- DL manuals

- Mahindra

- Tractor

- 10 Cab Series 4510C

- Operator's Manual

Mahindra 10 Cab Series 4510C Operator's Manual

Summary of 10 Cab Series 4510C

Page 1

Contactus@almats.Com operator manual 10’ cab series 4510c ' click here to go on index main menu.

Page 2: Mahindra

Mahindra operator’s manual for tractors (4510) mahindra u.S.A. Inc. 17723, fm 2920 tomball, texas u.S.A..

Page 3

Daedong off-road compression-ignition engine emission control system warranty statement emission related system defect warranty the warranty period shall begin on the date the engine or equipment is delivered to an ultimate purchaser. The use of alternative fuels shall not void the warranties on any...

Page 4

This warranty covers the following emission-related parts and components. -fuel injection pump -nozzle assembly -injection pipe -turbocharger (if equipped) -intake,exhaust manifold if failure of one of these components results in failure of another part,both will be covered by this warranty. Any rep...

Page 5

Limitation the emission control system defects warranty and the emission control system performance warranty shall not apply to: -malfunctions in any part directly caused by abuse,misuse,modification,improper adjustment except those done by a dealership during warranty service work,alterations,tempe...

Page 6

California emission control warranty statement your warranty rights and obligations the california air resources board and daedong-usa, inc. Are pleased to explain the emission control system warranty on your 2004 and later engine. In california, new off-road engines must be designed, built, and equ...

Page 7

— your engine is designed to operate on diesel fuel only. Use of any other fuel may result in your engine no longer operating in compliance with california’s emissions requirements. — you are responsible for initiating the warranty process. The carb suggests that you present your off- road compressi...

Page 8

Fuel injection pump or nozzles – fuel injection pumps or nozzles are subject to tip wear as a result to fuel contamination. This damage can cause an increase in fuel consumption,the engine to emit black smoke misfire or run rough. Inspect, test, and replace if necessary. Fuel injection pumps can be ...

Page 9

Foreward thank you very much for purchasing our tractor, which, we feel sure, will give you many years of troubling the service. The introduction in this manual set out the correct manner of operating, maintaining and checking the tractor to ensure long-term durability. Please ensure correct operati...

Page 10

Contents 1. Tractor identification 3 2. About this manual 4 3. Introduction & description 5~7 4. Owner assistance 8 5. Rops (roll over protection structures) 9 6. Safety instructions, do’s & don’ts 12~25 7. Safety signs 26~28 8. Universal symbols 29 section a 9. Controls, instruments & operations 31...

Page 11

Tractor identification the engine number is stamped on the left hand side of the engine block. The chassis number is shown on the left hand side of the tractor as shown in the drawing. Illustration a warranty of the product. The manufacturer warrants this product and full details of the warranty are...

Page 12

About this manual this manual has been prepared to assist you in following/adopting the correct procedure for running-in operation and maintenance of your new mahindra tractor. Your tractor has been designed and built to give maximum performance, with good fuel economy and ease of operation under a ...

Page 13

Introduction & description tractor an introduction the word, ’tractor’ has been derived from ‘traction’ which means pulling. A tractor is required to pull or haul an equipment, implement or trolley which are coupled to the tractor body through suitable linkage. A tractor can also be used as a prime ...

Page 14

Description ■ general construction the transmission case, clutch, clutch housing, engine and front axle support are bolted together to form a rigid unit ■ front axle & wheels the 4wd front axle is a center-pivot, reverse eliot type. The front wheel drive mechanism is incorporated as a part of the ax...

Page 15

■ steering it consists of hydrostatic power steering system, which has a hydraulic cylinder and tandem type hydraulic pump ■ electrical system a 12 volt lead acid propylene battery is used to activate the engine through the starter motor and the electrical system comprising horn, head lamp. Side ind...

Page 16

Owner assistance we at mahindra usa inc and your mahindra dealer/distributor wants you to be completely satisfied with your investment. Normally any problems with your equipment will be handled by your dealer/distributor’s service departments, however, misunderstanding can occur. If you feel that yo...

Page 17

(rops) roll over protective structures 9 roll over protective structures (rops) tym tractors are equipped with a frame for the protection of operators. In the case of cab tractors the frame is incorporated in the cab structure. The objective of the frame or cab structure is to protect the operator i...

Page 18

10 damage of the rops if the tractor has rolled over or the rops has damaged (such as striking an overhead object during transport), it must be replaced to provide the original protection. After an accident, check for damages to the 1.Rops.2.Seat 3.Seat belt & seat mountings. Before you operate a tr...

Page 19

Note: do not use solvents to clean the seat. Use warm water with a little detergent added. Before operating a tractor it is important to adjust the seat to the most comfortable position & check whether it is properly locked in its position. Figure 1 identifies the seat fitted to your tractor. For sl...

Page 20

Safety instructions danger warning caution signal words. A signal word ―danger, warning or caution―is used with safety alert symbol. Danger identifies the most serious hazards. Safety signs with signal word ―danger or warning ―are typically near specific hazards. General precautions are listed on ca...

Page 21

Use of rops and seat belt the roll over protective structure(rops) has been certified to industry and/or government standards. Any damage or alternation to the rops, mounting hard-ware, or seat belt voids the certification and will reduce or eliminate protection for the operator in the event of a ro...

Page 22

Handle fuel safely-avoid fires handle fuel with care; it is highly flammable. Do not refuel the tractor while smoking or near open flame or sparks. Always stop engine before refueling tractors. Always keep your tractor clean of accumulated grease, and debris. Always clean up spilled fuel. Stay clear...

Page 23

Avoid high-pressure fluids escaping fluid under pressure can penetrate the skin causing serious injury. Keep hands and body away from pinholes and nozzles, which eject fluids under high pressure. If any fluid is injected into the skin. Consult your doctor immediately. Prevent battery explosions keep...

Page 24

Safety starter switch is to be replaced after every 2000 hours/4 years, whichever is earlier tractor runaway 1. The tractor can start even if the transmission is engaged position causing tractor to runaway and serious injury to the people standing nearby the tractor. 2. For additional safety keep th...

Page 25

17 safe operation of your tractor the manufacturer of your tractor has made every effort to make it as safe as is humanly possible. Beyond this point it is the responsibility of the operator to avoid accidents and we ask that you read and implement our suggestions for your safety. Ensure that only t...

Page 26

18 safety tips during maintenance 1. At least on a daily basis check all oil levels. Water level in the radiator and electrolyte level in the battery and perform services according to the service schedule. 2. Ensure tire pressure are even and the correct pressure for the job being done is maintained...

Page 27

19 ► mounting and demounting implements (1)ensure that all mounting and removal of implements is done on safe flat ground. Ensure no one is between the tractor and implement and do not get under the implement to avoid accidental injuries. (2) after mounting the implement, ensure that all sway chains...

Page 28

20 the following precautions are suggested to help prevent accidents. A careful operator is the best operator. Most accidents can be avoided by observing certain precautions .Read and take the following precautions before operating the tractor to prevent accidents. Tractor should be operated only by...

Page 29

21 ■ operating the tractor 1. Before starting the tractor apply the parking brake, place the pto (power take off) lever in the “off” position, the hydraulic control levers in the downward position, the remote control valve levers in the neutral position( if fitted) and the transmission in neutral. 2...

Page 30

22 ■ driving the tractor 1. Watch where you are going especially at row ends, on roads, around trees and low hanging obstacles. 2. To avoid upsets, drive the tractor with care and at speeds compatible with safety, especially when operating over rough ground, crossing ditches or slopes, and when turn...

Page 31

23 7.Wipe up spilled fuel immediately. 8.Always tighten the fuel cap securely. 9.If the original fuel tank cap is lost, replace it with genuine cap. A none approved cap may not be safe. 10.Do not drive equipment near open fire. 11.Never use fuel for cleaning purpose. 12.Arrange fuel purchases so tha...

Page 32

24 do’s and don’t’s do’s-for better performance do-ensure that safety shields are in place and in good condition. Do-read all operating instructions before commencing to operate tractor. Do-carry out all maintenance tasks without fail. Do-keep the air cleaner clean. Do -ensure that the correct grade...

Page 33

25 don’t-use the independent brakes for making turns on the highway or at high speeds. Don’t-refuel the tractor with the engine running. Don’t-mount or dismount from the right side of the tractor. Don’t-temper the hydraulic control levers’ upper limit stops. Don’t-use draft control lever for lifting...

Page 34: Warning

26 safety signs (replace all missing, damaged or illegible signs) general safety information important: this “general safety information” should be kept with the machine at all times as reference data. This symbol means attention! Your safety is involved. The message that follows the symbol contains...

Page 35

27 to protect engine and hydraulic components. ● idle engine for 1 minute before shut down or full load operation. ● do not exceed 1/2 throttle for first 5 minutes of operation. Caution keep hands and clothing away from rotating fan and belts to prevent serious injury warning location: on dash cover...

Page 36

28 blindness can result from battery explosion. Keep sparks or open frames away from battery. Do not jump start. Burns can result from battery acid. In case of contact flush immediately with water . Danger location: on battery bracket rh part no.: 1260-904-066-0 ● pull only from drawbar. Pulling fro...

Page 37

29 universal symbols some of the universal symbols have been shown below with an indication of their meaning see operator’s manual lift arm/lower battery charge ”hare” fast or maximum setting warning engine coolant temperature differential lock lift arm/raise air filter parking brake power take off ...

Page 38

31 section - a controls, instruments and operations the following pages in this section detail the location and function of various instruments, switches and controls on your tractor. Even if you operate other tractors, you should read through this section of the manual and ensure that you are thoro...

Page 39

32 description of tractor controls instrument and switches ►main switch [off]-the key can be inserted or removed [on]- the electric circuit is on. [glow]-glow plugs preheat the combustion chamber [start]-the starter motor is engaged. When the key is released it will return to the on position.

Page 40

33 ►light switch, indicators and horn high and low beam are operated on the main switch position 1. High beam position 2. Low beam ►tachometer this meter shows the revolutions of the engine and the pto shafts as well as the travel speed in top gear (1) right needle indicates speed in top gear. (2) l...

Page 41

34 ►warning lights charge lamp this light will go off as soon as the engine starts to run to indicate that the alternator is changing. (please note, as broken fan belt can cause the light to come on, please stop the engine as overheating can occur if not rectified immediately) oil pressure lamp will...

Page 42

35 ►independent pto pto monitor lamp two switches operate the independent pto. 1.Pto on/off switch: pto on/off switch is situated on the lhs. On the steering column and can be identified easily with its built in red colored indicator. When the switch is pushed down to start the pto indicator glows t...

Page 43

36 first select the specified speed for the pto by using the pto shifter on the lhs, below the driver seat. Glows blinks blinks glows pto monitor lamp on the dash panel stationary either raised or lowered pressed auto mode on rotates lowered released auto mode on stationary raised either pressed or ...

Page 44

37 tractor controls ►hand throttle pulling the hand throttle towards the driver increases revolutions. Pushing it away from the driver decreases revolution. ►clutch disconnecting arm for long term storage of the tractor it is possible to latch the clutch in the disengaged position. Push the clutch d...

Page 45

38 ► brake pedal right and left brake pedals are provided to assist in turning the tractor in the field. Caution a connecting latch is provided to connect the right and left brake pedals for high speed or road use. In the interest of safety always use it on the road or at high speed as using one sid...

Page 46

39 when changing from forward to reverse or back to forward again while in high range make sure the tractor comes to a stop before changing direction. Failure to do so is likely to result in damage to the mechanism and place the driver at risk of injury. Important operate the shuttle shift only whil...

Page 47

40 do not use high engine rpm when engaging diff lock if the diff lock does not release after removing the foot from the diff lock pedal alternatively brake with the left and right brake until it gets released. Important never use the diff lock at high speed or on the road as this can cause roll ove...

Page 48

41 pto gear selection lever your tractor is equipped with 1 speed pto (4510) to suit range of applications and conditions. Always use the clutch when engaging or disengaging the pto or changing pto speed. Let the pto driven implement come to a complete stop before changing. Important caution do not ...

Page 49

42 warning after finishing the work, always lower the implement to the ground and switch off the engine, set the parking brake to avoid injuries and accidents . ▶lowering speed control knob for the 3 point hitch this knob controls the downward speed of the hydraulics three point linkage and is posit...

Page 50

43 operating the 3 point linkage (tpl) exterior hydraulic lever (optional) move the lever up or down and hold.This will raise or lower the implement (rotavator or hydraulic plow). Lever will return to neutral by itself. Important: -do not hold the lever in the “pull” or “push”position once the remot...

Page 51

▶adjustment of lower link the adjustment is done with the adjusting handle on the right hand yoke rod to shorten it wind the handle clockwise and to lengthen it wind it anti-clockwise. When adjusted correctly hold the turn buckle with the stopper provided. ▶telescopic stabilizers adjustment the stab...

Page 52

45 caution do not attach a pto shaft with the engine running and ensure all safety shields are in place. Only use drawbar to tow and keep the 3 point linkage in raised position when toeing with the drawbar. Position can create unbalance causing the tractor to roll-over & result the death or serious ...

Page 53

46 driving the tractor starting the engine before starting the engine carry out the pre-operational checks as set out on page 17. (1) sit on the driver seat (2) apply the footbrake. (3) put the hydraulic lever in the down position. (4) push down the clutch to activate the safety-starting switch. (5)...

Page 54

47 warming up when starting the engine allow it to warm up to operating temperature by allowing it to idle 5-10 minutes to ensure full lubrication and operating temperature. Failure to do so can shorten engine life substantially. ▶warming up in cold weather cold weather will change the viscosity of ...

Page 55

48 do not ”ride” the clutch to control speed, use a lower gear. Do not travel with your foot on the clutch pedal. Caution always connect the brake pedals when traveling on the road. Never tow anything except with the drawbar. Do not tow loads which are too large for the tractor’s capacity to brake e...

Page 56

49 ▶ driving downhill use the engine’s ability to brake when traveling downhill. Never rely on the brakes only and never travel downhill with the gears in neutral. When operating in hilly terrain the risk of the rollover is increased substantially, please drive with extra care. When towing trailers ...

Page 57

50 ▶fuel gauge. To avoid excessive condensation in the fuel tank refill at the end of each day’s work and ensure during the day that it does not drop to a low level where the fuel system will require bleeding to expel air in the system after refilling the tank. ▶ engine cooling water. If the gauge i...

Page 58

51 ▶ track adjustment as some models of mahindra are front wheel assist the front track can be set in 2 positions the rear track can be set in 5 positions as illustrated. Unit : mm(in).

Page 59: Lubrication

53 section-b lubrication & maintenance this section gives full details of the service procedures necessary to maintain your tractor at peak efficiency while the lubrication and maintenance chart provides a ready reference to these requirements..

Page 60

54 checks and service pre-start checks to avoid problems it is recommended that a range of checks be carried out daily before starting the tractor. For full details of the items and frequency please refer to the tables on page 57,58, and 59 . ▶engine coolant remove the radiator cap and ensure that t...

Page 61

55 ▶ fuel use the fuel gauge to check the fuel level and top up if too low. It is a good practice to refill the tank immediately after use to avoid condensation ▶ tire pressure the air pressure used in the tires has a direct bearing on the life of the tire and its performance in the field. Ensure th...

Page 62

56 ▶ steering ensure that the steering wheel does not have excessive free play. ▶ brake ensure that the left and right brakes are adjusted correctly so they operate simultaneously. The correct free play on the brake is 1.18-1.57 in (30~40 mm). ▶ clutch ensure that the clutch is adjusted correctly. C...

Page 63

57 maintenance and adjustment schedule periodical check and service table ○ check, top-up or adjust ● replace △ clean or wash ★ consult the service dealer ● △ ○ △ ○ ○ ● △ ○ △ ○ fuel filter fill tank ○ fuel check daily for damages leakage ○ radiator see page 54 check daily top up if required ○ radiat...

Page 64

58 about 50mm (1.97 in) of wheel circumference check daily ○ free play of steering wheel smooth operation check daily ○ operation of each lever adjust so that both operate simultaneously and brake at the same time check daily ○ state of both brake pedals (1.18-1.57) check daily ○ free play of brake ...

Page 65

59 replace if leaking check every 100 hours. Change every 600 hours ○ ○ ○ ○ ○ ○ ● oil of the 4wd front axle change every 300 hours ● ● hydraulic oil filter check once a year with the lower plug pulled out check the leakage of oil at the clutch chamber tighten to proper torque check daily ○ loose bol...

Page 66

Filling diagram & capacity table gear oil #80 or #90 43.5 ℓ(11.49 us gal) as required as required 9.3 ℓ(2.46 us gal) 34 ℓ(9 us gal) 7.0 ℓ (1.85 gal) 9 ℓ(2.38 us gal) 4510 quantity liter (gal.) model grease ball joint 7 grease clutch pedal shaft 6 see next page * transmission case 3 api : cd/ce grade...

Page 67

L recommended transmission oil ① rpm tractor hydraulic fluid or textron tdh premium (caltex) ② tdh oil or tdh oil special (texaco) ③ chevron 1000thf (chevron) opening method of each cover ▶ opening method of hood with the hood up,the hard nose can be removed by pulling forward,having first detached ...

Page 68

62 bleeding the fuel system 1) fuel filter cock 「 on 」 2) open the cock on the fuel injection pump 3) fill the tank with fuel and turn the ignition key to on. 4) start the engine and allow it to run for a while 5) close the fuel injection pump cock. 6) the bleeding of the system is now finished. Cha...

Page 69

63 important when changing the oil always change the filter. Always use the same oil, as using different oils or specifications can cause damage. Dispose off the old oil as per local regulations. ▶ changing the transmission oil remove the drain plug from bottom of the transmission and drain the oil....

Page 70

64 cleaning and changing filters ■ engine oil filter using a filter wrench turn the filter anti clockwise to remove it. Lightly smear the rubber seal on the new filter with oil to ensure, turn it clockwise until the seal contacts the base and then turn it another 2/3 turn to tighten it. ■ fuel filte...

Page 71

65 ▶ hydraulic oil filter remove the filter with a filter wrench. To replace, apply oil or grease on the seal, fit by hand until seal contacts bare, then turn it 2/3 rd turn further to tighten it check for leaks..

Page 72

66 changing the coolant (1) open the tap in front of the gear pump to drain the coolant. (2) open the radiator cap at the same time. (3) to give a thorough clean run a hose into the radiator and flush it out. (4) close the tap and refill the radiator with a coolant mixture of water and corrosion inh...

Page 73

67 important water or air under high pressure can distort the cooling fins on the radiator and reduce its efficiency. Greasing the tractor grease the tractor according to the service schedule (page 57 and 59 ) ensure that grease nipples are cleaned well before any attempt is made to grease them. Gre...

Page 74

68 gap adjustment on the front axle lift the front with a hydraulic jack to get the wheels of the ground. Then loosen the nut and tighten the bolt fully and turn the bolt ½ to loosen again in order to roll the center pivot metal freely and tighten the nut again. While the wheels arte still off the g...

Page 75

69 uneven adjustment of the left and right pedal will result in one sided braking when the pedals are connected and can cause serious accidents, especially at high speeds. Double check to ensure free play is the same on both pedals caution adjusting the throttle lever if this lever is either loose o...

Page 76

70 ▶battery maintenance low temperatures will affect the performance of batteries so take particular care of it in winter. For long-term storage of the tractor remove the battery and keep it in a cool dry room. If it is on the tractor while stored, disconnect the negative terminal. Batteries will se...

Page 77

Servicing the air cleaner to remove the dust from the evacuator valve squeeze it between thumb and fingers to let excess dust out and wipe around the valve to keep it clean from outside. To clean the main element, remove the right fan cover. Remove the element by unloading the wing nut. Remove dust ...

Page 78

72 checking the wiring harness and fuses loose wires make inferior connections and damaged wires can cause short circuits, fires burnt wiring or reduce efficiency of components. Replace or repair any faulty wiring or insulation. If a fuse burns out again after it has been replaced, do not replace it...

Page 79

73 3.Maintenance for daily or short term storage clean the tractor and remove all dirt from field work. Fill the fuel tank to avoid condensation and rust. Lower the implement to the ground.. Keep it in a machinery shed or, if not available cover the unit if left outside. In very cold conditions it i...

Page 80

74 long-term storage. When the tractor will not be used for a long time carry out the cleaning as for short term storage. Drain the oil and replace with new oil. Run the engine for approx. 5 min. To ensure that it has new oil throughout the engine. Drain the coolant from the radiator and remove the ...

Page 81

Section - c cabin the cab fully conforms to the international standard as far as safety and soundproofing are concerned. It can be provided with ventilation, heating and air-conditioning system. It is available in the following version.: ● cab with ventilation and heating systems ● cab with ventilat...

Page 82

Remember that steering, braking and operational performances are highly influenced by the implements mounted, the trailers transported and the ballasts applied to the tractor. When transporting heavy loads (exceeding the weight of the tractor) reduce the speed under 15 km/h.. All the implements moun...

Page 83

Working lamps (front and rear) : the working lamps are located on the cab roof (two in the front and two in the rear) .They are switched on by means of the special switches on the roof console rearview mirrors.: the cab is provided with rearview mirrors on both sides. They can be adjusted and folded...

Page 84

Ventilation the ventilation unit is housed in the cab ceiling. To switch it on and adjust it, turn the electrical fan switch to the desired speed. The cab becomes slightly pressurized when the ventilation system is in operation, so that the fresh air can enter only by way of the filter installed in ...

Page 85

Blower control switch three position rocker switch circulation diffuses with the circulation vent set in any position outside air will still be pulled into the cab. Air conditioner switch to operate the air conditioner,the blower must be on.The blower speed temperature control and all vents must be ...

Page 86

Heating system general description the heater is switched on and adjusted by rotating the control knob at the roof console, then switching on the blower and setting the selector at the preferred speed . To warn the cab up quickly, the knob should be rotated fully clockwise and the blower set to spee...

Page 87

System configulation 1.The heating system consist of two units: 1-electric heater and blower unit installed behind roof console. 2-power supplying set, consisting of an auxiliary alternator located front of the engine and driven by a belt directly linked to the engine pulley. If the air does not com...

Page 88

Air conditioner system 1.Alternator 2. Compressor 3.Speed fan 4.Electric resistance 5.Evaporator 6. Condenser 9.Air filter 10.Recirculation inlets 11.Pivotal air diffusers the system is designed to ensure optimum temperature inside the cab and maximum comfort and safety for the operator. However, it...

Page 89

Roof hatch( if equipped) ventilation-push the latch towards the front of the tractor and then push the hatch up. Emergency exit-push firmly upwards to release the support struts from the lower retainer clips. Cab air intake filter the 《paper》 filter is not suitable for the treatment of pesticides an...

Page 90

1.Safety procedures. This safety alert symbol indicates important safety messages in this manual. When you see this symbol, carefully read the message that follows and be alert to the possibility of personal injury or death warning refrigerant r134a is the most stable and easiest to work with refrig...

Page 91

2. Operation the air conditioner system contains five major components: compressor, receiver drier, expansion valve and evaporator. These components are connected by tubes and hoses and operate as a closed system. The air conditioner system is charged with r-134a refrigerant.. The compressor receive...

Page 92

3. Checking the air conditioning system. ①economic friendly refrigerant : r134a 0.7∼0.85kg. The presence of air and water in the system could jeopardize its efficiency. -the air is uselessly compressed by the compressor and no cooling effect is produced. -the moisture has a tendency rise to obstruct...

Page 93

Normal ● normal refrigerant gas situation ● high pressure pipe is hot low pressure pipe is cool ● high low pressure is normal with below. Low: 1.5~2.0kg/ ㎡ high: 14.5~15kg/ ㎡ ● refrigerant in the sight is shown clearly ● when engine rpm operates with high low some bubbles disappear slowly abnormal ●...

Page 94

Check battery low voltage slip during rotation slip replace malfunction no defect wire adjust clutch gap large engaged to push with hand check wire wire defect engaged sometimes disengage control the compressor direction interference with pulley regular noise irregular noise noise 3. Clutch check,ti...

Page 95: Specifications

89 specifications the specifications on the following pages are given for your information and guidance. For further information concerning your tractor and equipment, consult your authorized mahindra dealer/distributor. Mahindra usa inc. Policy is one of continuous improvement and the right to chan...

Page 96

90 specifications model: 4510 engine four strokes, direct injection, water-cooled diesel engine. Model :4a220-dy no. Of cylinders :4 swept volume :133.656 in³(2,197cc) bore :3.42 in stroke :3.64 in compression ratio :22:1 horse power (hp) :45/2600 rpm (manufacturing rating) rated speed : 2,600 rpm h...

Page 97

91 ▶ main specifications position ,draft control lifter cat 1 type mounting 16 stage forward shifting stages 2.4 (94.4") minimum turning radius(m) synchromesh shift method 9.5-16 pr front tire starting with motor starting system 43.5 fuel tank capacity diesel fuel fuel 45/2600 output/speed(hp/rpm) 2...

Page 98

92 fuel saving tips to save fuel & oil in your tractor, following things should always be kept in mind. A) air cleaning system 1) clean the air cleaner regularly so that dust does not settle down. 2) for every 50 hours & everyday in sandy/dusty conditions. (a) clean the air cleaner filter element wi...

Page 99

93 e) cooling system 1) always use recommended grade of oil. 2) everyday before starting the engine, check the oil level with a dipstick & refill between the minimum & maximum level. 3) charge the engine oil, replace filter & “o” ring, as & when required. F) cooling system 1) check the fan belt tens...

Page 100

94 fill the tank and bleed the fuel system contact dealer for repair lack of fuel faulty injectors seized engine due to lack of oil, the wrong oil or lack of coolant the engine stops suddenly engine refill with coolant adjust or replace clean or replace air filter clean the core replace the oil to c...

Page 101

95 fill to correct level change to correct oil replace faulty part contact dealer for repair low oil level wrong oil faulty light or switch clogged oil filter oil warning light comes on with the engine running contact dealer for repair contact dealer for repair contact dealer for repair contact deal...

Page 102

96 for any other hydraulic problems please consult your dealer who has the correct equipment to diagnose and repair the system h y draulic system replace spring remove rust and lubricate with grease faulty return spring lack of grease on the joints brake pedal not returning adjust to correct free pl...

Page 103

97 replace button repair or replace replace faulty horn button faulty wiring faulty horn horn not working electric instruments before anything else,check the electrolyte level of the battery and the connections.Top up it required and clean and retighten the terminal repair,reconnect or tighten as ne...

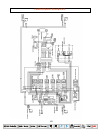

Page 104

99 4510 wiring diagram.

Page 105

4510 wiring diagram 101.

Page 106

Cabin wiring diagram 1. 102.

Page 107

Cabin wiring diagram 2. 103.

Page 108

104 ▶drawing for fixing position of the fuse ▶wiring diagram of the electric instrument coupler for the power max rated ampere 7 units for direction signal relay for the power 5 3 pieces of fuse blinks 2 coupler for the trailer 8 pto monitor pto safety relay 6 power for the working 3 fuse box 1 12v2...

Page 109

Wiring diagram of independent pto 105.

Page 110

◎ 4510 power train 106.

Page 111

107 remarks w/claim no. And date parts replacement nature of defect job card no. Date tractor history card.

Page 112

108 nature/type of repair/service carried out tractor hours date service record.

Page 113

109 remarks engine oil topped up fuel consumption machine hours job done date end start daily operation log.

Page 114

110 part replacement record cost qty part description date cost qty part description date.

Page 115

107 4510 operator’s manual for tractors code no. 1451-940-001-0 printed on march. 2005 2nd edition.