- DL manuals

- Main

- Water Heater

- Multipoint BF

- User Operating, Installation And Servicing Instructions

Main Multipoint BF User Operating, Installation And Servicing Instructions

Summary of Multipoint BF

Page 1

Multipoint bf gas fired balanced flue water heater user operating, installation and servicing instructions 6 7 20 60 7 0 9 0 g b ( 04. 1 0 ) js please leave these instructions with the user.

Page 2

2 6 720 607 090 natural gas main multipoint bf g.C. No 52-467-01 user information your main multipoint bf is designed to meet all relevant standards. Main provide a 12 month guarantee on the appliance. The guarantee operates from the date installation is completed for the customer who is the origina...

Page 3

3 6 720 607 090 1. User’s operating instructions ..................................... 4 2. General layout .............................................................. 5 3. Technical data ............................................................... 6 4. Dimensions and fixings .....................

Page 4

4 6 720 607 090 1. User’s operating instructions pilot ignition: 1. Depress slide control and hold it in. 2. Press the igniter repea- tedly until the pilot is alight. 3. Release the slide control approx 10 seconds after pilot lights. 4. Repeat these steps if the pilot does not remain alight. Burner ...

Page 5

5 6 720 607 090 2. General layout fig. 3 appliance water flow diagram. Fig. 4 1 pilot burner 2 spark electrode 3 thermocouple 4 heat exchanger 5 main burner 6 burner injector 7a burner pressure test point 7b inlet gas pressure test point 8 gas setting screw 9 pilot gas filter 10 pilot gas valve 11 e...

Page 6

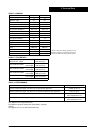

6 6 720 607 090 3. Technical data table 1 - general table 3 - performance table 2 - flue details the appliance has a permanent pilot. The appliance and flue components are packed in separate cartons. The appliance is for use with natural gas only. Maximum cold water supply inlet pressure 12 bar (180...

Page 7

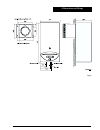

7 6 720 607 090 4. Dimensions and fixings fig. 5.

Page 8

8 6 720 607 090 5. General information 5.1 general installation if the appliance is to be fitted into a compartment, the compartment must conform to the requirements of bs 6798. Do not place anything on top of the appliance. The clearances specified for servicing must be maintained. 5.2 showers if a...

Page 9

9 6 720 607 090 7. Siting the appliance 7.1 the appliance is not suitable for external installation. 7.2 this appliance is suitable for installation in conjunction with a “seduct” flue system that complies with the requirements of bs 5440 - 1 2000 & is 813:2002. 7.3 the appliance is suitable for rep...

Page 10

10 6 720 607 090 8. Siting the flue terminal see fig. 8. 8.1 the flue must be installed as specified in bs 5440:part 1. 8.2 if the terminal discharges onto a pathway or passageway, check that the combustion products will not cause a nuisance and that the terminal will not cause an obstruction. 8.3 i...

Page 11

11 6 720 607 090 9. Air supply 9.1 the appliance does not require a separate vent for combustion air. 9.2 the appliance may be installed in an unvented compartment. 9.3 there must be sufficient clearance around the appliance to allow proper circulation of air. The clearences required for operation w...

Page 12

12 6 720 607 090 11.5 unfasten the two retaining screws and lift the case clear. 11.6 remove the flue hood from the appliance by undoing the three fixing screws and lift the hood clear. 11.7 place the appliance on its side, obtain the flue terminal sealing strip from the kit and fit into the recess ...

Page 13

13 6 720 607 090 fig. 16 - burner pressure test point 12. Commissioning before commissioning the appliance, the gas installation must be purged and tested for gas soundness in accordance with bs 6891. 12.1 ensure that the gas isolation valve in the gas inlet pipe is turned off. 12.2 loosen screw a a...

Page 14

14 6 720 607 090 13. Inspection and servicing for reasons of safety and economy it is recommend that the appliance is serviced annually. The servicing must be carried out by a competent person. Before commencing any service operation turn off the gas supply at the main gas service cock. Ensure that ...

Page 15

15 6 720 607 090 13.3 main burner disconnect the pilot gas pipe at the gas valve. Disconnect the pilot gas pipe from the pilot burner and remove from the appliance complete with seal. Take care not to lose the pilot injector. Remove the two screws retaining the pilot bracket and lift complete assemb...

Page 16

16 6 720 607 090 14. Replacement of parts any servicing or parts replacement must be carried out by a competent person. Use only genuine manufacturer’s parts. Before commencing servicing or parts replacement turn off the gas supply at the main gas isolation valve and ensure that the appliance is coo...

Page 17

17 6 720 607 090 outlet connections and lift the heat exchanger clear. Replace the heat exchanger and re-assemble in reverse order. 14.5 igniter unit pull off the two wires from the rear of the unit, unscrew the plastic retaining nut on the control panel and push out the piezo unit. Replace and re-a...

Page 18

18 6 720 607 090 15.Fault finding 16. Short parts list fig. 23 problem cause solution incorrect water temperature. Incorrect gas rate. Check the gas supply to appliance gas isolation valve. Open the gas isolation valve. Check the burner pressure. Check the inlet pressure. Water section sticking or f...

Page 19

19 6 720 607 090 17. Notes.

Page 20

General enquiries (gb) 08706 060 780 technical (gb) 08706 049 049 service (gb) 08706 096 096 literature request (gb) 08706 060 623 technical (ie) 1850 560 570 comp n o 5111036 – iss 2 – 10 / 04 baxi potterton a trading division of baxi heating u.K. Ltd brownedge road bamber bridge preston lancashire...