- DL manuals

- Main

- Water Heater

- MULTIPOINT FF

- User Operating, Installation And Servicing Instructions

Main MULTIPOINT FF User Operating, Installation And Servicing Instructions

Summary of MULTIPOINT FF

Page 1

Multipoint ff room sealed fan-assisted water heater 6 7 2 0 6 0 7 1 6 0 (0 4 .0 2 ) js please leave these instructions with the user user operating, installation and servicing instructions.

Page 2

2 6 720 607 160 natural gas main multipoint ff g.C. No 52-467-02 user information your main multipoint ff is designed to meet all relevant standards. Main provide a 12 month guarantee on the appliance. The guarantee operates from the date installation is completed for the customer who is the origina...

Page 3

3 6 720 607 160 1. User’s operating instructions ...................................... 4 2. General layout ............................................................... 5 3. Technical data ............................................................... 6 4. Dimensions and fixings ...................

Page 4

4 6 720 607 160 1. User’s operating instructions switching on and off: on 1. Turn the main switch to position i. Water temperature control: 1. Turn the control to the desired temperature. Fault indication: the appliance incorporates a fault indication system. Fault indication is shown by a red light...

Page 5

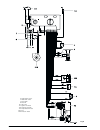

5 6 720 607 160 2. General layout fig. 3 appliance water flow diagram. Fig. 4 appliance components 4 electronic control box 5 heat sensor 6 water flow sensor 10 main switch 11 temperature control 12 reset button 13 burner indicator button 17 safety solenoid ev1 25 water filter 28 hot water pipe 29 c...

Page 6

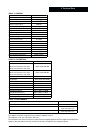

6 6 720 607 160 3. Technical data table 1 - general table 3 - performance table 2 - flue details the appliance and flue components are packed in separate cartons. The appliance is for use with natural gas only. The installation notes in these instructions, particularly those regarding maximum flue l...

Page 7

7 6 720 607 160 4. Dimensions and fixings fig. 5.

Page 8

8 6 720 607 160 5. General information 5.1 general installation if the appliance is to be fitted into a compartment, the compartment must conform to the requiremens of bs 6798. Do not place anything on top of the appliance. The clearances specified for servicing must be maintained. 5.2 showers if a ...

Page 9

9 6 720 607 160 7. Siting the appliance 7.1 the appliance is not suitable for external installation. 7.2 the appliance is n ot suitable for se du ct application. 7.3 the appliance does not require any special wall protection. 7.4 the wall must be capable of supporting the weight of the appliance. Se...

Page 10

10 6 720 607 160 8. Siting the flue terminal see fig. 7. 8.1 the flue must be installed as specified in bs 5440:part 1. 8.2 the terminal must not cause an obstruction nor the discharge cause a nuisance. 8.3 if the terminal is fitted within 1000 mm of a plastic or painted gutter or within 500 mm of p...

Page 11

11 6 720 607 160 9. Air supply 9.1 the appliance does not require a separate vent for combustion air. 9.2 the appliance may be installed in an unvented compartment. 9.3 there must be sufficient clearance around the appliance to allow proper circulation of air. The clearances required for operation w...

Page 12

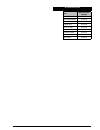

12 6 720 607 160 fig. 8 5 temperature sensor 6 water flow sensor 7 fuse1,25a 8 fuse 2a 92 gas valve 117 ignition electrode 118 sensing electrode 119 temperature limit stat 226 fan 228 pressure switch.

Page 13

13 6 720 607 160 the installation must be carried out by a competent person. 12.1 initial preparation 12.1.1 unpack the appliance and take care to remove the fascia and the installation kit which are located on the top and on the bottom of the polystyrene packing. Remove the white painted flue elbow...

Page 14

14 6 720 607 160 fig. 12 12.2 flue restriction the installation notes in these instructions, particularly those regarding maximum flue lengths and configuration options, take precedence over any universal instructions included in flue component packs. To ensure the correct operation of the appliance...

Page 15

15 6 720 607 160 measure 40mm top view wall rear flue side flue 10mm wall thickness drip ring 10mm fig. 14 12.3.1 standard telescopic flue installation: determine appropriate flue length (fig. 14) rear flue application - measure wall thickness, add 60mm. Side flue application – measure distance from...

Page 16

16 6 720 607 160 12.4 fitting a vertical flue possible configurations of flue are as per fig. 17. Vertical flue kits and flue extension components are detailed in section 3, page 6, table 2 - flue details. For vertical application the white painted elbow is discarded. The maximum and minimum flue le...

Page 17

17 6 720 607 160 12.4.2 extended vertical installation vertical flue lengths may be extended to the limits as stated in table 12 using standard 1m extension kits and 45 and 90 degree elbows. Secure the flashing kit to the roof. Refer to fig. 20. From the roof, slide the terminal assembly through the...

Page 18

18 6 720 607 160 fig. 22 before commissioning the appliance, the gas installation must be purged and tested for gas soundness in accordance with bs 6891. 13.1) ensure the gas isolation valve is turned off. 13.2) remove the appliance outer case. 13.3) to increase access to the pressure test point, th...

Page 19

19 6 720 607 160 14. Performance optimization performance optimization is a process that informs the appliance about its installation/working conditions so that it can adjust itself accordingly. The appliance is thus more responsive. 14.1) set the main switch to position o (off). 14.2) on the contro...

Page 20

20 6 720 607 160 15. Inspection and servicing warning isolate electrical supply before servicing the appliance. For reasons of safety and economy it is recommend that the appliance is serviced annually. The servicing must be carried out by a competent person. Before commencing any service operation ...

Page 21

21 6 720 607 160 15.5 service adjustment 15.5.1 max and min gas rate adjustment do not use magnetic tools to adjust the gas valve. Always adjust the maxim u m rate b efor e the minimum. It is only necessary to adjust the minimum gas rate if the burner frequently goes out when the water flow is reduc...

Page 22

22 6 720 607 160 16. Replacement of parts warning : isolate electrical supply before servicing the appliance. Any servicing or parts replacement must be carried out by a competent person. Use only genuine manufacturer’s parts. Before commencing servicing or parts replacement turn off the gas supply ...

Page 23

23 6 720 607 160 as per section 15.5.1. 16.6 control unit unfasten the two screws securing the front panel of the control unit and remove. Disconnect inlet cable and all wiring connections. Remove control unit by depressing the two curved finger tabs on top of the box and withdraw forward. Replace t...

Page 24

24 6 720 607 160 17. Fault finding note: installation, maintenance and repairs must be carried out only by a competent person..

Page 25

25 6 720 607 160 18. Short parts list item baxi potterton number spark electrode 5111115 sensing electrode 5111116 flow sensor 5111117 control unit 5111118 fuse t 1.25a 5111119 fuse 2a 5111120 pressure switch 5111121 fan 5111122 gas valve 5111123.

Page 26

26 6 720 607 160 19. Notes.

Page 27

27 6 720 607 160

Page 28

General enquiries (gb) 08706 060 780 technical (gb) 08706 049 049 service (gb) 08706 096 096 literature request (gb) 08706 060 623 technical (ie) 1850 560 570 baxi potterton a trading division of baxi heating u.K. Ltd brownedge road bamber bridge preston lancashire pr5 6sn www.Baxipotterton.Co.Uk co...