- DL manuals

- Makita

- Cordless Saw

- BLS712

- Instruction Manual

Makita BLS712 Instruction Manual

Summary of BLS712

Page 1

I n s t r u c t i o n m a n u a l warning: for your personal safety, read and understand before using. Save these instructions for future reference. Cordless slide compound saw equipped with electric blade brake 190 mm (7-1/2”) model bls712 002165.

Page 2: Specifications

2 specifications blade diameter ........................................................................................... 190 mm (7-1/2”) hole (arbor) diameter ................................................................................. 15.88 mm (5/8”) max. Miter angle ..........................

Page 3: Before Operating Tool

3 for your own safety read instruction manual before operating tool save it for future reference general safety precautions usa005-1 (for all toois) 1. Know your power tool. Read the owner’s manual carefully. Learn the tool’s applications and limitations, as well as the specific potential hazards pe...

Page 4: Additional Safety Rules

4 18. Never stand on tool. Serious injury could occur if the tool is tipped or if the cutting tool is unintentionally contacted. 19. Check damaged parts. Before further use of the tool, a guard or other part that is damaged should be carefully checked to determine that it will operate properly and p...

Page 5

5 and pitch remover, hot water or kerosene. Never use gasoline to clean blade. 14. While making a slide cut, kickback can occur. Kickback occurs when the blade binds in the workpiece during a cutting operation and the saw blade is driven back rapidly towards the operator. Loss of control and serious...

Page 6: Save These Instructions

6 save these instructions warning: misuse or failure to follow the safety rules stated in this instruction manual may cause serious personal injury. Important safety instructions for charger & battery cartridge usc002-3 1. Save these instructions- this man- ual contains important safety and operat- ...

Page 7: Battery Cartridge

7 12. To reduce risk of electric shock, unplug charger from outlet before attempting any maintenance or cleaning. Turning off con- trols will not reduce this risk. 13. The battery charger is not intended for use by young children or infirm persons without supervision. 14. Young children should be su...

Page 8: Symbols

8 symbols the following show the symbols used for the charger. Be sure that you understand their meaning before use. .......... Ready to charge ............. Charging ............. Charging complete ........... Delay charge (cooling) ........ Defective battery .... Conditioning ........... Cooling a...

Page 9: Installation

9 installation bench mounting when the tool is shipped, the handle is locked in the lowered position by the stopper pin. Release the stopper pin by lower- ing the handle slightly and pulling the stopper pin. This tool should be bolted with two bolts to a level and stable surface using the bolt holes...

Page 10: Charging

10 charging 1. Plug the battery charger into the proper ac voltage source. Two charging lights will flash in green color repeatedly. 2. Insert the battery cartridge into charger until it stops adjusting to the guide of charger. Terminal cover of charger can be opened with inserting and closed with p...

Page 11

11 • if the charging light flashes alternately in green and red color, charging is not possible. The terminals on the charger or battery cartridge are clogged with dust or the battery cartridge is worn out or damaged. Cooling system • this charger is equipped with cooling fan for heated battery in o...

Page 12: Blade Guard

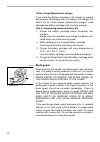

12 trickle charge (maintenance charge) if you leave the battery cartridge in the charger to prevent spontaneous discharging after full charge, the charger will switch into its “trickle charge (maintenance charge)” mode and keep the battery cartridge fresh and fully charged. Tips for maintaining maxi...

Page 13: Positioning Kerf Board

13 if the blade guard is especially dirty and vision through the guard is impaired, use the supplied socket wrench to loosen the hex bolt holding the center cover. Loosen the hex bolt by turning it counterclockwise and raise the blade guard and center cover. With the blade guard so positioned, clean...

Page 14: Stopper Arm

14 maintaining maximum cutting capacity this tool is factory adjusted to provide the maximum cutting capacity for a 190 mm (7-1/2”) saw blade. When installing a new blade, always check the lower limit position of the blade and if necessary, adjust it as follows: first, remove the battery cartridge. ...

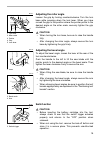

Page 15: Adjusting The Miter Angle

15 adjusting the miter angle loosen the grip by turning counterclockwise. Turn the turn base while pressing down the lock lever. When you have moved the grip to the position where the pointer points to the desired angle on the miter scale, securely tighten the grip clockwise. Caution: • when turning...

Page 16: Electric Brake

16 • do not pull the switch trigger hard without pressing in the lock-off button. This can cause switch breakage. To prevent the switch trigger from being accidentally pulled, a lock-off button is provided. To start the tool, press in the lock- off button and pull the switch trigger. Release the swi...

Page 17: Socket Wrench Storage

17 socket wrench storage the socket wrench is stored as shown in the figure. When using the socket wrench, pull it out of the wrench holder. After using the socket wrench, return it to the wrench holder. Installing or removing saw blade caution: • always be sure that the tool is switched off and the...

Page 18

18 press the shaft lock to lock the spindle and use the socket wrench to loosen the hex bolt clockwise. Then remove the hex bolt, outer flange and blade. To install the blade, mount it carefully onto the spindle, mak- ing sure that the direction of the arrow on the surface of the blade matches the d...

Page 19: Dust Bag

19 dust bag the use of the dust bag makes cutting operations clean and dust collection easy. To attach the dust bag, fit it onto the dust nozzle. When the dust bag is about half full, remove the dust bag from the tool and pull the fastener out. Empty the dust bag of its contents, tapping it lightly ...

Page 20: Vertical Vise

20 vertical vise the vertical vise can be installed in two positions on either the left or right side of the guide fence or the holder assembly (optional accessory). Insert the vise rod into the hole in the guide fence or the holder assembly and tighten the screw to secure the vise rod. Position the...

Page 21: Holders and Holder Assembly

21 holders and holder assembly (optional accessories) the holders and the holder assembly can be installed on either side as a convenient means of supporting workpieces horizontally. Install them as shown in the figure. Then tighten the screws firmly to secure the holders and the holder assembly. Wh...

Page 22

22 1. Press cutting (cutting small workpieces) workpieces up to 50 mm (2”) high and 97 mm (3-13/16”) wide can be cut in the following way. Push the carriage toward the guide fence fully and tighten the clamp screw on the turn base clockwise to secure the carriage. Secure the workpiece with the vise....

Page 23

23 • never perform the slide cut with the handle locked in the lowered position by pressing the stopper pin. • never loosen the clamp screw which secures the carriage while the blade is rotating. This may cause serious injury. 3. Miter cutting refer to the previously covered “adjusting the miter ang...

Page 24

24 when performing compound cutting, refer to “press cut- ting”, “slide cutting”, “miter cutting” and “bevel cut” explanations. 6. Cutting crown and cove moldings crown and cove moldings can be cut on a compound miter saw with the moldings laid flat on the turn base. There are two common types of cr...

Page 25

25 example: in the case of cutting 52/38° type crown molding for position (1) in fig. A: • tilt and secure bevel angle setting to 33.9° left. • adjust and secure miter angle setting to 31.6° right. • lay crown molding with its broad back (hidden) surface down on the turn base with its ceiling contac...

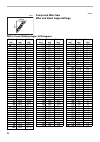

Page 26: Compound Miter Saw

26 en0002-1 compound miter saw miter and bevel angle settings 000031 52˚ 38˚ ceiling w all wall to crown molding angle: 52/38 degrees wall angle (deg.) bevel angle (deg.) miter angle (deg.) wall angle (deg.) bevel angle (deg.) miter angle (deg.) wall angle (deg.) bevel angle (deg.) miter angle (deg....

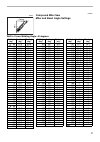

Page 27: Compound Miter Saw

27 en0003-1 compound miter saw miter and bevel angle settings 000032 45˚ 45˚ ceiling w all wall to crown molding angle: 45 degrees wall angle (deg.) bevel angle (deg.) miter angle (deg.) wall angle (deg.) bevel angle (deg.) miter angle (deg.) wall angle (deg.) bevel angle (deg.) miter angle (deg.) 6...

Page 28: Carrying Tool

28 7. Cutting repetitive lengths when cutting several pieces of stock to the same length, ranging from 220 mm (8-5/8”) to 385 mm (15-1/8”), use of the set plate (optional accessory) will facilitate more efficient operation. Install the set plate on the holder (optional accessory) as shown in the fig...

Page 29: Maintenance

29 carry the tool by carrying grip as shown in the figure. If you remove the holders, dust bag, etc., you can carry the tool more easily. Caution: • always secure all moving portions before carrying the tool. • stopper pin is for carrying and storage purposes only and not for any cutting operations....

Page 30

30 make sure that the pointer points to 0° on the miter scale. If the pointer does not point to 0°, loosen the screw which secures the pointer and adjust the pointer so that it will point to 0°. 2. Bevel angle (1) 0° bevel angle push the carriage toward the guide fence and tighten the clamp screw on...

Page 31: Replacing Carbon Brushes

31 (2) 45° bevel angle adjust the 45° bevel angle only after performing 0° bevel angle adjustment. To adjust left 45° bevel angle, loosen the lever and tilt the blade to the left fully. Make sure that the pointer on the arm points to 45° on the bevel scale on the arm holder. If the pointer does not ...

Page 32: Accessories

32 accessories caution: • these accessories or attachments are recommended for use with your makita tool specified in this manual. The use of any other accessories or attachments might present a risk of injury to persons. Only use accessory or attachment for its stated purpose. If you need any assis...

Page 33: Makita Canada Inc.

33 fold cut stamp timbre makita canada inc. 1950 forbes street, whitby, ontario l1n 7b7.

Page 34

34 your answers to the following questions are appreciated. Date purchased model no. Serial no. Initial last name street address city province age: male female married single month day year 20 under 19 20-29 30-39 40-49 over 50 paste paste paste paste paste paste paste paste p aste p aste p aste p a...

Page 35: Factory Service Centres

35 factory service centres for the authorized service centre nearest you please refer to the local yellow pages directory under “tools” or con- tact our customer service department (tel) 1-800-263-3734 when you need service... • explain the problem in a letter • enclose the letter with the tool • pa...

Page 36

Warranty policy every makita tool is thoroughly inspected and tested before leaving the factory. It is warranted to be free of defects from workmanship and materials for the period of one year from the date of original purchase. Should any trouble develop during this one year period, return the comp...