- DL manuals

- Megger

- Test Equipment

- SMART THUMP ST16

- User Manual

Megger SMART THUMP ST16 User Manual

Summary of SMART THUMP ST16

Page 1

Avtmst16-en rev 1 may 2016 user manual portable fault locating system smart thump st16 read this entire manual before operating. M valley forge corporate center 2621 van buren avenue norristown, pa 19403-2329 u.S.A. 610-676-8500 www.Megger.Com.

Page 2

M.

Page 3: Smart Thump St16

Portable fault locating system smart thump st16 user manual.

Page 4

M copyright© 2016 by megger. All rights reserved. No part of this handbook may be copied by photographic or other means unless megger have before- hand declared their consent in writing. The content of this handbook is subject to change without notice. Megger cannot be made liable for technical or p...

Page 5

Local megger offices australia canada france megger pty limited unit 1, 11-21 underwood road homebush nsw 2140 t: +61 (0)2 9397 5900 f:+61 (0)2 9397 5911 110 milner avenue unit 1 scarborough ontario m1s 3r2 canada t: 1 416 298 6770 f: 416 298 0848 23 rue eugène henaff za du buisson de la couldre 781...

Page 6

M m.

Page 7

Avtmst16 rev 1 may 2016 i table of contents 1 safety ................................................................................................................................................................ 1 precautions ...........................................................................

Page 8

M avtmst16 rev 1 may 2016 ii 5 how to perform a test ...................................................................................................................... 21 detecting and locating a cable fault in a shielded medium voltage power cable ............................... 21 locating a f...

Page 9: Receiving Instructions

Avtmst16 rev 1 may 2016 iii receiving instructions 1. Check the equipment received against the packing list to ensure that all materials are present. Notify megger of any shortage. Email your local service representative or send to vfcustomersupport@megger.Com. 2. Examine the equipment for damage re...

Page 10

M avtmst16 rev 1 may 2016 iv m.

Page 11: Safety

Avtmst16 rev 1 may 2016 1 1 safety precautions this manual contains basic instructions on commissioning and operating the smart thump system. For this reason, it is important to ensure that the manual is available at all times to authorised and trained personnel. Any personnel who will be using the ...

Page 12: Working With The Product

M avtmst16 rev 1 may 2016 2 working with the product it is important to observe the general electrical regulations of the country in which the device will be installed and operated, as well as the current national accident prevention regulations and internal company rules (work, operating and safety...

Page 13

Safety avtmst16 rev 1 may 2016 3 instruments should only be operated under tempered conditions. It is not allowed to operate megger products in direct contact with humidity, water or near aggressive chemicals nor explosive gases and fumes. What to do if equipment malfunctions the equipment may only ...

Page 14

M avtmst16 rev 1 may 2016 4 f warning - dangers when working with hv special attention and safety awareness is needed when operating hv equipment and especially non-stationary equipment. The regulations vde 0104 about setting up and operation of electric test equipment, i.E. The corresponding en 501...

Page 15: Technical Description

Avtmst16 rev 1 may 2016 5 2 technical description system description functional description the smart thump is a compact, battery or ac operated fault location system typically to be used for fault locating of solid dielectric low voltage and medium voltage cables. It is ideally suited for use in ur...

Page 16

M avtmst16 rev 1 may 2016 6 features the smart thump system combines the following features and functions as a single device: quick steps and expert mode (full feature mode), automatic detection and localization of transformers automatic fault prelocation and localization with regard to the 2 cl...

Page 17: Technical Data

Technical description avtmst16 rev 1 may 2016 7 available accessories the following accessories can be ordered from megger, if required: accessories description item number elbow adaptor with 14 mm female mc connector (nafta market) used to connect hv output cable 865000100100000 (15 kv) 86500020010...

Page 18

M avtmst16 rev 1 may 2016 8 storage temperature 25 °c to +70 °c dimensions (w x h x d) 690 x 1165 x 600 mm weight 145 kg, hand truck mounted incl. Battery/ inverter and 50ft (17m) each of hv and safety ground cable protection class (in accordance with iec 61140) i protection rating (in accordance wi...

Page 19

Technical description avtmst16 rev 1 may 2016 9 control elements, indicators and connectors the smart thump has the following control elements, indictors and connectors:.

Page 21: Power Supply

Technical description avtmst16 rev 1 may 2016 11 power supply battery operation introduction the smart thump can be equipped with an internal battery. In this case there is no requirement for an ac line supply to operate the unit in the field. For a good trade-off between weight and operation time, ...

Page 22

M avtmst16 rev 1 may 2016 12 backup battery if the internal battery is becoming drained while fault locating, any 12 v battery providing more than 50 a (e.G. A car battery) can be connected to the 12 v terminals in order to extend the operation time or the unit must be connected to an ac source (see...

Page 23: Setting Up The System

Avtmst16 rev 1 may 2016 13 3 setting up the system f warning - safety instructions for setting up the guidelines to maintain occupational safety when operating a non-stationary test system often differ between network operators and it is not uncommon to use national regulations (like, i.E. The ger...

Page 24: Connection Diagram

M avtmst16 rev 1 may 2016 14 connection diagram the following figure shows the simplified connection diagram. Connection sequence connect the unit in the following order: step description connect the safety ground lead to a reliable ground (e.G. Station-ground, transformer ground rod. Do not drive a...

Page 25: Operating Instructions

Avtmst16 rev 1 may 2016 15 4 operating instructions power on the system once the “on / off” button is pressed, the system starts up. After start- up, the system is in the 'ready for operation' state and the main menu is displayed: in this state, the high voltage source is still switched off and the ...

Page 26: Safety Circuit

M avtmst16 rev 1 may 2016 16 the currently selected menu item is identified by a red circle. Not selected selected with the aid of the rotary knob, the individual menus can be accessed and values can be entered. If a selected menu item requires a value to be adjusted, the following dialog is display...

Page 27: User Modes

Operating instructions avtmst16 rev 1 may 2016 17 supply off and discharges and grounds the hv output. A message will be displayed on the lcd display which must be acknowledged before hv operation can be re-activated again. Conditions of the safety circuit the following conditions must be met in ord...

Page 28

M avtmst16 rev 1 may 2016 18 system settings (only accessible in expert mode) in order to change the system settings, expert settings from the main menu must be accessed. These settings are only available, if the system is operated in expert mode. If this is not the case, the rotary knob must pushed...

Page 29

Operating instructions avtmst16 rev 1 may 2016 19 menu item description >> automatic hv release the way a hv test is started, automatic or manual. Automatic means that after initializing hv by pushing the hv on button, hv will build up in the test mode or will charge the capacitor and fire as soon a...

Page 30

M avtmst16 rev 1 may 2016 20 menu item description import from usb imports a cable list from an inserted usb drive. The cable list must be located in the cablelists folder. Export to usb exports the selected cable list to the cablelists folder on the usb drive. Remove cable list removes the selected...

Page 31: How to Perform A Test

Avtmst16 rev 1 may 2016 21 5 how to perform a test detecting and locating a cable fault in a shielded medium voltage power cable locating a faulty cable section (sectionalizing) introduction the sectionalizing technique is used to trouble shoot a distribution loop circuit in order to identify the fa...

Page 32

M avtmst16 rev 1 may 2016 22 the procedure called "comed" in the configuration set up will perform the following steps: pattern 2 low voltage trace to identify cable end (blue trace) high voltage trace to identify fault (negative reflection in red trace) low voltage trace to identify all trans...

Page 33

How to perform a test avtmst16 rev 1 may 2016 23 step description 3 select to start the fault location. 4 adjust the surge voltage and select to confirm the value (not required in automatic mode). 5 press the green illuminated “hv on” button . 6 select to charge the surge capacitor (only if measurem...

Page 34

M avtmst16 rev 1 may 2016 24 how to verify whether it is actually a bad section the hipot test within the context of sectionalizing is done to confirm, that the section of cable identified as bad during the sectionalizing procedure can be verified to be actually bad. Proceed as follows to perform a ...

Page 35

How to perform a test avtmst16 rev 1 may 2016 25 locating a cable fault (shielded mv power cable) how to test the dielectric strength of the cable a hipot/breakdown test is used to test the dielectric strength of a cable and, if the test fails, to determine the breakdown voltage. For this purpose, a...

Page 36

M avtmst16 rev 1 may 2016 26 how to pre-locate the fault arc reflection method (arm) for pre-location of high resistance fault the smart thump applies the widely approved and well-known arm (arc reflection method). Locating the fault becomes possible by comparing a reflection image taken with a lv p...

Page 37

How to perform a test avtmst16 rev 1 may 2016 27 step description in case the software cannot determine the end of the cable, a message will be displayed stating “cable end not clearly visible” and offering to proceed by “ignore” this fact. Do not acknowledge the ignore message, but turn to the icon...

Page 38

M avtmst16 rev 1 may 2016 28 step description 6 select to discharge the capacitor (only if measurement start option is set to manual. See page 18. Result: a capacitor discharge (shot) is initiated. If a breakdown / flashover takes place, the red fault trace typically has a strong negative reflection...

Page 39

How to perform a test avtmst16 rev 1 may 2016 29 current decoupling (ice) as an alternative way for pre-location of high resistance faults, the smart thump provides the current decoupling method (ice, surge pulse). The capacitive discharge of the surge capacitor via the surge switch triggers and ign...

Page 40

M avtmst16 rev 1 may 2016 30 step description 6 if necessary, adjust the display settings, tdr settings and marker position through the menu in order to identify the fault distance as precisely as possible. See page 38. 7 go into the simple options menu in order to measure out the distance. Use the ...

Page 41

How to perform a test avtmst16 rev 1 may 2016 31 how to pinpoint the fault (shielded mv power cable) the thumping mode can be used to pinpoint a fault between two phase conductors or between a phase conductor and the neutral conductor or on unshielded cables between the phase conductor and earth gro...

Page 42: Buried)

M avtmst16 rev 1 may 2016 32 detecting a sheath fault or a ground fault in an unshielded, low voltage cable (both must be directly buried) note: the methods described to detect and pinpoint sheath faults in shielded cables or ground faults in unshielded cables assumes that in both situations the cab...

Page 43

How to perform a test avtmst16 rev 1 may 2016 33 step description 3 adjust the test voltage and select to confirm the value. 4 press the green illuminated “hv on” button . 5 select to start the test (only if measurement start option is set to manual. See “system settings on page 17). Result: the sel...

Page 44: Buried)

M avtmst16 rev 1 may 2016 34 how to pinpoint a sheath fault or a ground fault in an unshielded low voltage cable (both must be directly buried) following a failed sheath test (see page error! Bookmark not defined.) fault location of the sheath fault in direct buried cables based on the step voltage ...

Page 45

How to perform a test avtmst16 rev 1 may 2016 35 step description result: the capacitor is charged up and a discharge takes place after 5 seconds injecting a pulsed voltage signal into the cable. This process is then repeated until the process is manually stopped. If required, you can adjust the pul...

Page 46

M avtmst16 rev 1 may 2016 36 m.

Page 47: Introduction

Avtmst16 rev 1 may 2016 37 6 customize tdr features (applicable to tdr and arm mode) introduction as soon as a trace has been recorded and is shown on the display, the operator can access the tdr features in order to adjust the display and tdr settings in order to optimize the trace. Depending on th...

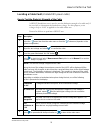

Page 48: Customized Tdr Features

M avtmst16 rev 1 may 2016 38 customized tdr features the following table lists and describes all tdr features included in the system: menu item description adjust gain adjusts the gain setting. By doing so, the amplification of the received signal and, thus, the amplitude of the y-axis can be adjust...

Page 49

How to perform a test avtmst16 rev 1 may 2016 39 menu item description put trace on hold makes an exact copy (blue trace) of the “live” trace. Note: this function is very helpful when making a phase comparison on a 3 phase circuit. It is also very helpful when just using the tdr function on low volt...

Page 50

M avtmst16 rev 1 may 2016 40 menu item description recall displays the selected trace on the screen. The screen view can then be adjusted using any function which does not require the trace to be updated. By selecting , the loaded trace is closed and the last recorded trace is displayed again. Adjus...

Page 51: Completing The Operation

How to perform a test avtmst16 rev 1 may 2016 41 completing the operation after the fault location procedure has been finished switch off the system by pressing the “on / off” button . The test object is to be grounded and shorted. Afterwards, the unit can be disconnected from the test object in acc...

Page 52

M avtmst16 rev 1 may 2016 42 m.

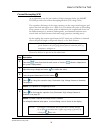

Page 53: Advanced System Settings

Avtmst16 rev 1 may 2016 43 7 advanced system settings how to edit the cable list introduction cable lists are xml files which are stored in the internal memory and can be imported and exported (see page 19). By default, one cable list with a selection of prevalent cable types is pre-installed on the...

Page 54

M avtmst16 rev 1 may 2016 44 the element consists of the following mandatory and optional child elements: cable type (mandatory / unique) area of the cable type (e.G. In kcmil or mm 2 ) (optional) rated voltage of the cable (optional) diameter of the cable type (e.G. American wire gauge value) (opti...

Page 55

Advanced system settings avtmst16 rev 1 may 2016 45 how to setup customer-specific tdr features thanks to the high level of configurability of the smart thump, the tdr features for both, "expert mode" and "quick steps mode", (see page 17) are customer configurable. In order to create your own custom...

Page 56

M avtmst16 rev 1 may 2016 46.

Page 57: Test Data

Advanced system settings avtmst16 rev 1 may 2016 47 how to use easyprot software to plot dc hipot/sheath test data the smart-thump allows recording and graphing of dc test data, either dc hipot test data or sheath test data. Before switching the st16 on, insert usb drive into front panel. Then start...

Page 58

M avtmst16 rev 1 may 2016 48 m.

Page 59: Care and Maintenance

Avtmst16 rev 1 may 2016 49 8 care and maintenance maintenance for installation and operation of the instrument it is not necessary to open the housing of the instrument. Opening the housing will void the warranty and liability of the manufacturer. Connections and connectors must be tested according ...

Page 60

M avtmst16 rev 1 may 2016 50 m.

Page 61: Appendix 1

Avtmst16 rev 1 may 2016 51 appendix 1 overview of tdr features see next page for complete chart..

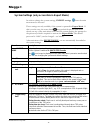

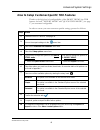

Page 62

M avtmst16 rev 1 may 2016 52 option recommended settings your settings (mark with x) quick steps mode expert mode disa. Simp. Ext. Disa. Simp. Ext. Cable velocity (option to adjust the cable velocity) quick steps: simple expert: simple xfmr sensitifity (option to adjust the transformer sensitivity) ...