- DL manuals

- Nacecare

- Scrubber

- TTV 300T

- Owner's instructions manual

Nacecare TTV 300T Owner's instructions manual

Summary of TTV 300T

Page 1

Owner instructions original instructions warning! Read instructions before using the machine ttv 678-300t ride-on scrubber dryer operator instruction manual.

Page 2

2 index machine overview control panel overview safety precautions rating label / personal protective equipment / recycling before continuing, please refer to quick set up guide on page 7 ! ! Quick set-up guide machine set-up fitting the side pod skirts fitting the floor-tool fitting the brushes set...

Page 3: Machine Overview

3 1. Operator control panel ( see page 4 ) 2. Brush load-adjuster knob 3. Brush deck-release lever 4. Brush deck-foot pedal 5. Clean-water tank fill point 6. Side pod and skirt 7. Brush deck motors x3 8. Brush deck cover adjustment / width lever 9. Floor-tool raise / lower lever 10. Seat adjustment ...

Page 4: Control Panel Overview

4 for full easy to follow instructions on control panel set up and use, see machine operation page 14. Control panel overview 9 10 1 2 3 4 5 6 7 8 11 12 13 14 15 16 1 battery charge level indicator 2 brush pressure / load indicator 3 clean speed button 4/5/6 operator pre-set buttons 7 water flow rat...

Page 5

5 caution floorsign charging leads: ho5vv-f x 1mm 2 x 3 core motor wheel & modified brake lead assmenbly (321450) pg controller (208169) battery charger (230v ) (115v ) scrubber dryer accessories and packaging should be sorted for environmentally-friendly recycling. Only for eu countries. Do not dis...

Page 6: Safety Precautions

6 safety precautions caution read the instruction manual before using the appliance. The ttv is a class 1 product when fitted with an ac supply lead, but a class 3 product during normal use. Note this product meets the requirements of csa / can 60335-22.72 sub clause 20.1 this machine is also suitab...

Page 7: Quick Set Up Guide

7 1 contents: 1 x operator manual 2 x battery charging lead 2 x keys 4 x 40 amp fuses (1 x spare) 2 x side pod skirts 1 x brake disengage key 1 x maxi fuse-puller fig.1 note: ensure that no metal objects come into contact with battery terminals while the batteries are exposed. When inserting the fir...

Page 8: Machine Set Up

8 always ensure that the machine is switched off before making any adjustments ! ! To fit the side pod skirts, first remove the steel retaining strip already fitted to the pod (fig.6a). Align the steel retaining strip within the locating grooves of the rubber skirt and refit using existing screws (f...

Page 9: Machine Set Up

9 featuring the new obs (octagonal brush system); the brushes simply push-fit up onto the chucks making fitting and removal a simple process. Pull the side pod adjustment lever and set to the top position (fig.10). The side pod will now pull open (fig.11). Fit middle brush first (brushes will click-...

Page 10: Machine Set Up

10 setting the width adjustment first push the side pod in (see fig.13), then pull the side pod adjustment lever and set it to one of the three width-settings (see fig.13a) repeat the operation on both sides. 650mm 750mm 850mm fig.13 fig.14 fig.16a fig.13a the ttv-678 is equipped with a large capaci...

Page 11

11 when handling and mixing chemicals. Always ensure that chemical manufacturers safety guidlines are followed. Only use chemicals recomended for use in auto scrubber-driers. Important do not operate machine unless the operator manual has been read and fully understood. After use, ensure the chemica...

Page 12: Machine Set Up

12 lowering the brush deck fig.20 fig.21 fig.22 fig.23 after preparing the floor (see previous section), we are now ready to set the controls to suit the cleaning conditions. Before any settings can be applied, ensure the brush deck is lowered. While depressing left-hand foot pedal (see fig.20), pre...

Page 13

13 50:1 100:1 75:1 25:1 insert the key into the ignition and quarter-turn it clockwise to the ‘on’ position. The battery charge-level indicator will illuminate. Set automatic chemical dosing mix as required, depending on floor type and level of soiling. Set desired brush speed as required, depending...

Page 14: Machine Operation

14 brush pressure / load adjustment settings can be stored using one of the three pre-set store buttons (s1/s2/s3). Once settings are entered (chemical dose, brush speed and water-flow), press and hold one of the three pre-set store buttons, a light will flash then remain constant; your settings are...

Page 15

15 emergency-stop button and horn machine in use the ttv-678 is equipped with an electronic braking system. Simply lift your foot from the accelerator and the machine will stop. In an emergency, strike the emergency-stop isolator button the machine will be disabled. To reset, turn isolator button cl...

Page 16: Machine Operation

16 breakaway floor-tool off-aisle cleaning kit (optional extra accessory) 606182 fig.29 fig.30 fig.31 the floor-tool design incorporates a breakaway feature allowing it to safely disengage from its mounting should it become caught on an obstruction. (see fig.29) to attach the blade to its holder, fi...

Page 17: Machine Cleaning

17 always ensure that the machine is switched off prior to any maintenance. ! ! After use, empty waste-water tank using emptying hose and flush-out with clean water. Next remove floor-tool vacuum hose and flush out with clean water. Next empty clean water tank, using emptying hose and again flush ou...

Page 18

18 fig.32 fig.34 fig.35 fig.33 ! ! Always ensure that the battery is disconnected prior to any maintenance note: floor tool adjusters are factory set for optimal performance. The blades are designed to be reversible, thus extending their useful working life. Changing the floor tool blades to clean t...

Page 19: Machine Charging

19 always ensure that the machine is switched off prior to charging. ! ! The battery meter displays the charge level of the batteries; when fully charged, all meter lights are illuminated (see fig.36). As the machine is used and the batteries are discharged, the meter lights will go out from right t...

Page 20: Free-Wheel Function

20 always ensure that the machine is on level ground before disengaging brake arm. Never disengage the brake when the machine is on a slope / gradient. Never tow the machine with the brake engaged. ! ! The ttv-678 is equipped with a free-wheel function that will enable the operator to move / tow the...

Page 21: Battery Care

21 showing location of viewing panel for charging-light sequence. Yellow:- charging normally, 23 hours max yellow flashing:- charging finished, (trickle charging) green:- fully charged red:- remove mains supply failure of charger profile – corrective action replace faulty battery charging stopped. T...

Page 22: Trouble Shooting

22 trouble shooting sleeping/rest mode: battery indicator flashes every 5 seconds indicates machine has been idle for more than 20 minutes. V ario functions disabled cycle key switch! Number of bars flashing on display fault possible cause ef fect on product investigate the following action required...

Page 23

23 number of bars flashing on display fault possible cause ef fect on product investigate the following action required if fault persists. * 6 bars flash continuously . * control system is inhibiting drive. * faulty controller . * machine will not operate. * check controller for water damage. * repl...

Page 24: Trouble-Shooting

24 diagnostic software is available via your service engineer. Nacecare dealer or the nacecare technical help line +44 (0) 900 1 905 785 0038 problem cause solution machine will not operate missing or blown fuses key in the ‘off’ position low battery charge machine isolator button in ‘off’ mode mach...

Page 25: Recommended Spare Parts

25 linatex blades: 208203 - linatex blade (650mm) (rear) 208201 - linatex blade (650mm) (front) 606196 - blade set (650mm) 208194 - linatex blade (850mm) (front) 208196 - linatex blade (850mm) (rear) 606198 - blade set (850) floor tools: 606216 - ttv squeeqee assembly (650mm) 606218 - ttv squeegee a...

Page 26

26 wd - 0359 (a18) 01/04/2014.

Page 27

27.

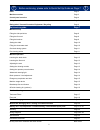

Page 28: Specifications

28 model - ttv678-300t brush motors vac motor power noise max decibel level at 1 meter time traction drive transit speed cleaning speed climbing gradient scrub widths 3 x 24v 400w 24v 400w 6 x 12v = 300ahr 72db (a) (iso 3744) uncertainty: 0.2db(a) 3.5 hrs 600w 7.0km/h 3.5km/h 11% 650mm 750mm 850mm b...

Page 29

29 notes: .............................................................................. .............................................................................. .............................................................................. ........................................................

Page 30

30 notes: .............................................................................. .............................................................................. .............................................................................. ........................................................

Page 31

31 notes: ....................................................... ....................................................... ....................................................... ....................................................... ....................................................... .............

Page 32

233890 11/14 (a13) this machine has been packed with the following: charging lead fuses isolator key / pin hose hook 38 / 32 mm adaptor signed.