin14oftheiocard2connector • iocard2channel2=pin15oftheiocard2connector 4. If calibrating a current output ...

Page 126

111 magtrol model dsp7000 dynamometer controller chapter 9 – calibration maintenance 9.3.4 c alibration f requency note: on units with firmware revision r1 and later speed calibration can be performed for greater accuracy note: a high-precision square wave signal generator or frequency counter is re...

Page 127: 10. Theory

112 maintenance 10. Theory 10.1 how the pid loop works the following diagram demonstrates the correlation between the variables in the pid loop. Derivative proportional integral set point reading - e(t) yd(t) yp(t) yi(t) yt(t) ys(t) + + scale a/d power amplifier brake coil tsc load cell amplifier am...

Page 128

113 magtrol model dsp7000 dynamometer controller chapter 10 – theory maintena cnce the speed correction factor is calculated on each entry into the pid loop equations. Speed correction factor = - 0.0001 * x * 2 + 0.0203 * x + 0.005 limited to 0.051 to 1 where x = rpm / nominal speed * 100 nominal sp...

Page 129

114 magtrol model dsp7000 dynamometer controller chapter 10 – theory maintenance 10.3 filter parameters the digital filters of the dsp7000 are used to remove undesired noise from the tsc inputs. This noise could be conducted from an undesired measured signal such as mechanical vibration or other ele...

Page 130: 11. Troubleshooting

115 maintenance 11. Troubleshooting if you require additional assistance, please contact magtrol customer service at 1-716-668-5555. Problem reason solution display indicates i/o error. Command does not match the unit’s programmed set of instructions. Use correct command and format. Speed command se...

Page 131

116 appendices appendix a: inertia correction a.1 inertial effect on motor test data a major advantage of the dsp7000 is its ability to obtain full motor performance data (free run to locked rotor) by continuous load application with an absorption dynamometer. Data acquisition is fast, resulting in ...

Page 132

117 magtrol model dsp7000 dynamometer controller appendix a: inertia correction appendices a.2.1 k ey c onditions • select appropriate value. The test point selection of 78% is typical for an induction motor. Use a value in the linear portion of the motor curve where there is a substantial torque ch...

Page 133

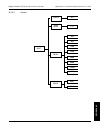

118 appendices appendix b: front panel/display menu flow charts the following flow charts are a reference for navigating through the key functions of the dsp7000 dynamometer controller. For step-by-step setup instructions, refer to the corresponding chapters in this manual. B.1 primary key functions...

Page 134

119 magtrol model dsp7000 dynamometer controller appendix b: front panel/display menu flow charts appendices the following flow charts are a reference for navigating through the key functions of the dsp7000 dynamometer controller. For step-by-step setup instructions, refer to the corresponding chapt...

Page 135

120 magtrol model dsp7000 dynamometer controller appendix b: front panel/display menu flow charts appendices b.2.2.1 dyno b.2.2.1.1 max power shift maxpower 0.000 -99,999 b.2.2.1.2 dynamometer shift dynamometer tsc1/tsc2 hd wb pb tm/tf hd5 note: refer to flow charts b.3.1.1 through b.3.1.5 for a mor...

Page 136

121 magtrol model dsp7000 dynamometer controller appendix b: front panel/display menu flow charts appendices b.2.2.1.4 alarms alarms shift alarm air flow yes no shift alarm water flow yes no shift alarms enable all yes no.

Page 137

122 magtrol model dsp7000 dynamometer controller appendix b: front panel/display menu flow charts appendices b.2.2.2 i/o channel 2 none 2 hz 5 hz 10 hz 20 hz 50 hz 100 hz shift channel 1 2 hz 5 hz 20 hz 50 hz 100 hz none 10 hz channel 1 channel 2 offset 0.000 -± 9,9999 gain 0.000 -± 9,9999 offset 0....

Page 138

123 magtrol model dsp7000 dynamometer controller appendix b: front panel/display menu flow charts appendices b.2.2.2 i/o channel 2 none 2 hz 5 hz 10 hz 20 hz 50 hz 100 hz shift channel 1 2 hz 5 hz 20 hz 50 hz 100 hz none 10 hz channel 1 channel 2 offset 0.000 -± 9,9999 gain 0.000 -± 9,9999 offset 0....

Page 139

124 magtrol model dsp7000 dynamometer controller appendix b: front panel/display menu flow charts appendices b.2.2.4 display shift none tsc2 ai1 ai2 b.2.3 p ower u nits power units shift w hp kw.

Page 140

125 magtrol model dsp7000 dynamometer controller appendix b: front panel/display menu flow charts appendices b.2.4 t orque u nits torque units shift n.M cn.M mn.M kg.Cm g.Cm lb.Ft. Lb.In. Oz.Ft. Oz.In. B.2.5 m ax s peed max speed shift 0.000–99,999.

Page 141

126 magtrol model dsp7000 dynamometer controller appendix b: front panel/display menu flow charts appendices b.2.6 s cale p scale p shift a b c d e f g h i.

Page 142

127 magtrol model dsp7000 dynamometer controller appendix b: front panel/display menu flow charts appendices b.2.7 s cale i scale i shift a b c d e f g h i.

Page 143

128 magtrol model dsp7000 dynamometer controller appendix b: front panel/display menu flow charts appendices b.2.8 s cale d scale d shift a b c d e f g h i.

Page 144

129 magtrol model dsp7000 dynamometer controller appendix b: front panel/display menu flow charts appendices b.3 test instrument setup note: all flow charts will be a continuation of c.2.2.1.2 beginning at shift*. B.3.1 h ysteresis d ynamometer s etup m enu shift input units mn.M n.M cn.M kg.Cm g.Cm...

Page 145

130 magtrol model dsp7000 dynamometer controller appendix b: front panel/display menu flow charts appendices b.3.2 e ddy -c urennt d ynamometer s etup m enu shift filter none 2 hz 5 hz 10 hz 20 hz 50 hz 100 hz scale factor 0.000-99,999 shift max torque 0.000-10,000 nominal speed 0.000-200,000 wb.

Page 146

131 magtrol model dsp7000 dynamometer controller appendix b: front panel/display menu flow charts appendices b.3.3 p owder b rake d ynamometer s etup m enu shift filter none 2 hz 5 hz 10 hz 20 hz 50 hz 100 hz scale factor 0.000-99,999 shift max torque 0.000-10,000 pb.

Page 147

132 magtrol model dsp7000 dynamometer controller appendix b: front panel/display menu flow charts appendices b.3.4 t orque t ransducer /t orque f lange s ensor s etup m enu shift scale factor 0.000-99,999 filter none 2 hz 5 hz 10 hz 20 hz 50 hz 100 hz shift max torque 0.000-10,000 nominal speed 0.00...

Page 148

133 magtrol model dsp7000 dynamometer controller appendix b: front panel/display menu flow charts appendices b.3.5 hd5 s etup m enu shift filter none 2 hz 5 hz 10 hz 20 hz 50 hz 100 hz scale factor 0.000-99,999 shift max torque 0.000-10,000 hd5.

Page 149

134 magtrol model dsp7000 dynamometer controller appendix b: front panel/display menu flow charts appendices b.3.6 e ddy -c urrent d ynamometer with e ddy -c urrent d ynamometer (t andem s etup ) shift filter wb scale factor 0.000-99,999 tsc1 shift max torque 0.000-10,000 nominal speed 0.000-200,000...

Page 150

135 magtrol model dsp7000 dynamometer controller appendix b: front panel/display menu flow charts appendices b.3.6 e ddy -c urrent d ynamometer with e ddy -c urrent d ynamometer (t andem s etup ) shift filter wb scale factor 0.000-99,999 tsc1 shift max torque 0.000-10,000 nominal speed 0.000-200,000...

Page 151

136 magtrol model dsp7000 dynamometer controller appendix b: front panel/display menu flow charts appendices b.3.7 e ddy -c urrent d ynamometer with p owder b rake d ynamometer (t andem s etup ) shift filter wb scale factor 0.000-99,999 tsc1 shift max torque 0.000-10,000 nominal speed 0.000-200,000 ...

Page 152: Appendix C: Schematics

137 appendices appendix c: schematics c.1 dsp7000 core block ra m 256k x 16 is si is 64 wv 25616 3.3v ar m st st r 912 fa w 44x 6 1.8v co re 3.3v io fp ga ac te l a3p250 2.5 v co re 3.3 io 48 mb ga 128 tq fp 256 bg a 1.5v re g jt ag -1 jt ag -2 xt al 25 me g re se t jp 1 core block 1.8v re g jp 2 jp...

Page 153

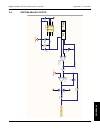

138 magtrol model dsp7000 dynamometer controller appendix c: schematics appendices c.2 dsp7000 analog inputs fp ga a/ d input + input - 499k r44 499k r48 63. 4k r42 665 k r43 63. 4k r47 665 k r46 120p f c61 120p f c62 120p f c6 0 1.2 5v 1 2 3 4 5 6 7 8 u2 1 ad 62 0a r +1 2v a -1 2v a 24. 9 r4 0 24. ...

Page 154

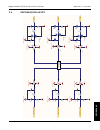

139 magtrol model dsp7000 dynamometer controller appendix c: schematics appendices c.3 dsp7000 digital inputs fpga 10k r52 22 k r54 .0 1 c72 .01 c67 +3.3vd co m dp a d5 ba t54s 2 4 5 3 u2 9 +5vd +3.3vd +3.3vd co m 10k r49 22 k r50 .0 1 c65 .01 c6 4 +3.3vd co m dp b d7 ba t54s 2 4 5 3 u2 7 +5vd +3.3v...

Page 155

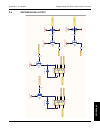

140 magtrol model dsp7000 dynamometer controller appendix c: schematics appendices c.4 dsp7000 encoder in 30 .1 k r29 1n f c48 120pf c39 10. 0k r22 12 .7 k r34 71. 5k r2 5 78 7 r33 2k r28 ta cha 5 6 7 u1 0b lm 29 03 m +5 vd +3 .3 vd +3 .3 vd co m 2 4 5 3 u1 2 +1 2v d 1k r36 d3 ba t5 4s ta chb 3 2 1 ...

Page 156

141 magtrol model dsp7000 dynamometer controller appendix c: schematics appendices c.5 dsp7000 analog output fp ga d/ a nc1 1 v+ 2 sd n 3 gn d 4 nc4 8 nc3 7 out 6 nc2 5 u2 3 ref 19 2 +5 va .1 c59 .1 c50 1.2k r38 2.5 0v +/ -12v a co m 10u f c49 10 pf c42 2 3 1 a u1 1a op a2 277u 10k r24 41. 2k r2 1 -...

Page 157

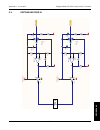

142 magtrol model dsp7000 dynamometer controller appendix c: schematics appendices c.6 dsp7000 digital output +5 v in 1 3 2 q3 np n 1k r1 2 +5 v in co m ba t5 4 1 3 d4 1 16 4 6 8 13 11 9 k2 re la y_ g5 v_ 2 io 1 re la y 2 +5 v in +5 v in co m 1 3 2 q4 np n 1k r1 3 ba t5 4 1 3 d3 1 16 4 6 8 13 11 9 k...

Page 158

143 appendices appendix d: additional scale factor table the additional scale factor table is the same as the m-test defaults file, which contains default values for all parameters used in the testing of magtrol dynamometers and torque transducers. The m-test defaults file is subject to change as ra...

Page 159: Service Information

144 service information returning magtrol equipment for repair and/or calibration before returning equipment to magtrol for repair and/or calibration, please visit magtrol’s web site at http://www.Magtrol.Com/support/rma.Htm to begin the return material authorization (rma) process. Depending on wher...

Page 160

Www.Magtrol.Com testing, measurement and control of torque-speed-power • load-force-weight • tension • displacement magtrol inc 70 gardenville parkway buffalo, new york 14224 usa phone: +1 716 668 5555 fax: +1 716 668 8705 e-mail: magtrol@magtrol.Com magtrol sa route de montena 77 1728 rossens / fri...