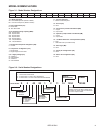

Modine Manufacturing 120 Installation and service manual

WArNING

This unit contains R-410A high pressure refrigerant.

Hazards exist that could result in personal injury

or death. Installation, maintenance, and service

must only be performed by an HVAC technician

qualifi ed in R-410A refrigerant and using proper

tools and equipment. Due to much higher pressure

of R-410A refrigerant, DO NOT USE service

equipment or tools designed for refrigerants other

than R-410A.

WArNING

Improper installation, adjustment, alteration,

service or maintenance can cause property

damage, injury or death, and could cause

exposure to substances which have been

determined by various state agencies to cause

cancer, birth defects or other reproductive harm.

Read the installation, operating and maintenance

instructions thoroughly before installing or

servicing this equipment.

ImpOrTANT

1. The use of this manual is specifi cally intended

for a qualifi ed installation and service agency.

A qualifi ed installation and service agency must

perform all installation and service of these

appliances.

2. GH/EH units contain the refrigerant R-410A.

Review the R-410A Material Safety Data Sheet

(MSDS) for hazards and fi rst aid measures.

3. Refrigerant charging should only be carried out

by an EPA-certifi ed air conditioning contractor.

GEO16-504.2

5H0835730000

INSTALLATION AND SERVICE MANUAL

hydronic ground source heat pumps

models GH and EH

August, 2015

NOTE:

Energy Star only

applies to certain

configurations.

Inspection On Arrival

1. Inspect unit upon arrival. In case of damage, report it

immediately to transportation company and your local factory

sales representative.

2. Check rating plate on unit to verify that power supply meets

available electric power at point of installation.

3. Inspect unit received for conformance with description of

product ordered (including specifi cations where applicable).

THIS MANUAL IS THE PROPERTY OF THE OWNER.

PLEASE BE SURE TO LEAVE IT WITH THE OWNER WHEN YOU LEAVE THE JOB.