Models: 300dvbh & 400dvbh dvbh series direct vent gas fireplace warnings if the information in these instructions are not followed exactly, a fire or explosion may result causing property damage, personal injury or loss of life. – do not store or use gasoline or other flammable vapors and liquids in...

54d5032 contents important safety information .......................... 3 product features .............................................. 5 code approval .................................................. 5 pre-installation information ......................... 6–9 high elevation installation ........

54d5032 3 4. Never install the fireplace • in a recreational vehicle • where curtains, furniture, clothing, or other flammable objects are less than 42" from the front, top, or sides of the fireplace • in high traffic areas • in windy or drafty areas 5. This fireplace reaches high temperatures. Keep...

4 54d5032 important safety information continued from page 3 12. Do not use this fireplace to cook food or burn paper or other objects. 13. Never place anything on top of fireplace. 14. Do not use any solid fuels (wood, coal, paper, cardboard, etc.) in this fireplace. Use only the gas type indicated...

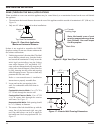

54d5032 5 product features and code approval off/pilot/on knob optional remote receiver figure 1 - 300dvbh and 400dvbh fireplace • this appliance has been certi - fied for use with either natural or propane gas. See appropriate data plates. • this appliance is not for use with solid fuels. • the app...

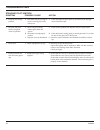

6 54d5032 pre-installation information orifice sizes, pressures and btus natural gas propane gas manifold press: (w.C.) 3.5" manifold press: (w.C.) 10" maximum supply pressure 10.5" maximum supply pressure 13" minimum supply pressure 4.5" minimum supply pressure 11" model number 300dvbh 400dvbh natu...

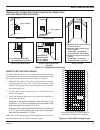

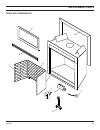

54d5032 7 b a a c e d f h c a a c g corner installation stud location inside chase installation figure 2 - framing dimensions 300 400 a 33 1 / " 37 1 / " b 37 1 / 4 " 40 7 / 8 " c 28 1 / 4 " 9 1 / 4 " d 14 1 / 8 " 13 1 / " e 55 11 / 16 " 60 7 / 8 " f 7 13 / 16 " 30 7 / 16 " g 13 3 / 4 " 16 1 / " h 3...

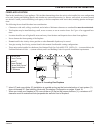

8 54d5032 e h d a g f l m o j 3½" ⅝" ⅝" ½" ½" i b 8¼" i n c k pre-installation information description key letter 300dvbh 400dvbh overall front width a 33 1 / 16 " 37 1 / 16 " inside width b 9 7 / 8 " 3" glass width c 7" 9" ctr pipe rear l/r d 16 1 / " 18 1 / " rear width e 8" 9" glass height f 18" ...

54d5032 9 y e a b c d f y x pre-installation information fireplace location plan for the installation of your appliance. This includes determining where the unit is to be installed, the vent configuration to be used, framing and finishing details, and whether any optional accessories (i.E. Blower, w...

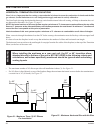

10 54d5032 0"–12" maximum depth 12" minimum 71"minimum minimum 4" from both side walls fireplace wall combustible material area 4" 3" 2.5" 45° 2.5" 2.5" 1" 1.5" 1.5" stud follow these instructions carefully to ensure safe installation. Failure to follow instructions exactly can create a fire hazard....

54d5032 11 the fireplace must be secured to the floor and/or to framing studs as shown in figure 5 . Use two (2) wood screws or masonry/ concrete screws to secure fireplace to the floor. Use four (4) screws to attach fireplace to framing. The side nailing flanges are 1/2" or 5/8" to accommodate diff...

1 54d5032 read all instructions completely and thoroughly before attempting installation. Failure to do so could result in serious injury, property damage or loss of life. Operation of improperly installed and maintained venting system could result in serious injury, property damage or loss of life....

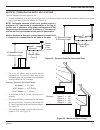

54d5032 13 3" 1" 1" 1" 3" 1" 1" vent installation this fireplace must be vented to the outside. The venting system must never be attached to a chimney serving a separate solid fuel burning appliance. Each gas appliance must use a separate vent system. Do not use common vent systems. W arning figure ...

14 54d5032 figure 9 - removing screws from flue pipe adapter and flue pipe cover figure 10 - removing flue pipe figure 11 - attaching flue pipe to top vent configurations screws flue pipe screws flue pipe flue cover flue pipe cover flue pipe adapter screws figure 8 - removing top box and insulation ...

54d5032 15 vent installation installation planning there are two basic types of direct-vent installation: • horizontal termination • vertical termination it is important to select the proper length of vent pipe for the type of termination you choose. It is also important to note the wall thickness. ...

16 54d5032 v v v v v v v v d l e b c f b b b b b m i a a j h g a operable fixed closed fixed closed opera- ble k a a a g vent installation always maintain minimum clearances around vent systems. The minimum clearances to combustibles for horizontal vent pipe are 3" at the top and 1" at the sides and...

54d5032 17 v g g=6" (152mm) f f=6" (152mm) v v g g = combustible 24"(610mm) noncombustible 18"(457mm) combustible & noncombustible h = 24" (610mm) j = 20" (508mm) v h j c = maximum depth of 48" (1219mm) for alcove location d = minimum width for back wall of alcove location combustible - 38" (965mm) ...

18 54d5032 9 1 / 2 " (241mm) 9 1 / 2 " (241mm) 3 3 / 4 " (92mm) 7 1 / 2 " (190mm) maximum 20" top view flat installation rear (through the wall) applications when installed as a rear vent unit this appliance may be vented directly to a termination located on the rear wall behind the appliance • the ...

54d5032 19 ho t ho t vent installation 4. Apply a bead of non-hardening mastic around the outside edge of vent cap. Position the vent cap in the center of hole on the exterior wall with the word “hot” on the vent cap facing up. Insure proper clearance of 1" to combustibles is maintained to the flue....

0 54d5032 vent installation horizontal termination configurations since it is very important that the venting system maintain its balance between the combustion air intake and the flue gas exhaust, certain limitations as to vent configurations apply and must be strictly adhered to. The vent graph, s...

54d5032 1 horizontal termination configuration (continued) • if a 90° elbow is used in the horizontal vent run (level height maintained) the horizontal vent length is reduced by 36". See figures 21 and 22, page 20. This does not apply if the 90° elbows are used to increase or redirect a vertical ris...

54d5032 vent installation below grade installations when it is not possible to meet the required vent terminal clearances of 12" above grade level, a snorkel kit is recommended. It allows installation depth down to 7" (178mm) below grade level. The 7" (178mm) is measured from the center of the horiz...

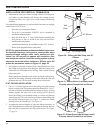

54d5032 3 40' maximum height 8' minimum height 10' maximum support straps every 3' 40' maximum height 8' minimum height 10' maximum support straps every 3' support straps every 5'vertical vertical (through-the-roof) applications this gas fireplace has been approved for, • vertical installations up t...

4 54d5032 9 1 / 2 " 9 1 / 2 " vent installation installation for vertical termination 1. Determine the route your vertical venting will take. If ceiling joist, roof rafters or other framing will obstruct the venting system, consider an offset. See figure 30 to avoid cutting load bearing members. For...

54d5032 5 roof pitch h (feet) flat to 6/12 1.0 over 6/12 to 7/12 1.5 over 7/12 to 8/12 1.5 over 8/12 to 9/12 .0 over 9/12 to 10/12 .5 over 10/12 to 11/12 3.5 over 11/12 to 12/12 4.0 *h = minimum height from roof to lowest discharge opening of vent. Figure 33 - minimum chimney clearance vent installa...

6 54d5032 ul1777 flex vent 5" radius figure 1 — typical appliance connection figure 2 — minimum radius for flex vent section ul1777 flex vent securing screws (3 places equidistant just above gear clamp) gear clamps dvfa/8 inner adapter outer adapter appliance starting collar 1¾ in. Flexible pipe and...

54d5032 7 termination cap figure 4 — typical pipe connection figure 3 — typical vertical flex vent installation figure 5 — typical horizontal flex vent installation storm collar flashing rigid pipe length flex to pipe adapter (fpa/8) fire stop ul1777 flex pipe dvfa/8 adapter roof support ul1777 flex...

8 54d5032 figure 39 - external regulator with vent pointing down (propane/lp only) use only new black iron or steel pipe. Internally tinned copper or copper tubing can be used per national fuel code, section 2.6.3, providing gas meets hydrogen sulfide limits, and where permitted by local codes. Gas ...

54d5032 9 3" m inim um fireplace installation a listed manual shutoff valve must be installed upstream of the appliance. Union tee and plugged 1 / 8 " npt pressure tapping point should be installed upstream of the appliance. See figure 39. Important: install main gas valve (equipment shutoff valve) ...

30 54d5032 checking gas pressure and electrical installation 1. Check gas type. The gas supply must be the same as stated on the appliance’s rating decal. If the gas supply is different from the fireplace, stop! Do not install the appliance. Contact your dealer immediately. 2. To ease installation, ...

54d5032 31 on off optional remote receiver on off rs pilot hi lo on off th tp th/tp on off optional wall switch gr ay blue black black black bl ue white rs tan tan white green black black black speed control optional thermostatic switch receptacle junction box 120vac remote wall mounted switch a rem...

3 54d5032 figure 44 - removing glass frame glass frame clamps glass removal & brick installation glass frame removal 1. Release two clamps on bottom of fireplace. See figure 44. 2. Tilt glass frame out and lift glass frame up until it clears three tabs on top of fireplace. 3. Set glass frame aside. ...

54d5032 33 log #1 figure 47 - placement of log 1 figure 46 - placement of rock wool on burner figure 45 a & b - placement of rock wool on burners cover with rock wool burner 400dvbh 300dvbh final installation placement of lava rock, rock wool and logs 1. Make sure that the grate is hooked onto the r...

34 54d5032 log #4 log #5 log #2 log #3 figure 49 - placement of log 3 figure 50 - placement of log 4 figure 51 - placement of log 5 figure 48 - placement of log 2 final installation 6a. For 400 models, place log #3 into place by matching the notch on the side of the log with the protrusion on the re...

54d5032 35 log #6 log #7 top andiron hole lower andiron hole top bracket slot lower bracket slot horizontal fireplace grate bar figure 52 - placement of log 6 figure 53 - placement of log 7 (hbdv400 only). Figure 54 a & b - andiron placement (400dvbh and 300dvbh). Figure 55 - universal andirons fina...

36 54d5032 a. This appliance is equipped with a pilot which must be lit with built-in piezo ignitor while following these instructions exactly. B. Before operating smell all around the appliance area for gas. Be sure to smell next to the floor because some gas is heavier than air and will settle on ...

54d5032 37 pilo t of f p il o t on continued on next page operating instructions (millivolt) approved leak testing method you may check for gas leaks with the following methods only: • soap and water solution • an approved leak testing spray • electronic sniffer if using a soap and water solution to...

38 54d5032 pilo t o ff pilo t o n o ff pilo t o n pilo t pilo t of f p il o t on of f on rs figure 60 - off position figure 59 - pilot position figure 58 - on position figure 57 - on/off/rs switch operating instructions (millivolt) main burner switch the “on/off/rs” switch for the main burner can be...

54d5032 39 figure 61 - pilot flame thermopile thermocouple figure 62 - burner flame appearance turn off gas before servicing fireplace. It is recommended that a qualified service technician perform these check-ups at the beginning of each heating season w arning cleaning and maintenance burner, pilo...

40 54d5032 cleaning and maintenance vent system the fireplace and venting system should be inspected before initial use and at least annually by a qualified field service person. Inspect the external vent cap on a regular basis to make sure that no debris is interfering with the airflow. Inspect ent...

54d5032 41 troubleshooting standing pilot ignition symptom possible cause action 1. Spark ignitor will not light pilot after repeated triggering of piezo. 2. Pilot will not stay lit after carefully follow - ing lighting instruc - tions. . Pilot burning, valve knob turned to “on”, switch is turned to...

4 54d5032 troubleshooting standing pilot ignition symptom possible cause action 4. Frequent pilot outage problem. 5. The pilot and main burner extinguish while in operation 6. Glass soots 7. Flame burn blue and lifts off burner (ghost - ing) a. Pilot flame may be too high or too low, causing pilot s...

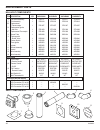

54d5032 43 1 2 3 5 6 7 10 4 9 11 replacement parts fireplace components.

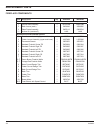

44 54d5032 item description qty 300dvbh 400dvbh standard features 1 junction box assembly 1 26d2128k 26d2128k black louver (each) 1 54d0246 26d0695 3 glass frame assembly 1 54d5113 54d5034 11 andiron kit (contains 2) 1 uai9 uai9 accessories/field installed options brass louver assembly (upper and lo...

54d5032 45 1 3 4 5 6 7 11, 12, 13, 14, 15 2t i 2c 8 8a (400dvbh) 8b (300hbdv) 10 millivolt engine replacement parts.

46 54d5032 hot 1 3 4 5 6 7 8 9 10 11 millivolt components replacement parts item description qty 300dvbhnv 300dvbhpv 400dvbhnv 400dvbhpv 1 gas valve assembly 1 37d0117 37d0118 37d0117 37d0118 2 pilot assembly 1 37d0018 37d0019 37d0018 37d0019 2c replacement thermocouple 1 37d1067 37d1067 37d1067 37d...

54d5032 47 replacement parts for more information about, or instructions for, the venting components referenced above, please contact the component manufaturer: selkirk corporation: www. Selkirkcorp.Com or 800-992-8368 simpson duravent: www. Duravent.Com or 800-835-4429 item qty/ box description cur...

48 54d5032 5 6 4 3 2 1 7 logs replacement parts item description qty 300dvbh 400dvbh 1 rear log 1 54d5125 54d5040 2 right log 1 54d5126 54d5041 3 left log 1 54d5127 54d5042 4 mid top log 1 54d5129 54d5043 5 right top log 1 54d5128 54d5044 6 left front log 1 54d5130 54d5045 7 right front twig 1 n/a 5...

54d5032 49 note regarding vented products this product must be installed by a licensed plumber or gas fitter when installed within the commonwealth of massachu - setts. Any residence with a direct vent product must have a co detector installed in the residence. Installation of the fireplace or vente...

50 54d5032 special requirements continued 2. Approved carbon monoxide detectors. Each carbon monoxide detector as required in accordance with the above provisions shall comply with nfpa 720 and be ansi/ul 2034 listed and ias certified. 3. Signage. A metal or plastic identification plate shall be per...

54d5032 51 limited lifetime warranty policy lifetime warranty the following components are warranted for life to the original owner, subject to proof of purchase: firebox, combustion chamber, heat exchanger, grate and stainless steel burners. Five year warranty the following components are warranted...

5 54d5032 august 2008 54d5032 • rev. 5 mhsc 149 cleveland drive • paris, kentucky 40361 www.Mhsc.Com.