Make mendel megabot megabot is a latest generation 3d printer, capable of printing 3d objects megabot uses high quality linear motion guides. So it is very easy to build. Self locking design ensures rigid frame with easy steps(without need of any measurements, during building) any person can easily ...

Make mendel page 2 technical specification : • machine size 400 x 1000 x 400 mm • build size 220 x 740 x 165 mm • nozzle diameter : 0.4mm • layer thickness : 0.1mm • speed : 60 mm/s • positioning precision : 27 microns • input format : stl • software : pronterface (available on site for free under d...

Make mendel page 3 assembly of megabot.

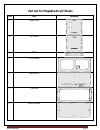

Make mendel page 4 part list for megabot-acrylic sheets qty part drawing 1 rightplate 1 leftplate 1 xplate 1 frontplate 1 backplate 1 topplate 1 bottomplate.

Make mendel page 5 1 printbed-supportplate 1 glassprint bed 1 acrylicprintbed 3 pcb heatbed 1 extruderbaseplate 1 extrudermotorplate 1 driven holder 1 idler holder 2 x-rail top plate 4 topsmoothrodcap(2 with counter sink for front side) 4 bottomsmoothrodcap 1 acrylic support for z mechanical switch ...

Make mendel page 6 hardware qty part drawing 57(36inbag+ 21attached) m3 nylock nut (16bigrail+ 8smallrail, 16flange bearing+8flangenut+ 1extruder idler+8 glass support) 28 m4 nylock nut (4 belt idler + 2 belt idler + 16smoothrodcap + 2motormountingplate + 4printbed) 6 m2.5x20 screw (4mechanical swit...

Make mendel page 7 5 smps mounting screw 103 m3 washer 54 m4 washer 14 m4x10 washer (12belt idler + 2z mechanical switch) 22 624-bearing (belt idler) 2 623-bearing (extruder) 2 flange nut 4 flange bearing 2 coupling 5 _8 2 soft spring (1extruder + 1zswitch) 4 hard spring (printbed) 3 dummy rails 1 f...

Make mendel page 8 hotend and electronics quantity part drawing 5 stepper motors-nema 17 3 steppermotor extension cable 2 t2.5 timing pulley_5mmbore (for x-y motor) 1 j hotend with cartridge heater 2 j-hotend extension cable 1 printrboard rev d electronics board 1 jumper for printrboard 1 lcd 1 lcd ...

Make mendel page 9 1 universal travel adaptor 1 smps 2 kapton tapes (50mm + 15mm) 1 magnetic leveler 1 10m sample pla 2 m8 threaded rod -285mm 1 spool holder-125mm 4 smooth rod(8mm dia)-333mm 1 paper tape 50mm wide 1 allan key 2 (m4-grubscrew, pulley+mk7) 1 allan key 2.5 (m3 socket cap head) 1 allan...

Make mendel page 10 list of frames 2x side plates: front plate: back plate : xplate.

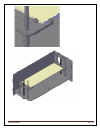

Make mendel page 11 assemble bottom plate : 1) attach the circuit board (printrboard) at the bottom of the bottom-plate, using plastic ties. 2) attach two z motors at the bottom plate. 3) use z prusa cable to connect two z motors, whose one end will go to printrboard. Z mechanical switch assembly 1)...

Make mendel page 12 frame assembly fix two side plates with bottom plate using plastic ties. Mechanical switch to limit the mechanical switch.

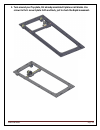

Make mendel page 13 assembly of x plate 1. Now we will assemble x plate. 2. Put rail along with block on x plate. Rail is pre assembly by our team. 3. Put two acrylic blocks on rail block. 4. On top of that put the extruder, which is pre assembled. Use screws to fix the extruder on rail..

Make mendel page 14 5. Now will assemble x mechanical switch on x plate. Use m2.5 x 25 screw to fix it at proper place. Mechanical switch is soldered to two pin molex already which will go to printrboard (x-stop). 6. Your x plate is ready with complete extruder placed on it..

Make mendel page 15 assembly of printbed support plate 1. Assemble flange bearing at both corners of printbed support plate using m3x20 cap screws. 2. Fix the flange nut of lead screw using m3x20 cap screws. 3. Assemble the other side support plate following step no.1 & 2. 4. Both side printbed supp...

Make mendel page 16 3. Place lead screw (threaded) at the center of bottom plate. Place smooth rods on either side of lead screw. Fix the base of smooth rod in smooth rod caps using screws. 4. Repeat step no.2 & 3 to do assembly of rods on right hand side. 5. Now your rods are fixed on bottom plate..

Make mendel page 17 glass printbed assembly 1. Place glass on printbed support plate. Be very careful with glass. Take your friends help while fixing glass to hold it from other side. 2. Using plastic ziplock ties fix the glass from all the 4 corners. 3. Use the small 8 x acrylic blocks given. They ...

Make mendel page 18.

Make mendel page 19 before moving to top plate assembly will keep the belt adjuster ready, so that belt placement will be much handy. Assemble a set of 624 bearings, m4x40 socket, mudguard, m4 washer, and m4 nylock nut. Top plate assembly 1. Place the two motors at each corner of top plate using m3 ...

Make mendel page 20 3. Turn around your top plate, put already assembled x plate on rail blocks. Use screws to fix it. Move x plate forth and back, just to check the rapid movement..

Make mendel page 21 4. Place the belt adjuster and t2.5 pulley on top plate. See below image for the places where they should be placed. 5. Place bearing stack on x plate. Use bearing support of x plate. They should be place on four corners of x plate. 2 bearing support at each corner..

Make mendel page 22 6. Now will assemble belt, follow the below sequence. Attaching belt to the extruderbase plate 1) take the extruderbase plate, apply some glue on side face (this is not must), then just use plastic ties to tie it. Start to fix the t2.5 belt from one side of extruder base plate. 2...

Make mendel page 23 7. You are done with top plate assembly. Now put all the frames together, starting from bottom plate. Your frame with rods , glass printbed is ready, just put the top frame and your machine is ready to print.. M4x20 driver gear.

Make mendel page 24 step 8 –j-hotend soldering: we have already, given you pre-soldered hotend with the kit. So you do not need to do below steps..

Make mendel page 25 1) thermistor with kapton tape and teflon sleeve 2) teflon wire with 4 pin molex connector solder the yellow and grey wire to resistor solder the red wire to thermistor.

Make mendel page 26 3) use the silicon glue to fill the gap between resistor and brass block of hotend. 4) final assembling of j head hotend extruder. Note: set extuder temperature to 185 degree, allow it to heat up to 180 degree then only hit “extrude” button on pronterface software. This will avoi...

Make mendel page 27 step 9: electrical wiring (printrboard) place printrboard on acrylic board with cap screw m3x12 connect the cables as shown above..

Make mendel page 28 steps to be followed while using printrboard electronics: 1. Check whether all the connections made on your printrboard board are proper. 2. Printrboard comes ready to print with marlin rc 2 firmware and lufa cdc bootloader, so you do not need to change any firmware, if you have ...

Make mendel page 29 printer images:.