- DL manuals

- Mahindra

- Front End Loaders

- 2816 HST

- Operator's Manual

Mahindra 2816 HST Operator's Manual

Summary of 2816 HST

Page 1

Contactus@almats.Com click here to go on index operator manual 2816 hst '16' series main menu.

Page 2

16 series, model - 2816 hst this manual has been prepared to assist you in following the correct procedure for break-in, operation and maintenance of your new mahindra tractor. Your tractor has been designed and built to give maximum performance, with good fuel economy and ease of operation under a ...

Page 3: Mitsubishi

16 series, model - 2816 hst mitsubishi heavy industries, ltd. General machinery & special vehicle headquarters mitsubishi diesel engine off-road diesel engine emission control system warranty statement.

Page 4: Off-Road Diesel Engine

16 series, model - 2816 hst a off-road diesel engine emission control system warranty statement emission related system defect warranty manufacturer statement mitsubishi heavy industries, ltd. (mhi) will give a warranty condition, required by the u.S. Environmental protection agency(epa) and the cal...

Page 5

16 series, model - 2816 hst manufacturer’s emission control warranty coverage applicable only to engines purchased in u.S.A. In 1997 and thereafter which are used in u.Sa. Emission control systems warranty coverage. The small off-road engines are warranted as to emission control parts defects for a ...

Page 6

16 series, model - 2816 hst fuel injection system • fuel injection pump • fuel injectors inlet system • intake manifold exhaust system • exhaust manifold turbocharger system • turbocharger (if equipped) miscellaneous items used in above systems • cylinder head gasket • valve stem seal length of cove...

Page 7

16 series, model - 2816 hst which are not original oems parts or because of abuse, neglect or improper maintenance as set forth in the oems engine warranty policy. Oems is not liable to cover failures of warranted parts caused by the use of add-on, non-original, or modified parts. Maintenance any wa...

Page 8

16 series, model - 2816 hst introduction this instruction manual contains information on the operation, lubrication and maintenance of your tractor. The information contained is compre- hensive and essential, and is designed to assist you, even if un- experienced, in utilizing your tractor. How well...

Page 9

16 series, model - 2816 hst write your machine model number and serial numbers of major components on the lines provided. If needed, give these numbers to your dealer when you need parts or information for your machine. 1. Tractor model number _______________________________ 2. Tractor serial number...

Page 10

16 series, model - 2816 hst safety/decals ....................................................................................... 1-19 specifications ..................................................................................... 20-24 instruments/controls ........................................

Page 11

16 series, model - 2816 hst 1 safety precautions remember: “safety” is only a word until it is put in to practice improper handling of the tractor could lead to an accident. Prior to the operation of the tractor, be sure to read this manual carefully and have a thorough understanding of all of the c...

Page 12

16 series, model - 2816 hst 2 3. Cover the pto shaft with a guard when not using. 4. Be sure to engage the brake and lower any attachment or implement before disassembling any part. 5. Never adjust or service the tractor when it is in motion or while the engine is running. Always adjust the brake or...

Page 13

16 series, model - 2816 hst 3 9. Before starting any work on electrical equipment or work that may cause you to touch the electrical part accidentally, first disconnect the battery cables. Never remove the rubber cap cover at the positive terminal of the battery cable end. Before connecting the batt...

Page 14

16 series, model - 2816 hst 4 c. Operation of the tractor before driving the tractor, fol- low these rules: c-1. Before starting and driving the tractor operate the tractor only when seated properly in operator’s seat and keep a firm grip on the steering wheel at all times. Never attempt to perform ...

Page 15

16 series, model - 2816 hst slow down when operating the tractor on rough round. Never attempt to jump on or off a moving tractor. When starting the tractor, operating any attachment or engaging the pto make sure that no one is in the way, especially children. When starting the engine in an enclosed...

Page 16

16 series, model - 2816 hst 6 c-3. Travelling on roads and streets for travelling on roads and streets, be sure to lock both brake pedals together before driving to prevent either brake from acting independently. C-4. Steering and turning the tractor slow down your tractor and disengage the differen...

Page 17

16 series, model - 2816 hst when operating the tractor on either a steep slope or flat ground, be sure not to suddenly steer, brake, clutch or operate attachments. Do not operate the tractor at the edge of cliff or steep slope. Be particularly careful right after the rain when soil is soft and may g...

Page 18

16 series, model - 2816 hst 8 decals important: install new decals if the old decals are destroyed, lost, painted over or can not be read. When parts are replaced that have decals, make sure you install a new decal with each new part. Note: new decals are available from your dealer. Batteries contai...

Page 19

16 series, model - 2816 hst 9 safety/decals_______________________________________________________ rotating machine parts stay clear, keep shields installed to help protect from clothing entanglement and injury. Warning 321-3710

Page 20

16 series, model - 2816 hst 10 roll over protective structure (rops) rops is foldable so that the tractor can be operated in places such as orchards where the height is restricted. See folding the rops in this manual. Normal operating position for normal operation, including transport, always use th...

Page 21

16 series, model - 2816 hst 11 low clearance positions for low clearance operation, such as operating in buildings, orchards or vineyards, the rops can be lowered and secured in the down position. No rollover protection is provided in the lowered positions and the seat belt should not be fastened. W...

Page 22

16 series, model - 2816 hst 12 rops is a special safety unit. After an accident the rops must be replaced so that you will get the same protection as a new rops. Rops, the seat, the seat belts and all the mounting, accessories and wiring inside the operators protective area must be carefully checked...

Page 23

16 series, model - 2816 hst 13 to fold the rops, put the tractor on level ground, put the range shift lever in the l position, apply the park brake and stop the engine. Folding the rops rops bar (normal operating position) important: do not fold the rops with a sunshade installed. Remove the lock pi...

Page 24

16 series, model - 2816 hst 14 step 10 step 7 step 8 position pin low clearance positions position pin low clearance positions rops bar lock pin lock pin rops bar lock nut to the low position tighten the jam nut on the lock bolts to a torque of 33 to 40 lb ft (44 to 54 nm). While holding the rops ba...

Page 25

16 series, model - 2816 hst 15 remove the lock nuts. Remove the lock pins. Securing the rops in the upright position lock pin lock nut position pin lock bolt jam nut rops bar (normal operating position) lock pin lock nut step 2 step 1 for normal operation, the rops must be in the secured upright pos...

Page 26

16 series, model - 2816 hst 16 carefully raise the rops bar to the upright position. While holding the rops bar, carefully remove the position pins. Install the position pins. If both pins can be installed, continue to step 10. Step 6 if the position pins cannot be installed, carefully lower the rop...

Page 27

16 series, model - 2816 hst 17 lock bolt position pin jam nut rops bar (normal operating position) lock pin lock nut step 9 to the upright position rops bar carefully move the rops bar to the upright position. Install the position pins. Align the holes of the position pins and rops brackets so that ...

Page 28

16 series, model - 2816 hst 18 step 15 for tractors with a sunshade, step 12, step 13 and step 14 must be followed for using the lock bolts. On tractors without a sunshade, it is recommended that step 12, step 13 and step 14 be used, however, if rops is folded frequently for low clearance tractor op...

Page 29

16 series, model - 2816 hst 19 rops bar (normal operating position) lock pin lock nut position pin jam nut lock nut step 18 step 17 install the lock pins. Install the lock nuts. Tighten the nuts to a torque of 33 to 40 lb ft (44 to 54 nm). Note: the lock nut installation cab be omitted for operator ...

Page 30: Diesel Engine

16 series, model - 2816 hst 20 general diesel engine type ................................................... Three cylinder, four stroke cycle, valve in cylinder head, cross flow porting firing order ....................................................................................... 1 – 3 – 2 b...

Page 31: Air Intake System

16 series, model - 2816 hst 21 cooling system type .................................................. Pressure system, thermostat con- trolled bypass, impeller type pump radiator .............................................................. Corrugated and louver fin type thermostat ...................

Page 32

16 series, model - 2816 hst 22 specifications_______________________________________________________ clutch type, diameter hydrostatic drive ........................... Dry, single disc, diaphragm type, 215 mm (8.46 inch) operation .......................................................................

Page 33

16 series, model - 2816 hst 23 mid power takeoff (pto) pto type hydrostatic drive ..................................................................... Live pto location ....................................................... At the bottom of transmission rotation ......................................

Page 34

16 series, model - 2816 hst 24 overall length (to end of lower link) overall width (to end of tire) height (to top of rops) wheelbase ground clearance turning radius (with brake assistance) weight 2920mm 1380mm 2140mm 1650mm 330mm 2400mm 1075kg 115.0inch 54.3inch 84.3inch 65.0inch 13.0inch 94.5inch ...

Page 35

16 series, model - 2816 hst 25 instruments/controls _____________________________________________ instruments and indicators 1. Tachometer and hourmeter – the tachometer shows the engine speed in revolutions per minute (rpm). A symbol on the face indicates the correct power takeoff (pto) operating s...

Page 36

16 series, model - 2816 hst 2. Engine coolant temperature gauge – the gauge indicates the coolant temperature when the starter key switch is in the on posi- tion. The gauge has a yellow area, green area and red area: the pointer is in this area when the engine is cool before and immediately after st...

Page 37

16 series, model - 2816 hst 27 5. Engine glow plug indicator – this signal indicates the cor- rect functioning of the glow plug circuit. When the glow plugs have reached the correct temperature for engine starting, the glow plug indicator lamp will be put out. 6. Charge indicator – the charge indica...

Page 38

16 series, model - 2816 hst 28 operating controls control switches position– (off) position– (heat) & (on) position – (start) turn the key fully clockwise against the force of the spring in the switch. The starter motor will turn the engine. Release the key immediately when engine starts. Note: to p...

Page 39

16 series, model - 2816 hst 29 2. Engine speed control lever – move the engine speed control lever to the rear to increase engine speed. Move the engine speed control lever forward to decrease engine speed. 3. Lamp switch – three position switch as follows: – all lamps are off. (turn signal and flas...

Page 40

16 series, model - 2816 hst 30 6. Turn signal switch – to indicate that you are going to turn the tractor to the right, move the turn signal switch up. To indicate that you are going to turn the tractor to the left, move the turn signal switch down. Center position is off. 7. Horn button (optional) ...

Page 41

16 series, model - 2816 hst control levers and pedals (hydrostatic drive) 1. Accelerator pedal (gear drive only) – use this pedal when operating the tractor on the road. Push the pedal down to increase engine speed. Note: the engine speed control level must be set to give the slowest engine speed wh...

Page 42

16 series, model - 2816 hst 32 caution: brake pedals must be locked together for road travel. This will insure uniform brake application and maximum stopping ability. 3. Brake pedals — the brake pedals when locked together, provides braking to both rear wheels for stop- ping the tractor. When the br...

Page 43

16 series, model - 2816 hst 33 (hydrostatic drive) 5. Park brake lever – the park brake must be on to prevent movement of the tractor during stationary power takeoff work or when the tractor is parked. To en- gage the park brake, lock the brake pedals together, push down on the brake pedals and move...

Page 44

16 series, model - 2816 hst 34 7. Clutch pedal — the clutch must be disengaged when starting the engine, stopping the tractor, storing the tractor and operating the following levers, gear shift lever, range lever, rear pto lever, mid pto lever, mfd lever, creep lever. 7-1. Single clutch pedal has tw...

Page 45

16 series, model - 2816 hst 35 (hydrostatic drive) instruments/controls _____________________________________________.

Page 46

16 series, model - 2816 hst 36 note: 1. The rear and mid pto shaft can be operated at the same time. 2. When not using the mid pto shaft, cover the shaft with the mid pto cover. A 2. Rear pto control lever – move the lever forward to engage the rear pto. Move the lever rearward to disen- gage the re...

Page 47

16 series, model - 2816 hst 37 (hydrostatic drive) 4. Hitch control lever – use this lever to control the position of the hitch. Move the lever forward to lower the hitch to the required depth. Move the lever to the rear to raise the hitch to the required height. Instruments/controls _______________...

Page 48

16 series, model - 2816 hst 38 5. Draft control lever (if equipped) – use draft control with soil engaging implements to main- tain a constant load on the tractor through variable soil conditions. For light load operation, move the lever to the rear. For heavy load opera- tion, move the lever forwar...

Page 49

16 series, model - 2816 hst 39 (hydrostatic drive) 1. Differential lock pedal – push the pedal down to engage the differential lock. A spring inside the differential lock will push it out of engagement when pedal is released. Hydrostatic drive instruments/controls ___________________________________...

Page 50

16 series, model - 2816 hst 40 note: when engaging the differential lock, push the clutch pedal down or bring speed ratio control pedal to neutral, to stop the wheels that are rotating, then push the differential lock pedal. Do not operate the differential lock pedal while the wheels are rotating. 2...

Page 51

16 series, model - 2816 hst 41 seat adjusting lever steering column tilt lever operators seat the seat can be adjusted in 5 fore/aft positions by the lever located under the rh side of the seat. The seat is adjustable fore and aft by moving a lever. 1. Move the lever upward. 2. Move the seat rearwar...

Page 52

16 series, model - 2816 hst 42 before starting the engine before starting your tractor for the first time and before each operating period after that, make these checks: 1. Make sure all persons who operate or do maintenance on the tractor understand that clean fuel is important. 2. Check all lubric...

Page 53

16 series, model - 2816 hst 43 if run-in instructions for a new engine are not followed, you can cause damage to piston rings and cylinder walls. Load never operate an engine immediately under full load. Allow the engine to warm up before operating it at full load. Run-in the engine carefully as sho...

Page 54

16 series, model - 2816 hst 44 open fuel shut-off valve make sure the fuel shut-off valve is open. The valve is located at the bottom rh side of the fuel tank. Normal starting procedure important: it is very important that enough lubricant reaches the engine parts before operating the engine at rate...

Page 55

16 series, model - 2816 hst 45 turn the starter key switch to the heat & on position. Wait until the glow plug indicator lamp is put out. (approximately 1 to 3 seconds.) put the range shift lever in the n (engine start) slot. Put the rear pto and mid pto control levers in the off (engine start) slot...

Page 56

16 series, model - 2816 hst 46 turn key switch to start position until engine starts, but no more than 10 seconds, then release the key. Run engine for two minutes at 1500 rpm. Step 8 when the engine starts, check the oil pressure indicator and charge indicator. If the indicators stay on, stop the e...

Page 57

16 series, model - 2816 hst 47 3. Do not use the starter motor for more than 10 seconds without stopping. Wait one minute between starts so the starter motor can cool. 4. If the engine stops when operating with a load, immediately start the engine again to prevent overheating caused by stopping the ...

Page 58

16 series, model - 2816 hst 48 step1 stop step3 off step 2 mid pto lever rear pto lever stopping the engine important: when stopping the engine after operating under heavy load, run the engine at 1500 rpm for a short period of time. This will allow the engine temperature to decrease gradually. Put t...

Page 59

16 series, model - 2816 hst 49 cold temperature operation to start and operate your tractor during cold ambient temperatures, use these procedures : 1. Battery – must have a full charge. 2. Fuel – must be clean and with no water. See fuel specifications in this manual. 3. Engine oil – must have the ...

Page 60

16 series, model - 2816 hst 50 important: during cold ambient temperatures, never run the engine at low idle speed for long periods of time. During cold ambient temperatures, the engine will not heat to or keep the rated operating temperature at slow engine speeds. Slow engine speeds in cold tempera...

Page 61

16 series, model - 2816 hst 51 when towing a tractor, follow these rules: 1. Never pull the tractor faster than a ground speed of 16 km/h (10 mph). 2. Make sure all controls are in the neutral or off position. 3. Because of a possible loss of steering and brakes when the tractor engine is not runnin...

Page 62

16 series, model - 2816 hst 52 hydrostatic drive transmission the hydrostatic drive transmission has a forward/reverse hydrostatic sec- tion and a three-speed range section. This arrangement gives three forward and three reverse speeds range. Transmission operation 1. Push the clutch pedal fully and...

Page 63

16 series, model - 2816 hst 53 your tractor has a differential lock that will make both rear wheels turn at the same speed. The differential lock prevents loss of power when one wheel does not have traction but the other wheel does have traction. It also provides a straight in line steering aid when...

Page 64

16 series, model - 2816 hst 54 rear pto control lever clutch pedal rear pto shaft power takeoff (pto) rear pto the rear pto is a 540 rpm with a 34.9 mm (1 3/8 inch) diameter 6 spline output shaft. Engage the rear pto as follows: 1. Push the clutch pedal fully. 2. Move the pto control lever forward o...

Page 65

16 series, model - 2816 hst hydrostatic drive left side of the transmission your tractor has a differential lock that will make both rear wheels turn at the same speed. The differential lock prevents loss of power when one wheel does not have traction but the other wheel does have traction. It also ...

Page 66

16 series, model - 2816 hst 56 rear pto control lever clutch pedal rear pto shaft power takeoff (pto) pto driven machinery can cause serious injury or death, usually due to wrapped clothing. When required by the job to be in the drive shaft area, stay clear of rotating parts. Before working on the d...

Page 67

16 series, model - 2816 hst 57 mid pto lever clutch pedal mid pto shaft the following table shows the required engine speed to get the required mid pto output shaft speed. Mid pto the mid pto has a 25.4 mm (1 inch) diameter 15 spline output shaft. Engage the mid pto as follows: 1. Push the clutch pe...

Page 68

16 series, model - 2816 hst 58 rear pto guard mid pto cover power takeoff guards all tractors have a safety guard for the rear pto shaft and a safety cover for the mid pto shaft m126a operating instructions _______________________________________________ whenever a pto driven machine is in operation...

Page 69

16 series, model - 2816 hst 59 pto operating safety for the safe operation of the pto, follow these safe operating proce- dures. Three point hitch connecting implements 1. Connect the implement to the hitch. See three point hitch system in this manual. 2. Connect the implement driveline to the tract...

Page 70

16 series, model - 2816 hst 60 rear upset can result if pulling from wrong location on tractor. Hitch only to the drawbar. Use 3 point hitch only with the implements de- signed for its use - not as a drawbar. M119 try to balance the load primarily on the implement wheels - as in loading a trailer or...

Page 71

16 series, model - 2816 hst 61 the lamp switch has three positions. Turn the switch clockwise to illuminate the headlamp, rear red lamp, and instrument panel lamps. Push the flasher control button down to operate the amber warning lamps. When the turn signal switch is moved upward to make a right tu...

Page 72

16 series, model - 2816 hst 62 rear work lamp (if equipped) the rear work lamp is turned on by the switch on the lamp. The starter key switch must be in the on position before the work lamp can be turned on. Important: do not turn on the rear work lamp while travelling on pub- lic roads. Operating i...

Page 73

16 series, model - 2816 hst 63 connecting implement to drawbar the correct connection of the implement to the drawbar will prevent stress on both the tractor and the implement. To assure proper tractor operation and optimum implement performance, the implement must be connected to the drawbar correc...

Page 74

16 series, model - 2816 hst 64 safety chain when towing equipment on a highway, use a safety chain as an auxiliary connection between the tractor and the towed equipment. The safety chain must have a rating greater than the gross load of the towed equipment. Connect the chain to the tractor drawbar ...

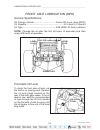

Page 75

16 series, model - 2816 hst 65 implement identification cat i dimensions implement a – gap in top of implement mast 44.5 mm (1-3/4 inch) b – diameter of holes in top of implement mast 19.1 mm (3/4 inch) c – diameter of hitch pins 22.2 mm (7/8 inch) d – lower hitch pin inner shoulder spread 682.6 mm ...

Page 76

16 series, model - 2816 hst 66 hitch system adjustments the upper and lower links must be adjusted correctly so the im- plement can work at the needed depth and the links are free to move up and down with the shape of the ground. Rh lift link turnbuckle lock nut lh lift link lower links stabilizers ...

Page 77

16 series, model - 2816 hst 67 upper link the length a of the upper link can be adjusted from 470 to 750 mm (18.5 to 29.5 inches). Turn the turnbuckle clockwise to shorten the link or counterclockwise to lengthen the link. Important: after the upper link is correctly adjusted, make sure the lock nut...

Page 78

16 series, model - 2816 hst 68 hitch operation connecting implement to hitch to connect an implement to the hitch, use the following procedure: note: be sure the tractor and implement are on level ground. 1. Put the drawbar in the storage position. 2. Slowly move the tractor backwards to the impleme...

Page 79

16 series, model - 2816 hst 69 hitch control lever important: position of the raise stop should not be set so rearward that a insufficient free play of the lift arms is available at the highest position when hitch control lever is moved until the lever is reached to the raise stop. Stop stop lower r...

Page 80

16 series, model - 2816 hst 70 move the draft control lever rear- ward to select the correct posi- tion of the lever. If the implement is lifting up, move the lever forward. If the engine rpm is decreasing, move the lever rear- ward. The depth of the implement will be automatically controlled by the...

Page 81

16 series, model - 2816 hst 71 operating with draft control (if equipped) for example, the draft control adjustment for a moldboard plow is as follows: 1. Set the upper link at the 560 mm (22-inches) length, pin to pin. 2. Place the draft control lever at the center of its operating range. 3. Starti...

Page 82

16 series, model - 2816 hst 72 note: when transporting the tractor on the road with the implement mounted on the three point hitch, always set the flow control knob to the lock position. Important: never park a tractor with an implement in the raised position. Moving the control lever forward will l...

Page 83

16 series, model - 2816 hst 73 remote hydraulic control valve (if equipped) remote hydraulic control lever hydraulic couplers field operation ________________________________________________________ a double acting remote hydraulic control valve with a “float position”, is available from your dealer...

Page 84

16 series, model - 2816 hst 74 float operation to operate the remote hydraulics in a float condition, move the control lever fully forward to the detent position. The lever will not return to neutral automatically when in the float position. Important: if implement is attached that has single acting...

Page 85

16 series, model - 2816 hst 75 important: never park a tractor with an implement in the raised position. Moving the control lever forward will lower the implement even though the engine is not running. If it is necessary to service the implement in the raised position, use jack stands to safely bloc...

Page 86

16 series, model - 2816 hst 76 adding fluid after connecting cylinders and hoses operate the engine at a moderate idle speed. Set the stroke stop at the yoke end of the cylinder rod to provide maximum stroke. Then operate the cylinder in both directions about ten times, by moving the control lever u...

Page 87

16 series, model - 2816 hst 77 memo.

Page 88

16 series, model - 2816 hst 78 tire and rim equipment tire inflation specifications for normal tractor operation use the inflation pressure shown in the tire and wheel chart. The inflation pressure are based on cold inflation pressure recommendations by tire and rim association inc. For maximum trac...

Page 89

16 series, model - 2816 hst 79 2816 tire cap. Tire @ 20 mph rolling position tire size tire type slr (in.) lb. @ psi circ. (in.) description rear 11.2x24 ag tire 20.1 1650 @ 18 130 4 ply, r-1 front 7x16 ag tire 13.4 1100 @ 36 87 6 ply, r-1 rear 15x19.5 industrial tire 17.9 4170 @ 30 117 6 ply, r-4 f...

Page 90

16 series, model - 2816 hst 80 check air pressure tire pressure check interval ...... Every 50 hours of operation or weekly. Check the condition of the tires and rims for wear or damage. Keep the tires inflated to the recommended pressures. See tire and wheel specifications in this manual for recomm...

Page 91

16 series, model - 2816 hst 81 wheel mounting torques front wheel disc to axle hub bolts ............................... 118 to 132 nm (87 to 98 lb ft) rear wheel disc to axle hub bolts ............................... 118 to 132 nm (87 to 98 lb ft) rear wheel rim to wheel disc nuts ....................

Page 92

16 series, model - 2816 hst 82 bolts and nuts positions torque front wheel disc 118 to 132 nm (87 to 98 lb ft) to axle hub bolts tie rod end nuts 59 to 88 nm (43 to 65 lb ft) front wheel adjustment the front wheels are tightened with six bolts for mfd to the axle hubs. Torques for wheel bolts and ti...

Page 93

16 series, model - 2816 hst 83 toe-in adjustment to check the toe-in, use the following procedure: 1. Put the tractor on level ground and the wheels in the straight ahead position. 2. Place chalk marks at points a on the centerlines of both front tires at the same height as the centerline of the hub...

Page 94

16 series, model - 2816 hst 84 to adjust the toe-in, use the following procedure: 1. Loosen the lock nuts at both turnbuckle ends to allow the tie rod turnbuckle to turn freely. 2. Turn the turnbuckle to shorten or lengthen the tie rod length. 3. Make sure the correct toe-in is obtained. If not, adj...

Page 95

16 series, model - 2816 hst 85 tire size combinations – mfd your mfd tractor must use front and rear tire combinations that are correctly matched. The use of recommended tire combinations will give maximum tractor performance, extended tire life and reduced wear on drive train components. Important:...

Page 96

16 series, model - 2816 hst 86 front end weight bracket tractor ballast ballast for your tractor includes front end weights, rear wheel weights and liquid ballast in the rear tires. Front end weights improve the steering characteristic when heavy hitch loads cause a movement of tractor weight from t...

Page 97

16 series, model - 2816 hst 87 too much correct ballast too little ballast ballast note: when you have too much ballast installed on the tractor, you will see the clear shape of the tire tread in the ground which is an indication of no slippage. With too little ballast, the tire tread marks will not...

Page 98

16 series, model - 2816 hst 88 hood to do maintenance work on the engine lubrication system, cooling system, fuel system and air induction system, you must lift the tractor hood. Pull the hood latch to release the hood. Remove both side covers. Lift the hood, and connect the support rod. Unlock the ...

Page 99

16 series, model - 2816 hst 89 lubrication table application kind of oil api classifi- cation ambient temperature grade (sae no.) description single multi recommendation oil brand engine engine oil cd transmis- sion oil, front diff. Oil hydraulic transmission fluid hydraulic transmission fluid greas...

Page 100

16 series, model - 2816 hst 90 the engine hourmeter shows the amount of actual hours of the tractor has operated at an average rpm. The first number to the right displays tenths of an hour and is a black number on a white surface. The remaining numbers are white on black. Use the hourmeter along wit...

Page 101

16 series, model - 2816 hst 1. Engine oil drain all the oil from the crankcase while the engine is warm and refill with new oil to the upper notch (full) on the engine oil dipstick. See engine oil change in this manual. 2. Engine oil filter replace the engine oil filter. See engine oil filter in thi...

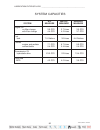

Page 102

16 series, model - 2816 hst system capacities system u.S. Metric imperial measure measure measure engine oil no filter change 3.9 qts 3.7 litres 3.2 qts with filter change 4.4 qts 4.2 litres 3.7 qts fuel tank 7.9 gallons 30 litres 6.6 gallons coolant engine and radiator 7.1 qts 6.7 litres 5.9 qts co...

Page 103

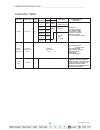

16 series, model - 2816 hst service point frequency in hours n o . O f p o i n t s d r a i n g r e a s e c h e c k c h a n g e c l e a n mark y: yearly or 1000 hours, whichever occur first. Ay: yearly or as needed. Note 1: consult your dealer. Note 2: replace element after 10 cleanings or yearly. No...

Page 104

10 hrs transmission oil – check (hydrostatic drive) fuel – drain fuel filter – change transmission oil – change hydraulic filter – change brake pedal – grease hydrostatic filter – change engine oil – check engine oil filter – change air cleaner – clean engine oil – drain engine oil – change radiator...

Page 105

Lubrication / maintenance charts 95 200 hrs mfd lubricant – change mfd lubricant – drain 200 hrs mfd lubricant – drain mfd lubricant – check 200 hrs 10 hrs mfd front axle use nlgi no.2 multipurpose lithium ep grease. 10 hrs tie rod end – grease 10 hrs front axle pivot pin – grease 200 hrs power stee...

Page 106

16 series, model - 2816 hst 96 engine lubrication service specifications engine oil level to check the engine oil level, put the tractor on level ground and stop the engine. Pull the dipstick out, wipe the dipstick with a dry cloth and install the dipstick to check the oil level. If the oil level is...

Page 107

16 series, model - 2816 hst 97 engine oil change to change the engine oil, put the tractor on level ground and stop the engine. Change the engine oil as follows: note: for best results change the oil while the engine is still warm. 1. Remove the oil pan drain plug and drain the oil from the engine. ...

Page 108

16 series, model - 2816 hst 98 important: change the oil filter at the recommended time interval. Your dealer has approved genuine filters. Do not use other type filters. Change the engine oil filter as fol- lows: 1. Drain the oil from the engine. See engine oil change in this manual. 2. Turn the oi...

Page 109

16 series, model - 2816 hst 99 cooling system service specifications coolant change interval ..........................Every 1000 hours or once each year whichever occurs first capacity of system engine and radiator .............................. 6.7 litres (7.1 qts) coolant bottle ....................

Page 110

16 series, model - 2816 hst 100 coolant solutions your tractor cooling system is equipped with an ethylene glycol coolant solution that has a high boiling point. Important: change the coolant solution at the change interval recommended in this manual (see lubrication and service chart). The heat gen...

Page 111

16 series, model - 2816 hst 101 coolant reserve bottle full low open close coolant drain plug clean the cooling system each time the coolant is changed. See the lubrication and service chart in this manual for recommended change intervals. Clean the system as follows: 1. Remove the drain plug to dra...

Page 112

16 series, model - 2816 hst 102 filter cup water removal from the filter cup before starting each day’s work, check for water or sediment in the filter cup. If water or sediment is in the cup, close the fuel shut-off valve, remove filter cup, clean and reinstall. Note: be careful not to allow dirt, ...

Page 113

16 series, model - 2816 hst 103 diesel fuel specifications use a good grade of number two diesel fuel in your diesel engine. Do not use other types or grades of fuel. The use of other fuels will result in loss of engine power and high fuel consumption. Note: when the temperature is very cold, the us...

Page 114

16 series, model - 2816 hst 104 close the fuel shut-off valve. Install new filter element. Assem- ble filter cup and retaining nut to filter body. Note: be sure o-ring is in place on the filter body and filter cup. Loosen the filter cup retaining nut. Remove filter cup. Remove old filter element and...

Page 115

16 series, model - 2816 hst 105 loosen the no. 1 air vent screw on the fuel filter until the fuel flowing from the fuel filter is free of air bubbles. Tighten the no. 1 air vent screw. Loosen the air vent screw on the injection pump and turn the key switch “on” position until the fuel flowing from t...

Page 116

16 series, model - 2816 hst 106 fuel injection pump and nozzle check the fuel injection pump and nozzles are precision units and must be serviced only by your dealer. The injection pump is correctly set and sealed at the factory and should not require an adjustment. Whenever adjustments or repairs a...

Page 117

16 series, model - 2816 hst 107 air cleaner inlet hose dump valve air induction system the air induction system components require service at different inter- vals according to local operating conditions. Service specifications dump valve .................................................. Clean dail...

Page 118

16 series, model - 2816 hst 108 stop the engine. Air filter element removal avoid over servicing the air filter element. The filter element should be removed for cleaning only when restriction causes a power loss. Remove the lh side cover. Lift the hood and connect the hood support rod. After replac...

Page 119

16 series, model - 2816 hst 109 element cleaning use clean, dry compressed air up and down the pleats on the clean side (inside) of the element. Continue this until the element is clean. Note: 1. The paper element must be handled with care. Do not hit the element against a hard surface. 2. Air press...

Page 120

16 series, model - 2816 hst 110 dipstick transmission oil level (hydrostatic drive) before checking the oil level of the hydrostatic drive tractor, run the engine for three to five minutes at 1500 rpm with the speed ratio control lever, range shift lever and pto control lever in neutral or off posit...

Page 121

16 series, model - 2816 hst 111 hydrostatic drive hydrostatic drive fill hole to change the transmission oil, use the following procedure: 1. Put the tractor on level ground, apply the park brake and stop the engine. Move the range shift lever to l position. 2. Remove the drain plugs from the transm...

Page 122

16 series, model - 2816 hst 112 hydraulic filter change the hydraulic filter as follows: 1. Put the tractor on level ground, move the range shift lever to the l position and apply the park brake. 2. Put an oil canister under the hydraulic filter. 3. Turn the filter counterclockwise to remove. Use a ...

Page 123

16 series, model - 2816 hst 113 hydrostatic system filter install remove head o-ring filter assembly hydrostatic system filter (hydrostatic drive) filter change interval ................................. Every 200 hours (see note) note: change the filter after the first 50 hours of operation and eve...

Page 124

16 series, model - 2816 hst front axle oil level to check the front axle oil level, put the tractor on level ground. Remove the oil level plugs located on the rear of the both gear cases. If the oil level is low, add the recommended oil type through the fill hole located on the rh side of axle housi...

Page 125

16 series, model - 2816 hst 115 front axle oil change 1. To change the front axle oil, put the tractor on level ground. Put the range lever in l, engage the park brake and stop the engine. Drain plug differential drain plug fill hole 2. Remove the fill cap located on the axle housing, the differenti...

Page 126

16 series, model - 2816 hst 116 cooling system grille screens and radiator area grille screens and radiator area service interval ................... Every 50 hours or more frequently if required. To clean the radiator screen, put the tractor on level ground, apply the park brake and stop the engine...

Page 127

16 series, model - 2816 hst 117 fan belt adjustment fan belt tension check interval .......................... Daily or after 10 hours pivot nut adjusting bolt to adjust the fan belt tension loosen the adjusting bolt and pivot nut of the alternator. Move the alternator away from the engine until cor...

Page 128

16 series, model - 2816 hst 118 fan belt replacement to replace the fan belt, use following procedure: raise the hood. Remove the lh side cover. Loosen the alternator adjusting bolt. Install new fan belt and adjust the belt tension. See fan belt adjust- ment in this manual for instruc- tions. Loosen...

Page 129

16 series, model - 2816 hst clutch rod clutch arm adjusting nuts clutch pedal adjustment service specifications free movement adjustment clutch pedal free movement is very important and must be checked at the recommended intervals. If there is no free movement, the clutch disc will wear quickly. If ...

Page 130

16 series, model - 2816 hst 120 maximum pedal movement adjustment the maximum pedal movement is very important and must be checked at the recommended intervals. If there is too little movement, the clutch can disengage. If there is too much movement, the clutch component parts can be damaged. Note: ...

Page 131

16 series, model - 2816 hst 121 brake rod lock nut free movement brake pedal adjustment service specifications loosen lock nut and rotate the brake rod to make a free play of 20 to 30 mm (0.79 to 1.18 in.) at the brake pedal. With this much play obtained, tighten the lock nut. Confirm that the right...

Page 132

16 series, model - 2816 hst 1. Disconnect an implement from the hitch. (see disconnecting imple- ment from hitch in this manual.) 2. Disconnect lh and rh lift rods from the lift arms. 3. Start the engine. 4. Move the hitch control lever rearward to raise the lift arm to the maximum lifting position....

Page 133

16 series, model - 2816 hst 123 electrical system specifications type of system ................................................... 12 volt, negative ground battery.............................................................. Exied 58-60 12v-540cca 9- { l; 7- { w; 7h alternator .......................

Page 134

16 series, model - 2816 hst general service information alternator charging system follow these general rules to prevent damage to the electrical system: 1. Before working on the electrical system, disconnect the battery cables. 2. Do not make a reverse battery connection. 3. When you use an auxilia...

Page 135

16 series, model - 2816 hst cartridge type fuses are used for head lamps, rear red lamp, instrument lamps, turn signal and flasher lamps, and rear work lamp (if equipped). The fuses are located in the fuse block, r.H. Rear of engine room. If a short circuit occurs, the fuse will burn out and break t...

Page 136

16 series, model - 2816 hst fusible link line fuse line fuse if the electrical circuit is accidently grounded or a reverse battery connec- tion is made, the line fuse located on the lh side of the engine will burn out and break the circuit to prevent the solenoid switch, wiring harness and alternato...

Page 137

16 series, model - 2816 hst 127 battery auxiliary battery connections important: always connect the negative cable last and disconnect the negative cable first so you do not cause a spark at the battery. A spark can cause a battery explosion and cause injury. Connect the negative ( – ) cable clamp o...

Page 138

16 series, model - 2816 hst 128 warning 321-6714 batteries contain acid and explosive gas. Explosion can result from sparks, flames, or wrong cable con- nections. To connect jumper cables or charger, see manual(s) for the correct procedure. Failure to follow the above instructions can cause serious ...

Page 139

16 series, model - 2816 hst 129 when charging the battery important: battery can explode during boosting or charging. Always wear proper eye protection, such as a safety goggles. If the electric circuit inside the battery is broken, charging can generate a spark inside the battery which can cause it...

Page 140

16 series, model - 2816 hst head lamp adjustment note: to keep maximum ground and road illumination, check and adjust the head lamps from time to time. Tire wear and different tire sizes will change the setting. The head lamps can be adjusted to various positions by adjusting the mounting screws in ...

Page 141

16 series, model - 2816 hst 131 when your tractor is not to be used for some time, it should be stored in a dry and protected place. Leaving your tractor outdoors, exposed to the elements, will shorten its life. Follow the procedure outlined below when your tractor is placed in storage for periods u...

Page 142

16 series, model - 2816 hst 132 removing from storage be sure that the grade of oil in the engine crankcase is as specified in engine oil selection in this manual. A. Loosen the fuel tank drain plug and fuel filter cup, and be sure all water and sediment has drained from the fuel system before closi...