- DL manuals

- Maier

- Sewing Machine

- 220

- Operating Instructions Manual

Maier 220 Operating Instructions Manual

Summary of 220

Page 1

Bedienungsanleitung operating instructions manuel d´instructions instrucciones de servicio 220, 221, 240, 241, 251, 261, 271, 281, 252, 352.

Page 2

2 contents index gb manufacturer's declaration…………………………………………………………………………………………………...3 general notes .......................................................................................................................................................... 5 directives .................................

Page 3

3 d herstellererklärung im sinne der eg-maschinenrichtlinie 89/392/ewg anhang ii b hiermit erklären wir, dass die bauart der maier- blindstichnähmaschine (nähmaschinenoberteil) klasse und seriennr. (siehe typenschild) zum einbau in eine näheinheit oder nähanlage bestimmt ist und dass ihre inbetriebn...

Page 4

4 with this machine, you have acquired a user-friendly, universal and robust high- performance blind stitch sewing machine. All important information relating to working with this machine and the various setting possibilities is provided on the following pages. If you need further information, or ha...

Page 5: General Notes

5 general notes directives the machine has been built in accordance with the european regulations stated in the manufacturer's declaration and conformity declaration. In addition to these operating instructions, you must take account of all generally applicable statutory and other regulations and ot...

Page 6

6 safety symbols danger spot! Items requiring special attention. Danger of injury to operators or specialist staff! Attention! Never work without finger guards and protective devices! Switch off main switch before threading, changing needles, cleaning etc. Items requiring the operator's special atte...

Page 7

7 operators and specialist staff operators operators are the persons who are responsible for preparing, operating and cleaning the machine, and for troubleshooting in the sewing zone. Operators have a duty to observe the following items: the safety notes specified in the operating instructions must ...

Page 8

8 hazard warnings when the machine is in operation, a 1 m working area must be kept clear in front of and behind the machine, so that unhindered access is possible at any time. No objects must be left lying on the table during setup and adjustment of the machine! The objects could be clamped or thro...

Page 9

9 risk of injury due to the machine being started again inadvertently. Oil holes marked in red are provided on the cover and on the machine body. The machine should be oiled at these points about two or three times per month, one drop of sewing machine oil per oil hole is sufficient. Attention: make...

Page 10: Assembly Of The Machine

10 assembly of the machine switch off the machine! Risk of injury due to the machine being started again inadvertently. Electrical assembly must only be carried out by a qualified electrician! Installation instructions fit the stand in accordance with the stand manufacturer's specification. In addit...

Page 11

11 mounting instructions for the mini-motor 46 attachment kit classes 221 /241/ 251 / 261 /271 dismantle the rear cover on the machine body. Remove blanking plug 240236, bolts 221212 and spring 221213. Remove shaft 221204. Refit shim 221204a and push the new shaft into the machine body. The shaft sh...

Page 12

12 automatic frame drop device frame drop device pfl-m consisting of: solenoid with bowden cable, mounting bracket and deflection pulley. Order reference: pfl-m frame drop device pfl-p consisting of: compressed air cylinder, regulating valve, solenoid valve and bowden cable. Order reference: pfl-p t...

Page 13

13 sewing machine table tops sewing machine table top for models 220, 221, 271 sewing machine table top for models 220, 221, 271 with sub-class 46.

Page 14

14 sewing machine table top for models 240, 241, 251, 252, 261, 281, 352 sewing machine table top for models 240, 241, 251, 252, 261, 281, 352 with sub-class 46/2.

Page 15: Operation

15 operation threading switch off the machine! Risk of injury due to the machine being started again inadvertently. Machine without thread cutter (fig. 1) the thread is run over the thread stand through the thread guide a, the rear thread eyelet, between the thread tensioning discs c (not round the ...

Page 16

16 inserting the cloth and sewing the needle must be in its extreme left-hand position when inserting the cloth. Press down on the treadle or knee-lift lever, then insert the cloth so that the hem fold is positioned on the right-hand side and is far enough under the feed dog for the feed dog to grip...

Page 17

17 when using a stop motor with frame drop device and thread cutter, then simply by stepping back off the treadle, the needle is automatically positioned, the thread cut off and the frame opened for removal of the material. If thread pulls are visible on the outside of the cloth after sewing, or if ...

Page 18

18 setting the stitch depth (penetration) classes 220, 221, 240, 241, 251, 261, 271 adjusting screw a for setting the stitch depth is located under the frame plate. To check the stitch depth, turn the hand-wheel until the needle point is positioned directly above the plunger (rib shaft) b. When corr...

Page 19

19 classes 252 and 352 with the above machine classes (double blind stitch), the cloth is inserted folded in an "s" shape (see fig. 4). In this case, the distance from the seam to the hem edges can be any value required. All other essential information on inserting the cloth is described on page 16....

Page 20

20 setting the stitch depth of the left-hand plunger/rib shaft the left-hand plunger/rib shaft is responsible for penetration of the outside of the hem and so must be adjusted with particular care. Penetration - = shallower + = deeper for design-related reasons, the right-hand plunger/rib shaft depe...

Page 21

21 setting the cloth retainers for classes 251, 261, 271, 281, 252, 352 (lowering over cross seams) for setting the cloth retainers, the cloth is inserted in the machine as for sewing (not on the cross seam). Cloth retainer a (the left-hand cloth retainer on classes 251,261,271 and 252/352) is adjus...

Page 22

22 fitting the needle switch off the machine! Risk of injury due to the machine being started again inadvertently. To fit the needle, turn the machine by hand until the needle lever is in the extreme left position. Now slacken the fixing screw a few turns, take out the old needle, fit the new needle...

Page 23

23 skip stitch device class 221, 241, 251, 261, 271 machines are equipped with a skip stitch device. When sewing thin cloths, this enables the top layer of cloth to be pierced with only every second (1:2) or every third (1:3) stitch. The plunger (rib shaft) either moves beyond the needle, or stops s...

Page 24

24 instructions for the mechanic setting the stitch plate switch off the machine! Risk of injury due to the machine being started again inadvertently. Spin the machine by hand. Here, the needle should slide on the needle plate a with no clearance until stitching the cloth, but it must not be lifted ...

Page 25

25 basic setting of the needle movement switch off the machine! Risk of injury due to the machine being started again inadvertently. Position the needle at the right-hand dead centre position by turning the hand-wheel. The needle point must now be 2 mm (0.7 mm on class 252 and 1.0 mm on class 352) a...

Page 26

26 adjusting the looper switch off the machine! Risk of injury due to the machine being started again inadvertently. Basically, the following rule must be borne in mind: when adjusting the eccentric cam g (fig. 18), the looper is raised or lowered at both points e and l. By turning looper holder b, ...

Page 27

27 adjusting the looper stroke if the long finger of the looper takes up the thread too far in front of the needle, or just behind it, as it passes over the needle, the looper must be set forward or back, so that it takes up the thread earlier or later. Adjusting the looper holder also adjusts the s...

Page 28

28 stitch length adjustment switch off the machine! Risk of injury due to the machine being started again inadvertently. Remove cover and slacken screw a. The adjustment eccentric b can now be adjusted to the required stitch length by turning it using the holes. A zero mark is provided on the eccent...

Page 29

29 plunger (rib shaft) adjustment switch off the machine! Risk of injury due to the machine being started again inadvertently. Radial position correct adjustment of the needle is prerequisite for adjusting the plunger (rib shaft). When correctly adjusted, the plunger (rib shaft) should stop with its...

Page 30

30 play once the alignment is complete, make sure that the plunger (rib shaft) has no axial play. Any play can be corrected by a tighter setting of the set collar or the pivot screws on the plunger shaft. If the plunger (rib shaft) has any radial play, this can be remedied by readjustment. On classe...

Page 31

31 feed dog adjustment switch off the machine! Risk of injury due to the machine being started again inadvertently. The feed dog must be adjusted such that – in its lowest position – it projects approx. 2 mm (at least tooth depth) beyond the underside of the stitch plate. In addition, it should be p...

Page 32

32 sewing faults and how to remedy them fault cause remedy thread tears thread tension too tight slacken thread tension needle worn out change needle, see page 16 looper wrongly adjusted see page 25 needle stroke wrongly adjusted see page 16 sharp edge in looper, stitch plate or feed dog polish the ...

Page 33: Sewing Tools

33 sewing tools the machines are equipped with special sewing tools for different purposes. The tools are also available separately: tool order no. Description suitable for classes 220, 221, 240, 241, 251, 271, 281 feed dog 220145 normal serration 220145 f fine serration 220145 g coarse serration 22...

Page 34: Technical Data

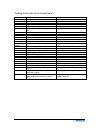

34 technical data class 220, 221, 240, 241, 251, 271 class 252 class 352 class 261 class 221-19/2, 221- 19/4 number of stitches/min up to 3000 2500 2500 2300 2000 length of stitch 3-8 mm 3-8 mm 3-8 mm 3-8 mm 2-8 mm hand-wheel diameter (effective) 63 mm 63 mm 63 mm 63 mm 63 mm v-belt width 10 mm 10 m...