- DL manuals

- Mahindra

- Tractor

- 2810

- Service Manual

Mahindra 2810 Service Manual

TRACTORS

2810/T290/T300/T330

SERVICE MANUAL

Chapter 1. Introduction

------------------------------------01

Chapter 2. Disassembly and reassembly of major point ------02

Chapter 3. Engine accessories ------------------------------------03

Chapter 4. Clutch system ------------------------------------------- 04

Chapter 5. Transmission ------------------------------------ 05

Chapter 6. Front axle (4WD) -----------------------------------06

Chapter 7. Rear axle and Brakes ----------------------------------07

Chapter 8. Power steering system--------------------------------- 08

Chapter 9. Hydraulic system --------------------------------------09

Chapter 10. Electric accessories and instruments -----------10

Chapter 11. Service standard and other information ---------11

Summary of 2810

Page 1

Tractors 2810/t290/t300/t330 service manual chapter 1. Introduction ------------------------------------01 chapter 2. Disassembly and reassembly of major point ------02 chapter 3. Engine accessories ------------------------------------03 chapter 4. Clutch system -------------------------------------...

Page 2: Introduction

Chapter 1 introduction introduction--------------------------------------------------------------1-1 safety introduction-------------------------------------------------1-2 warning signs in this manual ----------------------------------1-5 safety signs -----------------------------------------------...

Page 3: Chapter 1 .Introduction

Chapter 1 .Introduction this tractor service manual is for qualified service personnel engaged in servicing and overhauling 2810/t290/t300/t330 tractor.Use of this publication is not recommended for field operators since they usually do not have access to special tools and shop equipment essential f...

Page 4: Safety Instruction

Safety instruction always practice safety by thinking before action avoid fire hazards. -keep fire extinguishers easily available and in good operating condition. All relevant personnel should know how to operate fire fighting equipment. -keep a first aid kit in an easily accessible location. -do no...

Page 5: Stay Clear of Pto

Stay clear of pto 1) entanglement in rotating drive line can cause serious injury or death. 2) keep tractor master shield and drive line shield in place at all times except for special applications as directed in the implement operator's manual. 3) wear fairly tight tight fitting clothing.Stop the e...

Page 6: Warning Signs In This Manual

Warning signs in this manual the following warning symbols in this manual draw additional attention to items of importance for the safe and correct operation of the tractor. Hazard or unsafe practice that can lead in injury or death. Caution instructions for the correct operation of the machine whic...

Page 7

Safety signs recognize safety information this symbol, safety-alert symbol, means attention! Your safety is involved. The message that follows the symbol contains important information about safety. Carefully read the message danger warning caution signal words. A signal word—danger, warning or caut...

Page 8

Use of rops and seat belt the roll over protective structure(rops) has been certified to industry and/or government standards. Any damage or alternation to the rops, mounting hard-ware, or seat belt voids the certification and will reduce or eliminate protection for the operator in the event of a ro...

Page 9

Handle fuel safely-avoid fires handle fuel with care; it is highly flammable. Do not refuel the tractor while smoking or near open flame or sparks. Always stop engine before refueling tractors. Always keep your tractor clean of accumulated grease, and debris. Always clean up spilled fuel. Stay clear...

Page 10

Avoid high-pressure fluids escaping fluid under pressure can penetrate the skin causing serious injury. Keep hands and body away from pinholes and nozzles, which eject fluids under high pressure. If any fluid is injected into the skin. Consult your doctor immediately. Prevent battery explosions keep...

Page 11

Tractor runaway 1. The tractor can start even if the transmission is engaged position causing tractor to runaway and serious injury to the people standing nearby the tractor. For additional safety keep the pull to stop knob (fuel shut off control) in fully pulled out position. Transmission in neutra...

Page 12: Warning

Safety decals the following safety decals are installed on the machine. If a decal become damaged,illegible or is on the machine,replace it.The decal part number is listed in the parts lists. Failure to follow any of the instructions above can cause serious injury to the operator. ● do not permit an...

Page 13: Caution

Caution to protect engine and hydraulic components. ● idle engine for 1 minute before shut down or full load operation. ● do not exceed 1/2 throttle for first 5 minutes of operation warning keep hands and clothing away from rotating fan and belts to prevent serious injury location: on dash cover sid...

Page 14: Danger

Danger blindness can result from battery explosion. Keep sparks or open frames away from battery. Do not jump start. Burns can result from battery acid. In case of contact flush immediately with water warning ● pull only from drawbar. Pulling from any other point can cause rear overturn. ● do not op...

Page 15: Universal Symbols

Universal symbols some of the universal symbols have been shown below with an indication of their meaning. Engine speed (rev/minx100) pressured- open slowly corrosive substance hours, recorded continuous variable ”tortoise” slow or minimum setting engine coolant temperature warning ”hare” fast or ma...

Page 16

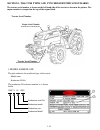

Section 1. Tractor types and punched identification marks the tractor serial number is shown on the left hand side of the tractor as shown in the picture. The engine number is stamped on the top of the engine block. Tractor serial number engine serial number tractor serial number 1.Model name plate ...

Page 17

3.Engine model and engine serial number plate on the head cover. 1-16.

Page 18

Section 2. Specifications 31 28 out put(ps/rpm) engine constant mesh(synchromeshed 3 rd and 4 th in main shift in both forward and reverse) transmission 12v50a alternator drive train 1.2kw starter capacity electronic with cell motor starting system 12v60ah battery electrical forced lubrication type ...

Page 19

Clutch dimensions 11.2-24 4ply rear 7-16 4ply front tire size 294(11.6”) 3290(129”) t290/t300/t330 central axle center pin 325(12.8”) 1640(64.6) 2,366(93.1”) 1315(51.8”) 3150(124”) multiple wet disk dry single disc,mechanic 2810 rear front min. Ground clearance wheel base overall height overall widt...

Page 20

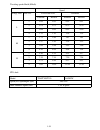

Traveling speeds:km/h (mile/h) 1.25 1.28 1.30 1.33 4 0.90 0.93 0.94 0.96 3 0.70 0.72 0.73 0.75 2 0.51 0.55 0.53 0.55 1 l 3.94 4.05 4.08 4.20 4 2.86 2.93 2.96 3.04 3 2.22 2.28 2.30 2.37 2 1.61 1.67 1.68 1.72 1 m 7.08 7.29 7.34 7.55 2 5.17 5.31 5.35 5.50 1 h reverse forward reverse forward 2810new t29...

Page 21

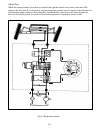

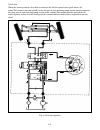

Section 3. Gear train diagrams fig.1-3 gear train diagram 1-20

Page 22

Section 4. Precaution for tractor operation 1. Instruments ①key switch ②temperature gauge ③tachometer ④hour meter ⑤fuel gauge ⑥light switch,indicators and horn ⑦hazard warning light switch ⑧ pto mode switch note; - oil pressure warning light and charge light on the monitor array will light when the ...

Page 23

Monitor light array ①high beam lamp ②low beam lamp ③pto monitor lamp ④cruise control lamp ⑥fuel empty warning lamp ⑦oil pressure lamp ⑧charge lamp ⑨glow signal lamp ⑩turn signal lamp 1-22.

Page 24: 2. Controls

2. Controls 1-23.

Page 25

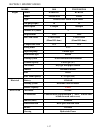

3. Filling diagram & capacity table 33ℓ(8.717 us gal) as required as required 8.2ℓ(2.166us gal) 32ℓ(8.453 us gal) 5.7ℓ (1.51 gal) 7ℓ t290/t300/t330 quantity liter (gal.) 2810new model as required grease ball joint 7 as required grease clutch pedal shaft 6 32ℓ(8.453 us gal) gear oil #80 transmission ...

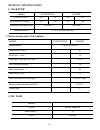

Page 26: 4. Maintenance Chart

4. Maintenance chart ○ inspection,replenish,and adjustment ● replacement △ cleaning and/or washing ★ consult your dealer □ engine electrolyte level hose clamps fan belt fuel filter fuel radiator fin & screen radiator radiator coolant air cleaner oil filter engine oil inspection items check after ○ e...

Page 27: □ Transmission

○ inspection,replenish,and adjustment ● replacement △ cleaning and/or washing ★ consult your dealer replenish every 50 hrs (everyday in dusty condition) ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ greasing each nipple all should be tighten ○ wheel tightening bolts check after ○ every 300 hrs ○ retightening ball joints ...

Page 28

Check after ○ every 100 hrs.Replace after every 600hrs ○ ○ ○ ○ ● 4wd front axle housing oil check after ○ every 100 hrs. ○ ○ ○ ○ rubber pipes check after 300 hours ★ ★ adjusting accelerator pedal and throttle lever all should work properly electric parentheses hydraulic fluid filter oil leaks in clu...

Page 29: Chapter 2

Chapter 2 disassembly and reassembly of major components section 1. General precautions and separation and reinstallation------------------------------------2-1 1. Before operation----------------------------------------------------------- 2-1 2. Precautions to be followed when installing standardiz...

Page 30: Chapter 2

Chapter 2 disassembly and reassembly of major components section 1. General precautions for separation and reinstallation 2. Precautions to be followed when installing standardized parts. (1) roller or ball bearings 1) when a bearing is fitted in by the outer race,use an installer which is an specia...

Page 31

2) during installation,be careful not to damage the lips,and assure that it is pushed in parallel to the shaft or hole. 3) when oil seals are installed,there should be no turnover of the lips nor dislocation of the springs. 4) when a multi-lip seal is installed, the grooves between lips should be fi...

Page 32

,be sure to wind the wire paying sufficient attention to its winding direction and bend the lock washer for secure looking. 4) when locking bolts and nuts with an adhesive,apply the adhesive on the thread and tighten securely. 5) apply an adhesive(three bond tb1104) to parts through which there is a...

Page 33

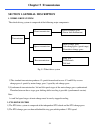

Section 2. Operation chart for disassembly and reassembly by major blocks 2-4.

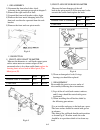

Page 34: 1.Separation of The Front

Section 3. Separation of major components 1.Separation of the front axle and axle bracket note: when working on the 4wd version,the drive shaft should be removed ahead of time. Parts which can be inspected during this operation -center pivot -final case -differential gear (1) removal 1) hold the fro...

Page 35

1.Separation of the engine and the front axle bracket 5) open the front grille. 6) detach the head light wiring. 7) remove the other wiring 8) remove the inlet pipe from the air cleaner. 9) remove the air cleaner. Parts which can be inspected during this operation -air cleaner -radiator -power steer...

Page 36

Fig.2-11 13) remove the battery and battery bracket. 14) remove the two hoses for the power steering system. 15) remove the mounting bolts of the right hand pivot metal(support) ahead of time. 16) at this stage,the power steering unit can be removed by disconnecting both right-hand and left hand tie...

Page 37

5) disconnect the battery cables. 8) disconnect the hydraulic hose from the power steering (orbitrol) fig.2-14 6) disconnect the panel instrument set removing bolts(4 nos.) fig.2-17 note: - disconnect the linear shift control cable - disconnect the cable from both the steering lever side and transmi...

Page 38

(2) engine separation from the chassis. When separating the engine from the chassis,the following steps are required as well as the ones mentioned above. 1)lift the engine with the hoist and hold the front axle bracket with a stands or the like. 2) disconnect the upper, lower ,and drain hoses from t...

Page 39

4.Separation of the front transmission and spacer transmission 7) remove the slow-return check valve knob parts which can be inspected during this operation -pto clutch -linear shift gears and related parts -main change gears slow return check valve 1) removal a:removal of the whole floor. 1) remove...

Page 40

9) remove the parking brake. 10) remove the main shift and transmission range shift levers.The levers can be separated in the middle. 11) remove the control rods of the pto shift and 4wd shift levers from the transmission. 12) remove the position control levers. Fig.2-28 rubber mounting 16) lift up ...

Page 41

18) lift the floor gradually taking care not to allow the shaft of the slow return check valve and its hole in the floor to interfere with each other. Slow return check valve fig.2-33 front wheel drive fig.2-31 slow return check valve 3) disconnect the brake rods. Slow return check valve fig.2-35 op...

Page 42

5) remove the suction and delivery pipes. 6) remove the delivery pipe for the pto clutch. 7) remove the reverse shift metal(support) (5) install the front wheel drive shaft. (6) position the floor taking care not to allow wiring or other parts to be pinched under it (7) with the floor lifted up a li...

Page 43

5.Separation of the spacer transmission and rear transmission (8) remove the operator’s seat (9) remove the position control lever (10) remove the lever guide. (11) when the tractor is equipped with an optional remote control valve,remove the remote control valve and relevant parts from the bracket....

Page 44

(20) remove two rubber mounts. Fig.2-44 frame rubber mounts. Rubber mounting bolts fig.2-46 sub change metal (29) remove all the spacer-rear transmission case tightening bolts and nuts except the bottom bolt. (21) lift up the rear end of the floor/fender assembly by about 10 mm,and place wood betwee...

Page 45

6.Separation of the rear transmission and rear axle housing (31) install the rear wheels(lh and rh) and the remained bolts.Then turn the rear wheels by hand to move the rear transmission case away from the spacer transmission case. Parts which can be inspected during this operation - diff lock - bra...

Page 46

Fig.2-55 rear axle housing (4) remove the brake rods. (5) remove the 3-point linkage and related parts. 2) installation reassemble in reverse order of disassembly. (1) join the rear axle and rear transmission note: make sure that the diff-lock shifter is fitted into the groove in the dif-lock metal ...

Page 47

7.Separation of the rear transmission and cylinder case (10) detach the delivery pipe from the cylinder case. (12) remove the slow-return check valve along with the shaft. (13) remove the 3-point lift link and related parts from the lift arm. (14) remove the cylinder case tightening bolts. (15) deta...

Page 48: Chapter 3

Chapter 3 engine accessories section 1. Radiator ---------------------------------------------------3-1 1. General description ------------------------------------------------------3-1 2. Radiator -------------------------------------------------------------------------------------------- 3-2 3. Spe...

Page 49: Chapter 3.Engine Accessories

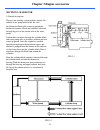

Chapter 3.Engine accessories section 1. Radiator 1.General description the pressure cooling system includes mainly the radiator,water pump,multi-blade fan, and the thermostat.During the warm-up period,the thermostat remains closed and coolant is directed through by-pass to the suction side of the wa...

Page 50: 2. Radiator

2. Radiator the radiator consists of radiator cores, a tank to flow coolant,side plates to install the radiator, and a fan guide. Fin-tube type cores are used and the cores and tank is made of anti corrosive copper and copper alloy. Fig.3-3 ① radiator assy ② radiator cap ③hose,radiator ④insulator ⑤n...

Page 51: 3. Specifications

3. Specifications 7 ℓ(contains in cylinder block) coolant capacity 4.2 mm radiator fin pitch 4 trains core train number flat water tube with corrugate fins radiator core type 1.8 kgf/㎠ test pressure 0.9±0.15kgf/ ㎠ pressure valve opening pressure 8.185㎡ thermal radiator area t290/t300/t330/2810new de...

Page 52

Fig.3-5 -clean with a detergent when cleaning the radiator with a detergent, follow the instructions given by its manufacturer. Different detergents have different characteristics. B. Cleaning the radiator exterior - cleaning the net (wire mesh) after the tractor has been operated in dusty condition...

Page 53

0.04-0.05 kgf/ ㎠ (0.57-0.71psi) vacuum valve opening pressure 1.05 kgf/ ㎠ (14.93 psi) pressure valve opening pressure fig.3-8 6. Radiator reassembly reassemble the radiator in the reverse order of disassembly. Note: - the rubber hoses should be clamped securely and must not interfere with the coolin...

Page 54

8. Trouble shooting (3)replace. (3) unbalanced fan (2)retighten or replace (2) loose or bent fan (1)replace (1) poor water pump bearing 4) noisy cooling fan (5) inspect cylinder head and replace gasket (5) water leakage through cylinder head gasket (4)repair or replace (4) leaking water pump (3)repl...

Page 55

Section 2. Air cleaning system 1.General description unfiltered air contains many particles harmful to the engine such as dust ,sand,or other foreign matter. When such foreign matter have entered in to the engine,they have mixed into the lubricant and promote wear of lubrication parts in addition to...

Page 56

2.Element air cleaner (1) specifications. Model 2810new/t290/t300/ t330 type dry,paper element filtering type rated intake air volume (㎡/min. (cu. Ft/ min) 2.6(91. 8) air venting resistance (㎜ag) 120 or less cyclone efficiency (%) 45 or over total filtering efficiency (% ) 99.9 or over dust holding ...

Page 57

Note: especially note the glue portions of the paper and metal parts. 3. Inspection of each part 1) inspection of the cleaner body (1) check the cleaner exterior for cracks, deformation,or damage and repair or replace if necessary. (2) check each packing for fatigue or damage and replace if necessar...

Page 58

-after soaking,rise it in fresh water. -let it in a shaded and well ventilated place. Forced drying by heat or compressed air is prohibited. Note: water applied to rinse the element should not have a pressure of more than 2.8kgf/㎠ (39.8psi). An element which has been washed 5 times must be replaced ...

Page 59: Chapter 4

Chapter 4 clutch system section 1. General description ----------------------------- 4-1 section 2. Specifications ----------------------------------------- 4-2 section 3. Disassembly,inspection,and reassembly---4-3 1. Main clutch -------------------------------------------------------------------4-...

Page 60: Chapter 4. Clutch System

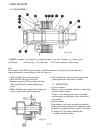

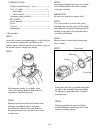

Chapter 4. Clutch system general description. The clutch is a device to engage and disengage the power of the engine.The construction of the clutch is as shown in the figure. It is composed of the flywheel which holds the clutch disc,the pressure plate,diaphragm springs,the clutch cover,and input ge...

Page 61

Section 2. Specifications 4-2 2.0 (0.079) clearance between lever plate and release bearing (㎜) (in) clutch pedal Ø25.0 (0.984) large dia. (㎜) (in) spline hub Ø225±1.0×Ø150±0.8 outer dia. ×inner dia. (㎜) y-02, y-07 facing material dry single type clutch disc. 20~30 (0.79~1.18) clutch pedal free play...

Page 62

Section 3. Disassembly, inspection, and reassembly fig. 4-3 clutch assembly 4.Bolt(s) 6.Main clutch 7.Clutch disc 8.Clutch cover 9.Pin(b) 12.Input metal 13.Seal bolt 14.Nut 15.Washer spring 18.Metal sleeve 19.Seal bolt 20.O-ring 21.Sleeve 22.Clutch release bearing 23.Tension spring 1.Main clutch 1-1...

Page 63

1-3. Inspection of pressure plate and flywheel. 1) inspect the diaphragm spring surface for up-and-down,scratches,stepped wear,or oil stains. 2) check the height differences of diaphragm springs. 3) if damage is found on the pressure plate. The clutch cover must be replaced. 4) shallow scratches may...

Page 64

(2)inspection of sleeve ensure smooth movement of the sleeve.If it does not move smoothly,clean and grease it. Use heat-proof grease. (3) inspection of tension springs. If there are some broken tension springs, replace them. (4) inspection of the fork. Inspect the contact faces of the fork and the s...

Page 65

3.Final adjustment of the clutch pedal clutch pedal play 1) loosen the lock nuts on the clutch rod and adjust the clutch rod length to achieve 20~30㎜ (0.79~1.18 in.) pedal play.Retighten the lock nut securely. Note: one lock nut has a right hand thread and the other has left-hand threads,so take car...

Page 66

Section 4. Troubleshooting 1.Problem :clutch slippage. The initial stage of clutch slippage is very hard to notice,but the following symptoms 1) the tractor is not generating adequate power when performing heavy duty operations. 2) output is not commensurate to increate in engine speed when the engi...

Page 67

4. Problem: abnormal noises there are abnormal noises emanating from the clutch. Replace -cracked disc plate replace -broken or insufficiently lubricated release bearing replace -seized or worn pilot bearing countermeasures probable causes 5. Problem: dashing or shifting the tractor does not startin...

Page 68: Chapter 5

Chapter 5 transmission section 1.General description------------------------------------5-1 1.Wheel driving system----------------------------------------------------------5-1 2.Pto drive system--------------------------------------------------------------5-1 3.Power train diagrams------------------...

Page 69: Chapter 5 .Transmission

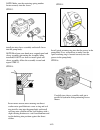

Chapter 5 .Transmission section 1.General description 1. Wheel drive system the wheel driving system is composed of the following major components: reverse change gears (linear shift mechanism) front transmission transmission space transmission main change gears sub-change gears (speed range) front ...

Page 70

3.Power train diagrams refer to page 5-49 and 50 at the end of this chapter. 4.Construction and function of the synchromesh mechanism ①shifter ②hub ③block pin ④synchro-ring ⑤synchro-cup ⑥thrust piece ⑦spring ⑧spline of hub(2) ⑨spline of synchro-cup(2) ⑩constant mesh gear ⑪spline of gear(10) ⑫constan...

Page 71

3rd stage: when hub(2)is pushed further,the tapered surface in the hole of the hub and the tapered surface on the block pin are pressed tightly against each other,this pushes synchro-ring(4) against synchro- cup(5).Consequently,as shown fig.5-6,the synchro- ring and the synchro-cup are pressed more ...

Page 72: Section 2. Specifications

Section 2. Specifications 1. Wheel drive system column shift linear shift operation methods 1 /4.363 drive pinion-ring gear 0.2619 (11/42) 0.8276 (24/29) 2.6429 (37/14) low mid high speed range shift 0.4250 (17/40) 0.5833 (21/36) 0.7500 (24/32) 1.0357 (29/28) 1 st 2 nd 3rd 4th main speed shift side ...

Page 73: Section 3.

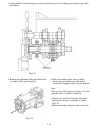

Section 3. Disassembly ,inspection,and reassembly 1. Input shaft and reverse change gears (front transmission) fig.5-8 1.Clutch release bearing 2.Sleeve 3.Spring,tension 4.Bolt(seal) 5.Metal sleeve 6.O-ring(g) 7.Bolt(seal) 8.Nut 9.Washer spring 10.Input metal 11.Ball bearing 12.Gear (helical/30) 13....

Page 74

C. Pull out input gear(19t) rearwards. D. Remove the sleeve metal tightening bolts and take off sleeve metal. E. Draw pto drive gear forwards. F. Pull out main change shaft firstly,and remove counter shaft and pto shaft. 1.1 disassembly (1)removal of input shaft and related parts separate the engine...

Page 75

1.2 inspection before and after disassembly,inspect each part for points mentioned below,and replace if necessary. 9.5 kgf (20.9lbs) 13.0-18.8 kgf (28.7-41.5lbs) synchro-hub thrust for shifting - 51.17 ㎜ (2.015 in) assembled width of synchromesh assembly 0.3 ㎜ (0.012 in) 0 ㎜(0 in) stepped wear of te...

Page 76

1.3 reassemlby (1) sub assembly of reverse shaft and related parts. Fig.5-12 a.Install synchro-cups(34) on gear(16) and gear(21) respectively and retain them securely with snap rings c b.Install synchro-hub comp(35) and above sub- assemblies on reverse shaft(18) note: as each synchromesh assembly ma...

Page 77

(2) installation of each sub-assembled shaft. Install each sub- assembled shift into the reverse metal(support). Note: when installing the pto clutch assembly,apply a thin coat of grease to the seal rings and install it taking care not to damage these rings. Fig.5-13 5-9.

Page 78

(3) installation of input metal and related parts. Fig.5-14 reassemble in reverse order of disassembly,following the next instructions. A.Install the idle shaft(120 so that the end with the tapped hole faces rearwards,that is ,on the snap ring installed side. B.Apply adhesive to the threads of the b...

Page 79

(4) installation of pto shaft ① pay attention to the direction of installation and check to see all the parts turns smoothly. ② when pushing the rbb's(6205 and 6005)into the gear,be careful only to push their outer races. ④ when installing the pto clutch assembly,apply a thin coat of grease to the s...

Page 80: 2. Pto Clutch

2. Pto clutch 2-1. Disassembly (38)rbb (40)rbb (44) snap ring (45)back-up plate (46) disc assembly (47)driven plate (48) piston (51) seal ring (52) seal ring (53) cover assembly (54)seal ring fig.5-16 note: disassembly of the pto clutch assembly should be done in a clean,dust-free place.Exercise spe...

Page 81

Fig.5-19 -inspection for disc thickness and serration wear. 0.2mm (0.008 in) - surface flatness 1.9mm (0.075 in) 2.2±0.1mm (0.087 in) disc thickness usable limit specified values inspection items e. If the combined thickness of the return plate and brake disc deviates from the specified value, repla...

Page 82

2.3 reassembly fig.5-22 reassemble the parts in reverse order of disassembly,following these instructions. Note: -each parts should be washed clean before reassembly. -apply multi-purpose,quality grease to needle bearings in advance. -each bolt and nut should be tightened to the respective specified...

Page 83

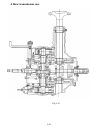

3.Main change,sub-change,and 4wd change gears. (1)synchromesh transmission version. Fig.5-24 synchromesh transmission version 5-15.

Page 84

Fig.5-25 main change gear and related parts. 5-16.

Page 85

3.1 disassembly fig.5-26 separation the spacer transmission case and rear transmission case from each other referring paragraph 5.(1) in section 4.Separation of major components in chapter 2. With this operation,the transmission is divided into parts a and b part a includes main speed shift and mech...

Page 86

(1) disassembly of main change gears(main speed shift),part of sub-change gears(speed range shift) and shifters. Fig.5-27 a. Remove the tightening bolts and pull out the assembly of the space metal(18) b.Pull out assembly of the reverse shifter metal,main speed shift gears,and shifters rearwards by ...

Page 87

Fig.5-29. Fig.5-31 fig.5-30 2.Disassembly of the sub-change gears (speed range shift) a.Remove the sub-shifter and shifter stay. B.Remove the space transmission case c. Pull out the pto shaft ,4wd shaft and gear d. Remove the snap ring from the end of the pinion gear shaft e. Remove the hub f. Remov...

Page 88

3.2 inspection before and after disassembly,inspect each part for points mentioned below,and replace if necessary. 0.5 mm (0.020 in) 0 mm thrust play of fixed gears - 51.17 (2.015in) assembled width of synchromesh assembly 0.5mm (0.020 in) 0.1-0.2mm(0.004-0.008in) backlash of each gear(measured in m...

Page 89

3.3 reassembly reassemble the parts in reverse order of disassembly,following these instructions. Note: -each part should be washed clean before reassembly. -apply multi-purpose,quality grease to needle bearings in advance. -each bolt and nuts should be tightened to the respective specified torque i...

Page 90

A.While holding the gear in the position shown in the drawing,install the assembly of the main change gears and related parts in position by tapping it slightly on the front of a plastic hammer and then the gears by tapping it on the rear. B. Sub assemble the shifter stay,spring, and steel ball(fig....

Page 91

B. Pay attention to the installed direction of gear fig.5-36 5-23.

Page 92: 4. Rear Transmission Case

4. Rear transmission case fig.5-38 5-24.

Page 93

3-1. Disassembly separate the spacer transmission and the rear transmission from each other and then remove the hydraulic cylinder case.Referring to paragraph 7.(1) of section 4. Separation of major components in chapter 2. (1) ring gear,drive pinion,and related parts. Fig.5-39 1.Diff case (l) 2.Dif...

Page 94

A.Dismount diff-case (rh) and diff-case metal(lh) by installing push bolt as shown in fig.5-40 f. Remove the pinion metal(support) tightening bolts and take put drive pinion(19) and related parts as an assembly.The number of installed shims should be written down or memorized for later reference. Fi...

Page 95

(2) pto shaft and related parts. Fig.5-29 1.O-ring 2.Plug(pto) 3.Bolt 4.Ball bearing(hl1) 5.Collar 6.Gear spur/37 7.Snap ring 8.Collar(35x50x2) 9.Ball bearing 10.Shim(b) 11.Shim(0.5) 12.Snap ring 13.Seal oil 14. Cover(plate) 15. Pto shaft 16.Seal a.Remove the rear hitch and the trailer hitch b.Remov...

Page 96

3-2. Inspection fig.5-30 before and after disassembly,inspect each part for the items mentioned below.Parts which deviate from the specified values should be replaced. -wash clean all disassembled parts and check them for wear,damage,deformation,burning ,etc. Defective parts should be corrected or r...

Page 97

When the drive pinion or the ring gear has been replaced, the proper number of shims to be installed should be determined based upon the following procedure: 9.0-11 kgf.M (39.8-69 ft.Lbs) ring gear tightening torque 5.5-7 kgf.M (39.8-69 ft.Lbs) drive pinion metal tightening torque fig.5-34 note: - a...

Page 98

Note: when reassembling the used pinion and ring gear,reinstall the same thickness of shims as was installed before disassembly in each shimming position. H.Backlash adjustment between the drive pinion and the ring pair(fig5-35) i.As the drive pinion and the ring gear make a pair,be sure not to mate...

Page 99

Note: strike the circumference of the ring gear both sides with a copper hammer by turning the ring gear manually,and check to see that the backlash remains unchanged.The backlash should be checked at four points 90 degrees apart to each other. ⅲ.Inspection of the tooth bearing apply an even coat of...

Page 100

(2) pto shaft and related parts. A.Pushing the pto counter gear end into the bearing until the stop on the gear is securely seated against the bearing.The seal should be coated with an adhesive (three bond tb1215) on the circumference before installing. B.Install the oil seal on the pto shaft,paying...

Page 101

5. Shifters and related parts. 5.1. Construction (1)forward and reverse control linkage mechanism(linear speed shifter) (synchromesh transmission version) fig.5-39 1.Metal(shifter,reverse) 2.Bolt(s) 3.Nut 4.Washer spring 5.Washer plain 6. Stay shifter reverse 7.Reamer bolt 8.Washer spring 9.Washer p...

Page 102

Fig.5-40 (2) main change mechanism(main speed shift) (synchromesh transmission version) 1.Fork (1-2 speed) 2.Fork( main shift/synchro) 3.Bolt 4.Pin(a) 5.Bolt 6.Washer 7.Metal(main shift) 8.Shift arm 9.Rod 10.Coupling(40) 11.Set bolt 12.Main shift bracket 13.Rod change speed fig.5-41 fig.5-43 fig.5-4...

Page 103

(3) range shifter (speed range shift) mechanism note: the bottom two tightening bolts should be coated with an adhesive on their threads before being tightened. Fig.5-44 1.Arm(sub shift) 2.Pin taper 3.Fork(sub shift) 4.Shift stay(sub shift) 5.Hook 6.Shifter spring 7.Steel ball 8.Oil seal(d) 9.Washer...

Page 104

(4) front drive change (4 wd shaft) mechanism fig.5-46 1.Boss 2.Spring shifter 3.Steel ball 4.Bolt(s) 5.Packing 7.Shifter arm 8.O-ring 9.Arm(4wd) 10.Spring pin 11.Lever(4wd) 12.Bush(chain guide) 14.Grip 18.E-type stop ring 19.Rod 20.Shim(03x16x26) 22.Split pin 23.Washer 27.Nut(fine) 28.Pin 29.Washer...

Page 105

(5) rear pto shift mechanism fig.5-48 1.O-ring 2.Plug(pto) 3.Bolt 4.Ball bearing(hl1) 5.Collar 6.Gear spur/37 7.Snap ring 8.Collar(35x50x2) 9.Ball bearing 10.Shim(b) 11.Shim(0.5) 12.Snap ring 13.Seal oil 14. Cover(plate) 15. Pto shaft 16.Seal fig.5-49 5-37.

Page 106

(6) rear pto counter shaft mechanism fig.5-50 1.Gear,spur 12 2.Gear spur 14 3. Snap ring(shaft) 4. Ball bearing(6205) 5. Ball bearing(6305) note: - when pushing the r.B.B’s(6305,6205) into the gear ,spur 12,be careful only to push their inner races. - the snap ring c should be securely seated in the...

Page 107

(7) drive pinion sub assembly fig.5-53 1.Metal pinion 2.Taper roller bearing 3.Pinion drive 10 4.Taper roller bearing 5.Gear spur 23t 6.Nut(m30x1.5) 7.Washer(28x46x03) 8.Needle bearing 9.Gear spur 40t 10.Hub(28x51x59) 11.Snap ring (shaft) 12.Gear spur 33t 13.Gear helical 22t 14.Needle bearing 15.Was...

Page 108

(8). Sub change counter shaft note: 1.Apply grease when installing needle bearing 2.Pay attention to the installed direction of gear(spur/30-35) 3.After installation,be sure to slide smoothly 1.Gear range(13x20x29t) 2.Ball bearing(6207) 3.Needle bearing 4.Gear spur(30x35t) 5.Washer(25x46x07) 6. Ball...

Page 109

5-2 precautions for disassembly, inspection,and assembly (1) disassembly when drawing a shifter stay from its shifter,be careful not to lose the steel ball.It can jump out of the shifter. (2) inspection -shifter –disengaging load: main change and sub change:18-22 kgf (40-49lbs) 4wd change:25-29 kgf ...

Page 110

Section 4. Troubleshooting 1. Wheel drive system repair or replace improper disengaged shift lever gears do not engage or disengage replace worn shifters replace broken shifter springs gears disengage by themselves replace wear in width of gears,splined hubs,collars,etc remove the foreign matter gea...

Page 111

2. Pto drive system replace deflected clutch plate wash clean poor pto valve( contamination) replace defective pto valve solenoid pto does not stop when pto switch is shifted to off wash clean poor pto valve (contamination) replace broken clutch piston return spring replace poor switch wash clean cl...

Page 112

5-44 fig.5-57 power train diagram.

Page 113: Chapter 6

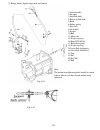

Chapter 6 front axle chapter 6. Front axle(4wd)-----------------------------------------6-1 section 1.General description-----------------------------------6-1 section 2. Specifications---------------------------------------------6-2 section 3.Disassembly,inspection,and reassembly--6-3 1. Center piv...

Page 114: Chapter 6 Front Axle(4Wd)

Chapter 6 front axle(4wd) 1. General description the 4wd front axle is a center pivot type.The front wheel drive mechanism is incorporated as a part of the axle. The front wheel drive power is taken off the rear transmission and transmitted to the differential in the front axle where the power is di...

Page 115: Section 2. Specifications

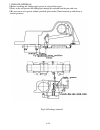

Section 2. Specifications 3°± 1° caster 3°± 1° camber 52˚ Φ75 Φ50 75x80x30 50x55x20 Φ80 front wheel steering angles housing (r) diameter (mm) housing (f) diameter (mm) pivot metal (r) bush (mm) pivot metal (f) bush (mm) pivot metal (r) bore (mm) Φ55 pivot metal (f) bore (mm) front axle 2~6 toe-in (m...

Page 116

Section 3. Disassembly,inspection,and reassembly 1. Center pivot fig.6-3 1.Housing,front axle 2.Oil cap 3.Plug 4.Connector 5.Hose(820) 6.Clamp,(worm/14.5) 8.Metal,pivot(r) 9.Bush(75x80x30) 10.Bolt (m16x40) 11.Washer,spring(m16) 12.O-ring(p) 13.O-ring 14.Spacer (r) 16.Metal pivot(f) 17.Bush(50x55x20)...

Page 117

2) front axle bush bore diameter 1.1.Disassembly 1) dismount the front wheel drive shaft, referring to the pertinent paragraph in chapter 2. 2) remove the right and left tie rods. 3) suspend the front axle bracket with a chain. 4) remove the front metal clamping bolts.The front axle can then be sepa...

Page 118

Fig.6-9 fig.6-7 note: slanted or forced installation of the bush should be avoided,and the bore surface of the bush should not damaged. 3) pay particular attention to the installed direction of thrust collar,that is,with the sharply-edged face turned towards the bevel gear case. 4) when the thrust c...

Page 119

2. Front differential fig.6-10 1.Oil seal 3.Pinion bevel 8t 4.Gear bevel 35t 5.Case front diff 6.Pinion diff (12) 7.Thrust collar 8.Gear diff side (20) 9.Washer thrust 10.Pin spring 11.Shaft diff pinion 12. Pin spring 13.Bearing ball(6212) 14.Snap ring 15.Snap ring( hole) 16.Shim(a) 17.Shim(b) 18.Be...

Page 120

2.1 disassembly snap ring snap ring diff case 6) remove the bearings from the axle housing and the ring gear,and then the ring gear can be separated from the axle housing. 7) remove the straight pin(4) which retains the axle housing. Note: discard the removed straight pin and oil seal and install a ...

Page 121

Reassembly the parts in reverse order of disassembly,following these instructions. 1)each friction surface should be coated with grease in advance. 2)the bevel pinion and the ring gear make a distinct pair after a mesh adjustment performed at the factory. Consequently, when reassembling the pair,be ...

Page 122

Fig.6-16 3) dif case and bevel pinion fig.6-17 note: discard the removed straight pin and oil seal and install a new pin and oil seal when reassembled,because this pin and oil seal is apt to be damaged when removed. 5) install the bearings from the axle housing and the ring gear,and then the ring ge...

Page 123

3. Final case 3-1. Front gear case 1. Fig.6-18 1.Final drive case(a) 2.Gear bevel(9) 3.Rbb(6208) 4.Pin,parallel 5.Bolt(fine) 6.Washer spring 7.Gear bevel(16) 8.Rbb(6207) 11.Final drive case(b)(l) 13.Final drive case(b)(r) 14. Housing seal 15.Seal 16.Rbb(6014) 17.Shaft 18.Gear bevel(12) 19.Rbb(6308) ...

Page 124

3-2. Front gear case 2. Fig.6-19 14.Gear bevel 38 15.Snap ring 17.Seal 18.Gear bevel 11 19.Rbb(6210) 20.Cover wheel shaft 30.O-ring 31.Bolt 34.Shaft wheel 35.Washer(50x60x2) 3.1 disassembly 1) drain oil from the final case by removing the drain plug. 2) remove the tie rod or the tie rod end. 3) remo...

Page 125

Note: the removed cap(90) (black plug) should be discarded and replaced when reassembled. 3.2 inspection 1) wheel shaft cover - inspect mechanical oil seal,o-rings, gears, cases,etc. And replace them if worn or damaged. -measure the diameter the part which makes contact with the wheel shaft,with a m...

Page 126

- wheel shaft cover 1) every snap ring(5) should be seated securely in its groove. 2) be sure the numbers of bevel gear is correct (teeth numbers are 41) 3.3 reassembly reassemble the parts in reverse order of disassembly, following these instructions. 1) apply an adhesive (three bond tb1215) to the...

Page 127

- final drive case and housing - steering cylinder fig.6-28 6-14 1) when installing the shaft,be sure that the gears are not damaged. 2) be sure the differences between the lh and rh shaft. 479mm lh 295mm specified length rh fig.6-30 1) when installing the steering cylinder,be sure that the rods are...

Page 128

Section 4. Trouble shooting adjust 1)lengths of rh and lh tie-rods are different ● different steering angles in both directions tighten correctly to specified torque replace replace lubricate or replace adjust 1)loose fasteners 2)worn or damaged final case bearing 3)worn bush 4)wear or poor movement...

Page 129: Chapter 7

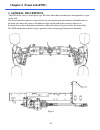

Chapter 7 rear axle and brakes section 1.General description-----------------------------------7-1 section 2. Specifications---------------------------------------------7-2 section 3.Disassembly,inspection,and reassembly--7-3 1.Rear axle housing and brake system--------------------------------------...

Page 130: 1. General Description

Chapter 7. Rear axle and brakes 1. General description the rear axle system is of the central axle type,which contains the final reduction gears, differential gears with diff-lock,and brakes.The power from the engine is transmitted to the right and left wheel pinions through the differential gears,a...

Page 131: Section 2. Specifications

Section 2. Specifications 60.5 mm(2.382 in) total brake thickness 36 ±0.1 mm(1.417 in) metal brake assembly installed thickness 2 on each side number of plates 2.5±0.09 mm(0.098 in) thickness Φ188mm(Φ7.4 in) outer diameter separator plate 4 on each side number of plates paper base lining material 3....

Page 132

Fig.7-2 1.Rear axle housing(l) 2.Rear axle housing (r) 3.Bolt(s) 4.Bolt(s) 5.Bolt(s) 7.Washer spring 10.Wheel shaft 12.Collar(56x65x240) 13.Ball bearing(hl1) 14.Ball bearing(hl1n) 15.Packing wheel shaft metal 16.Wheel gear(helical/54t) 17.Stop ring 18.Metal wheel shaft seal 19.Dif-lock shifter 20.Di...

Page 133

1.1 disassembly 1) release the bolt and nut and remove them. 2) extract the bearing(13) with a puller and remove wheel gear(16) fig.7-4 3) remove the collar and pull out wheel shaft(3) fig.7-6 note: removed oil seal(22) should be replaced with a new one when reassembled 1.2. Inspection 1) friction p...

Page 134

2) metal brake check the pressure plate,and brake rod for abnormality.Replace defective parts.Replace the metal brake whose thickness exceeds the usable limit. 4) wheel shaft check the shaft for abnormalities like wear, damage,etc,and replace a defective one. 5) bearings check them for abnormalities...

Page 135

4) replace the oil seal. Install the bearing,snap ring,and collar into the axle housing,and then press in the oil seal by applying force only to the circumference as shown in the figure( fig.7-11) apply force only to the shaded parts fig.7-11 take care not to deform these portions 5) press in the wh...

Page 136

Section 4. Troubleshooting problem causes countermeasures 1) rear axle noises · worn or damaged bearing · worn gear or wheel shaft replace replace 2) brake system (1)insufficient braking force · insufficient depressing of brake pedals · improper pedal free play · worn friction plates depress pedals ...

Page 137: Chapter 8

Chapter 8 power assisted steering system section 1.General description-----------------------------------8-1 section 2. Specifications---------------------------------------------8-2 2.1 gear pump-------------------------------------------------------------- 8-2 2.2 steering valve-------------------...

Page 138

Chapter 8. Power assisted steering system. Section 1. General description the hydraulics of this power-assisted steering system are actuated by a specially designed steering valve system. Non load reaction valve blocks the l,r cylinder ports in neutral condition and does not transmits the reaction l...

Page 139: Section 2. Specifications

Section 2. Specifications 1) gear pump 180 4.8 500~3500 210 9.0 t290/t300/t330 210 9.0 2810new c.C.W as viewed from shaft rotation direction 500~3500 rated operation speed (rpm) 180 maximum pressure(kgf/㎤) 4.8 delivery (cc/rev) model 2. Power steering valve unit( orbitrol) ubs110b08awd t290/t330/t33...

Page 140: Section 3. Function

Section 3. Function 1.Open center non load reaction 1.Neutral position when the steering control valve is in the neutral position,inlet flow(p) from the priority valve moves the flow selector spool against its spring.This flow is blocked at the control valve control spool.The signal port is connecte...

Page 141

2)right turn when the steering control valve shaft is rotated to the right,the control valve moves off center.This connects the inlet port (p) to one port of each metering pump section and also connects the other port of each metering pump section to the cylinder.The amount that the spool moves off ...

Page 142

3)left turn when the steering control valve shaft is rotated to the left,the control valve spool moves off center.This connects the inlet port(p) to the one port of each metering pump section and also connects the other port of each metering pump section to the cylinder.The amount that the spool shi...

Page 143

4) manual steering when there is no piston pump supply pressure the flow selector is moved to the left by its spring.This connects together the inlet and outlet ports of the lower gyrotor pump and disconnects this pump from the system.When the steering is operated manually,only the upper gyrotor pum...

Page 144

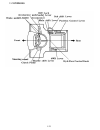

Section 4. Disassembly,inspection,and reassembly 1. Major component of steering valve (orbitrol) 1 19 20 21 17 18 15 16 15 9 10 13 11 25 24 12 23 7 22 8 4 22 5 3 2 fig.8-6 1.Cover bolt(6) 2. Cover bolt(1) 3. End cap(1) 4.Gyrotor(1) 5. Spacer(1) 7.Spacer plate(1) 8.Driver shaft(1) 9.Pump body(1) 10.S...

Page 145

2.Special tools ①torque wrench(torque 5㎏f·m) ------------------1 ②5/12″-12 socket ----------------------------------1 ③“- ”driver(big) ------------------------------------- 1 ④“- ”driver(small) -----------------------------------1 ⑤centering spring installer ------------------------- 1 (p/n : 600057...

Page 146

Step 9. Lubricate and install new o-rings onto check valve seat.Install check ball retainer,check ball and check valve seat into the pump body.Make sure the threaded end of check valve is facing outward.Install and tighten plug to a torque of 11nm(100 lb in). O-ring spacer gyrotor step 11. Remove pl...

Page 147

Note: make sure the centering spring notches locate correctly into the sleeve. Step 13 step 15. Pin install pin into sleeve assembly and install sleeve into the pump body. Note:heat from your hands may expand spool and sleeve assembly,preventing the assembly being installed,do not use force to insta...

Page 148

Install rotor onto drive shaft.Make sure one of the rotor teeth is aligned with the connector mounting face.Lubricate and install a new o- ring into the groove in plate.Align the marks made in step 2, and install stator.Make sure the o-ring groove in stator is facing outwards. Note: pin must remain ...

Page 149

Align the marks made in step 2,and install the end cap.Install and evenly tighten the torx hand screws in two stages to a torque of 17 nm(12 lb ft) then to 25 to 30 nm (19 to 22lb ft) in the sequence shown. Note: the torx head bolts must by dry and clean of oil. Step 23 install a new dust seal into ...

Page 150

Section 5. Troubleshooting counter measures problems and probable causes 1. Steering wheel is very heavy to turn -wash and replenish oil -adjust backlash 4)trouble machine mechanism. (1)poor link work (2)excessive sector gear pre-load -adjust fluid level properly -wash clean or replace 3)trouble int...

Page 151

Counter measures problems and probable causes 3. Free play of steering wheel -adjust fluid level and pressure properly -wash -check column and adjust 2) depressed control set (1) excessive fluid and pressure (2) depressed by foreign material (3) depressed from external when assemble with column -rep...

Page 152

Counter measures problems and probable causes 8.Serious kick-back each side -reassemble (1)poor assemble the gyrotor lower the unit 9. Steering wheel is very heavy to begin turning -replace oil (1)oil density is too high or cool 10. External oil leakage -replace oil seal,slide ring -replace o-ring -...

Page 153: Chapter 9

Chapter 9 hydraulic system section 1. General description --------------------------------9-1 section 2. Specifications -------------------------------------------9-2 section 3. Major component of the hydraulic system ----------------------------------------------------9-3 1.Hydraulic system -------...

Page 154: Chapter 9 Hydraulic System

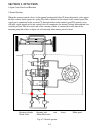

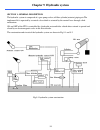

Chapter 9 hydraulic system section 1. General description the hydraulic system is composed of a gear pump,valves,oil filter,cylinder(actuator),piping,etc.The implement lift is operated by a control valve which is actuated by the control lever through a link mechanism. On and off of the pto is contro...

Page 155

Section 2.Specifications t300/t330 2810new piston and cylinder lift(㎏f) (at lower link top end) 1,330 900 control valve cylinder port leaks (㏄/min) (under a pressure of 9800kpa(100 ㎏f/㎠) with gear oil sae 80w 5 (0.305cu.In) 10 main relief valve cracking pressure (㎏f/㎠) 145 120 relief pressure(㎏f/㎠) ...

Page 156

Section 3. Major component of the hydraulic system 1.Hydraulic system fig.9-2 2.O-ring(pg6) 3.Ring-back up 4.Piston 7.Rod 8. Pin spring 9.Iron wire 10.Cylinder head 11.O-ring 12. Bolt 13.Washer spring 14.Lift crank 15.Plug 16.Bolt 17.Flow con.Valve 18.Dust seal 19. O-ring(p) 20.O-ring(p) 21.Knob 22....

Page 157

2.Flow-divider general description this valve is installed to bypass working fluid of a specified pressure from the main circuit into the pto circuit through a fixed orifice.It includes a changeover valve for engaging and disengage the pto clutch by means of a solenoid and a sequential valve for pto...

Page 158

-when the solenoid is switched 「on」 the fluid from the pump flows to port b through port p,the pressure-reducing valve,and the changeover valve. The pressure of the pto clutch circuit and that of passage(2) are the same and will be set as p₂.The pressurized fluid acts on the left-hand side of the va...

Page 159

-when the solenoid is switched 「off」: the fluid in the pto clutch is unloaded to the bank through port b.Consequently pressure p2 at passage(2) becomes zero,whereas the pressure at passage (1) is p1.Then the force imposed upon the left side of spool (p1)overcomes the force imposed upon the right sid...

Page 160

3.Flow-control valve(slow-return check valve) 3.1. General description this valve regulates the lowering speed of the lift by controlling the unloading flow from the lift cylinder to the tank. ①dust seal ②snap ring ③collar ④body ⑤0-ring ⑥adjust screw ⑦back-up ring ⑧0-ring ⑨stop ring ⑩poppet ⑪spring ...

Page 161

3.2 operations 1) down position the fluid from port b pushes up stop ring (9) of poppet(10) until the ring comes into contact with adjust screw(6),as it reaches chamber(r). Consequently,the extent choke (c) is opened is determined by the positioning of adjust screw (6):that is,when adjust screw(6) i...

Page 162

4. Main relief valve 1)general description this valve regulates the maximum pressure in the whole hydraulic circuit.The regulated pressure can be set with the adjust screw. 2) precautions for disassembly and reassembly (1)tightening torque of lock nut (9)5.0~6.0 ㎏f·㎠(36.2~43.4 ft.Lbs) (2)install sea...

Page 163

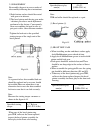

5.Gear pump 1) general description this pump induces fluid from one side and delivers it from the other side,by rotating two gears meshed with each other. The actual delivery is as mentioned below,considering the consequences of fluid temperature and volume efficiency in accordance with revolution s...

Page 164

③remove front and rear pump. Be sure not to be damaged the o-ring or steel ball 4)disassembly note: ①before disassembling the pump,wash the outside clean.In the course of disassembling operation,all disassembled parts should be kept aside in a clean place such as on clean paper or cloth and be handl...

Page 165

3) reassembly ① install the rear pump. ▶install the bushing seal to bushing. ▶install the bushing,drive gear,gear,and bushing to the housing. ▶install the o-ring to the cover. ▶install the cover to the housing. ④tightening sequence and torque of the pump cover tightening bolts. ▶tightening torque: 2...

Page 166

4) inspection and repair (1)check all disassembled parts for damage and wash undamaged or usable parts in clean diesel fuel or kerosene except rubber parts.Inspect all parts referring to these points,and repair or replace defective parts. (2) housing(casing) ①the gear pump is originally designed so ...

Page 167

(4) gear ①with clean working fluid,surfaces are rarely scratched and should be smooth. ②if roughness can be felt by a finger nail,they are darkened,or the shaft diameter is less than 0.03 mm replace the shaft. ③usable shaft diameter is as below fig.9-28 gear shaft (5) oil seal the oil seal prevents ...

Page 168

6. Filter fig. 9-30 filter 1)general description the tractor is equipped with two oil filters: suction filter(1) and line filter(4),for better filtration. 2)specifications -suction filter 4) replacement check the o-rings for damage or deformation and replace defective ones.When installing the filter...

Page 169

Section 4. Remote hydraulic control (optional) -30 ~130℃ operating temperature range( ºc) less than 9 a and b port leak(cc/min) ①under a load of 100kgf/㎠ ② oil temperature:50 ºc 145 system pressure (kgf/㎠)(at 26 ℓ/min) donax td or rpm thf500 recommended fluid 400 maximum pressure(kgf/㎠) 26 maximum f...

Page 170

Section 5. Hydraulic system 1.Hydraulic cylinder 1)hydraulic system must be washed clean,and care must be taken not to let any foreign substances. 2)the o-ring and back-up ring should be coated with grease ahead of time.Install with care so as not to damage them. 3)install the piston from the cylind...

Page 171

Fig.9-34.Lift arm 9)adjust the angle of the roll bush from horizontal is 30° 10)apply grease to the roll bush. 11)apply grease to the cylinder case and lift arm face which touched with each other. 12) when assemble the lift crank on the lift shaft, mesh their splines using the alignment marks which ...

Page 172

2. Linkage (internal) 1)before installing the linkage,apply grease to relayed drive parts. 2)drive in the roll pin into the linkage pin through the rod and lock the pin with wire. 3)be sure not to over operate within specified spool stroke(12mm between up and down at neutral position) fig.9-36 linka...

Page 173

3.Linkage (external) fig. 9-37 linkage(external) 9-19.

Page 174

4. Main control valve 4.1 general description this valve controls the lifting and lowering operation of the hydraulic cylinder.It has especially been developed to control the working height of the implement.It consists of a feed back valve;direction control valve,flow-control unloading valve,and hol...

Page 175

4.3 disassembly and inspection 4.4 operation 1)neutral position in the neutral position,convensater spool(711) in open(unload),main spool(311) and check valve(511,531) is closed and its pressure is enough to rest the force of lift arm.. 9-21 fig.9-43 circuit diagram in the neutral position.

Page 176

2) lifting position as main spool is moved to lifting position pump pressure is increased and open the check valve(511,531).The lift arm moved to lifting position by flowing to cylinder and operate piston. Circuit diagram in the lifting position fig.9-44 9-22.

Page 177

2) lowering position if main spool moved to lower positions,pump is unloading and the lift arm moved to lower position by flowing to tank in the cylinder fig.9-45 9-23.

Page 178

5. Servicing instructions. 1) required tools -6mm set screw wrench and torque wrench -19mm spanner and torque wrench -22mm spanner and screw wrench -conventional screw driver[3mm(0.12 in) in blade width] -plastic rod [Ø10mm(Ø0.394 in)] oil stone,cleanser,tweezers,etc. 2) tightening torque note: the ...

Page 179

Put the poppet into hole b as shown in the figure and make sure that the poppet slides smoothly.Then put the spring in and tighten the plug,on which the o-ring must be installed,to the specified torque. -unloading valve(1) and related parts. Install the spool into hole c(fig.9-19) in the correct dir...

Page 180

Section 6. Troubleshooting 14)broken slow-return check valve disassemble and wash spool clean. If it is damaged seriously,replace it as an assembly.If damage is minor,correct surface with oil stone and finish by lapping. 12)broken flow divider (stuck sequential valve spool) inspect cylinder and valv...

Page 181

Inspect and adjust 1)excessively high working pressure 7.Fluid overheating maintain specified level by replenishing 3)insufficient fluid replace with fluid of adequate viscosity. 2)too high or low viscosity of working fluid. Inspect,readjust,repair,or replace link mechanism if necessary. 2) poor lin...

Page 182

Replace broken or fatigues oil seal or o-ring 10.Oil leaks outside pump inspect and replace defective parts. 5) broken or worn pump parts 8.Pump noise inspect and reset pressure 2) port b regulated pressure is too slow disassemble and wash clean. 1) clogged fixed orifice of flow divider 13.Independe...

Page 183

Refer to paragraph for "fluid overheating" 5) overheated fluid 14.Independent pto clutch is too quick in engaging clear clogged with compressed air or with a sharp point. 8) clogged orifice in pressure- reducing valve spool lap after correcting flaws with oil stone 7) stuck pressure-reducing valve s...

Page 184

Chapter 10 electrical accessory and instruments section 1. General description -----------------------------10-1 section 2. Specifications --------------------------------------- 10-1 section 3. Battery----------------------------------------------------10-2 1.1. Inspection--------------------------...

Page 185

Chapter 10 electrical accessory and instruments section 1. General description the basic electrical system of tractors consists of the engine cranking system ,battery charging system,lighting system,meters,switches,etc. For further information concerning the engine cranking equipment and battery cha...

Page 186

Section 3. Battery 1.Inspection 1.1 inspection of electrolyte level as the battery repeats charging and discharging during operation.The water content in the electrolyte gradually evaporates, and as a result,the level should be inspected at the specific level;replenish with distilled water. Fig.10-1...

Page 187

1.4 battery testing charts step 1. Visual inspection check for obvious damage such as cracked or broken case that shows loss of electrolyte,thermal damage,etc. Obvious damage no obvious damage replace battery check electrolyte level electrolyte level is below top of plates in one or more cells elect...

Page 188

Step 3 load test 1.Connect voltmeter and ampere load equal to ½ the cold cranking amperes(18℃) rating of the battery for 15 seconds. 2. Observe voltage at 15 seconds with load on.Disconnect load 3.Place thermometer in one cell to take temperature of electrolyte. 4.Refer to voltage table voltage belo...

Page 189

Section 4. Meters and switches 1.Meters 1.1 removal a. Disconnect the cable from the negative post. B. Remove the philips screw which hold the meter panel and lift up the panel assembly a little the generated pulses are converted into voltage output through a converter.Then the voltage is divided in...

Page 190

B.Inspection -fuel meter connect the fuel gauge to form a circuit with the resisters as shown fig.10-6 and check to see if the gauge pointer swings to each position: f.1/2 and e by changing the resistance value. If it does not,change the gauge assembly. Note: 1) figures in parentheses are reference ...

Page 191

(2) inspection a.The main switch circuit,switching positions, and terminals are as shown in the figures. Check the continuity across respective terminals referring to the switch circuit diagram. Replace a defective switch as an assembly fig.10-12 (3) release the ring nut with a conventional screw dr...

Page 192

-lighting 4. Stop light switch off ** 2 2 1 t b1* 1 ● ● ● 1 ● rg (red/ green) ● r (red) ● 2 ry (red/ yellow) rw (red/ white) color code fig.10-15 stop light switch * 1 :terminals ** 2 : switching positions 8mm total stroke 3 ±0.5mm stroke to on 10~20a (dc12v) capacity -flasher ● ● 1** 2 l r b2* 1 of...

Page 193

Each fuse is connected as follows fig.10-18 the circuit has 8 blade type fuses in its wiring circuit.When a fuse has blown replace it with one of the same value. Fig.10-19 note: using a large capacity fuse or wire burn out the wiring system. Use fuse tongs to replace fuses 10-9.

Page 194

8.Trailer socket a hella’s 7-pin trailer socket is equipped as a standard equipment.Lamp on a trailer can be operated through the socket. Fig.10-23 5 avss 0.85 gy turn signal (rh) 5 4 avss 0.85 wl stop light 4 3 avss 0.85 gb turn signal (lh) 3 1 avss 2.0 b earth 1 7 avss 0.85 wg reserve light 7 6 av...

Page 195

Section 5. Earthing point 1 3 fig.10-24 a 1) front axle bracket (rh) earthed at upper upper tapped hole in the axle bracket a. Fig.10-26 3) right surface of the frame comp.Where the battery bracket is to be installed. Fig.10-25 2) contact surfaces of the axle bracket and engine where they tightened ...

Page 196

A b fig.10-27 hood frame 10-12.

Page 197

Section 6. Wiring diagram 10-13.

Page 198

Section 7. Troubleshooting important: whenever effecting a repair the reason for the cause of the problem must be investigated and corrected to avoid repeating failure. The following table lists problems and their possible causes with the recommended remedial action 1. Lighting system inspect and re...

Page 199

Inspect,clean,and tighten connections or renew wiring faulty wiring or connections check and renew defective flasher unit check and renew faulty bulb turn signal pilot light is inoperative inspect,clean,and tighten connections or renew wiring poor ground connection or damage wiring inspect,clean,and...

Page 200

Check and renew defective horn check and renew defective horn switch inspect circuit,tighten connections,or renew wiring loose or broken wires of connections inspect and renew.Check circuit before re- connecting power burnt out fuse inoperative horn countermeasures causes problems 3.Glow system chec...

Page 201

10-17 check and renew defective controller check and renew defective push switch inspect ,adjust neutral faulty reverse or forward pedal inspect and try to push brake pedal defective master brake pedal check circuit connections and repair or renew faulty wiring excessive resistance in starter circui...

Page 202

Inspect circuit,clean,and tighten connections.Repair or renew faulty wiring faulty external charging circuit warning light flashes intermittently inspect,repair,or renew faulty rotor,slip rings,or brushes check and renew defective diodes check and adjust tension or renew loose or worn alternator dri...

Page 203: -------------------

Chapter 11. Service standards and other information section 1. Service standards ------------------- 11-1 1.Engine accessories -------------------------------------- 11-1 2.Clutch damper -------------------------------------------------- 11-2 3.Transmission ------------------------------------------...

Page 204

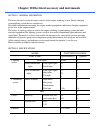

Chapter 11. Service standards and other information section 1. Service standards. Service instructions and remarks usable limits standard value for reassembly nominal dimensions part names and inspection items 1.Engine accessories(chapter 3) 1) radiator whole cooling system 12.7 ℓ 0.9 ±0.15㎏f·㎠ radi...

Page 205

Service instructions and remarks usable limits standard value for reassembly nominal dimensions part names and inspection items 2. Main clutch (chapter 4) adjust with the clutch rod (turn buckle) 20 ~ 30 ㎜ free play of clutch pedal 97 ㎜ total stroke 13 no.Of teeth spline hub 0.05 ㎜ or less clutch co...

Page 206

Service instructions and remarks usable limits standard value for reassembly nominal dimensions part names and inspection items 3. Transmission (chapter 5) 1) front and spacer transmissions measure at the shifter 4 - 6 ㎏f front wheel drive synchronizer assembly measure at the shifter 8 - 10 ㎏f pto s...

Page 207

Service instructions and remarks usable limits standard value for reassembly nominal dimensions part names and inspection items 2) rear transmission (1) drive pinion & ring gear 0.1 ~ 0.2 ㎜ 0.08 - 0.11 ㎏·m 0.5 ㎜ backlash starting torque available shims on drive pinion metal(support) shim a : 0.1 ㎜ s...

Page 208

Service instructions and remarks usable limits standard value for reassembly nominal dimensions part names and inspection items 4.Front axle (chapter 6) 1) front drive axle (4wd) shim:0.1, 0.2 ㎜ 0.1 ~ 0.3 ㎜ thrust play drive pinion/ring gear backlash diffe rent ial thrust play play in bush rear cent...

Page 209

Service instructions and remarks usable limits standard value for reassembly nominal dimensions part names and inspection items 5.Rear axle (chapter 7) 1) disk brake 3.4 ㎜ 3.4 ± 0.1 ㎜ friction plate thickness (wear and carbonizer ) 2)separate plate 2.5 ㎜ 2.5 ± 0.09 ㎜ thickness (wear and damage) 3) b...

Page 210

Service instructions and remarks usable limits standard value for reassembly nominal dimensions part names and inspection items 2) dynamic lift 2000 ㎏f·㎠ t290/t300/2810 3) cylinder case bush wear limit: 0.2 ㎜ Ø 60.2 ㎜ Ø 60 ㎜ 60 ×65 ×50 right side wear limit: 0.2 ㎜ Ø 55.2 ㎜ Ø 55 ㎜ 55 ×60 ×50 left sid...

Page 211

Service instructions and remarks usable limits standard value for reassembly nominal dimensions part names and inspection items 6) slow return check valve(flow control valve) 1 ㏄/min.At a pressure of 90 ㎏f/㎠ cylinder port leaks gear oil sae #80 ~ #90 at a temperature of 50 ± 5℃ 280 ㎏f/㎠ maximum pres...

Page 212

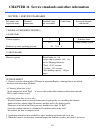

8.Electrical equipment 1)battery (1)battery terminal post charge or replace 10.8 v 12 v - terminal voltage repair or replace - - - corrosion (2) battery cells replace battery - - - damage (3) electrolite replace battery - - - cloudy fluid correct - 1.24 - 1.26 - specific gravity as specified on case...

Page 213

(3) turn signal switch replace a defective switch assembly. ●turn signal switch ● ● ● ● color coding 1 off 2 (4) horn switch replace a defective switch assembly. ● horn switch ● ● r gw off on color coding (5) parking and light switch replace a defective switch assembly. Continuity across each termin...

Page 214

(9) hazard warning switch replace a defective switch assembly. Continuity across each terminal ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ on 11 10 9 7 6 4 3 1 2 5 8 11 off 11-11.

Page 215

Section 2.Tightening and starting torque specified for major parts 1. T290/t300/t330/2810new 16.0 ~ 18.0 9.0 ~ 11.0 13.0 ~ 15.0 9.0 ~ 11.0 2.0 ~ 2.4 5.5 ~ 7.0 16.0 ~ 18.0 1.3 ~ 1.8 1.3 ~ 1.8 1.3 ~ 1.8 m 16 (7t) m 12 (7t) m 14 (7t) m 12 (7t) m 18 (7t) m 110 (7t) m 16 (7t) m 8 m 8 m 8 1)front axle hou...

Page 216

Section 3. Conversion tables mm in mm in mm in mm in 1 0.0394 26 1.0236 51 2.0079 76 2.9921 2 0.0787 27 1.0630 52 2.0472 77 3.0315 3 0.1181 28 1.1024 53 2.0866 78 3.0709 4 0.1575 29 1.1417 54 2.1260 79 3.1102 5 0.1969 30 1.1811 55 2.1654 80 3.1496 6 0.2362 31 1.2205 56 2.2047 81 3.1890 7 0.2756 32 1...

Page 217

Ft 0 1 2 3 4 5 6 7 8 9 ft m m m m m m m m m m 0 0.0000 0.3050 0.6100 0.9150 1.2200 1.5250 1.8300 2.1350 2.4400 2.7450 0 10 8.0532 3.3550 3.6600 3.9650 4.2700 4.5750 4.8800 5.1850 5.4900 5.7950 10 20 21.1097 6.4050 6.7100 7.0150 7.3200 7.6250 7.9300 8.2350 8.5400 8.8450 20 30 34.1661 9.4550 9.7600 10...

Page 218

In2 0 1 2 3 4 5 6 7 8 9 in2 cm2 cm2 cm2 cm2 cm2 cm2 cm2 cm2 cm2 cm2 0 0.000 6.462 12.924 19.386 25.848 32.310 38.772 45.234 51.696 58.158 0 10 64.620 71.082 77.544 84.006 90.468 96.930 103.392 109.854 116.316 122.778 10 20 129.240 135.702 142.164 148.626 155.088 161.550 168.012 174.474 180.936 187.3...

Page 219

Us gal 0 1 2 3 4 5 6 7 8 9 us gal liters liters liters liters liters liters liters liters liters liters 0 0.000 3.785 7.571 11.356 15.142 18.927 22.712 26.498 30.283 34.069 0 10 37.854 41.639 45.425 49.210 52.996 56.781 60.566 64.352 68.137 71.923 10 20 75.708 79.493 83.279 87.064 90.850 94.635 98.4...

Page 220

Lbs 0 1 2 3 4 5 6 7 8 9 lbs kg kg kg kg kg kg kg kg kg kg 0 0.000 0.454 0.907 1.361 1.814 2.268 2.722 3.175 3.629 4.082 0 10 4.536 4.990 5.443 5.897 6.350 6.804 7.258 7.711 8.165 8.618 10 20 9.072 9.526 9.979 10.433 10.886 11.340 11.794 12.247 12.701 13.154 20 30 13.608 14.062 14.515 14.969 15.422 1...

Page 221

B/in2(psi) 0 1 2 3 4 5 6 7 8 9 lb/in2(psi) kg/cm2 kg/cm2 kg/cm2 kg/cm2 kg/cm2 kg/cm2 kg/cm2 kg/cm2 kg/cm2 kg/cm2 0 0.0000 0.0703 0.1406 0.2109 0.2812 0.3516 0.4219 0.4922 0.5625 0.6328 0 10 0.7031 0.7734 0.8437 0.9140 0.9843 1.0547 1.1250 1.1953 1.2656 1.3359 10 20 1.4062 1.4765 1.5468 1.6171 1.6874...

Page 222

0 1 2 3 4 5 6 7 8 9 ft lbs kg-m kg-m kg-m kg-m kg-m kg-m kg-m kg-m kg-m kg-m 0.138 0.276 0.414 0.552 0.690 0.828 0.966 1.104 1.242 10 1.380 1.518 1.656 1.794 1.932 2.070 2.208 2.346 2.484 2.622 10 20 2.760 2.898 3.036 3.174 3.312 3.450 3.588 3.726 3.864 4.002 20 30 4.140 4.278 4.416 4.554 4.692 4.83...

Page 223

Temperature ˚f ˚c ˚f ˚c ˚c ˚f ˚c ˚f -20 -28.9 95 35.0 -30 -22.0 36 96.8 -15 -26.1 100 37.8 -28 -18.4 38 100.4 -10 -23.3 105 40.6 -26 -14.8 40 104.0 -5 -20.6 110 43.3 -24 -11.2 42 107.6 0 -17.8 115 46.1 -22 -7.6 44 111.2 1 -17.2 120 48.9 -20 -4.0 46 114.8 2 -16.7 125 51.7 -18 -0.4 48 118.4 3 -16.1 13...