- DL manuals

- Makita

- Chainsaw

- DCS3410TH

- Instruction Manual

Makita DCS3410TH Instruction Manual

1

Instruction Manual

Original Instruction Manual

Important:

Read this instruction manual carefully before putting the chain saw into operation and strictly observe the safety

regulations!Only persons who have completed training in working from elevated platforms (cherry pickers, lifts), from

platforms mounted on ladders or who are profi cient in climbing with ropes are permitted to operate this chain saw.

Keep this Instruction Manual!

DCS3410TH

Summary of DCS3410TH

Page 1

1 instruction manual original instruction manual important: read this instruction manual carefully before putting the chain saw into operation and strictly observe the safety regulations!Only persons who have completed training in working from elevated platforms (cherry pickers, lifts), from platfor...

Page 2

2 thank you for purchasing a makita product! Congratulations on choosing a makita chain saw! We are confi dent that you will be satisfi ed with this modern piece of equipment. The dcs3410th (tophandle) is a very light and handy chain saw with the handle on the top. This model was developed especiall...

Page 3

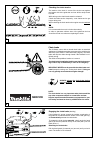

3 in case one of the parts listed should not be included in the delivery inventory, please consult your sales agent. Symbols you will notice the following symbols on the chain saw and in the instruction manual: chaine brake fuel and oil mixture chain oil saw chain oil adjustment screw direction of c...

Page 4

4 4 5 6 7 1 2 3 1 safety precautions power chain saws this power chain saw may be used only for sawing wood out of doors. It is intended for the followung uses depending on its class: - professional and mid-class: use on small, medium and large trees: felling, limb removal, cutting to length, thinni...

Page 5

5 5 fuels / refuelling - stop the engine before refuelling the chain saw. - do not smoke or work near open fi res (5). - let the engine cool down before refuelling. - fuels can contain substances similar to solvents. Eyes and skin should not come in contact with mineral oil products. Always wear pro...

Page 6

6 kickback - when working with the chain saw dangerous kickbacks may occur. - kickback occurs when the upper part of the end of the guide bar inadvertently touches wood or other hard objects (10). - before the saw chain enters the cut, it can slip to the side or jump (caution: high risk of kickback)...

Page 7

7 - be careful when cutting splintery wood. Cut pieces of wood may be pulled along (risk of injuries). - when cutting with the upper edge of the guide bar, the chain saw may be pushed in the direction of the user if the chain gets clamped. For this reason use the lower edge of the bar whenever possi...

Page 8: Service

8 transport and storage - when changing your location during work switch off the chain saw and actuate the chain brake in order to prevent an inadvert- ent start of the chain. - never carry or transport the chain saw with the chain running. - when transporting the chain saw over long distances the g...

Page 9

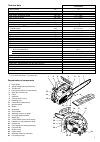

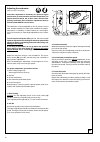

9 denomination of components 1 rear handle 2 safety locking button (throttle lock) 3 throttle lever 4 hand guard (release for chain brake) 5 spike bar (accessories) 6 chain 7 guide bar 8 chain protection cover 9 retaining nuts 10 chain catch (safety device) 11 sprocket guard 12 muffl er 13 spark plu...

Page 10

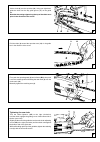

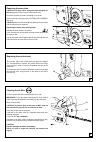

10 5 6 position the guide bar (7). Make sure that the pin (8) of the chain tightener is in the hole on the guide bar. Turn the chain adjusting screw (5) to the left (counter clockwise) until the pin (6) is at the left stop. A c d putting into operation caution: before doing any work on the guide bar...

Page 11

11 3 2 13 9 9 12 9 10 11 f pull the chain (9) around the sprocket nose (12) of the guide bar in the direction of the arrow. Lift the chain (9) over the sprocket (10). Using your right hand, guide the chain into the top guide groove (11) on the guide bar. Note that the cutting edges along the top of ...

Page 12: Service

12 checking the chain tension the tension of the chain is correct if the chain rests against the bottom side of the guide bar and can still be easily turned by hand. While doing so the chain brake must be released. Check the chain tension frequently - new chains tend to get longer during use! When c...

Page 13

13 gasoline + 1000 cm 3 (1 litre) 20 cm 3 20 cm 3 5000 cm 3 (5 litres) 100 cm 3 100 cm 3 10000 cm 3 (10 litres) 200 cm 3 200 cm 3 oil chain oil use an oil with adhesive additive for lubricating the chain and guide bar. The adhesive additive prevents the oil from being fl ung off the chain too quickl...

Page 14: Waste Oil

14 refuelling follow the safety precautions! Be careful and cautious when handling fuels. The engine must be switched off! Thoroughly clean the area around the caps, to prevent dirt from getting into the fuel or oil tank. Unscrew the cap and fi ll the tank with fuel (fuel/oil mixture) or chain oil a...

Page 15

15 2 3 1 adjusting the chain lubrication the engine must be switched off. You can adjust the oil pump feed rate with the adjusting screw (1). The amount of oil can be adjusted using the universal wrench. Recommended settings: - 25 cm guide bar - 30 cm guide bar - 35 cm guide bar - 40 cm guide bar to...

Page 16

16 cold start: prime the fuel pump (6) by pressing it several times until you can see fuel in the pump. Move the short-circuit switch (3) forward in the direction of the arrow. Turn the choke lever (5) up (see “cold start” illustration). This simultaneously actuates the half-throttle lock. Slowly pu...

Page 17

17 checking the chain brake do not work with the chain saw without fi rst checking the chain brake! Start the engine as described (make sure you have a good footing, and place the chain saw on the ground in such a way that the guide bar is free of contact). Grasp the tubular handle fi rmly with one ...

Page 18

18 8 9 adjusting the carburetor (only for not eu-countries) e carburetor adjustment is necessary for optimum engine performance, for safer and more economical operation. The engine should be warm, the air fi lter clean, and the chain properly tensioned. Have carburetor adjustment done by an authoris...

Page 19

19 proper sharpening: caution: use only chains and guide bars designed for this saw (see the extract from the spare-parts list)! All cutters must be of the same length (dimension a). Cutters with different lengths result in rough running of the chain and can cause cracks in the chain. Minimum cutter...

Page 20

20 all cutters must be sharpened to the same angle, 30°. Different angles result in a roughly, irregularly running chain, increase wear and tear and cause chain beakage. The 85° front rake of the cutter results from the cut depth of the round fi le. If the proper fi le is used in the right manner, t...

Page 21

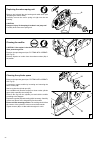

21 1 2 4 5 6 3 cleaning the guide bar, lubricating the sprocket nose caution: protective gloves must be worn. Regularly inspect the bearing surfaces of the guide bar for damage, and clean them with a suitable tool. If the saw is used intensively it will be necessary to lubricate the return sprocket ...

Page 22

22 12 7 8 9 10 11 replacing the suction head the felt fi lter (12) of the suction head can become clogged. It is recommended to replace the suction head once every three months in order to ensure unimpeded fuel fl ow to the carburetor. To remove the suction head for replacement, pull it out through ...

Page 23

23 2 3 6 7 8 4 5 12 10 9 11 12 1 replacing the spark plug caution: do not touch the spark plug or plug cap if the engine is running (high voltage). Switch off the engine before starting any maintenance work. A hot engine can cause burns. Wear protective gloves! The spark plug must be replaced in cas...

Page 24

24 13 cleaning the muffl er caution: if the engine is hot there is a risk of burning. Wear protective gloves. Remove the sprocket guard (see ”putting into operati- on” fig. B). Remove deposits of carbon from the exhaust outlets (13) of the muffl er. D e cleaning the cylinder space remove the sprocke...

Page 25

25 instructions for periodic maintenance to ensure long life, prevent damage and ensure the full functioning of the safety features the following maintenance must be performed regularly. Guarantee claims can be recognized only if this work is performed regularly and properly. Failure to perform the ...

Page 26

26 spare parts reliable long-term operation, as well as the safety of your chain saw, depend among other things on the quality of the spare parts used. Use only original makita parts, marked only original spare parts and accessories guarantee the highest quality in material, dimensions, functioning ...

Page 27

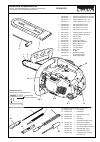

27 extract from the spare parts list use only original makita parts. For repairs and replacement of other parts, see your makita service centre. Dcs3410th identifi cation plate indicate when ordering spare parts serial number year of manufacture 15 17 16 18 19 20 21 5, 6, 7 8, 9 6, 7 11 10 3 4 2 12 ...

Page 28

28 form: 995 707 421 (7.09 gb) specifi cations subject to change without notice to fi nd your local distributor, please visit www.Makita-outdoor.Com makita werkzeug gmbh postfach 70 04 20 d–22004 hamburg germany.