- DL manuals

- Moeller

- DC Drives

- DF5 series

- Hardware And Engineering

Moeller DF5 series Hardware And Engineering

Hardware and Engineering

DF5-...

09/01 AWB8230-1412GB

1st published 2001, edition 09/01

© Moeller GmbH, Bonn

Author:

Holger Friedrich, Jörg Randermann

Editor:

Michael Kämper

Translator:

David Long

All brand and product names are trademarks or registered

trademarks of the owner concerned.

All rights reserved, including those of the translation.

No part of this manual may be reproduced in any form

(printed, photocopy, microfilm or any otherprocess) or processed,

duplicated or distributed by means of electronic systems without

written permission of Moeller GmbH, Bonn.

Subject to alterations without notice.

Summary of DF5 series

Page 1

Hardware and engineering df5-... 09/01 awb8230-1412gb 1st published 2001, edition 09/01 © moeller gmbh, bonn author: holger friedrich, jörg randermann editor: michael kämper translator: david long all brand and product names are trademarks or registered trademarks of the owner concerned. All rights ...

Page 2: Warning!

I before commencing the installation • disconnect the power supply of the device. • ensure that devices cannot be accidentally restarted. • verify isolation from the supply. • earth and short circuit. • cover or enclose neighbouring units that are live. • follow the engineering instructions (awa) of...

Page 3

Ii • all shrouds and doors must be kept closed during operation. • in order to reduce hazards to persons or equipment, the user must include in the machine design measures that restrict the consequences of a malfunction or failure of the drive (increased motor speed or sudden standstill of motor). T...

Page 4: Contents

09/01 awb8230-1412gb 1 contents about this manual 5 abbreviations and symbols 5 1 about df5 series frequency inverters 7 system overview 7 type code 8 inspecting the items supplied 9 layout of the df5 10 – frequency inverter characteristics 11 selection criteria 11 intended use 12 service and guaran...

Page 5

Contents 09/01 awb8230-1412gb 2 4 df5 operation 43 initial startup 43 lcd keypad 44 operation with lcd keypad 44 – menu overview 44 – changing display and basic parameters 45 – changing the parameters of the extended parameter groups 46 display after the supply voltage is applied 47 operational warn...

Page 6

09/01 awb8230-1412gb contents 3 6 setting parameters 75 setting the display parameters 75 basic functions 76 – input/display frequency value 76 – acceleration time 1 76 – deceleration time 1 77 – direction of rotation 77 setting the frequency and start command parameters 78 – definition of frequency...

Page 7

Contents 09/01 awb8230-1412gb 4 appendix 107 technical data 107 dimensions and weights 111 cables and fuses 112 mains contactors 113 radio interference filter 115 mains choke 116 connection examples 117 – operation through an external potentiometer 117 – operation through an analog setpoint value 11...

Page 8: About This Manual

09/01 awb8230-1412gb 5 about this manual this manual describes the frequency inverters of the df5 series. This manual contains special information which is required for engineering, installation and operation of the df5 series frequency inverters. The features, parameters and functions are described...

Page 9

09/01 awb8230-1412gb 6.

Page 10

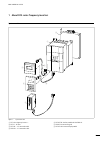

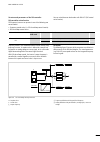

09/01 awb8230-1412gb 7 1 about df5 series frequency inverters system overview figure 1: system overview a df5 series frequency inverters-... B de5-lz... Rfi filter c de5-cbl-...-icl connection cable d dex-cbl-...-ics connection cable e de5-net-dp interface module for profibus-dp f dex-dey-10 externa...

Page 11

About df5 series frequency inverters 09/01 awb8230-1412gb 8 type code type code and type designation of the df5 series frequency inverter: examples: figure 2: type code df5 series frequency inverters df5-322-075 frequency inverters of the df5 series single-phase or three-phase supply: 230 v assigned...

Page 12

09/01 awb8230-1412gb inspecting the items supplied 9 inspecting the items supplied frequency inverters of the df5 series frequency inverters are care- fully packed before delivery. The device may be transported only in its original packaging with a suitable transport system (see weight details). Obs...

Page 13

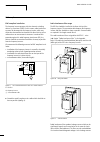

About df5 series frequency inverters 09/01 awb8230-1412gb 10 layout of the df5 figure 4: designations of the df5 a front cover, can be opened without tools b integrated keypad c terminal shroud d front cover flap with keypad e signalling relay terminals f heat sink g optional radio interference filt...

Page 14

09/01 awb8230-1412gb selection criteria 11 frequency inverter characteristics the df5 series convert the voltage and frequency of an existing three-phase supply to a dc voltage and use this voltage to gene- rate a three-phase supply with adjustable voltage and frequency. This variable three-phase su...

Page 15

About df5 series frequency inverters 09/01 awb8230-1412gb 12 intended use the df5 series frequency inverters are not domestic appliances. They are designed only for industrial use as system components. The df5 series frequency inverters are electrical apparatus for controlling variable speed drives ...

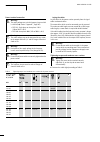

Page 16: 2 Engineering

09/01 awb8230-1412gb 13 2 engineering this chapter describes the ”features of the df5” as well as guide- lines and regulations concerning the following subjects: • connection to the mains • emc guidelines features of the df5 ambient temperatures operation 1) ta = –10 to +40 °c with rated current i e...

Page 17

Engineering 09/01 awb8230-1412gb 14 connection to the mains the df5 series frequency inverters can be used without limitation with every type of electrical grid (electrical grids according to iec 364 - 3). Electrical grid types electrical grids with a direct earthing point (tt/tn - systems): • opera...

Page 18

09/01 awb8230-1412gb connection to the mains 15 interaction with compensation devices the df5 series frequency inverters only accept a minimal funda- mental reactive power from the ac voltage supply. Compensation is therefore unnecessary. Fuses and cable cross-sections when the devices are connected...

Page 19

Engineering 09/01 awb8230-1412gb 16 mains contactor the mains contactor is connected to the mains side input cables l1, l2, l3 (type dependant). It allows the operational switch on and off of the df5 series frequency inverters from the mains supply as well as shutdown during a fault. Mains contactor...

Page 20

09/01 awb8230-1412gb emc guidelines 17 emc guidelines the limit values for emitted interference and immunity with vari- able speed drives are described in the iec/en 61800 - 3 product standard. When operating the frequency inverters of the df5 series in coun- tries which are part of the european uni...

Page 21

09/01 awb8230-1412gb 18.

Page 22: 3 Installation

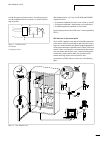

09/01 awb8230-1412gb 19 3 installation the df5 series frequency inverters should be installed in a control panel or in a metal enclosure (e.G. Ip54). Df5 installation the df5 series frequency inverters must be installed vertically on a non-flammable base. Mounting position h during installation or a...

Page 23

Installation 09/01 awb8230-1412gb 20 installation dimensions a free space of 100 mm minimum is required above and below the device (thermal air circulation). Please ensure that the front cover of the enclosure can always be opened and closed without impediment to ensure that the control terminals ca...

Page 24

09/01 awb8230-1412gb df5 installation 21 df5 attachment install the df5 series frequency inverter according to fig. 8 and tighten the screws with the following torques (a table 1): table 1: tightening torque's of the attachment screws figure 8: df5 attachment o [mm] 5 m4 3 nm 26 lbin 7 m6 4 nm 35 lb...

Page 25

Installation 09/01 awb8230-1412gb 22 emc compliance emc compliant installation the frequency inverter operates with fast electronic switching devices e.G. Transistors (igbt). For this reason, radio interference can occur on the output of the frequency inverter, which may effect other electronic devi...

Page 26

09/01 awb8230-1412gb emc compliance 23 are high frequency interference sources, the earthing measures must be undertaken with low resistance's on surfaces which as large as possible. With leakage currents f 3.5 ma, the vde 0160 and en 60335 stipulate that either: • the protective conductor must have...

Page 27

Installation 09/01 awb8230-1412gb 24 fit additional rfi filters or mains filters and frequency inverters as closely as possible to each other and on a single metal plate (mounting plate). Lay cables in the control cabinet as near as possible to the ground potential. Cables that hang freely act as an...

Page 28

09/01 awb8230-1412gb emc compliance 25 the screened cable between frequency inverter and motor should be as short as possible. Connect the screen to earth at both ends of the cable using a large contact surface connection. Lay the cables for the supply voltage separately from the signal cables and c...

Page 29

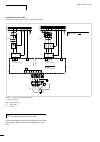

Installation 09/01 awb8230-1412gb 26 electrical connection in this section, you will find information for connection of the motor and the supply voltage to the power terminals, and the signal cables to the control terminals and signalling relay. An overview of the connections can be found in the fol...

Page 30

09/01 awb8230-1412gb electrical connection 27 figure 18: power connection, example with 400 v a network configuration, mains voltage, mains frequency interaction with p.F. Compensation systems b fuses and cable cross-sections c protection of persons and domestic animals with residual-current protect...

Page 31

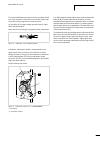

Installation 09/01 awb8230-1412gb 28 connecting the power section the flap on the front enclosure must be opened in order to connect the cables to the supply voltage and signal relay terminals. Open the front cover and the front of the enclosure x first of all open the front cover x loosen the screw...

Page 32

09/01 awb8230-1412gb electrical connection 29 x flap open the front cover and remove the terminal shroud . Power terminal arrangement the arrangement of the power terminals can be seen in the following figure. Table 2: description of the power terminals figure 21: open the front cover and remove the...

Page 33

Installation 09/01 awb8230-1412gb 30 power terminal connection laying the cables lay the cables for the power section separately from the signal cables and control cables. The motor cables which are to be connected must be screened. The maximum cable length must not exceed 50 m. With larger cable le...

Page 34

09/01 awb8230-1412gb electrical connection 31 connecting the supply voltage x connect the supply voltage to the power terminals: – single-phase supply voltage: l, n and pe – three-phase supply voltage: l1, l2, l3 and pe figure 23: cable connection to the power terminals pes pe e.

Page 35

Installation 09/01 awb8230-1412gb 32 connecting the motor cable x connect the motor cable to the u, v, w and pe terminals: the stator winding of the motor can be connected as a star or delta configuration in accordance with the rating data on the name- plate. Figure 24: power terminal connection exa...

Page 36

09/01 awb8230-1412gb electrical connection 33 if you use a motor filter or a sinusoidal filter here, the rate of voltage rise can be limited to values of approx. 500 v/ms (din vde 0530, iec 2566). In the factory default setting, frequency inverters of the df5 series have a clockwise rotating field. ...

Page 37

Installation 09/01 awb8230-1412gb 34 parallel connection of motors on a frequency inverter the df5 series frequency inverters can control multiple motors connected in parallel. If differing motor speeds are required, they must be selected via the number of pole pairs and/or the gear transmission rat...

Page 38

09/01 awb8230-1412gb electrical connection 35 motor filters, dv/dt - filters, sinusoidal filters motor filters (chokes) compensate for capacitive currents with long motor cables and with grouped drives (multiple connection of parallel drives to a single inverter). The use of motor filters is recomme...

Page 39

Installation 09/01 awb8230-1412gb 36 connecting the signalling relay the following figure indicates the position of the signalling relay. Table 4: description of the signalling relay terminals table 5: signalling relay conductor cross-sections and tightening torques figure 30: connecting the signall...

Page 40

09/01 awb8230-1412gb electrical connection 37 x fit the terminal shroud to the enclosure again and close the enclosure front. Figure 31: close the power section pes pe 1 2.

Page 41

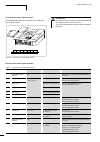

Installation 09/01 awb8230-1412gb 38 connecting the control signal terminals the following figure shows the arrangement of the individual control signal terminals. Function of the control signal terminals table 6: meaning of the control signal terminals figure 32: location of the control signal term...

Page 42

09/01 awb8230-1412gb electrical connection 39 control signal terminal wiring wire the control signal terminals to suit their application. For a description of how to change the functions of the control signal terminals, see section ”programming the control signal terminals” from page 49 . Use twiste...

Page 43

Installation 09/01 awb8230-1412gb 40 when connecting a relay to one of the digital outputs 11 or 12, connect a free-wheel diode in parallel with the relay, so that the self-induction voltage generated when the relay is switched off cannot destroy the digital outputs. Figure 34: relay with free-wheel...

Page 44

09/01 awb8230-1412gb electrical connection 41 example for the protective circuit of the digital inputs when the internal p24 supply voltage is used, or when a separate external 24 v power supply is used: figure 36: triggering of the digital inputs 5 4 3 2 1 q.. Q.. Q.. Q.. Q.. 0 v l p24 +24 v +24 v ...

Page 45

Installation 09/01 awb8230-1412gb 42 caution! Before commissioning, remove the covering on the upper ventilation slots and openings, as the frequency inverter will otherwise overheat a fig. 37. Figure 37: removing the upper cover.

Page 46: 4 Df5 Operation

09/01 awb8230-1412gb 43 4 df5 operation this section describes how to commission the df5 series frequency inverters and deals with issues that need to be observed during its operation. Initial startup observe the following points before you take the frequency inverter into operation: • ensure that t...

Page 47

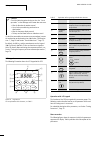

Df5 operation 09/01 awb8230-1412gb 44 if a fault has occurred due to overcurrent or overvoltage, increase the acceleration or deceleration time (a section ”acceleration time 1”, page 76 and section ”deceleration time 1” page 77). By default, the on key and the potentiometer on the keypad (a fig. 39 ...

Page 48

09/01 awb8230-1412gb operation with lcd keypad 45 table 8: explanation of the parameters for a detailed explanation of the parameters, see section ”setting parameters”, page 75. Changing display and basic parameters press the prg key to switch from display or run mode to programming mode. The prg la...

Page 49

Df5 operation 09/01 awb8230-1412gb 46 example for changing acceleration time 1: pnu f02 the frequency inverter is in the display mode and the run lamp is lit. X press the prg key. The frequency inverter changes to the programming mode, the prg lamp lights up and d 01 or the most recently modified pa...

Page 50

09/01 awb8230-1412gb display after the supply voltage is applied 47 the frequency inverter changes over to the display mode and displays the current frequency. Display after the supply voltage is applied after the supply voltage is switched on, the last screen which was visible before switch off wil...

Page 51

Df5 operation 09/01 awb8230-1412gb 48 operational warning message warning! If the supply voltage recovers after a brief failure, the motor may restart automatically if a start signal is still present. If personnel are endangered as a result, an external circuit must be provided which excludes a rest...

Page 52

09/01 awb8230-1412gb 49 5 programming the control signal terminals this section describes how to assign various functions to the control signal terminals. Overview table 9 provides an overview of the control signal terminals and a brief description of the functions which you can assign to the progra...

Page 53

Programming the control signal terminals 09/01 awb8230-1412gb 50 ext 12 external fault when the ext input is switched on, the fault signal activates pnu e12 and the motor switches off. The fault signal can be acknowledged, for example, with the rst input. Usp 13 restart inhibit when the usp input is...

Page 54

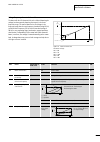

09/01 awb8230-1412gb overview 51 digital outputs 11 and 12 parameter definition under pnu c21 and c22 fa1 01 signal when frequency is reached or exceeded connection of a signal relay to digital output 11 or 12: transistor output (open collector) (maximum 27 v h, 50 ma) f s = setpoint frequency fa2 0...

Page 55

Programming the control signal terminals 09/01 awb8230-1412gb 52 frequency display fm the fm terminal provides the output frequency or the motor current as a frequency signal. The selection between the frequency display and display of the motor current is made under pnu c23. Analog frequency display...

Page 56

09/01 awb8230-1412gb frequency display fm 53 digital frequency display the frequency of this signal (pnu c23 = 02) changes proportio- nally to the output frequency. The pulse duty factor remains constant at about 50 %. The signal frequency results from the product of the current output frequency and...

Page 57

Programming the control signal terminals 09/01 awb8230-1412gb 54 programmable digital inputs 1 to 5 you can assign various functions to terminals 1 to 5. Depending on your requirements, these terminals can be configured as follows: • clockwise start signal (fwd), • anticlockwise start signal (rev), ...

Page 58

09/01 awb8230-1412gb start/stop 55 start/stop clockwise rotation fwd if you activate a digital input which has been configured as a fwd input, the motor starts to run in a clockwise direction. If you deac- tivate the input, the motor coasts to a stop. If the fwd and the rev inputs are activated simu...

Page 59

Programming the control signal terminals 09/01 awb8230-1412gb 56 fixed frequency ff1 to ff4 selection with the digital inputs configured as ff1 to ff4 you can select up to 16 user-definable fixed frequencies (including frequency setpoints), depending on which of the inputs is active or inactive (a t...

Page 60

09/01 awb8230-1412gb fixed frequency ff1 to ff4 selection 57 specifying frequency setpoints the frequency setpoint value can be assigned in one of three ways, dependent on pnu a01: • via the installed potentiometer on the keypad, pnu a01 = 00; • via analog input o (0 to 10 v) or oi (4 to 20 ma), pnu...

Page 61

Programming the control signal terminals 09/01 awb8230-1412gb 58 current setpoint value at (4 to 20 ma) when the digital input which has been configured as at is active, the setpoint value is defined by the current flow (4 to 20 ma) on terminal oi. If however the at input is inactive, the setpoint v...

Page 62

09/01 awb8230-1412gb fixed frequency ff1 to ff4 selection 59 second time ramp 2ch if the digital input which has been configured as 2ch is active, the motor will be accelerated or braked with the second acceleration or deceleration time. If the 2ch input is again deactivated, a chan- geover to the f...

Page 63

Programming the control signal terminals 09/01 awb8230-1412gb 60 controller inhibit and coasting of the motor frs (free run stop) if you activate the digital input configured as frs, the motor is switched off and coasts to a stop (for example if an emergency- stop is made). If you deactivate the frs...

Page 64

09/01 awb8230-1412gb fixed frequency ff1 to ff4 selection 61 external fault message ext if the digital input configured as ext is activated, the fault message e12 is initiated (e.G. An input used for the bimetal contacts). The fault message remains active even if the ext input is deactivated again a...

Page 65

Programming the control signal terminals 09/01 awb8230-1412gb 62 restart inhibit usp if the digital input configured as usp is activated, the restart inhibit is also activated. This prevents restart of the motor, when the voltage recovers after a mains fault if a simultaneous start command (active s...

Page 66

09/01 awb8230-1412gb fixed frequency ff1 to ff4 selection 63 reset: rst a fault message can be acknowledged by activating and subse- quently deactivating (i.E. Resetting) the digital input configured as rst. X program one of the digital inputs 1 to 5 as rst, by inputting the value 18 under the respe...

Page 67

Programming the control signal terminals 09/01 awb8230-1412gb 64 jog mode (jog) when the digital input configured as jog is activated, the motor can be operated in jog mode. This mode is used, e.G. For manual setting actions on machinery by issuing a start command on the fwd or rev input with a rela...

Page 68

09/01 awb8230-1412gb fixed frequency ff1 to ff4 selection 65 ptc thermistor input: ptc if programmable digital input 5 is configured as ptc, the motor temperature can be monitored with a thermistor with a positive temperature coefficient (ptc) connected to terminals 5 and l. If the resistance of the...

Page 69

Programming the control signal terminals 09/01 awb8230-1412gb 66 software protection sft if you activate the digital input configured as sft, the configured parameters cannot be overwritten unintentionally. X first of all set under pnu b31 if the software protection should also apply for the frequen...

Page 70

09/01 awb8230-1412gb programmable digital outputs 11 and 12 67 programmable digital outputs 11 and 12 the programmable digital outputs 11 and 12 are open collector transistor outputs (a fig. 65), to which e.G. Relays can be connected. These outputs can both be utilized for various func- tions, for e...

Page 71

Programming the control signal terminals 09/01 awb8230-1412gb 68 frequency value messages fa1/fa2 the digital output configured as fa1 will be activated as soon as the setpoint frequency is achieved. The digital output configured as fa2 is activated as long as the frequencies set under pnu c42 and c...

Page 72

09/01 awb8230-1412gb frequency value messages fa1/fa2 69 pnu name adjustable in run mode value function we c42 frequency from which fa2 becomes active during accelera- tion – 0 to 360 hz the digital output (11 or 12) configured as fa2 becomes active when the frequency entered here is exceeded during...

Page 73

Programming the control signal terminals 09/01 awb8230-1412gb 70 run operational the digital output configured as run remains activated as long as a frequency not equal to 0 hz is present, i.E. As long as the motor is driven in a clockwise or anticlockwise direction. X program one of the digital inp...

Page 74

09/01 awb8230-1412gb frequency value messages fa1/fa2 71 overload message ol the digital output configured as ol is activated when a freely selectable motor current is exceeded. The ol output is active as long as the motor current is higher than this threshold. X if you want to configure a programma...

Page 75

Programming the control signal terminals 09/01 awb8230-1412gb 72 pid controller deviation message od the digital output configured as od is activated when a user defi- nable pid deviation (actual value versus setpoint value) is exceeded. The od output remains active as long as this differential is e...

Page 76

09/01 awb8230-1412gb frequency value messages fa1/fa2 73 error message al the digital output configured as al activates when a fault has occurred. X program one of the digital inputs 11 or 12 as the al output, by setting the value 05 under pnu c21 or c22. When the al output is configured as a break ...

Page 77

Programming the control signal terminals 09/01 awb8230-1412gb 74 signalling relay terminals k11, k12, k14 if a fault occurs, the signalling relay (changeover) is triggered. The switching conditions can be programmed as required. Table 18: default setting of the signalling relay x use the above table...

Page 78: 6 Setting Parameters

09/01 awb8230-1412gb 75 6 setting parameters the parameters listed in this section can be set using the keypad. The adjustment and setting possibilities listed below are themati- cally arranged according to their function. This provides a clear overview of all parameters assigned to a particular fun...

Page 79

Setting parameters 09/01 awb8230-1412gb 76 basic functions input/display frequency value pnu f01 displays the current frequency setpoint value or the current fixed frequency. You can change the frequencies with the arrow keys and save the settings in accordance with the setting of pnu a01 and the fi...

Page 80

09/01 awb8230-1412gb basic functions 77 deceleration time 1 deceleration time 1 defines the time in which the motor brakes to 0 hz after a stop command. Direction of rotation the direction of rotation defines the direction in which the motor turns after a start command is issued. Pnu name adjustable...

Page 81

Setting parameters 09/01 awb8230-1412gb 78 setting the frequency and start command parameters this section describes the methods for adjusting and setting the start command and basic frequency-related parameters. Definition of frequency setpoint value with pnu a01, you set how the frequency setpoint...

Page 82

09/01 awb8230-1412gb setting the frequency and start command parameters 79 base frequency the base frequency is the frequency at which the output voltage has its maximum value. Maximum end frequency if you want to set another frequency range with a constant voltage that lies beyond the base frequenc...

Page 83

Setting parameters 09/01 awb8230-1412gb 80 analog setpoint value matching the external setpoint signal can be specifically matched with para- meters pnu a11 to a16, which are described below. A configu- rable voltage or current setpoint range can be assigned to a confi- gurable frequency range. Furt...

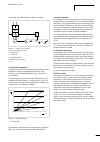

Page 84

09/01 awb8230-1412gb voltage/frequency characteristics and boost 81 voltage/frequency characteristics and boost the boost with the v/f characteristic has the effect of boosting the voltage (and consequently boosting the torque) in the lower frequency range. The manual boost raises the voltage in the...

Page 85

Setting parameters 09/01 awb8230-1412gb 82 dc braking (dc-break) to activate dc braking, apply a stop signal (pnu a51 to a55). By applying a pulsed dc voltage to the motor stator, a braking torque is induced in the rotor and acts against the rotation of the motor. With dc braking, a high level of st...

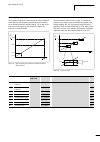

Page 86

09/01 awb8230-1412gb operating frequency range 83 operating frequency range the frequency range which is determined by the values configured under pnu b82 (start frequency) and pnu a04 (end frequency) can be limited by pnu a61 and a62 (a fig. 79). As soon as the frequency inverter receives a start c...

Page 87

Setting parameters 09/01 awb8230-1412gb 84 pid controller the df5 series frequency inverter is a pid controller. This can be used, for example, for flow and throughput controllers with fans and pumps. Pid control has the following features: • the setpoint value can be issued via the frequency invert...

Page 88

09/01 awb8230-1412gb pid controller 85 the example in the following figure shows a fan control: p: proportional component this component ensures that the output frequency and the system deviation are subject to a proportional relationship. Using pnu a72, the so-called proportional gain (k p ), expre...

Page 89

Setting parameters 09/01 awb8230-1412gb 86 setting the pid parameters values for the pid parameters must be chosen depending on the application. And the system’s control characteristics. To ensure correct pid closed loop control, the following points should be observed: • stable steady-state behavio...

Page 90

09/01 awb8230-1412gb pid controller 87 structure and parameters of the pid controller pid controller active/inactive df5 frequency inverters can operate in one of the following two control modes: • frequency control active (i.E. Pid closed loop control inactive) • pid closed loop control active you ...

Page 91

Setting parameters 09/01 awb8230-1412gb 88 internal regulator-based calculations all calculations within the pid algorithm are carried out in percen- tages, so that different physical units can be used, such as • pressure (n/m 2 ), • flow rate (m 3 /min), • temperature (°c), etc. The setpoint and re...

Page 92

09/01 awb8230-1412gb pid controller 89 setpoint definition there are three ways of entering the setpoints: • keypad • digital control signal terminal input (4 bit) • analog input (terminals o-l or oi-l) if the digital setpoints are defined through the control signal termi- nals, define the required ...

Page 93

Setting parameters 09/01 awb8230-1412gb 90 scaling adjustment scaling adjustment and scaling allow the setpoint and actual value to be displayed and the setpoint value to be entered directly in the correct physical unit. For this purpose, 100 % of the returned actual value is taken as a basis. By de...

Page 94

09/01 awb8230-1412gb pid controller 91 settings in the frequency control mode before you use the pid mode, you must configure the parameters in frequency control mode. Observe the following two points: acceleration and deceleration ramp the output frequency calculated by the pid algorithm is not imm...

Page 95

Setting parameters 09/01 awb8230-1412gb 92 . If, for example, you only require up to four different setpoint values, only ff1 and ff2 need to be used; for five to eight different setpoint values, only ff1 to ff3 are required. Activating pid mode x set pnu a71 to 01. You can make this setting at the ...

Page 96

09/01 awb8230-1412gb pid controller 93 application examples this section contains some setting examples for practical applications. Flow control the example shown in the figure below has the setpoint values 150 m 3 /min and 300 m 3 /min: figure 91: examples for flow control w: setpoint value, 4 bit ...

Page 97

Setting parameters 09/01 awb8230-1412gb 94 temperature control with the flow control in the previous example, the frequency inverter’s output frequency increases if the feedback signal is less than the setpoint and falls if the feedback signal is greater than the setpoint. With temperature control, ...

Page 98

09/01 awb8230-1412gb automatic voltage regulation (avr) 95 automatic voltage regulation (avr) the avr function stabilizes the motor voltage if there are fluctua- tions on the dc bus voltage. These deviations result from, for example: • unstable mains supplies or • dc bus voltage dips or peaks caused...

Page 99

Setting parameters 09/01 awb8230-1412gb 96 time ramps during operation, you can switch over from the time ramps confi- gured under pnu f02 and f03 to those configured under pnu a92 and a93. This can be done either by applying an external signal to input 2ch at any time or when the frequencies config...

Page 100

09/01 awb8230-1412gb automatic restart after a fault 97 automatic restart after a fault with the default settings, each malfunction triggers a fault message. An automatic restart is possible after the following fault messages have occurred: • overcurrent (pnu e01 to e04, up to four restart attempts ...

Page 101

Setting parameters 09/01 awb8230-1412gb 98 electronic motor protection the df5 series frequency inverters can monitor the temperature of connected motors with an electronic bimetallic relay. With pnu b12, you can match the electronic motor protection to the rated current of the motor. If the values ...

Page 102

09/01 awb8230-1412gb current limit 99 current limit with the current limit parameter, the motor current can be limited. To reduce the load current, the frequency rise ends in the accele- ration phase or the output frequency is reduced in the static phase, as soon as the output current exceeds the se...

Page 103

Setting parameters 09/01 awb8230-1412gb 100 parameter protection the four following methods of parameter protection are available: magnetizing current set the magnetizing current with smaller motors or multiple- motor operation accordingly. Pnu name adjustable in run mode value function we b31 softw...

Page 104

09/01 awb8230-1412gb other functions 101 other functions carrier frequency high carrier frequencies result in less motor noise and lower power losses in the motor but a higher dissipation in the power amplifiers and more noise in the mains and motor cables. You should there- fore set the carrier fre...

Page 105

Setting parameters 09/01 awb8230-1412gb 102 inhibit of the off key the off key located on the keypad or remote operating unit can be inhibited here. Motor restart after cancellation of the frs signal activation of the digital input configured as frs causes the inverter to shut down, leaving the moto...

Page 106: 7 Messages

09/01 awb8230-1412gb 103 7 messages in this section, the messages issued by the df5 series frequency inverters are listed and explained. Fault messages at overcurrent, overvoltage and undervoltage conditions, the output of the df5 series frequency inverters is shut down to protect against damage. Th...

Page 107

Messages 09/01 awb8230-1412gb 104 other messages this section describes the messages issued by the df5 series frequency inverters in standby mode, when the mains voltage is switched off, etc. Display cause the frequency inverter is in standby mode or a reset signal is active. The mains voltage has b...

Page 108: 8 Fault Correction

09/01 awb8230-1412gb 105 8 fault correction fault condition possible cause remedy the motor will not start. There is no voltage present at outputs u, v and w. Is voltage applied to terminals l, n and/or l1, l2 and l3? If yes, is the on lamp lit? Check terminals l1, l2, l3 and u, v, w. Switch on the ...

Page 109

Fault correction 09/01 awb8230-1412gb 106 to be observed when saving changed parameters: after saving changed parameters with the enter key, no inputs can be made using the keypad of the frequency inverter for at least six seconds. If, however, a key is pressed before this time elapses, or if the re...

Page 110: Appendix

09/01 awb8230-1412gb 107 appendix technical data the following table contains the technical data for the 230 v series. Df5-322-... 018 037 055 075 1k1 1k5 2k2 protection class according to en 60529 ip20 overvoltage category iii maximum permissible effective motor power in kw, details for four pole t...

Page 111

Appendix 09/01 awb8230-1412gb 108 digital control inputs programmable as • fwd: start/stop clockwise rotation • rev: start/stop anticlockwise rotation • ff1 to ff4: fixed frequency selection • jog: jog mode • at: use setpoint value 4 to 20 ma • 2ch: second time ramp • frs: free run stop • ext: exter...

Page 112

09/01 awb8230-1412gb technical data 109 the following data contains the technical data for the 400 v series. Df5-340-... 037 075 1k5 2k2 3k0 4k0 5k5 7k5 protection class according to en 60529 ip20 overvoltage category iii maximum permissible effective motor power in kw, details for four pole three-p...

Page 113

Appendix 09/01 awb8230-1412gb 110 digital control inputs programmable as • fwd: start/stop clockwise rotation • rev: start/stop anticlockwise rotation • ff1 to ff4: fixed frequency selection • jog: jog mode • at: use setpoint value 4 to 20 ma • 2ch: second time ramp • frs: free run stop • ext: exter...

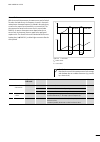

Page 114

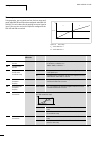

09/01 awb8230-1412gb dimensions and weights 111 dimensions and weights figure 95: sizes for df5 a b b b figure 96: dimensions for df5 df5- a a1 b b1 b2 c o [kg] 322-018 322-037 88.5 67 126 110 7 117 5 0.85 a 322-055 322-075 340-037 118 98 136 118 7 140 5 1.3 b 340-075 340-1k5 118 98 136 118 – 167 5 ...

Page 115

Appendix 09/01 awb8230-1412gb 112 cables and fuses the cross-sections of the cables and line protection fuses used must correspond with the applicable standards. Control cables should be screened with a maximum cross-section of 0.75 mm 2 . Use cables with a larger cross-section for supply voltage an...

Page 116

09/01 awb8230-1412gb mains contactors 113 mains contactors h the mains contactors listed here assume the network’s rated current (i ln ) without mains choke/mains filter. Their selection is based on the thermal current (ac-1). Caution! Jog mode must not be used through the mains contactor (pause tim...

Page 117

Appendix 09/01 awb8230-1412gb 114 3 ~ 400 v connection 340-037 2 20/16 dileem – 340-075 3.3 340-1k5 5 340-2k2 7 340-3k0 10 dil00m 340-4k0 11 dil00m 340-5k5 16.5 35/30 dil0m 340-7k5 20 35/30 dil0m 1) for a single-phase supply connection, supplement the mains contactors with the corresponding parallel...

Page 118

09/01 awb8230-1412gb radio interference filter 115 radio interference filter rfi filters have discharge currents to earth, which can be higher than the nominal values in the event of a fault (phase failure, load unbalance). To avoid dangerous voltages, the filters must be earthed before use. For dis...

Page 119

Appendix 09/01 awb8230-1412gb 116 mains choke figure 99: de4-ln... Mains choke h when the frequency inverter is operating at its rated current limit, the main choke causes a reduction of the frequency inverter's greatest possible output voltage (u 2 ) to about 96 % of the mains voltage (u ln ). Df5-...

Page 120

09/01 awb8230-1412gb connection examples 117 connection examples operation through an external potentiometer configuration of the parameters method of operation the frequency inverter can be started via terminal 1 in a clockwise direction and via terminal 2 in an anticlockwise direction. If both ter...

Page 121

Appendix 09/01 awb8230-1412gb 118 operation with fixed frequencies configuration of the parameters method of operation inputs 1 and 2 function exactly as described in the first example. With the activation of one or both fixed frequency inputs ff1 and ff2, the current frequency setpoint applied to t...

Page 122

09/01 awb8230-1412gb abbreviations of parameters and functions 119 abbreviations of parameters and functions designation message function, description 2ch 2-stage acceleration und deceleration al alarm signal at analog input voltage/current select avr automatic voltage regulation ext external trip f...

Page 123

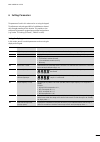

Appendix 09/01 awb8230-1412gb 120 standard form for user defined parameter settings the df5 series frequency inverters have programmable parame- ters. In the free setpoint columns below, you can list the changes you have made from the default settings. Pnu function we setpoint f01 frequency setpoint...

Page 124

09/01 awb8230-1412gb standard form for user defined parameter settings 121 a34 14th fixed frequency 0.0 a35 15th fixed frequency 0.0 a38 frequency in jog mode 1.0 a39 motor stop in jog mode via • 00: free run • 01: deceleration ramp • 02: dc braking 00 a41 boost characteristics • 00: manual • 01: au...

Page 125

Appendix 09/01 awb8230-1412gb 122 a92 2nd acceleration time 15.0 a93 2nd deceleration time 15.0 a94 switch-over from the 1st time ramp to the 2nd time ramp via • 00: input 2ch • 01: pnu a95 or a96 00 a95 changeover frequency from first to second acceleration time 0.0 a96 changeover frequency from fi...

Page 126

09/01 awb8230-1412gb standard form for user defined parameter settings 123 pnu function we setpoint b01 restart mode • 00: fault message • 01: 0 hz start • 02: synchronization to current motor speed and acceleration • 03: synchronization and deceleration 00 b02 permissible power failure duration 1.0...

Page 127

Appendix 09/01 awb8230-1412gb 124 pnu function we setpoint c01 function of digital input 1 • 00: fwd, clockwise rotation • 01: rev, anticlockwise rotation • 02: ff1, first fixed frequency input • 03: ff2, second fixed frequency input • 04: ff3, third fixed frequency input • 05: ff4, fourth fixed fre...

Page 128

09/01 awb8230-1412gb ul ® caution, warnings and instructions 125 ul ® caution, warnings and instructions preparation for wiring determination of wire and fuse sizes the maximum motor currents in your application determines the recommended wire size. The following table gives the wire size in awg. Th...

Page 129

Appendix 09/01 awb8230-1412gb 126 terminal dimensions and tightening torque the terminal screw dimensions for all df5 inverters are listed in table 3 (a page 30) and table 5 (a page 36). This information is useful in sizing spade lug or ring lug connectors for wire terminations. When connecting wiri...

Page 130: Index

09/01 awb8230-1412gb 127 index a abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5, 119 acceleration ramp . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91 acceleration time 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . 76 actual value pid configuration . . ....

Page 131

Index 09/01 awb8230-1412gb 128 i iec/en 61800-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17 initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101 input digital . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54 ptc thermistor . . . . ....

Page 132

09/01 awb8230-1412gb index 129 s screening . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 servo-motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33 setpoint value matc...