- DL manuals

- Nacecare

- Pressure Washer

- 1120 T

- Operating Manual

Nacecare 1120 T Operating Manual

G B

G B

G B

G B

G B

High Pr

High Pr

High Pr

High Pr

High Pressur

essur

essur

essur

essure Cleaners

e Cleaners

e Cleaners

e Cleaners

e Cleaners

Operating manual

Operating manual

Operating manual

Operating manual

Operating manual

Read and conform

Read and conform

Read and conform

Read and conform

Read and conform

safety instructions

safety instructions

safety instructions

safety instructions

safety instructions

before use

before use

before use

before use

before use

( 220-240 V / 50/60 Hz )

( 110-127 V / 60 Hz

)

Summary of 1120 T

Page 1

G b g b g b g b g b high pr high pr high pr high pr high pressur essur essur essur essure cleaners e cleaners e cleaners e cleaners e cleaners operating manual operating manual operating manual operating manual operating manual read and conform read and conform read and conform read and conform read...

Page 2

2 dear customer we would like to congratulate you on your new high pressure cleaner with integrated undercarriage and integrated hose drum and to thank you for the purchase. To ease your introduction to the use of the cleaner, we have provided the following pages of explanations, tips and hints, whi...

Page 3

3 construction description description description description description the krÄnzle 1120 / 1120 t + 1150 / 1150 t - high pressure cleaners are mobile machines. The design can be seen from the diagram. Item 1 water inlet connection with filter 1 water inlet connection with filter 1 water inlet con...

Page 4

4 description description description description description water and cleaning / pflegemittel system water can be connected at mains pressure to the high pressure pump or it can be sucked directly from a storage tank. The water is then forced under pressure by the high pressure pump to the lance. ...

Page 5

5 description description description description description the motor is protected from overload by a motor protection switch, which automatically cuts out the motor in the event of overload. However should the switch trip frequently, the cause of the malfunction should be located and rectified (s...

Page 6

6 electrical connection the machine is supplied with an electrical power cord with plug. The mains plug must be fitted to a standard grounded socket with a 30ma residual current operated device. The socket must be protected with a 16a delay action fuse on the mains side. KrÄnzle 1150 / 1150 t - 220-...

Page 7

7 description description description description description please check that the high pressure cleaner has available the quantity of water specified on page 2 (techn. Specs.) (litres per minute) . Water connection: test: allow the water supply hose to run for 1 minute into a bucket. The received ...

Page 8

8 brief operating instructions description the high pressure hose and spraying device supplied with the machine are made of high grade material, they are also optimized for the machine and marked as required by the appropriate regulations. - hose length max. 20m. If replacement parts are required, o...

Page 9

9 safety notes safety notes safety notes safety notes safety notes as to the recoil - as to the recoil - as to the recoil - as to the recoil - as to the recoil - see notice on page see notice on page see notice on page see notice on page see notice on page 2 ! 2 ! 2 ! 2 ! 2 ! Always aim the always a...

Page 10

10 1. Dirtkiller with nozzle 045 (at 1120 t and 1150 t) 2. Spray lance with vario - jet nozzle 3. Spray gun with insulated pistol grip and screw connection 4. KrÄnzle - high pressure cleaners 1120 t / 1150 t (50/60 hz) with hose drum and 15 m high pressure hose with steel reinforcement this is what ...

Page 11

11 hose drum with hp-hose receptacle for gun receptacle for lances put high pressure cleaner into upright position. Remove the screw from the brass element. Put the crank on the hexagon and fasten with the screw. How to assemble and furnish your high pressure cleaner.

Page 12

12 3 3 preparation for use 2. Connect the high pressure lance to the spray gun. High pressure hose connected to machine and spray gun. 1. Put high pressure cleaner into horizontal position! The high pressure cleaner is only to be operated in horizontal position ! Unroll hose without kinks and connec...

Page 13

13 3 3 4 . 4 . 4 . 4 . 4 . The machine can be connected to the machine can be connected to the machine can be connected to the machine can be connected to the machine can be connected to a pressurised water line with a pressurised water line with a pressurised water line with a pressurised water lin...

Page 14

14 1. Switch off the machine. 1. Switch off the machine. 1. Switch off the machine. 1. Switch off the machine. 1. Switch off the machine. 2. Cut of 2. Cut of 2. Cut of 2. Cut of 2. Cut off the water supply f the water supply f the water supply f the water supply f the water supply..... 3. Open the s...

Page 15

15 never direct the water jet at the machine itself ! Never direct the water jet at a power socket ! Never allow children to use the high pressure cleaner ! This is prohibited ! This is prohibited ! This is prohibited ! This is prohibited ! This is prohibited !.

Page 16

16 this is prohibited ! Never direct the water jet at people or animals ! Do not damage the power cord or repair it incorrectly ! Never pull the high pressure hose if it has formed kinks or “nooses”! Never pull the hose over sharp edges !.

Page 17

17 rotary scrubbing brush rotary scrubbing brush rotary scrubbing brush rotary scrubbing brush rotary scrubbing brush order no. 41.050 1 drain and pipe cleaning hose drain and pipe cleaning hose drain and pipe cleaning hose drain and pipe cleaning hose drain and pipe cleaning hose 10 m - order no. 4...

Page 18

18 car cleaning, glass, caravan, boat etc. Rotary washing brush with 40 cm exten- sion and st 30 nipple m 22 x 1,5 underbody cleaning of cars, trailers and equipment: lance 90 cm with high pressure nozzle and st 30 nipple m 22 x 1,5. The lance must be aimed when spraying. Cleaning cars and all smoot...

Page 19

19 the pressure gauge shows a 10% higher pressure than the working pressure. You only get a weak flow of water or no water at all! Small repairs - do it yourself! Small repairs - do it yourself! Small repairs - do it yourself! Small repairs - do it yourself! Small repairs - do it yourself! The injec...

Page 20: The Nozzle Is Blocked!

20 the nozzle is blocked! No water but the gauge shows full pressure ! No water but the gauge shows full pressure ! No water but the gauge shows full pressure ! No water but the gauge shows full pressure ! No water but the gauge shows full pressure ! Small repairs - small repairs - small repairs - s...

Page 21: Nozzle Dirty Or Sticky!

21 nozzle dirty or sticky! - do it yourself! - do it yourself! - do it yourself! - do it yourself! - do it yourself! Pressure gauge does not show full pressure. Water comes out in spurts. If you do not use the high-pressure cleaner for some time the valves can stick the high-pressure hose vibrates. ...

Page 22

22 small repairs - do it yourself! Small repairs - do it yourself! Small repairs - do it yourself! Small repairs - do it yourself! Small repairs - do it yourself! Stopping leaks from hose or gun stopping leaks from hose or gun stopping leaks from hose or gun stopping leaks from hose or gun stopping ...

Page 23

23 dirtkiller (special accessory) dirtkiller (special accessory) dirtkiller (special accessory) dirtkiller (special accessory) dirtkiller (special accessory) no description qty. Ord.-no 1 sprühkörper 1 41.520 2 o-ring 6,88 x 1,68 1 41.521 3 düsensitz 1 41.522 4 düse 045 1 41.523 5 stabilisator 1 41....

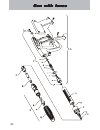

Page 24

24 gun with lance gun with lance gun with lance gun with lance gun with lance.

Page 25

25 spar e par ts list krÄnzle 1120/1120 t ; 1150/1150 t gun with lance krÄnzle 1120 - 1150 t krÄnzle 1120 - 1150 t krÄnzle 1120 - 1150 t krÄnzle 1120 - 1150 t krÄnzle 1120 - 1150 t . 5 rohranschlußteil r1/4" 1 12.125 incl. Pos. 3, 4, 21 6 scheibe 5,3 din9021 1 50.152 7 abzug-hebel kpl. 1 12.144 1 15...

Page 26

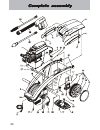

26 complete assembly complete assembly complete assembly complete assembly complete assembly.

Page 27

27 krÄnzle 1120 - 1150 t krÄnzle 1120 - 1150 t krÄnzle 1120 - 1150 t krÄnzle 1120 - 1150 t krÄnzle 1120 - 1150 t no description qty. Ord.-no spare parts list krÄnzle 1120 - 1150t complete assembly 1.1 motor-pumpe k1150 ohne schaltkasten 1 44.542 1.2 motor-pumpe k1150 mit schaltkasten 1 44.542 1 1.3 ...

Page 28

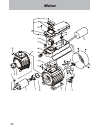

28 motor.

Page 29

29 no description qty. Ord.-no 1 Ölgehäuse 1 44.501 2 motorgehäuse mit stator 230 v / 50 hz 1 23.002 2.1 motorgehäuse mit stator 110 v / 60 hz 1 23.002 2 2.2 motorgehäuse mit stator 230 v / 60 hz 1 23.002 3 3 motorwelle mit rotor 230 v / 50 hz 1 43.024 3.1 motorwelle mit rotor 110 v / 60 hz 1 43.104...

Page 30

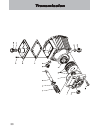

30 t t t t transmission ransmission ransmission ransmission ransmission.

Page 31

31 krÄnzle 1120 - 1150 t krÄnzle 1120 - 1150 t krÄnzle 1120 - 1150 t krÄnzle 1120 - 1150 t krÄnzle 1120 - 1150 t n o description q t y . Ord.-no 1 gehäuseplatte 1 43.003 2 Öldichtung 14 x 24 x 7 3 41.631 3 o-ring 83 x 2 1 43.039 4 plungerfeder 3 43.040 5 federdruckscheibe 14 mm 3 43.041 6 plunger 14...

Page 32

32 v v v v valve housing k 1120 t - k 1150 t alve housing k 1120 t - k 1150 t alve housing k 1120 t - k 1150 t alve housing k 1120 t - k 1150 t alve housing k 1120 t - k 1150 t.

Page 33

33 krÄnzle 1120 t - 1150 t krÄnzle 1120 t - 1150 t krÄnzle 1120 t - 1150 t krÄnzle 1120 t - 1150 t krÄnzle 1120 t - 1150 t n o description q t y . Ord.-no 3 1 leckagering 3 43.053 3 2 manschette 14 x 20 x 4/2 3 43.054 3 3 zwischenring mit abstützung 3 43.055 3 4 rückschlagfeder 1 14.120 1 3 5 versch...

Page 34

34 v v v v valve housing k 1120 - k 1150 alve housing k 1120 - k 1150 alve housing k 1120 - k 1150 alve housing k 1120 - k 1150 alve housing k 1120 - k 1150

Page 35

35 krÄnzle 1120 - 1150 krÄnzle 1120 - 1150 krÄnzle 1120 - 1150 krÄnzle 1120 - 1150 krÄnzle 1120 - 1150 spare parts list krÄnzle 1120 - 1150 v alve housing n o description q t y . Ord.-no n o description q t y . Ord.-no 1 v enti lg eh ä us e 1 44. 523 2 v enti ls topf en 5 41. 011 3 v enti ls topf en...

Page 36

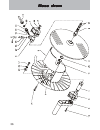

36 hose drum hose drum hose drum hose drum hose drum.

Page 37

37 krÄnzle 1120 t - 1150 t krÄnzle 1120 t - 1150 t krÄnzle 1120 t - 1150 t krÄnzle 1120 t - 1150 t krÄnzle 1120 t - 1150 t spare parts list krÄnzle 1120 t - 1150 t hose drum n o description q t y . Ord.-no 1 schale groß 1 40.160 2 schale klein 1 40.161 3 knickschutz 1 40.162 4 antriebswelle 1 44.517...

Page 38

38 terminal strip weber-unimat wt 22 - 551 13,5a excess current release motor-stator wiring diagram for krÄnzle k 1120 - k1150 t wiring diagram wiring diagram wiring diagram wiring diagram wiring diagram c : 40µf ( 80 µf bei 110v / 60 hz ) braun = brown blau = blue schw = black rt = red ge = yellow ...

Page 39

39 inspections the machine must be inspected according to the “guidelines for liquid spray devices” at least once every 12 months by a qualified person, to ensure that continued safe operation is guarateed. The results of the inspection are to be recorded in writing. This may be done in any form. Ac...