- DL manuals

- Majestic

- Indoor Fireplace

- 500DVH Series

- Installation and operating instructions manual

Majestic 500DVH Series Installation and operating instructions manual

DVH SERIES

DIRECT VENT

GAS FIREPLACE

INSTALLATION AND OPERATING

INSTRUCTIONS

MODELS: 500DVHNV/PV/NE/PE/RNV/RPV

READ BEFORE INSTALLING. SAVE THESE INSTRUCTIONS

WARNINGS

DUE TO HIGH TEMPERATURES, THE

APPLIANCE SHOULD BE LOCATED OUT OF

TRAFFIC AND AWAY FROM FURNITURE AND

DRAPERIES.

CHILDREN AND ADULTS SHOULD BE

ALERTED TO THE HAZARDS OF HIGH

SURFACE TEMPERATURE AND SHOULD

STAY AWAY TO AVOID BURNS OR CLOTHING

IGNITION.

YOUNG CHILDREN SHOULD BE SUPERVISED

WHEN THEY ARE IN THE SAME ROOM AS THE

APPLIANCE.

CLOTHING OR OTHER FLAMMABLE

MATERIAL SHOULD NOT BE PLACED ON

OR NEAR THE APPLIANCE.

KEEP THE ROOM AREA CLEAR AND

FREE FROM COMBUSTIBLE MATERIALS,

GASOLINE, AND OTHER FLAMMABLE

VAPORS AND LIqUIDS.

WARNINGS

IF THE INFORMATION IN THESE INSTRUCTIONS ARE

NOT FOLLOWED ExACTLY, A FIRE OR ExPLOSION

MAY RESULT CAUSING PROPERTY DAMAGE,

PERSONAL INjURY OR LOSS OF LIFE.

– Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any other

appliance.

– WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any

phone in your building.

• Immediately call your gas supplier from a

neighbor's phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call the fire

department.

– Installation and service must be performed

by a qualified installer, service agency or the

gas supplier.

WARNING: Improper installation, adjustment, alteration,

services or maintenance can cause injury or property

damage. Refer to this manual. For assistance or

additional information consult a qualified installer,

service agency or the gas supplier.

This appliance may be installed in an OEM installation

in manufactured home (USA only) or mobile home and

must be installed in accordance with the manufacturer's

instructions and the manufactured home construction

and safety standard,

Title 24 CFR, Part 3280 or Standard

for Installation in Mobile Homes. CAN/CSA Z3-240MH.

This appliance is only for use with the type(s) of gas

indicated on the rating plate unless a certified kit is

used.

Summary of 500DVH Series

Page 1

Dvh series direct vent gas fireplace installation and operating instructions models: 500dvhnv/pv/ne/pe/rnv/rpv read before installing. Save these instructions warnings due to high temperatures, the appliance should be located out of traffic and away from furniture and draperies. Children and adults ...

Page 2: Majestic Fireplace.

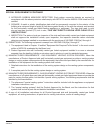

56d3049 contents important safety information .......................... 3 product features .............................................. 5 code approval .................................................. 5 pre-installation information installing above 000 feet ............................ 6 orific...

Page 3

56d3049 3 4. Never install the fireplace • in a recreational vehicle • where curtains, furniture, clothing, or other flammable objects are less than 42" from the front, top, or sides of the fireplace • in high traffic areas • in windy or drafty areas 5. This fireplace reaches high temperatures. Keep...

Page 4

4 56d3049 important safety information continued from page 3 12. Do not use this fireplace to cook food or burn paper or other objects. 13. Never place anything on top of fireplace. 14. Do not use any solid fuels (wood, coal, paper, cardboard, etc.) in this fireplace. Use only the gas type indicated...

Page 5

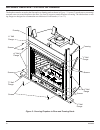

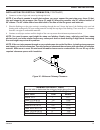

56d3049 5 product features and code approval off/pilot/on knob optional remote receiver figure 1 - 500dvh fireplace (millivolt unit shown - also available in electronic ignition and remote hi/lo with blower models) • this appliance has been certified for use with either natural or propane gas. See a...

Page 6

6 56d3049 pre-installation information installing above 2000 feet • in the usa, the appliance must be derated 4% for every 1,000 ft above 2,000 ft elevations. • in canada, these appliances are certified for altitudes of 0 – 2000 ft, and must be de-rated by 10 percent for installations between 2000 a...

Page 7

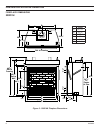

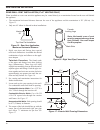

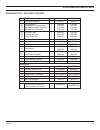

56d3049 7 b a h a e c d f g 1 / 2 " or 5 / 8 " 1 / 2 " or 5 / 8 " c a g c g a 1 / 2 " or 5 / 8 " pre-installation information fireplace framing firebox framing can be built before or after the appliance is set in place. Construct firebox framing following figure 2 and the chart below for your specif...

Page 8

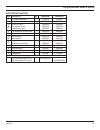

8 56d3049 f b 14 9 / 16 " 22 5 / 16 " 20 3 / 4 " 46 5 / 16 " ref. To framing 15 / 16 " 42 7 / 16 " ref. To wall 34 5 / 8 " to center of pipe 23 3 / 16 " 3 3 / 8 " 40 3 / 8 " 5 / 8 " 5 / 8 " 1 / 2 " 1 / 2 " 34 1 / 2 " 5" 2 1 / 2 " 2" a ref. To framing c d e ref. To wall 7 3 / 8 " 12 1 / 16 " pre-inst...

Page 9

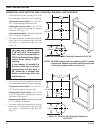

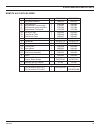

56d3049 9 y e a b c d f y x pre-installation information fireplace location plan for the installation of your appliance. This includes determining where the unit is to be installed, the vent configuration to be used, framing and finishing details, and whether any optional accessories (i.E. Blower, w...

Page 10

10 56d3049 the fireplace must be secured to the floor and/or to framing studs as shown in figure 5 . Use two (2) wood screws or masonry/ concrete screws to secure fireplace to the floor. Use four (4) screws to attach fireplace to framing. The side brackets or nail - ing flanges are designed to accom...

Page 11

56d3049 11 10 3 / 4 "9 1 / 2 " 8 1 / 4 " 7" 12" 6" 12" 10" 8" 6" 4" 2 1 / 2 " 12" maximum depth 12" minimum 72" minimum minimum 6" from both side walls clearances clearances to combustibles mantel clearances note: the combustible area around the fireplace must not protrude more than 1 / 2 " from the...

Page 12

1 56d3049 installation precautions consult local building codes before beginning the installation. The installer must make sure to select the proper vent system for installation. Before installing vent kit, the installer must read this fireplace manual and vent kit instructions. Only a qualified ins...

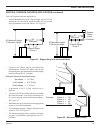

Page 13

56d3049 13 1" 1" 1" 1" 3" vent installation figure 8 - combustible clearances for vent pipe a minimum of 3" clearance to the top is required along horizontal length until flue pipe penetrates outside wall. W arning a minimum 1" clearance to combustibles permitted all around flue at outside wall main...

Page 14

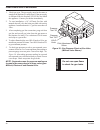

14 56d3049 vent installation optional top vent application the appliance is shipped as a rear vent unit. If the installation layout requires the unit to be a top vent configuration the appli - ance can be converted by following the steps below. When removing and refitting the plates and adapter be s...

Page 15

56d3049 15 vent installation installation planning there are two basic types of direct-vent installation: • horizontal termination • vertical termination it is important to select the proper length of vent pipe for the type of termination you choose. It is also important to note the wall thickness. ...

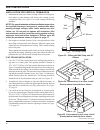

Page 16

16 56d3049 v v v v v v v v d l e b c f b b b b b m i a a j h g a operable fixed closed fixed closed opera- ble k a a a g vent installation figure 12 - horizontal vent termination location vent terminal air supply inlet area where terminals not permitted inside corner detail for horizontal terminatio...

Page 17

56d3049 17 v g g = combustible 24"(610mm) noncombustible 18"(457mm) combustible & noncombustible h = 24" (610mm) j = 20" (508mm) v h j c = maximum depth of 48" (1219mm) for alcove location d = minimum width for back wall of alcove location combustible - 38" (965mm) noncombustible - 24" (610mm) e = c...

Page 18

18 56d3049 maximum 20" 10 1 / 2 " (267mm) 10 1 / 2 " (267mm) 8 1 / 2 " (216mm) combustible wall noncombustible wall rear wall vent installation (5" x 8" venting only) when installed as a rear vent unit this appliance may be vented directly to a termination located on the rear wall behind the applian...

Page 19

56d3049 19 hot ho t vent installation 4. Apply a bead of non-hardening mastic around the outside edge of vent cap. Position the vent cap in the center of hole on the exterior wall with the word “up” on the vent cap facing up. Insure proper clearance of 1" to combustibles is maintained. Attach the ve...

Page 20

0 56d3049 vent installation horizontal with vertical rise (through-the-wall) termination configura - tions since it is very important that the venting system maintain its balance between the combustion air intake and the flue gas exhaust, certain limitations as to vent configurations apply and must ...

Page 21

56d3049 1 horizontal (through-the-wall) termination configuration (continued) • if a 90° elbow is used in the horizontal vent run (level height maintained) the horizontal vent length is reduced by 36" (914 mm) (fig. 21 a and b) this does not apply if the 90° elbows are used to increase or redirect a...

Page 22

56d3049 10 1 / 2 " (267mm) 10 1 / 2 " (267mm) 8 1 / 2 " (216mm) combustible wall noncombustible wall 9 1 / 2 " (241mm) 9 1 / 2 " (241mm) 3 3 / 4 " (92mm) 7 1 / 2 " (190mm) vent installation 1. Locate and cut the vent opening in the wall. For combustible walls first frame in opening. Combustible inte...

Page 23

56d3049 3 vent installation below grade installations when it is not possible to meet the required vent terminal clearances of 12" above grade level, a snorkel kit is recommended. It allows installation depth down to 7" (178mm) below grade level. The 7" (178mm) is measured from the center of the hor...

Page 24

4 56d3049 vertical through-the-roof applications vent installation figure 30 - installing restrictor disc into stove collar restrictor disc stove collar notice a restrictor disc must be installed on any vertical termination that is higher than 12'. Install restrictor disc as shown in figure 30 for v...

Page 25

56d3049 5 figure 32 - maximum elbow usage • up to two 45° elbows may be used within the horizontal run. For each 45° elbow used on the horizontal plane, the maximum horizontal length must be reduced by 18" (450mm). Example: maximum horizontal length no elbows = 10’ (3m) 1x45° elbows = 8.5’ (2.6m) 2x...

Page 26

6 56d3049 10 1 / 2 " 10 1 / 2 " vent installation installation for vertical termination 1. Determine the route your vertical venting will take. If ceiling joist, roof rafters or other framing will obstruct the venting system, consider an offset. See figure 33 to avoid cutting load bearing members. N...

Page 27

56d3049 7 h x 12" vent installation installation for vertical termination (continued) 4. Connect a section of pipe and extend up through the hole. Note: if an offset is needed to avoid obstructions, you must support the vent pipe every three (3) feet. Use wall straps for this purpose. See figure 33,...

Page 28

8 56d3049 figure 37 - external regulator with vent pointing down (propane/lp only) fireplace installation check gas type use proper gas type for the fireplace you are installing. If you have conflicting gas type, do not install fireplace. See dealer where you purchased the fireplace for proper firep...

Page 29

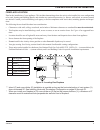

56d3049 9 3" m inim um fireplace installation a listed manual shutoff valve must be installed upstream of the appliance. Union tee and plugged 1 / 8 " npt pressure tapping point should be installed upstream of the appliance. See figure 38. Important: install main gas valve (equipment shutoff valve) ...

Page 30

30 56d3049 checking gas pressure 1. Check gas type. The gas supply must be the same as stated on the appliance’s rating decal. If the gas supply is different from the fireplace, stop! Do not install the appliance. Contact your dealer immediately. 2. To ease installation, a 18" (457mm) flex line with...

Page 31

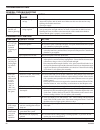

56d3049 31 on off optional remote wall switch on off optional remote wall switch pilot hi lo on of f th tp th/tp on off rs remote wall mounted switch for millivolt valves only a remote wall switch and up to fifteen (15) feet of 18 ga. Wire may be used with this appliance. Attach the wall switch in a...

Page 32

3 56d3049 #1 #2 #3 #4 #5 #6 7# electronic valve gray #7 red #2 red #2 black #4 green #6 blue #1 blue yellow yellow white #3 magenta #5 15’ wall switch wire black white switch rs off on transformer secondary 24v white white green black black primary - 120v to junction box pilot assembly spark sense i...

Page 33

56d3049 33 pilot on off th tp th/tp to junction box to junction box primary - 120v/ac cord extension a/c adaptor secondary 8v/dc remote hi/lo valve remote control receiver wire harness blower #1 blower #2 on rs off electrical installation figure 42 - remote hi/lo with blower wiring diagram remote hi...

Page 34

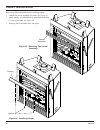

34 56d3049 canopy installation remove top louver assembly before installing canopy. 1. Unhook top louver assembly. Set aside. See figure 43. 2. Attach canopy to underside of top outer shell with three (3) screws provided. See figure 44. 3. Hook top louver assembly back into place. Figure 43 - removi...

Page 35

56d3049 35 glass removal glass frame removal 1. Remove louver assembly from the top. 2. Release three (3) clamps on bottom of fireplace. See figure 45. 3. Tilt glass frame out and lift glass frame up until it clears hook on top of fireplace. 4. Set glass frame aside. Figure 45 - removing glass frame...

Page 36

36 56d3049 brick installation floor brick installation install floor brick before installing logs or rock wool. 1. Remove floor brick from packaging. 2. Put left and right brick pieces together as shown in figure 46. 3. Match two (2) firebox tabs with two (2) slots on bottom of brick. See figure 46....

Page 37

56d3049 37 log and rock wool installation continued installing logs and rock wool (ember material) in firebox figure 49 - installing rear log (#1) rear log (#1) pins bottom left log (#2) pins figure 50 - installing bottom left log (#6) figure 48 - installing bottom right log (#3) bottom right log (#...

Page 38

38 56d3049 log and rock wool installation figure 51 - installing right mid log (#7) left mid log (#6) pins figure 52 - installing right mid log (#6) pins right mid log (#7) 7. Place right mid log (#7) on two right pins on burner assembly. See figure 51. 8. Place left mid log (#6) on two left pins on...

Page 39

56d3049 39 figure 57 - rock wool placement after logs are installed (top view) rock wool rock wool installation 11. Place top center log (#8) across rear log (#1) and left mid log (#6). See figure 55. 12. Cover any exposed burner surface with rock wool. For best flame and glow, do not block air spac...

Page 40

40 56d3049 a. This appliance is equipped with a pilot which must be lit with built-in ignitor while following these instructions exactly. B. Before operating smell all around the appliance area for gas. Be sure to smell next to the floor because some gas is heavier than air and will settle on the fl...

Page 41: Pilo

56d3049 41 pilo t of f p il o t on continued on next page operating instructions - millivolt and remote hi/lo approved leak testing method you may check for gas leaks with the following methods only: • soap and water solution • an approved leak testing spray • electronic sniffer note: remove any exc...

Page 42: Pilo

4 56d3049 50 pilo t o ff pilo t o n o ff pilo t o n pilo t pilo t of f p il o t on figure 59 - on/off/rs switch rs off on operating instructions - millivolt main burner switch the “on/off/rs” switch for the main burner can be found behind door of the fireplace. This switch allows you to turn on and ...

Page 43

56d3049 43 o n o f f pil ot lo hi figure 63 - electronic gas valve operating instructions - electronic ignition 1. Stop! Read the safety information above. 2. Set switch to “off”. 3. Turn off all electric power to the appliance. 4. This appliance is equipped with an ignition device which auto - mati...

Page 44: Pilo

44 56d3049 pilo t o ff pilo t o n o ff pilo t o n pilo t pilo t of f p il o t on operating instructions - remote hi/lo with blower lighting pilot and burner lighting pilot see instructions on pages 40 and 41 . Lighting the burner depress and turn the knob counterclockwise to the “on” position. See f...

Page 45

56d3049 45 operating instructions - remote hi/lo with blower this remote control system provides a safe, reliable and user-friendly remote control for the millivolt valve gas, blower speed and flame height adjustment. The system can be manually or thermostatically turned on and off with the transmit...

Page 46

46 56d3049 on dip 1 2 3 4 on dip 1 2 3 4 on dip 1 2 3 4 on dip 1 2 3 4 operating instructions - remote hi/lo with blower remote transmitter installing batteries the remote transmitter uses three (3) “aaa” batteries. To install batteries… 1. Press down the battery door tab. Pull out to remove the bat...

Page 47

56d3049 47 f 88 ° on off set f 88 ° fan ambient auto flame 70 °f 70 °f 70 ° 75 ° f f set operating instructions - remote hi/lo with blower transmitter - see figure 68 general this remote control has two (2) operating modes — manual and thermostatic. The control system can be set to temperature range...

Page 48

48 56d3049 70 °f 05 08 ° f 02 70 °f operating instructions - remote hi/lo with blower 3-speed blower control - see figure 72 1. Press fan button once to enter blower speed setup mode at low speed initially and one of the three blade icon will display darken on lcd display. 2. Continue to press fan b...

Page 49

56d3049 49 70 °f hi on off rs operating instructions - remote hi/lo with blower child-proof protection - see figure 76 1. Press and hold the on and off buttons simultaneously for 3 seconds to enter childproof mode as shown in this picture. 2. The transmitter will not send a signal again until childp...

Page 50

50 56d3049 operating instructions - remote hi/lo with blower testing your new remote control system 1. Light your gas appliance following the appliance lighting instructions on page 41. 2. Slide the 3 position button on the remote receiver to the on position and the main gas flame should ignite. 3. ...

Page 51

56d3049 51 figure 79 - pilot flame burner flame the flames from the burner should be visually checked as soon as the heater is installed and periodically during normal operation. In normal operation, at full rate, and after operating for about 15 to 30 minutes, the flame should be yellow and slightl...

Page 52

5 56d3049 cleaning and maintenance vent system the fireplace and venting system should be inspected before initial use and at least annually by a qualified field service person. Inspect the external vent cap on a regular basis to make sure that no debris is interfering with the airflow. Inspect enti...

Page 53

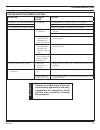

56d3049 53 2 3 6 7 4 1 5 8 logs item description qty 500dvh 1 rear log 1 56d3034k bottom left log 1 56d3035k 3 bottom right log 1 56d3036k 4 left top log 1 56d3037k 5 right top log 1 56d3038k 6 left mid log 1 56d3039k 7 right mid log 1 56d3040k 8 center log 1 56d3041k illustrated parts list.

Page 54

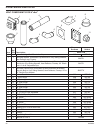

54 56d3049 vent components for 4" x 6 5 / 8 " hot 1 3 4 5 6 7 8 9 10 illustrated parts list item qty/ box description simpson duravent selkirk mhsc p/n 1 1 horizontal high wind termination cap 985 4dt-hc 1 1 horizontal square termination cap with built-in vinyl siding standoff, heat deflector and fi...

Page 55

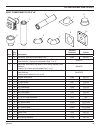

56d3049 55 vent components for 5" x 8" hot 1 3 4 5 6 7 8 9 10 illustrated parts list item qty/ box description simpson duravent selkirk mhsc p/n 1 1 horizontal high wind termination cap 185 5dt-hc 1 1 horizontal termination cap with built-in vinyl siding standoff, heat deflector, firestop and adjust...

Page 56

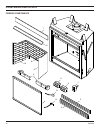

56 56d3049 1 5 10 3 2 4 6 9 8 13 7 12 11 11 illustrated parts lists firebox components.

Page 57

56d3049 57 firebox components illustrated parts lists item description qty 500dvh standard features 1 junction box assembly 1 26d2128k top louver assembly 1 56d2134k 3 bottom louver door assembly 1 56d2135k 4 glass frame assembly 1 56d3050 5 canopy 1 56d2056k 6 firebrick floor 1 56d3055 7 insulation...

Page 58

58 56d3049 illustrated parts lists additional accessories 1 3 4 5.

Page 59

56d3049 59 illustrated parts lists additional accessories/field installed options available item description qty 500dvh 1 1 1 metal trim - brass metal trim - pewter metal trim - black 1 1 1 brmtk500 pwmtk500 blmtk500 brass louvers pewter louvers 8 8 l36brm l36pwm 3 screen frame - black 1 sdv500sdc 4...

Page 60

60 56d3049 illustrated parts lists 1 3a, 3b, 3c 4 5 6 7 10 standing pilot — millivolt control 2t i c 9 11,12, 13, 14, 15, 16 8b 8a.

Page 61

56d3049 61 standing pilot – millivolt control illustrated parts lists item description qty 500dvhnv 500dvhpv 1 gas valve assembly 1 37d0117 37d0118 c i 2t pilot assembly replacement thermocouple replacement igniter and wire replacement thermopile 1 1 1 1 0h048 37d1067 37d1069 37d1068 0h049 37d1067 3...

Page 62

6 56d3049 #1 #2 #3 #4 #5 #6 7# lo hi illustrated parts lists 1 3a, 3b, 3c 4 5 6 9 electronic ignition 8 10 11 7b 7a.

Page 63

56d3049 63 electronic ignition illustrated parts lists item description qty 500dvhne 500dvhpe 1 gas valve assembly 1 37d0016 37d0017 pilot assembly 1 54d2004 54d2005 3a 3b 3c valve/tee tube front burner tube rear burner tube 1 1 1 56d3045 56d3046 56d3047 56d3045 56d3046 56d3047 4 flex hose with shut...

Page 64

64 56d3049 on off rs illustrated parts lists 1 3a, 3b, 3c 4 6 7 10 standing pilot — remote hi/lo with blower 2t i c 9 5 8b 8a 11.

Page 65

56d3049 65 remote hi/lo with blower illustrated parts lists item description qty 500dvhrnv 500dvhrpv 1 gas valve assembly 1 56d3074 56d3075 c i 2t pilot assembly replacement thermocouple replacement igniter and wire replacement thermopile 1 1 1 1 0h048 37d1067 37d1069 37d1068 0h049 37d1067 37d1069 3...

Page 66: Special Requirements

66 56d3049 massachusetts residents only massachusetts residents only: please read and follow these special requirements note regarding vented products this product must be installed by a licensed plumber or gas fitter when installed within the commonwealth of massachusetts. Any residence with a dire...

Page 67

56d3049 67 massachusetts residents only 2. Approved carbon monoxide detectors. Each carbon monoxide detector as required in accordance with the above provisions shall comply with nfpa 720 and be ansi/ul 2034 listed and ias certified. 3. Signage. A metal or plastic identification plate shall be perma...

Page 68

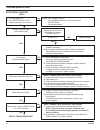

68 56d3049 standing pilot ignition troubleshooting symptom possible cause action 1. Spark ignitor will not light pilot after repeated triggering of piezo. A. Wire disconnected. A. Open door and check to make sure wire is connected to ignitor. B. Defective ignitor. B. Check for spark at electrode and...

Page 69

56d3049 69 troubleshooting remote system symptom possible cause action 1. Battery icon on lcd on transmitter. 1. Low battery 1. Replace batteries. Change batteries every 6 months. 2. Lcd display is blank 2. Check battery installation or replace batteries. 3. Lcd display shows “funny” display 3. Pres...

Page 70

70 56d3049 electronic ignition troubleshooting start 1. Turn gas supply off. 2. Turn on/off switch to “on” power to module (24v normal) yes is there a spark across ignitor sensor gap? Yes turn on gas. Does pilot burner light? Yes does spark stop when pilot is lit? Yes does main burner light? Yes doe...

Page 71

56d3049 71 limited lifetime warranty policy lifetime warranty the following components are warranted for life to the original owner, subject to proof of purchase: firebox, combustion chamber, heat exchanger, grate and stainless steel burners. Five year warranty the following components are warranted...

Page 72

7 56d3049 mhsc 149 cleveland drive • paris, kentucky 40361 www.Mhsc.Com august 2008 56d3049 • rev. 3.