- DL manuals

- Makita

- Chainsaw

- EA6100P

- Operator's And Safety Manual

Makita EA6100P Operator's And Safety Manual

Operator’s and Safety Manual

for Gasoline Chain Saws

WARNING!

Read and understand this Manual. Always follow safety precautions in the Operator’s and Safety Manual.

Improper use can cause serious injury! Preserve this Manual carefully!

WARNING!

FUELS WITH MORE THAN 10% ETHANOL ARE NOT APPROVED FOR USE IN MAKITA 2-STROKE ENGINES!

Use of alternative fuels, such as E-20 (20% ethanol), E-85 (85% ethanol) or any fuels not meeting MAKITA

requirements are not approved for use in MAKITA 2-stroke gasoline engines!

USE OF ALTERNATIVE FUELS CAN CAUSE THE FOLLOWING PROBLEMS:

Poor engine performance, loss of power, overheating, fuel vapor lock, improper clutch engagement, premature

deterioration of fuel lines, premature deterioration of gaskets, premature deterioration of carburetors.

USING ALTERNATIVE FUELS AND/OR 2-STROKE OILS NOT ACCORDING TO JASO FC OR ISO-L-EGD IN

MAKITA 2-STROKE ENGINES WILL VOID YOUR ENGINE WARRANTY!

EA6100P

EA6101P

Summary of EA6100P

Page 1

Operator’s and safety manual for gasoline chain saws warning! Read and understand this manual. Always follow safety precautions in the operator’s and safety manual. Improper use can cause serious injury! Preserve this manual carefully! Warning! Fuels with more than 10% ethanol are not approved for u...

Page 2

2 federal (usepa) and/or california emission control warranty statement your warranty rights and obligations the united states environmental protection agency (usepa or epa), the california air resources board and makita are pleased to explain the emissions control system warranty on your 2014* smal...

Page 3

3 (6) the small off-road engine/equipment owner will not be charged for diagnostic labor that is directly associated with diagnosis of a defective, emission-related warranted part, provided that such diagnostic work is performed at a warranty station. (7) makita is liable for damages to other engine...

Page 4

4 the ea6100p and ea6101p will be delivered in a protective cardboard box to prevent transport damage. Cardboard is a basic raw material and is consequently reuseable or suitable for recycling (waste paper recycling). This product complies with: american national standard institute b 175.1-2012 chai...

Page 5

5 1 4 5 6 7 3 2 delivery inventory 1. Chain saw 2. Guide bar 3. Saw chain 4. Chain protection cover 5. Universal wrench 6. Offset screwdriver 7. Screwdriver for carburetor adjustment 8. Operator’s and safety manual (not shown) in case one of the parts listed should not be included in the delivery in...

Page 6

6 additional safety precautions the following additional safety precautions must be ob- served by all users of chain saws: - a chain saw is intended for two-handed use. Do not operate a chain saw with one hand! Serious injury to the operator, helpers, bystanders may result from one- handed operation...

Page 7

7 - when cutting a limb that is under tension, be alert for spring back so that you will not be struck when the tension in the wood fibers is released. - when felling, keep at least two tree lengths away from other persons or animals. - beware of carbon monoxide poisoning. Operate the chain saw in w...

Page 8: General Safety Precautions

8 general safety precautions the use of any chain saw may be hazardous. At full throttle chain speed can reach 45 mph (20 m/s). It is important that you read; fully understand and observe the following safety precautions and warnings. Read the operator’s manual and the safety instructions periodical...

Page 9: The Saw

9 3 the saw parts of the chain saw: illustrations and description of parts see page 20. Warning ! Never modify a chain saw in any way. Only attachments supplied by makita or expressly approved by makita for use with the specific saw are authorized. Warning ! Bow guide bars substantially increase the...

Page 10

10 6 5 10 feet 5a 6a wipe off any spilled fuel before starting your saw and check for leakage. Check for fuel leakage while refueling and during opera- tion. If fuel or oil leakage is found, do not start or run the engine until leak is fixed and spilled fuel has been wiped away. Clothing with fuel o...

Page 11: Important Adjustments

11 7 8 important adjustments warning! At correct idle speed, chain should not turn. For di-rec- tions to adjust idle speed, see the appropriate section of this operator’s manual. Do not use a saw with incorrect idle speed adjust- ment. Adjust the idle speed yourself according to the appropriate sect...

Page 12

12 9 10 11 12 position the chain saw in such a way that your body is clear of the cutting attachment whenever the engine is running (fig. 10). Don’t put pressure on the saw when reaching the end of a cut. The pressure may cause the bar and rotating chain to pop out of the cut or kerf, go out of cont...

Page 13

13 13 to avoid kickback the best protection from personal-injury that may result from kickback is to avoid kickback situations: 1. Hold the chain saw firmly with both hands and maintain a secure grip. 2. Be aware of the location of the guide bar nose at all times. 3. Never bring the nose of the guid...

Page 14: Cutting Techniques

14 16 14 15 to avoid pushback 1. Be alert to forces or situations that may cause mate- rial to pinch the top of the chain. 2. Do not cut more than one log at a time. 3. Do not twist the saw when withdrawing the bar from a plunge cut or under buck cut (figures 25 to 27 and 33, pages 16 and 18), becau...

Page 15: 45°

15 45° 45° = cutting down area 2 1 2 17 18 19 1/10∅ 1/5∅ 1 1 / 2 " (4cm) 20 21 22 23 45° second cut first cut direction of fall felling notch hinge felling cut hinge felling notch first clear the tree base and work area from inter -fering limbs and brush and clean its lower portion an axe (see fig. ...

Page 16

16 24 25 26 27 28 begin the felling cut slighty higher than the felling notch and on the opposite side of the tree (fig. 22). Then cut horizontally through towards the felling notch. Apply the chain saw with its spikes directly behind the uncut portion of wood and cut toward the notch (fig. 23). Lea...

Page 17

17 29 30 31 32 warning! There is an extreme danger of kickback at this point. Extra caution must be taken to maintain control of the saw. To make the felling cut, follow the sectioning method described previously (fig. 29). If you are inexperienced with a chain saw plunge- cutting should not be atte...

Page 18

18 1. Relieving cut 2. Cross cut tension side pressure side 1. Relieving cut 2. Cross cut tension side pressure side 33 34 35 maintenance and repair never operate a chain saw that is damaged, improperly adjusted or not completely or securely assembled. Follow the maintenance and repair instructions ...

Page 19

19 packing your makita chain saw comes delivered in a protective cardboard box to protect against shipping damage. Cardboard is a basic raw material and is consequently reuseable or suitable for recycling (waste paper recycling). Stroke volume cu. In (cm 3 ) 3.7 (61) 3.7 (61) bore inch (mm) 1.85 (47...

Page 20

20 2 26 25 18 17 19 20 3 4 1 6 7 5 8 9 11 12 21 22 23 24 10 15 14 16 13 1 handle 2 cover 3 hood lock 4 tubular handle 5 hand guard (release for chain brake) 6 muffler 7 spike bar 8 chain tensioning screw 9 retaining nuts 10 chain catch 11 sprocket guard 12 adjusting screw for oil pump (bottom side) ...

Page 21

21 5 7 6 5 4 1 2 3 put on the guide bar (7). Make sure that the pin (5) of the chain tensioner engages in the hole in the guide bar. Mounting the guide bar and saw chain use the universal wrench delivered with the chain saw for the following work. Put the chain saw on a stable surface and carry out ...

Page 22

22 2 4 9 12 2 11 3 8 11 10 9 replace the sprocket guard (3). Note: the saw chain must remain on the chain catch (11). Tighten the nuts (2) only hand-tight to begin with. Lift the chain (9) over the sprocket (8). Caution: do not insert the chain between the chain sprocket and the disc. Guide the chai...

Page 23

23 stop 2 4 a b 1 checking the chain tension the tension of the chain is correct if the chain rests against the bottom side of the guide bar and can still be easily turned by hand. While doing so the chain brake must be released. Check the chain tension frequently - new chains tend to get longer dur...

Page 24

24 chain oil use an oil with adhesive additive for lubricating the chain and guide bar. The adhesive additive prevents the oil from being flung off the chain too quickly. We recommend the use of chain oil which is bio-degradable in order to protect the environment. The use of bio-degradable oil may ...

Page 25

25 refuelling follow the safety precautions! Be careful and cautious when handling fuels. The engine must be switched off! Thoroughly clean the area around the caps, to prevent dirt from getting into the fuel or oil tank. Unscrew the tank cap (use the universal wrench if necessary, see illustration)...

Page 26

26 2 3 1 + - checking the chain lubrication never work with the chain saw withoute sufficient chain lubri - ca tion. Otherwise the service life of the chain and guide bar will be reduced. Before starting work check the oil level in the tank and the oil feed. Check the oil feed rate as described belo...

Page 27

27 1 4 5 3 2 starting the engine do not start the chain saw until after it is completely as- sembled and checked! Move at least 3 meters / 10 feet away from the place where the chain saw was fuelled. Make sure you have a secure footing, and place the saw on the ground in such a way that the guide ba...

Page 28

28 8 7 working in winter in order to prevent carburetor icing in conditions of low tem- perature combined with high humidity, and below + 5°c (40°f) in order to get up to operating temperature faster, heated air can be taken from the cylinder. Remove the cover (see “cleaning the air filter”). Remove...

Page 29: Service

29 service t adjusting the carburetor caution: carburetor adjustment may only be done by a specialist makita service center! Only adjusting screw (t) can be manipulated by the user. If the saw chain moves in idle (i.E. Without the throttle being pressed), it is imperative to correct the idle speed! ...

Page 30

30 α α β β min. 3 mm (0.11”) the sharpening angle (α) must be identical for all cutters! 25° for chain type 496 30° for chain type 082, 086 the teeth will have the proper angle (ß) automatically if the proper round file is used. 60° for chain type 496 85° for chain type 082, 086 different angles res...

Page 31

31 1 2 4/5 chain typ 082, 086, 496 files and how to work with them use a special saw chain round file for sharpening. Standard round files are unsuitable. For the order number, see “accessories”. Type 082, 086: saw chain round file, dia. 3/16” (4,8 mm). Type 496: saw chain round file, dia. 7/32” (5,...

Page 32: Service

32 cleaning the inside of the sprocket guard caution: before doing any work on the guide bar or chain, always switch off the engine and pull the plug cap off the spark plug (see „replacing the spark plug“). Always wear protective gloves! Caution: start the chain saw only after having assembled it co...

Page 33

33 8 11 10 9 check the sprocket before mounting a new chain. Worn out sprockets (8) may damage the new chain and must therefore be replaced. Remove the sprocket guard (see „putting into opera- tion“). Remove the chain and guide bar. Remove circlip (9). Caution: the circlip will pop out of the groove...

Page 34

34 2 5 3 3 6 4 1 cleaning the air filter caution: to prevent eye injury, always wear eye protection when cleaning the filter with compressed air! Do not clean the air filter with fuel or flammable liquids! Disengage the hood clips (5) with the combination tool and remove the hood (2). Push up the co...

Page 35

35 10 checking the muffler screws careful! Do not tighten the muffler screws when the engine is hot! Check the muffler screws (10) for tightness. If they are loose, hand-tighten them. Important - do not overtighten! First remove the two plugs. Using a small screwdriver. Put the plugs back in after c...

Page 36

36 1 3 2 10 5 11 13 8 9 7 6 14 4 15 16 12 replacing the starter cable/ replacing the return spring pack/replacing the starter spring disengage the hood clip (3) with the combination tool. Unscrew four screws (1). Spread out the handguard strut slightly and remove the fan housing (2). Remove the air ...

Page 37

37 1 5 7 14 4 replacing the return spring pack disassemble the fan housing and cable drum (see page 26). Careful! Injury hazard! The return spring can pop out! Always wear eye protection and protective gloves! Lightly tap the fan housing on a wooden surface with the entire surface of the hollow side...

Page 38

38 2 replacing the suction head the felt filter (2) of the suction head can become clogged. It is recommended to replace the suction head once every three months in order to ensure unimpeded fuel flow to the carburetor. To remove the suction head for replacement, pull it out through the tank filler ...

Page 39

39 instructions for periodic maintenance to ensure long life, prevent damage and ensure the full functioning of the safety features the following maintenance must be per- formed regularly. Guarantee claims can be recognized only if this work is performed regularly and properly. Failure to perform th...

Page 40

40 service, spare parts and guarantee maintenance and repair the maintenance and repair of modern engines as well as all safety devices require qualified technical training and a special work- shop equipped with special tools and testing devices. Any work not described in this manual may be performe...

Page 41

41 trouble shooting malfunction system observation cause chain does not run chain brake engine runs chain brake actuated. Engine does not start or ignition system ignition spark malfunction in fuel supply system, com- only with difficulty pression system, mechanical malfunction. No ignition spark st...

Page 42

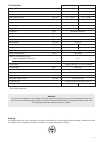

42 ea6100p ea6101p extract from the spare parts list use only original makita parts. For repairs and replacement of other parts, see your makita service center. 8 9 15 16 26 27 28 29 25 7 6 5 4 19 20 1 2 3 14 13 17 10 11 12 18 21, 22 23 24.

Page 43

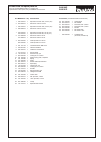

43 extract from the spare parts list use only original makita parts. For repairs and replacement of other parts, see your makita service center. Ea6100p ea6101p pos. Makita-no. Qty. Denomination 1 445 045 641 1 sprocket nose bar .325“, 45 cm (18“) 2 523 082 672 1 saw chain .325“ for 45 cm 1 445 045 ...

Page 44

Specifications subject to change without notice form: 995 708 078 (2014-08 gb) the engine exhaust from this product contains chemicals known to the state of california to cause cancer, birth defects or other reproductive harm. Makita u.S.A., inc. 14930 northam street la mirada ca 90638-5753 usa maki...