- DL manuals

- MAKINEX

- Pressure Washer

- DPW-4000

- Operator's Manual

MAKINEX DPW-4000 Operator's Manual

Summary of DPW-4000

Page 1

[type text] dual pressure washer dpw-4000, dpw-4000-0aha, dpw-4000-0ahu operator’s manual rev 13 date: 04/15.

Page 2

Page 2 of 56 table of contents introduction ...................................................................................................................................................... 4 disclaimer ...............................................................................................

Page 3

Page 3 of 56 changing pump oil ....................................................................................................................................... 31 checking the oil level ..............................................................................................................

Page 4

Page 4 of 56 introduction thank you for purchasing a makinex product. This manual provides information and procedures to safely operate and maintain the dual pressure washer dpw-4000 range. For your own safety and protection from injury, carefully read, understand and observe the safety instructions...

Page 5

Page 5 of 56 about this manual this manual uses the following symbols to help differentiate between different kinds of information. The safety symbol is used with a key word to alert you to potential hazards in operating and owning power equipment. Follow all safety messages to avoid or reduce the r...

Page 6

Page 6 of 56 product information safety information warning read this manual thoroughly before operating your pressure washer. Failure to follow instructions could result in serious injury or death warning makinex dual pressure washer is designed for professional operators only, instruct operators i...

Page 7

Page 7 of 56 always operate pressure washer in a well-ventilated area. Avoid enclosed areas such as garages, basements etc. Always keep exhaust gas from entering a confined area through windows, doors, ventilation intakes, or other openings. Always follow manufacturer’s recommendations, use a respir...

Page 8

Page 8 of 56 warning risk of fluid injection the high pressure stream of water that this equipment produces can cut through skin and its underlying tissues, leading to serious injury and possible amputation. Spray guns trap high pressure, even when engine is stopped and water is disconnected, which ...

Page 9

Page 9 of 56 danger risk of chemical burn use of acids, toxic or corrosive chemicals, poisons, insecticides, or any kind of flammable solvent with this product could result in serious injury or death. Wear protective clothing to protect eyes and skin from contact with sprayed material. Danger risk o...

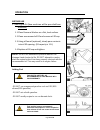

Page 10

Page 10 of 56 safety decals note: model dpw-4000

Page 11

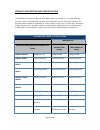

Page 11 of 56 product description and specifications the makinex dual pressure washer dpw-4000 range is a versatile, 2 in 1 compact 4000 psi pressure cleaner. It is designed and engineered to simplify the process of pressure washing. The pressure washer includes a combination of a rotary cleaner, a ...

Page 12

Page 12 of 56 gear box direct drive 2:1 reduction direct drive noise level @ handle 92dba 92dba 92dba noise level @ 7m 88dba 88dba 88dba rotoclean 610mm (24’’) 610mm (24’’) 610mm (24’’) ball valve 500 bar/7200 psi rated 3 way ball valve 500 bar/7200 psi rated 3 way ball valve 500 bar/7200 psi rated ...

Page 13

Page 13 of 56 overall machine dimensions note: model dpw-4000

Page 14

Page 14 of 56 pump specifications makinex aus makinex usa ar xw15.30n (with gear reduction) for model dpw-4000 rkv3.5g40hd-f34 (direct drive) for model dpw-4000-0ahu pressure output max 4000 psi/275.8 bar 4000 psi/275.8 bar flow rate max 15l/min (4 gal/min) 13.2l/min (3.5 gal/min) oil type sae30 sae...

Page 15

Page 15 of 56 max power output 13hp (9.6kw) @ 3600 rpm net torque 19.5 lb-ft (26.4nm) @ 2500 rpm pto shaft rotation counter-clockwise (from pto shaft side) compression ratio 8.2:1 lamp/charge coil options 25w, 50w/1a, 3a,10a,18a carburator butterfly float type ignition system digital cdi with variab...

Page 16

Page 16 of 56 controls and features note: model dpw-4000

Page 17

Page 17 of 56 features adjustable valve for easy operation switch adjustable pressure 1000-4000 psi built in pressure gauge durable galvanised frame easy manoeuvrable trolley with front swivel castors electric start motor (dpw-4000) pull start motor (dpw-4000-0aha, dpw- 4000-0ahu) gear box reduction...

Page 18

Page 18 of 56 operation before use 1. Add engine oil (new machines will be pre-oiled from makinex) 1.1 place pressure washer on a flat, level surface. 1.2 clean area around oil fill and remove oil fill cap. 1.3 using oil funnel (optional), slowly pour contents into oil fill opening. (oil capacity is...

Page 19

Page 19 of 56 when adding fuel to pressure washer, observe the following steps: 2.1 turn pressure washer off and let it cool for at least two minutes before removing fuel cap. Loosen fuel cap slowly to release pressure. 2.2 fill fuel tank outdoors. 2.3 do not overfill fuel tank. Leave room for fuel ...

Page 20

Page 20 of 56 operating your pressure washer 1. How to pre-start your pressure washer to start your pressure washer for the first time, follow these instructions. This information also applies if you let the pressure washer sit idle for at least a day. 1.1 place pressure washer near an outside water...

Page 21

Page 21 of 56 3. Connect garden hose to water inlet connector 3.1 before connecting the garden hose to the water inlet connector, inspect the filter 3.2 run water through your garden hose for 30 seconds to clean put any debris 3.3 release any pressure from spray gun by pulling the trigger. 3.4 conne...

Page 22

Page 22 of 56 4. Adjust valve position to roto-clean warning risk of eye injury. Spray can splash back or propel objects always wear safety goggles when using this equipment or in vicinity of where equipment is in use. Before starting the pressure washer, be sure you are wearing adequate safety gogg...

Page 23

Page 23 of 56 6. Checking/adjusting pressure the makinex dual pressure washer operating pressure is pre-adjusted to 4000 psi. Over adjusting pressure will void warranty. ***important*** do not run the pump without the water supply connected and turned on. Damage to equipment resulting from failure t...

Page 24: Roto-Clean Operation

Page 24 of 56 7. Two types of operations by using the valve, you can choose between two types of operation. Roto-clean operation spray gun operation.

Page 25

Page 25 of 56 8. Nozzle selection the nozzle on the spray gun that comes with the makinex dual pressure washer is a ¼ npt m 15° size 4. Your roto-clean will come installed with one set of 25020 nozzles (25 degree 2.0 orifice). The minimum orifice to be used in your roto-clean is half that which is b...

Page 26

Page 26 of 56 9. Foldable handle 8.1 release the lock pin by pressing down on spring tab of the handle lock tab. Refer to above. 8.2 use both hands at the same time. 8.3 lock pin will spring into place at their designated grooves..

Page 27

Page 27 of 56 10. How to stop your pressure washer 10.1 turn off the engine 10.2 release pressure from spray gun, always point gun in safe position before pressing trigger. Note: spray gun traps high water pressure, even when engine is stopped and water is disconnected. 10.3 move throttle control le...

Page 28

Page 28 of 56 maintenance general recommendations: regular maintenance will improve the performance and extend the life of the pressure washer. The pressure washer’s warranty does not cover items that have been subjected to operator abuse or negligence. To receive full value from the warranty, the o...

Page 29

Page 29 of 56 pressure washer maintenance clean debris daily or before use, clean accumulated debris from cleaning system. Keep the unit clean at all times. Keep area around and behind muffler free from any combustible debris. Inspect cooling air slots and openings on the pressure washer. These open...

Page 30

Page 30 of 56 check spray gun examine the hose connection to the spray gun and make sure it is secure, and make sure the ‘safety lock’ is present and attach on the trigger, it helps to prevent any accidental jets when in operation. Replace spray gun immediately if the safety lock is damaged or not f...

Page 31

Page 31 of 56 12. Use same nozzle maintenance with the roto-clean. If pressure drops off check nozzle for wear. Nozzles should be replaced on a regular basis (suggestion: every month for machines in regular use, every three months for machines used intermittently). Using the machine with the incorre...

Page 32

Page 32 of 56 checking the oil level check the oil with the pump level and cold. Check the amount of oil through the level gauge (a). If necessary, top up with oil with the characteristics specified in the ‘lubricants table’. To top up with oil proceed as described below. 1. Unscrew the plug (b) and...

Page 33

Page 33 of 56 lengthy pump lay-offs if the pump is to be unused for a long time, proceed as described below. 1. Run the pump with clean water for a few minutes. 2. Operate the pump without water for 10 seconds with the end of the delivery pipeline open to empty the pump and the delivery circuit and ...

Page 34

Page 34 of 56 roto-clean maintenance the roto-clean must be maintained to ensure correct function and longevity of life. There are two nozzles attached and they need to be checked before every use and are similar to nozzle maintenance of the spray gun. We recommend that you supply grease to the rota...

Page 35

Page 35 of 56 storage long term storage instructions (fuel in tank) gasoline fuel can become stale when stored over 30 days. Stale fuel causes acid and gum deposits to form in the fuel system or crucial carburetor parts. To keep fuel fresh, add a fuel stabiliser liquid additive to fuel. The fuel sta...

Page 36

Page 36 of 56 storage of pressure washer 1. Drain all water from high pressure line, coil it and store it in cradle of pressure washer handle. 2. Drain all water from spray gun and spray wand by holding spray gun in vertical position with nozzle pointed downward. Squeeze trigger to remove fluids fro...

Page 37

Page 37 of 56 charge the battery for pressure washer equipped with batteries for electric starting, proper battery maintenance and storage should be followed. An automatic battery charger with automatic trickle charging capability should be used to charge the battery. Maximum charging rate should no...

Page 38: Trouble Shooting Guide

Page 38 of 56 troubleshooting trouble shooting guide problem cause remedy pump does not reach the specified pressures pump sucking air restore the tightness of the intake line intake flow rate insufficient increase the size of the intake pipelines remove and kinks from the pipes increase the filter ...

Page 39

Page 39 of 56 water in oil guide piston gasket worn replace the gaskets (1) high humidity percentage in air change the oil twice as often worn gaskets replace the gaskets (1) oil leak from pump worn gaskets replace the gaskets (1) worn pistons replace the pistons (1) loose drain plug tighten drain p...

Page 40

Page 40 of 56 limited warranty in order to take advantage of the makinex limited warranty, you must have maintenance performed according to the schedule (contained in relevant owner’s manual supplied with this product), by an authorised makinex dealer or makinex service technician. You are free to h...

Page 41

Page 41 of 56 warranty exclusions: this warranty does not cover the following repairs and equipment: normal wear pressure washers need periodic parts and service to perform well. This warranty does not cover repair when normal use has exhausted the life of a part or the equipment as a whole. Install...

Page 42

Page 42 of 56 - strict adherence to the maintenance daily checks and schedule with proof of scheduled maintenance service required by an authorised agent or qualified mechanic and/or electrician. - maintenance services are not covered under warranty. - it is the consumer’s responsibility to deliver ...

Page 43

Page 43 of 56 warranty contact information: australia tel + 61 2 9460 8071 fax +61 2 9439 9815 d.Lobban@makinex.Com.Au 15 waltham st, artarmon, nsw 2064 australia usa tel 407-446-1966 407-826-0000 j.Spencer@makinexusa.Com m.Spencer@makinexusa.Com europe tel +31 (0)6 24881203 +31 (0)6 50841849 servic...

Page 44

Page 44 of 56 contact information australia/ new zealand united states of america europe w makinex.Com e sales@makinex.Com.

Page 45

Page 45 of 56 appendices appendix a – general exploded parts diagram appendix b – pump assembly parts appendix c – handle assembly parts appendix d – frame assembly parts appendix e – pump exploded parts appendix f- rotary cleaner exploded parts appendix g- risk assessment.

Page 46

Drawing/part no: drawing size: drawn by: app'd: date: scale: dwp-4000-0ahu unit assy nts alc b 2/8/2015 dwp-4000-0ahu unit assy mi-t-m corporation qty r/q p/l description vendor part # item 1 x n/a dpw-4000-0ahu pump/eng assy - n/a 1 4 hhcs-zi gr 8.8 m10-1.5p x 16mm dpw4a-46-1470 27-8060 2 4 lockwas...

Page 47

Drawing/part no: drawing size: drawn by: app'd: date: scale: dpw-4000-0aha unit assy nts alc b 2/8/2015 dpw-4000-0aha unit assy mi-t-m corporation qty r/q p/l description vendor part # item 5 hhcs-zi gr 8.8 m10-1.5p x 16mm dpw4-27-8060 27-8060 1 5 lockwasher - med 7/16 dpw4-29-0009 29-0009 2 1 x n/a...

Page 48

Drawing/part no: drawing size: drawn by: app'd: date: scale: dpw-4000-0ahu pump/eng assy nts alc b 2/8/2015 dpw-4000-0ahu pump/eng assy mi-t-m corporation qty r/q description vendor part # item 1 engine - honda 13hp recoil gx390 dpw4-301 1-0086 1 4 hex nylon locknut-zinc m10-1.5 dpw-30-3159 30-3159 ...

Page 49

Drawing/part no: drawing size: drawn by: app'd: date: scale: dpw-4000-0aha pump_eng assy nts alc b 2/8/2015 dpw-4000-0aha pump/eng assy mi-t-m corporation qty r/q description vendor part # item 1 engine - honda 13hp recoil gx390 dpw4-301 1-0086 1 1 2.00" double sided white foam tape dpwa-33-0503 33-...

Page 50

Drawing/part no: drawing size: drawn by: app'd: date: scale: dpw-4000 handle assembly nts alc b 2/8/2015 dpw-4000 handle assembly mi-t-m corporation qty description vendor part # item 1 handle - dpw4000 dpw4-200 7-0249a77 1 2 pfhms - m4-0.7 x 12mm dpw-27-9609 27-9609 2 2 hex nylon locknut-zinc m4-0....

Page 51

Drawing/part no: drawing size: drawn by: app'd: date: scale: dpw-4000 frame assy nts alc b 2/8/2015 dpw-4000 frame assy mi-t-m corporation qty r/q description vendor part # item 1 hex nylon locknut-zinc m6-1.0 dpw-30-3157 30-3157 1 1 washer-zi sae type a 1/4" dpw-28-0002 28-0002 2 1 isolator - Ø 1 1...

Page 52: Model Dpw-4000

Page 50 of 56 appendix e - pump parts break down model ar xw15.30n model dpw-4000

Page 53

Page 51 of 56 model 2: sxw15.35.

Page 54

Page 52 of 56 model 3: rkv3.5g40hd-f24.

Page 55

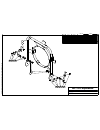

Page 53 of 56 appendix f- rotary cleaner exploded parts.

Page 56

Page 54 of 56.

Page 57

[type text] appendix g- risk assessment.

Page 58

Page 56 of 56.