- DL manuals

- Majestic

- Indoor Fireplace

- 400DVBL

- Installation And Operating Instructions Manual

Majestic 400DVBL Installation And Operating Instructions Manual

FRONT COVER IMAGE

PLEASE ADD LOGS INSIDE

MODELS: 400DVBL & 500DVBL

DVBL SERIES

DIRECT VENT GAS

FIREPLACE

INSTALLATION AND

OPERATING INSTRUCTIONS

READ BEFORE INSTALLING. SAVE THESE INSTRUCTIONS

DUE TO HIGH TEMPERATURES, THE

APPLIANCE SHOULD BE LOCATED OUT OF

TRAFFIC AND AWAY FROM FURNITURE AND

DRAPERIES.

CHILDREN AND ADULTS SHOULD BE

ALERTED TO THE HAZARDS OF HIGH

SURFACE TEMPERATURE AND SHOULD

STAY AWAY TO AVOID BURNS OR CLOTHING

IGNITION.

YOUNG CHILDREN SHOULD BE SUPERVISED

WHEN THEY ARE IN THE SAME ROOM AS THE

APPLIANCE.

CLOTHING OR OTHER FLAMMABLE

MATERIAL SHOULD NOT BE PLACED ON

OR NEAR THE APPLIANCE.

KEEP THE ROOM AREA CLEAR AND

FREE FROM COMBUSTIBLE MATERIALS,

GASOLINE, AND OTHER FLAMMABLE

VAPORS AND LIqUIDS.

IF THE INFORMATION IN THESE INSTRUCTIONS IS NOT

FOLLOWED ExACTLY, A FIRE OR ExPLOSION MAY

RESULT CAUSING PROPERTY DAMAGE, PERSONAL

INjURY OR LOSS OF LIFE.

–

Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any other

appliance.

– WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any

phone in your building.

• Immediately call your gas supplier from a neighbor's

phone. Follow the gas supplier's instructions.

• If you cannot reach your gas supplier, call the fire

department.

– Installation and service must be performed by a qualified

installer, service agency or the gas supplier.

WARNING: Improper installation, adjustment, alteration,

services or maintenance can cause injury or property

damage. Refer to this manual. For assistance or additional

information consult a qualified installer, service agency

or the gas supplier.

This appliance may be installed in an aftermarket*,

permanently located, manufactured home (USA only) or

mobile home, where not prohibited by local codes.

This appliance is only for use with the type of gas indicated

on the rating plate. This appliance is not convertible for

use with other gases, unless a certified kit is used.

* Aftermarket: Completion of sale, not for purpose of resale, from the

manufacturer.

WARNING

Summary of 400DVBL

Page 1

Front cover image please add logs inside models: 400dvbl & 500dvbl dvbl series direct vent gas fireplace installation and operating instructions read before installing. Save these instructions due to high temperatures, the appliance should be located out of traffic and away from furniture and draper...

Page 2

74d0010 contents important safety information .......................... 3 product features .............................................. 5 code approval .................................................. 5 pre-installation information installing above 000 feet ............................ 6 orific...

Page 3

74d0010 3 4. Never install the fireplace • in a recreational vehicle • where curtains, furniture, clothing, or other flammable objects are less than 42" from the front, top, or sides of the fireplace • in high traffic areas • in windy or drafty areas 5. This fireplace reaches high temperatures. Keep...

Page 4: Arning

4 74d0010 important safety information continued from page 3 12. Do not use this fireplace to cook food or burn paper or other objects. 13. Never place anything on top of fireplace. 14. Do not use any solid fuels (wood, coal, paper, cardboard, etc.) in this fireplace. Use only the gas type indicated...

Page 5

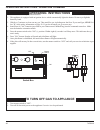

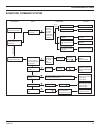

74d0010 5 product features and code approval off/pilot/on knob figure 1 - dvbl series fireplace (millivolt control shown) • this appliance has been certified for use with either natural or propane gas. See appropriate data plates. • this appliance is not for use with solid fuels. • the appliance is ...

Page 6

6 74d0010 pre-installation information installing above 2000 feet • in the usa, the appliance must be derated 4% for every 1,000 ft above 2,000 ft elevations. Where the heating value of the gas has been reduced, these rules do not apply. • in canada, these appliances are certified for altitudes of 0...

Page 7

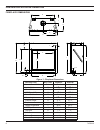

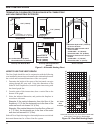

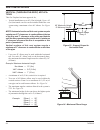

74d0010 7 h g d f e a c b a 1/2” or 5/8” c a g c g a 1/2” or 5/8” firebox framing firebox framing can be built before or after the appliance is set in place. Construct firebox framing following figure 2 and the chart below for your specific installation requirements. See figure 3 on page 8 for fireb...

Page 8

8 74d0010 a n f c k l j i 31 7/8 3 m b d e h g 15/16 11 3/8 pre-installation information figure 3 - fireplace dimensions fireplace dimensions e h j a d l k c f n m b i g description key letter 400dvbl 500dvbl overall front width a 37 1 / 16 " 41 1 / 16 " inside width b 31 15 / 16 " 35 15 / 16 " glas...

Page 9

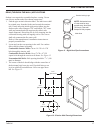

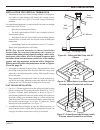

74d0010 9 y e a b c d f y x pre-installation information fireplace location plan for the installation of your appliance. This includes determining where the unit is to be installed, the vent configuration to be used, framing and finishing details, and whether any optional accessories (i.E. Blower, w...

Page 10

10 74d0010 13" min. 6" min. From opening 71" minimum cieling mantel shelf : 0-12” ma x depth follow these instructions carefully to ensure safe installation. Failure to follow instructions exactly can create a fire hazard. The appliance cannot be installed on a carpet, tile or other combustible mate...

Page 11

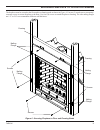

74d0010 11 the fireplace must be secured to the floor and/or to framing studs as shown in figure 6. Use two (2) wood screws or masonry/ concrete screws to secure fireplace to the floor. Use four (4) screws to attach fireplace to framing. The side nailing flanges are 1/2" or 5/8" to accommodate diffe...

Page 12

1 74d0010 read all instructions completely and thoroughly before attempting installation. Failure to do so could result in serious injury, property damage or loss of life. Operation of improperly installed and maintained venting system could result in serious injury, property damage or loss of life....

Page 13

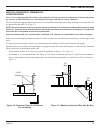

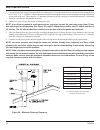

74d0010 13 vent installation figure 7 - combustible clearances for vent pipe a minimum of 3" clearance to the top is required along horizontal length until flue pipe penetrates outside wall. A minimum 1" clearance to combustibles permitted all around flue at outside wall horizontal sections of this ...

Page 14

14 74d0010 vent installation installation planning there are two basic types of direct-vent installation: • horizontal termination • vertical termination it is important to select the proper length of vent pipe for the type of termination you choose. It is also important to note the wall thickness. ...

Page 15

74d0010 15 v v v v v v v v d l e b c f b b b b b m i a a j h g a operable fixed closed fixed closed opera- ble k a a a g vent installation always maintain minimum clearances around vent systems. The minimum clearances to combustibles for horizontal vent pipe are 3" at the top and 1" at the sides and...

Page 16

16 74d0010 v g g=6" (152mm) f f=6" (152mm) v v g g = combustible 24"(610mm) noncombustible 18"(457mm) combustible & noncombustible h = 24" (610mm) j = 20" (508mm) v h j c = maximum depth of 48" (1219mm) for alcove location d = minimum width for back wall of alcove location combustible - 38" (965mm) ...

Page 17

74d0010 17 vent installation rear (through-the-wall) applications sealant is not required to assemble fireplace venting. Do not use silicone sealant at the flue exhaust connections. 1. Find the pipe section's direction label. The label arrow shall be pointed away from the firebox and toward the term...

Page 18

18 74d0010 vent installation rear (through-the-wall) applications (continued) 4. Apply a bead of non-hardening mastic around the outside edge of vent cap. Position the vent cap in the center of hole on the exterior wall with the word "hot" on the vent cap facing up. Insure proper clearance of 1" to ...

Page 19

74d0010 19 12" min. • the maximum number of 90° elbows per side wall installation is three (3). See figure 16. • a minimum of 12" is required before a 90° elbow. If a 90° elbow is fitted directly after 12" vertical section mounted to the top of the fireplace, the maximum horizontal vent run before t...

Page 20

0 74d0010 vertical/horizontal termination configurations (continued) • if a 90° elbow is used in the horizontal vent run (level height maintained) the horizontal vent length is reduced by 36". See figures 16 and 17, page 19 . This does not apply if the 90° elbows are used to increase or redirect a v...

Page 21

74d0010 1 vent installation below grade installations when it is not possible to meet the required vent terminal clearances of 12" above grade level, a snorkel kit is recommended. It allows installation depth down to 7" (178mm) below grade level. The 7" (178mm) is measured from the center of the hor...

Page 22

74d0010 40' maximum height 8' minimum height 10' maximum support straps every 3' vertical (through-the-roof) applica- tions this gas fireplace has been approved for, • vertical installations up to 40' (12m) in height. Up to a 10' (3m) horizontal vent run can be installed within the vent system using...

Page 23

74d0010 3 9 1 / 2 " 9 1 / 2 " vent installation installation for vertical termination 1. Determine the route your vertical venting will take. If ceiling joist, roof rafters or other framing will obstruct the venting system, consider an offset. See figure 25 to avoid cutting load bearing members. For...

Page 24

4 74d0010 vent installation 3. Cut a hole in the roof using the locating hole as a center point. (cover any exposed open vent pipes before cutting hole in roof). The 9 1 / 2 "x9 1/2 " (241mm x 241mm) hole must be measured on the horizontal. Actual length may be larger depending on the pitch of the r...

Page 25

74d0010 5 flex vent installation 1. Flexible ul177 listed venting may be used in any venting application where rigid direct vent components can be used. All restrictions, clearances and allowances that pertain to the rigid piping apply to the flexible venting. Flex kits may not be modified. Flex kit...

Page 26

6 74d0010 flex vent installation 3. Do not allow the flexible vent to bend in radius tighter than 5" (127 mm). Refer to figure 30. 4. Horizontal runs of flexible vent shall be supported at maximum 2 foot intervals; vertical runs, five feet intervals. Metal strapping, properly secured, is an acceptab...

Page 27

74d0010 7 figure 34 - external regulator with vent pointing down (propane/lp only) use only new black iron or steel pipe. Internally tinned copper or copper tubing can be used per national fuel code, section 2.6.3, providing gas meets hydrogen sulfide limits, and where permitted by local codes. Gas ...

Page 28

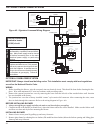

8 74d0010 3" m inim um fireplace installation a listed manual shutoff valve must be installed upstream of the appliance. Union tee and plugged 1/8" npt pressure tapping point should be installed upstream of the appliance. See figure 35. Important: install main gas valve (equipment shutoff valve) in ...

Page 29

74d0010 9 millivolt - checking gas pressure and electrical installation 1. Check gas type. The gas supply must be the same as stated on the appliance’s rating decal. If the gas supply is different from the fireplace, stop! Do not install the appliance. Contact your dealer immediately. 2. To ease ins...

Page 30

30 74d0010 on off optional remote wall switch on off optional remote wall switch pilot hi lo on of f th tp th/tp on off rs remote wall mounted switch a remote wall switch and up to fifteen (15) feet of 18 ga. Wire may be used with this appliance. Attach the wall switch in a junction box at the desir...

Page 31

74d0010 31 thermal sensor clip blower motor blower motor 110/115v ac blower plug black white green fp1910 sc blower wiring diagram 8/08 variable fan control off on 1 2 fan light switch (n.O.) tan (hi temp) ta n (h i t em p ) white black the side walls of the fireplace. Install blowers with the blowe...

Page 32

3 74d0010 a. This appliance is equipped with a pilot which must be lit with built-in piezo ignitor while following these instructions exactly. B. Before operating smell all around the appliance area for gas. Be sure to smell next to the floor because some gas is heavier than air and will settle on t...

Page 33: Pilo

74d0010 33 pilo t of f p il o t on continued on next page approved leak testing method you may check for gas leaks with the following methods only: • soap and water solution • an approved leak testing spray • electronic sniffer if using a soap and water solution to test for leaks, do not spray solut...

Page 34: Pilo

34 74d0010 t pilo t o ff pilo t o n o ff pilo t o n pilo t figure 41 - on position pilo t of f p il o t on figure 40 - on/off/rs switch of f on rs operating instructions (milli-volt) lighting burner main burner switch the “on/off/rs” switch for the main burner can be found behind door of the firepla...

Page 35

74d0010 35 signature command - checking gas pressure and electrical installation 1. Check gas type. The gas supply must be the same as stated on the appliance’s rating decal. If the gas supply is different from the fireplace, stop! Do not install the appliance. Contact your dealer immediately. 2. To...

Page 36

36 74d0010 command center 4-aa battery compartment master swtich to junction box in fireplace conversion ng/lp rf receiver on/off button white black white black black white green connector pin to control box optional ac box { { { optional blower optional light optional aux plug in connect or on/hi o...

Page 37

74d0010 37 figure 46 - junction box wiring diagram fp1912 junction box wiring 8/08 junction box factory supplied not supplied 10v ac 60hz 3. Remove logs. 4. Remove grate from engine by lifting upwards. 5. Remove hearthbrick and wall brick panels. 6. Disconnect the gas line to the valve. 7. Remove sc...

Page 38

38 74d0010 optional fan blower system to junction box in fireplace white black white black black white green connector pin to control box optional ac box { { optional light optional aux control box blower right blower left white white fp1915 ac box wiring 8/08 figure 46c - blower wiring diagram fini...

Page 39

74d0010 39 operating instructions - signature command a. This appliance is equipped with an ignition device which automatically lights the pilot. Refer to the instructions for match lightin. B. Before operating smell all around the appliance area for gas. Be sure to smell next to the floor because s...

Page 40: Operating Instructions

40 74d0010 operating instructions - signature command operating instructions 1. Stop! Read the safety information above. 2. This appliance is equipped with an ignition device which automatically lights the burner. Do not try to light the burner by hand. 3. With five (5) minutes to clear out any gas....

Page 41

74d0010 41 signature command system operation instructions features command center • easy access function operation and system configuration • operation confirmation/fault diagnostic indications (led/ buzzer) • on/off/hi/low operation control board • electronic ignition • pilot lockout safety featur...

Page 42

4 74d0010 signature command system operation instructions 1. When the master switch is in the on position (“-”), pressing the on button and the off button on the command center simultaneously will toggle between enabling and disabling the six-hour shutdown option. 2. After the above operation, one b...

Page 43

74d0010 43 signature command system operation instructions functions/operation (continued) flame height control 1. Press the on button (on the command center) once to turn on the main burner with maximum flame height. 2. Press the off button to decrease flame height. The first two presses will decre...

Page 44

44 74d0010 glass removal figure 48 - removing glass frame glass frame each clamp has a quick spring force. When reinstalling clamps, keep fingers clear. Caution glass frame removal 1. Remove access panel by lifting up and out. 2. Release two clamps (500 model has three clamps) on bottom of fireplace...

Page 45

74d0010 45 final installation figure 50 - rock wool placement rock wool placement 1. Place rock wool on burner to provide glowing embers. For best results, pull the rock wool apart into pieces the size of a dime or smaller. 2. Distribute one layer of rock wool to cover the burner. S ee figure 49. 3....

Page 46

46 74d0010 6. Place the small twig (#4) by having the small pointed end of the log toward the front of the fireplace and the fat end rest - ing evenly with the pointed ends of the right and left front logs. Also, the notch on this log will match the middle tong on the grate. Final installation step ...

Page 47

74d0010 47 figure 51 - pilot flame thermopile thermocouple sensor sparker burner, pilot and control compartment keep the control compartment, logs, and burner areas surrounding the logs clean by vacu - uming or brushing at least twice a year. Make sure the burner porting, pilot air opening and burne...

Page 48

48 74d0010 cleaning and maintenance vent system the fireplace and venting system should be inspected before initial use and at least annually by a quali - fied field service person. Inspect the external vent cap on a regular basis to make sure that no debris is interfering with the airflow. Inspect ...

Page 49

74d0010 49 troubleshooting standing pilot ignition symptom possible cause action 1. Spark ignitor will not light pilot after repeated triggering of piezo. 2. Pilot will not stay lit after carefully follow - ing lighting instruc - tions. . Pilot burning, valve knob turned to “on”, switch is turned to...

Page 50

50 74d0010 troubleshooting standing pilot ignition symptom possible cause action 4. Frequent pilot outage problem. 5. The pilot and main burner extinguish while in operation 6. Glass soots 7. Flame burn blue and lifts off burner (ghost - ing) a. Pilot flame may be too high or too low, causing pilot ...

Page 51

74d0010 51 troubleshooting operation install batteries and/or plug in the ac board flip the master switch (rocker switch) to the on position press the on button on the command center fault no beep in about 8 seconds no beep or no sound from the valve indicating pilot solenoid open no sparking on the...

Page 52

5 74d0010 3 4 5 6 7 illustrated parts lists firebox components.

Page 53

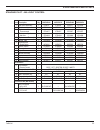

74d0010 53 item description qty 400dvbl 500dvbl standard features 1 junction box assembly (not shown) 1 26d2128k 26d2128k front brick (black) 1 74d0052k 74d0127 3 4 glass frame assembly control cover 1 1 74d0096k 74d0038k 74d0204 74d0119 accessories/field installed options 5 5 t-stat blower with spe...

Page 54

54 74d0010 illustrated parts lists 1 3 4 5 6 7 8 10 11,12,13, 14 standing pilot — millivolt control 2t i c 8.

Page 55

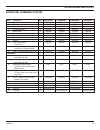

74d0010 55 item description qty 400dvblnv 400dvblpv 500dvblnv 500dvblpv 1 gas valve assembly 1 37d0117 37d0118 37d0117 37d0118 2 pilot assembly 1 37d0018 37d0019 37d0018 37d0019 2c replacement thermocouple 1 37d1067 37d1067 37d1067 37d1067 i replacement igniter and wire 1 37d1069 37d1069 37d1069 37d...

Page 56

56 74d0010 illustrated parts lists signature command system 0009 sg parts 8/08 1 2 3 4 17 5 6 7 8 9 13, 14, 15.

Page 57

74d0010 57 illustrated parts list signature command system item description qty. 400dvblns 400dvblps 500dvblns 500dvblps 1 gas valve assembly 1 80d0001 80d0002 80d0001 80d0002 2 pilot assembly 1 80d0006 80d0007 80d0006 80d0007 3 control box 1 80d0018 80d0019 80d0018 80d0019 4 command center 1 80d000...

Page 58

58 74d0010 vent components illustrated parts list hot 1 3 4 5 6 7 8 9 10 11 for more information about, or instructions for, the venting components referenced above, please contact the component manufaturer: selkirk corporation: www. Selkirkcorp.Com or 800-992-8368 simpson duravent: www. Duravent.Co...

Page 59

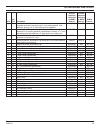

74d0010 59 current current simpson simpson duravent duravent qty./ or mhsc or mhsc selkirk item box description part no. Part no. Part no. 1 1 side wall flexible pipe termination kit bhsftka bhsftk -- includes termination cap with built-in vinyl siding standoff, heat deflector, firestop, 20" to 48" ...

Page 60

60 74d0010 logs illustrated parts lists 1 2 3 4 5 6 item description qty 400dvbl 500dvbl 1 log #1 1 74d0053 74d0053 2 log #2 1 74d0054 74d0054 3 log #3 1 74d0055 74d0055 4 log #4 1 74d0056 74d0056 5 log #5 1 74d0057 74d0057 6 log #6 1 74d0058 74d0058.

Page 61: Special Requirements

74d0010 61 notes note regarding vented products this product must be installed by a licensed plumber or gas fitter when installed within the commonwealth of massachu - setts. Any residence with a direct vent product must have a co detector installed in the residence. Installation of the fireplace or...

Page 62

6 74d0010 2. Approved carbon monoxide detectors. Each carbon monoxide detector as required in accordance with the above provisions shall comply with nfpa 720 and be ansi/ul 2034 listed and ias certified. 3. Signage. A metal or plastic identification plate shall be permanently mounted to the exterior...

Page 63

74d0010 63 limited lifetime warranty policy lifetime warranty the following components are warranted for life to the original owner, subject to proof of purchase: firebox, combustion chamber, heat exchanger, grate and stainless steel burners. Five year warranty the following components are warranted...

Page 64

64 74d0010 september 2008 74d0010 • rev. 10 mhsc 149 cleveland drive • paris, kentucky 40361 www.Mhsc.Com.