- DL manuals

- NAiS

- Recording Equipment

- FP1

- Hardware Manual

NAiS FP1 Hardware Manual

Summary of FP1

Page 1

Programmable controller fp1 is a global brand name of matsushita electric works. Hardware.

Page 2: Before Beginning

Before beginning this manual and everything described in it are copyrighted. You may not copy this manual, in whole or part, without written consent of matsushita electric works, ltd. Matsushita electric works, ltd. Pursues a policy of continuous improvement of the design and performance of its prod...

Page 3: Contents

Contents chapter 1: features 1-1. Features ................................................................................................................ 2 1. Advanced control functions .......................................................................... 2 2. Communication functions ...........

Page 4: Chapter 3:

2) fp1 i/o link unit ................................................................................... 36 3) c-net adapter s1 type......................................................................... 36 5. Dimensions ................................................................................

Page 5: Chapter 5:

1. System configuration .....................................................................................67 2. Features of npst-gr software ver. 3 ..........................................................68 3. Npst-gr configuration ..................................................................

Page 6

Nop no operation....................................................................114 tmr 0.01s units timer ..............................................................115 tmx 0.1s units timer ................................................................115 tmy 1s units timer ...................

Page 7: Chapter 6:

3) enabling duplicated output...................................................................141 4) output state in one scan ......................................................................141 chapter 6: high-level instructions 6-1. Configuration of high-level instructions ....................

Page 8: Chapter 7:

2) overflow and underflow in binary operations (16-bit or 32-bit) ........198 3) overflow and underflow in bcd operations (4-digit or 8-digit).........199 chapter 7: troubleshooting 7-1. Self-diagnostic function ....................................................................................202 ...

Page 9: Chapter 1

Chapter 1 features 1-1. Features ..................................................................................2 1. Advanced control functions .............................................2 2. Communication functions .................................................5 1-2. Table of fp1 units .......

Page 10: 1-1. Features

2 1-1. Features 1-1. Features 1. Advanced control functions ■ high-speed counter function (all series) the built-in high-speed counter function supports four modes: two-phase input, up, down, and up/down. The fp1 can read the input regardless of the scan time. • application: pattern output function ...

Page 11

3 1-1. Features ■ interrupt input function (c24, c40, c56, and c72 series) this function executes an interrupt program immediately after an external interrupt input (minimum pulse width of 0.2 ms) occurs, regardless of the input timing. It enables high-speed processing at a fixed timing and is not a...

Page 12

4 1-1. Features ■ forced on/off control function (all series) this function allows the state of the input and output contacts to be forced on or off with a programming tool (npst-gr software, etc.). By forcing the output contact on or off, the connection on the output side can be checked. By forcing...

Page 13

5 1-1. Features 2. Communication functions ■ computer link function (mewtocol) this function allows the reading and writing of fp1 contact information and data register content from a host computer. It can be used for such applications as data collection and the monitoring of operating conditions. C...

Page 14

6 1-1. Features ■ modem communication (c24, c40, c56, and c72 series) using a modem, data transfer and long-distance communication between a personal computer and an fp1 unit can be performed. This can be done even when using npst-gr software. Select a cable in accordance with the specifications of ...

Page 15

7 1-1. Features ■ mewnet-f (remote i/o control) system using a fp1 i/o link unit, this function allows the exchange of i/o information with the host fp series programmable controller through a two-conductor cable. • refer to remote i/o system technical manual for details about i/o link function (rem...

Page 16: 1-2. Table of Fp1 Units

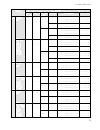

8 1-2. Table of fp1 units 1-2. Table of fp1 units 1. Control units c14 c16 c24 description eeprom eeprom ram ram 14 input: 8 output: 6 16 input: 8 output: 8 24 input: 16 output: 8 24 input: 16 output: 8 operating voltage 24 v dc 100 v to 240 v ac 24 v dc 100 v to 240 v ac 24 v dc 100 v to 240 v ac 2...

Page 17

9 1-2. Table of fp1 units c40 c56 c72 ram ram ram ram ram ram 40 input: 24 output: 16 40 input: 24 output: 16 56 input: 32 output: 24 56 input: 32 output: 24 72 input: 40 output: 32 72 input: 40 output: 32 24 v dc 100 v to 240 v ac 24 v dc 100 v to 240 v ac 24 v dc 100 v to 240 v ac 24 v dc 100 v to...

Page 18

10 1-2. Table of fp1 units 2. Expansion units e8 e16 e24 e40 8 input: 8 8 input: 4 output: 4 8 output: 8 16 input: 16 16 input: 8 output: 8 16 output: 16 24 input: 16 output: 8 40 input: 24 output: 16 24 v dc 100 v to 240 v ac 24 v dc 100 v to 240 v ac relay transistor (npn open collector) relay tra...

Page 19

3. Intelligent units 4. Link units fp1 transmitter master unit fp1 i/o link unit c-net adapter c-net adapter s1 type (for fp1 control unit only) operating voltage 24 v dc 100 v to 240 v ac 24 v dc 100 v to 240 v ac 24 v dc 100 v to 240 v ac part number afp1752 afp1756 afp1732 afp1736 afp8532 afp8536...

Page 20

12 1-3. Expansion and configurations 1-3. Expansion and configurations 1. Expansion of units be sure to check that the units are expanded according to the following restrictions: 1) expansion units note: • expansion units (e8 and e16 series) which do not require power supply cannot be connected in s...

Page 21

13 1-3. Expansion and configurations 2) intelligent units and link unit • number of expandable units together: fp1 a/d converter unit: 1 unit; fp1 d/a converter unit: 2 units; fp1 transmitter master unit and fp1 i/o link unit: 1 of each unit; fp1 i/o link unit: 1 unit • there are no restrictions on ...

Page 22

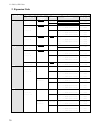

14 1-3. Expansion and configurations 64 72 80 88 40 32 40 48 40 32 36 40 40 48 40 44 48 40 44 48 32 40 48 40 48 56 48 40 48 56 48 40 44 48 56 56 48 52 56 48 52 56 40 48 56 24 32 24 16 24 32 28 24 32 24 32 28 24 32 28 24 40 32 24 40 32 24 32 40 32 24 32 40 36 32 32 32 40 36 32 40 36 32 48 40 32 c24 c...

Page 23

15 1-3. Expansion and configurations 96 104 112 120 128 136 152 48 56 64 56 48 56 64 56 64 64 64 56 60 64 56 60 64 56 64 72 64 56 64 72 72 72 72 64 68 72 64 72 80 80 80 88 48 40 32 40 48 40 32 40 40 40 40 48 44 40 48 44 40 56 48 40 48 56 48 40 48 48 48 56 52 48 64 56 48 56 56 64 c40 c56 c72 c24 c40 ...

Page 24: 1-4. Programming Tools

16 1-4. Programming tools 1-4. Programming tools ■ system configurations of programming tools 1. Programming tools program editing can be done with a commercially available personal computer and fp programmer ii. 1) npst-gr software using the npst-gr program editing software, programs can be easily ...

Page 25

17 1-4. Programming tools notes: 2) fp programmer ii with the hand-held fp programmer ii, such operations as writing, reading, and retrieval of programs can be performed. Necessary tools • fp1 peripheral cable: 0.5 m / 1.640 ft.: afp15205 3 m / 9.843 ft.: afp1523 • fp programmer ii: afp1114 note: 2....

Page 26

■ writing a program to the memory (eprom) via the master memory (eeprom) with a commercially available rom programmer [program in fp1’s internal ram → master memory (eeprom) → commercially available rom programmer’s internal memory → memory (eprom)] procedure: 1 attach master memory (eeprom) to fp1 ...

Page 27

■ writing a program to the memory (eprom) with npst-gr software and a commercially available rom programmer [program with npst-gr software → commercially available rom programmer’s internal memory → memory (eprom)] procedure: 1 transfer the program from the personal computer to the commercially avai...

Page 28

20

Page 29: Chapter 2

Chapter 2 specifications 2-1. Parts terminology and functions..........................................22 1. Control unit......................................................................22 1) c14 and c16 series ...............................................22 2) c24, c40, c56, and c72 series ....

Page 30

22 2-1. Parts terminology and functions 2-1. Parts terminology and functions 1. Control unit 1) c14 and c16 series (illustration: c16 series, ac type) 0 1 2 3 4 5 6 7 0 1 2 3 4 5 6 7 com 0 1 2 3 4 5 6 7 f.G. 100-240v ac run prog. Err. Alarm run remote prog. Com 0 1 2 3 4 5 6 7 output input x y (rela...

Page 31

23 2-1. Parts terminology and functions 2) c24, c40, c56, and c72 series (illustration: c72 series, ac type) 0 run remote prog. Output input x y (relay) (12-24v dc) v0 max. Min. Run prog. Err. Alarm 1 2 3 4 5 6 7 8 9 a b c d e f 0 1 2 3 4 5 6 7 8 9 a b c d e f 0 1 2 3 0 1 2 3 4 5 6 7 8 9 a b c d e f...

Page 32

24 2-1. Parts terminology and functions 2. Expansion unit 1) e8 and e16 series (illustration: e16 series, i/o type) 2) e24 and e40 series (illustration: e40 series, dc type) output input x y (tr) (24v dc) 0 1 2 3 4 5 6 7 8 9 a b c d e f 0 1 2 3 0 1 2 3 4 5 6 7 8 9 a b c d e f 0 1 2 3 com 0 1 2 7 3 4...

Page 33

25 2-1. Parts terminology and functions 3. Intelligent unit 1) fp1 a/d converter unit (illustration: dc type) 2) fp1 d/a converter unit (illustration: dc type) note: • terminals marked with “•” cannot be used as output terminals. F.G. Range i 0 + fp1-2d/a matsushita erectric works, ltd. Fp1-003-93-b...

Page 34

26 2-1. Parts terminology and functions 4. Link unit 1) fp1 transmitter master unit notes: • the operation mode selectors are set to all off position when shipped. • operation mode selector upper state is “off( )” and the lower state is “on ( )”. • be sure to power is off when changing the switch po...

Page 35

2) fp1 i/o link unit f.G. + - f.G. Fp1-003-93-b.C + - 24v dc rs485 p ower supply terminals (ac type/dc type) din rail attachment lever 0 123 45 6 789 0 123 45 6 789 station no. Power com. Alarm pc fp1 i/o link mode sw. On off 1 2 3 4 station number selector: set the slave station number of the remot...

Page 36

3) c-net adapter s1 type " " " rs485 interface connects to the rs485 interface on the c-net adapter or other c-net adapter s1 type using transmission cable (shielded twisted pair or 2-conductor cable). Power led (green) flashes: off: send data monitor led (green) flashes: off: receive data monito...

Page 37: 2-2. Specifications

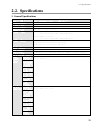

29 2-2. Specifications 2-2. Specifications 1. General specifications ambient temperature ambient humidity storage temperature storage humidity breakdown voltage insulation resistance vibration resistance shock resistance noise immunity operating condition rated operating voltage operating voltage ra...

Page 38

30 2-2. Specifications note: • when the expansion unit e16 output type (part number: afp13110) is connected, the rated current consumption is 0.4 a or less. Current consumption built-in dc power output for inputs no-influence time by momentary power drop ac type c14, c16 series: c24, c40 series: c56...

Page 39

31 2-2. Specifications 2. Performance specifications of control unit and expansion unit 1) control specifications programming method control method program memory program capacity operation speed kinds of instruction external input (x) external output (y) internal relay (r) special internal relay (r...

Page 40

32 2-2. Specifications notes: 2) input specifications of control unit and expansion unit ■ wiring diagram examples note: • c14, c56, c72 and e16 (input type only) series do not have (+) common input version. + – 3 k Ω" 12 v to 24 v dc com (+) input terminals " " " fp1 control/expansion unit • (+)...

Page 41

33 2-2. Specifications 3) output specifications of control unit and expansion unit ■ relay output type ■ transistor output type (pnp or npn open collector) (fp1 control/expansion unit) l internal circuit " " " output terminals • wiring diagram l com l internal circuit " " " output terminals l ...

Page 42

34 2-2. Specifications ■ triac output type l internal circuit " " " output terminals l com l: load (fp1 expansion unit) • wiring diagram ~ led insulation method output type rated load voltage range operating load voltage range max. Load current min. Load current max. Surge current off state leaka...

Page 43

35 2-2. Specifications 3. Performance specifications of intelligent unit 1) fp1 a/d converter unit ■ i/o conversion characteristics 2) fp1 d/a converter unit analog output points analog output range resolution overall accuracy response time output impedance maximum output current allowable load resi...

Page 44

36 2-2. Specifications ■ i/o conversion characteristics 4. Performance specifications of link unit 1) fp1 transmitter master unit 2) fp1 i/o link unit 3) c-net adapter s1 type rs485 × 1 port, rs422 × 1 port between rs485 and rs422 interfaces interface conversion format item description 64 points (in...

Page 45

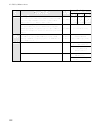

5. Dimensions 1) control unit 2) expansion unit e24 series e40 series w (mm/in.) 190/7.480 260/10.236 (unit: mm/in.) item com 0 com 1 com 2 com 3 com 4 com 5 com 6 com 7 + - 24v dc f.G. Com f 8 9 e a b c d (+) - com 7 0 1 6 2 3 4 5 (+) - e24 and e40 series w 74/2.913 45/1.772 ac type dc type pc fp1-...

Page 46

3) intelligent unit 4) link unit c-net adapter s1-type on off rd sd power terminate nais f. G + - rs485 45/1.772 50/1.969 81/3.189 20/0.787 300/11.811 c-net adapter s1 type fp1 i/o link unit 120/4.724 74/2.913 81/3.189 45/1.772 ac type dc type fp1-021-93-h f.G. + - f.G. + - 24v dc rs485 0 12 345 6 7...

Page 47: Chapter 3

Chapter 3 installation and wiring 3-1. Installation ............................................................................40 1. Panel mounting ...............................................................40 2. Din rail mounting ..........................................................40 3. ...

Page 48: 3-1. Installation

40 3-1. Installation 1. Panel mounting mount the control unit, expansion unit, fp1 a/d converter unit, fp1 d/a converter unit, and fp1 i/o link unit on the mounting panel with m4 size screws. Mounting hole dimensions 2. Din rail mounting to mount the control unit, expansion unit, fp1 a/d converter u...

Page 49: Incorrect

41 3. Cautions • install and remove the control unit, expansion unit, fp1 a/d converter unit, fp1 d/a converter unit, and fp1 i/o link unit when all power is turned off. • do not drop the unit or apply excessive force to it. • do not allow pieces of wire or other objects to fall into the unit when w...

Page 50: 3-2. Expansion

42 3-2. Expansion 1. Expansion cable 2. Unit expansion • connect the control unit to the expansion unit, intelligent unit (fp1 a/d converter unit, fp1 d/a converter unit) or fp1 i/o link unit using expansion cable that folds out of sight and out of the way. In addition, concealing the expansion cabl...

Page 51: 3-3. Wiring

43 3-3. Wiring 1. Crimp terminal • m3.5 screws are used for the i/o terminal block. • use of crimp terminals is recommended for wiring to the terminals. • be sure to connect the cables and the interface terminals correctly using crimp terminals. • suitable crimp terminals are ring terminals, insulat...

Page 52

2) power supply lines • the power supply lines for the fp1, i/o devices and motorized devices should be isolated as shown below. • design the power supply lines for the control unit, expansion unit, and intelligent units (fp1 a/d converter unit and fp1 d/a converter unit) and fp1 i/o link unit so th...

Page 53

45 3. Input terminals of control unit and expansion unit 1) wiring example for input terminals (illustration: fp1 control unit) note: 2) description • keep the input lines as far away from output lines as possible. • keep the input lines at least 100 mm/3.937 in. Away from the motor and high voltage...

Page 54

46 3) input wiring examples ■ wiring the photoelectric sensors due to the difference in the photoelectric sensor’s output scheme, connect as shown below: • relay output type • universal output type • npn open collector output type • two-wire type • pnp open collector output type (control units and e...

Page 55

47 ■ wiring the led-equipped reed switch ■ connecting an input device with a different voltage (ex.: a 5 v sensor, etc.) note: 4) input terminal layouts notes: • do not connect input devices to the input terminals indicated with a “•” symbol. • the + common input type is also available for c16, c24 ...

Page 56

48 notes: • do not connect input devices to the input terminals indicated with a “•” symbol. • the + common input type is also available for c40, e40, e8 series and e16 series i/o type. • c56 series: ac type dc type • c72 series: ac type dc type • e8 series: dc type input only type (i: 8-point) i/o ...

Page 57

4. Output terminals of control unit and expansion unit 1) wiring example for output terminals (illustration: fp1 control unit) note: 2) description • a different voltage can be used with each independent common. • when more than one loade is connected to the same power supply, short the com terminal...

Page 58

3) output wiring examples • connect a protective circuit such as the one shown below when switching inductive loads. When switching dc type inductive loads with a relay type output unit, be sure to connect a diode across the ends of the load. When using an ac inductive load when using a dc inductive...

Page 59

4) output terminal layouts notes: • do not connect output devices to the output terminals indicated with a “•” symbol. • there are differing output types such as relay, npn open collector, pnp open collector, and triac output, therefore, take care when selecting the type of load to be connected. • c...

Page 60

Notes: • do not connect output devices to the output terminals indicated with a “•” symbol. • there are differing output types such as relay, npn open collector, pnp open collector, and triac output, therefore, take care when selecting the type of load to be connected. • e8 series: output only type ...

Page 61

5. Wiring the fp1 a/d converter unit 1) wiring for voltage input connect the input device to the analog voltage input terminal (v). Switch the input range with the voltage range selection terminal (range), as shown below. 2) wiring for current input after connecting the analog voltage input terminal...

Page 62

6. Wiring the fp1 d/a converter unit 1) wiring for voltage output connect the load device to the analog voltage output terminals (v+, v-). Switch the output range with the voltage range selection terminal (range), as shown below. ■ analog voltage output range 0 to 5 v range: the voltage range select...

Page 63

7. Wiring the fp1 transmitter master unit connect the rs485 interfaces on the fp1 transmitter master unit and on the other programmable controller with a communication cable. When connecting the communication cable, be sure to connect positive (+) to positive, and negative (-) to negative of the rs4...

Page 64

56 3-3. Wiring twisted pair cable: 1-pair notes: 1. Three or more parts of cable should not be connected to one rs485 port. 2. Grounding example conductors insulation jacket • conductor size: min. 0.5 mm 2 (awg20 or lager) • cable insulation material: polyethylene insulation thickness: max. 0.5 mm/0...

Page 65: Chapter 4

Chapter 4 before programming 4-1. Operating principles of the programmable controller..........58 1. Basic configuration..........................................................58 2. Basic operation ................................................................60 4-2. How to program the programma...

Page 66: Programmable Controller

58 4-1. Operating principles of the programmable controller 4-1. Operating principles of the programmable controller 1. Basic configuration a programmable controller is composed of four basic sections: 1 cpu, 2 memory, 3 input interface, and 4 output interface. An inside look at these sections will ...

Page 67

59 4-1. Operating principles of the programmable controller ■ functions of the four sections 1 1 cpu (central processing unit) controls the operation of the programmable controller including the i/os according to the program 2 2 memory memory areas where the program and information needed for operat...

Page 68

60 4-1. Operating principles of the programmable controller 2. Basic operation the basic operation of the programmable controller is: - to read data from all the input field devices - to execute the program according to the logic programmed - to turn the output field devices on or off the process of...

Page 69

■ scan time of the programmable controller • the process of input update, program execution, and output update is referred to as a scan and the process repeated over and over in the same manner is referred to as the cyclic execution method . • in the cyclic execution method, since the process of inp...

Page 70: Controller

62 4-2. How to program the programmable controller 4-2. How to program the programmable controller 1. Making a ladder diagram originally, programmable controllers were designed as a replacement for relay-controlled systems. Therefore, programs can be easily created with a relay sequence circuit as s...

Page 71

2. Relays and timer/counter contacts in the fp1 the fp1 programmable controller contains many relays and timer/counter contacts as follows. Input terminals external input relay (x) this relay feeds signals to the programmable controller from an external input device such as a limit switch or photoel...

Page 72

■ memory area ■ external input relay (x), external output relay (y), internal relay (r) • the lowest digit for these relay's x, y, and r numbers is expressed in hexadecimals and the second and higher digits are expressed in decimal to enable both bit and word processing. ■ timer contact (t), counter...

Page 73

3. I/o allocation in the fp1 the i/o addresses for the fp1 control unit, primary and secondary expansion units, and intelligent units (fp1 transmitter master unit, fp1 i/o link unit) are assigned as follows. Notes: • x50 to x67 and y50 to y5f are allocated for the fp1 transmitter master unit when it...

Page 74

Example: when an e24 series expansion unit is connected to a c40 series control unit, inputs and outputs are allocated as follows: notes: • the maximum number of expansion units that can be connected to the control unit is as follows: - fp1 c14 and c16 series: 1 expansion unit (including fp1 transmi...

Page 75

4-3. Programming with npst-gr software npst-gr software ver. 3.1 offers program entry, editing, and monitoring of fp series programmable controllers. With this software, you can concentrate on the control pattern rather than wasting time learning how to enter the program. 1. System configuration ■ c...

Page 76

2. Features of npst-gr software ver. 3 npst-gr software is a programming support tool for the fp1 programmable controller. The things you can do with the npst-gr are briefly introduced in the following: • programming npst-gr provides three programming modes. - programming by entering ladder symbols:...

Page 77

3. Npst-gr configuration the npst-gr software is configured as follows. • programming screen the screen where a program is created or edited. Just after the software is activated, the programming screen is displayed in the ladder symbol mode. Next, the menu window appears over it. • menu window the ...

Page 78

When you are in the online mode, it indicates whether you are monitoring the program or not, and which mode the programmable controller is currently in. When you are in the offline mode 1 indicates which mode you are in: the offline mode or the online mode. In the offline mode, the software cannot c...

Page 79

When you are in the online mode when you are in ladder symbol mode 1 to 4 are the same when you are in the offline mode. 5 indicates whether npst-gr is monitoring a program or not. While monitoring a program, “monitor” will be displayed here. When not monitoring, “waiting” will be displayed here. 6 ...

Page 80

• programmable controller information area plc type indicates the type of programmable controller currently specified. Plc type: fp1 0.9 k fp1/fp-m 2.7 k fp1/fp-m 5 k fp3 10 k fp3/fp-c 16 k fp5 16 k fp10/fp10s 30 k fp10 60 k plc mode indicates the operation mode of the programmable controller. When ...

Page 81

73 4-3. Programming with npst-gr software 2) npst-gr installation this section describes how to install npst-gr. Make a backup disk of the software and use it for installation. Procedure 1. If the current drive is other than drive a, change to drive a by typing “a:” at the dos prompt. 2. Insert the ...

Page 82

74 4-3. Programming with npst-gr software 5. Make sure that the source drive and the target drive are specified correctly. The “ source drive ” shows the drive which the npst-gr system disk is in. The “ target drive ” shows the drive onto which you want to install npst-gr. When the source drive and ...

Page 83

75 4-3. Programming with npst-gr software 3) how to use npst-gr effectively the flowchart shown below is an example of how you can use npst-gr before you run a program in the field. Except for the settings for npst-gr and programmable controller configuration, you can freely change the order of the ...

Page 84

76 4-3. Programming with npst-gr software 5) configuring npst-gr ■ selecting [npst configuration] from the menu window before you create a program, you must first configure the settings and change the default settings if necessary. If the programming screen is displayed, press to display the “npst m...

Page 85

77 4-3. Programming with npst-gr software • screen mode you can select the npst-gr screen mode between color and black/white. Mono: displays the screen in black and white. Color: displays the screen in color. (black/cyan/red/magenta/green/bright blue/yellow or brown/white) • plc type before setting ...

Page 86

■ logging or saving the parameters after you set the parameters in [1.Npst configuration], you must log the settings so that npst-gr will be reconfigured according to the parameters you set. If you go to the programming screen or use other functions without logging the parameters you set, they will ...

Page 87

6. Basic key operation for programs input the following program using the ladder symbol mode. When you first start npst-gr, you will be in the ladder symbol mode. The [1.Programming style] option changes the programming style to the boolean non-ladder mode. Procedure 1. Select the [edit a program] o...

Page 88

7. Downloading a program to the programmable controller the [4.Load a program to plc] option downloads the program and/or the i/o comments which are on the screen of the programmable controller. After you complete the program, you must download the program so that the programmable controller execute...

Page 89

8. Saving a program to disk the [2.Save a program to disk] option saves the program and/or the i/o comments which exist on the screen to the disk of your personal computer. Procedure 1. Select the [program manager] option from the npst menu. 2. Select the [2.Save a program to disk] option from the [...

Page 90

9. Printing the [a.Print out] option prints out: ■ the program displayed on the screen, as a ladder diagram or in boolean. ■ the list of the relays, registers or control instructions used in the program. ■ the parameters set with the [npst configuration] menu ■ the parameters set for system register...

Page 91

83 4-4. Programming with the fp programmer ii 4-4. Programming with the fp programmer ii the fp programmer ii performs program entry, editing, and monitoring of fp series programmable controllers. 1. System configuration ■ connection between a programmable controller and an fp programmer ii • an fp1...

Page 92

84 4-4. Programming with the fp programmer ii 2. Downloading a program to the programmable controller procedure 1. Connect fp programmer ii and the fp1 programmable controller using the fp1 peripheral cable. 2. Set the mode selector of the fp1 to prog. 3. Press the keys on the fp programmer ii, as s...

Page 93

85 4-4. Programming with the fp programmer ii ■ key operations for correcting input errors • correcting the contents of the program procedure example 1. Read the contents of address 3. 2. Clear the display for address 3. 3. Rewrite with the correct instructions. • adding/inserting instructions proce...

Page 94

86 4-5. Memory unit creation and rom operation 4-5. Memory unit creation and rom operation 1. Memory unit • the program may be downloaded to a memory unit and saved only for the c24, c40, c56, and c72 series. Using memory units makes it easy to rewrite and transfer programs. • the contents of the pr...

Page 95

87 4-5. Memory unit creation and rom operation 2. How to program rom • using an fp rom writer or a commercially available rom programmer, the contents of the fp1’s internal ram can be written to the memory (rom). • the following types of memory (rom) are available: - memory unit (eprom): afp1201 mem...

Page 96

88 4-5. Memory unit creation and rom operation ■ writing a program to the memory (eprom) via the master memory (eeprom) with a commercially available rom programmer [fp1’s internal ram → master memory unit (eeprom) → rom programmer memory → memory (eprom)] procedure: 1 attach master memory unit (eep...

Page 97

89 4-5. Memory unit creation and rom operation 3. Operation with installed memory unit (rom operation) when the fp1 is operated with the installed memory unit (rom), the mode selector causes the following operational changes to occur. ■ when the power is turned on in prog. Mode • in the prog. Mode, ...

Page 98

90

Page 99: Chapter 5

Chapter 5 basic instructions 5-1. Configuration of basic instructions ......................................92 1. Types of basic instructions...............................................92 2. Configuration of basic instructions..................................92 3. Operands for basic instructions...

Page 100

5-1. Configuration of basic instructions 1. Types of basic instructions basic sequence instructions: these basic instructions perform bit unit logic operations and are the basis of the relay sequence circuit. Basic function instructions: these are the timer, counter and shift register instructions. ...

Page 101

3. Operands for basic instructions 1) description of operands ■ external input relay (x), external output relay (y), internal relay (r) • the lowest digit for these relay’s x, y, and r numbers is expressed in hexadecimal and the second and higher digits are expressed in decimal to enable both bit an...

Page 102

■ timer contact (t), counter contact (c) • the timer contact (t) and counter contact (c) numbers are expressed in decimal. Timer contact (t) counter contact (c) notes: ■ hold type and non-hold type of the internal relay (r), timer contact (t), and counter contact (c) • setting is possible so that th...

Page 103

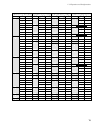

5-2. Table of basic instructions 1. Basic sequence instructions • a: available, n/a: not available • details about the instructions with a * mark are described in this manual. Refer to the pages in the far right column of the above table. A a a a a a a a a a a a a a a a a a a a a a a a a a a a a a a...

Page 104

2. Basic function instructions 3. Control instructions • a: available, n/a: not available • details about the instructions with a * mark are described in this manual. Refer to the pages in the far right column of the above tables. For other instructions without a * mark, refer to “fp-m/fp1 programmi...

Page 105

4. Compare instructions • a: available, n/a: not available • details about the instructions with a * mark are described in this manual. Refer to the pages in the far right column of the above tables. For other instructions without a * mark, refer to “fp-m/fp1 programming manual”. N/a n/a n/a a a a a...

Page 106

• a: available, n/a: not available • details about the instructions with a * mark are described in this manual. Refer to the pages in the far right column of the above tables. N/a n/a n/a n/a n/a n/a n/a n/a n/a n/a n/a n/a n/a n/a n/a n/a n/a n/a n/a n/a n/a a a a a a a a a a a a a a a a a a a a a ...

Page 107

• a: available, n/a: not available • details about the instructions with a * mark are described in this manual. Refer to the pages in the far right column of the above tables. 133 135 137 133 135 137 133 135 137 133 135 137 c14/ c16 page availability c56/ c72 c24/ c40 description step operand boolea...

Page 108

5-3. Description of basic instructions basic instruction reference 100 5-3. Description of basic instructions 5-3. Description of basic instructions 101 outline st: begins a logic operation with a form a (normally open) contact. St/: begins a logic operation with a form b (normally closed) contact. ...

Page 109: St/

5-3. Description of basic instructions 101 outline st: begins a logic operation with a form a (normally open) contact. St/: begins a logic operation with a form b (normally closed) contact. Ot: outputs the operated result to the specified output. Program example ■ operands ■ time chart ■ explanation...

Page 110

5-3. Description of basic instructions 102 outline inverts the operated result up to this instruction. Program example ■ explanation of example ■ time chart • y0 goes on when both x0 and x1 turn on. • y1 goes on when x0 or x1 turns off. Description • the / instruction inverts the operated result up ...

Page 111: An/

5-3. Description of basic instructions 103 outline an: connects a form a (normally open) contact serially. An/: connects a form b (normally closed) contact serially. Program example ■ operands ■ time chart ■ explanation of example • y0 goes on when both x0 and x1 turn on and also x2 turns off. Descr...

Page 112: Or/

5-3. Description of basic instructions 104 outline or: connects a form a (normally open) contact in parallel. Or/: connects a form b (normally closed) contact in parallel. Program example ■ operands ■ time chart ■ explanation of example • y0 goes on when either x0 or x1 turns on or x2 turns off. Des...

Page 113: Ans

5-3. Description of basic instructions 105 outline performs an and operation on multiple instruction blocks. Program example ■ explanation of example ■ time chart • y0 goes on when x0 or x1 and x2 or x3 turn on. Description • the ans instruction is used to connect blocks in series. • a block begins ...

Page 114: Ors

5-3. Description of basic instructions 106 outline performs an or operation on multiple instruction blocks. Program example ■ explanation of example ■ time chart • y0 goes on when both x0 and x1 or both x2 and x3 turn on. Description • the ors instruction is used to connect blocks in parallel. • a b...

Page 115: Rds

5-3. Description of basic instructions 107 outline pshs: stores the operated result up to this instruction. Rds: reads the operated result stored by the pshs instruction. Pops: reads and clears the operated result stored by the pshs instruction. Program example ■ explanation of example ■ time chart ...

Page 116

5-3. Description of basic instructions 108 description note: • refer to page 139, “5-4. Hints for programming basic instructions”, for details about basic instructions, such as the pshs , rds , pops instructions, which are not displayed on the fp programmer ii key. • pshs: stores the operated result...

Page 117: Df/

109 5-3. Description of basic instructions df/ trailing edge differential df leading edge differential outline df: turns on the contact for only one scan when the leading edge of the trigger is detected. Df/: turns on the contact for only one scan when the trailing edge of the trigger is detected. P...

Page 118: Incorrect

5-3. Description of basic instructions 110 notes: ■ application examples r1 r0 x0 x0 r3 ( df/ )! R0 x0 r0 ( df )! R3 r2 r3 r0 y0 r1 x0 r1 ( df/ )! R3 r0 r2 x0 r2 ( df )! R3 r1 r2 r2 y0 r0 x1 x0 y0 x1 r0 ( df )! X0 y0 ( df )! R0 y0 y0 a program with a df instruction r0 x1 x0 y0 x1 r0 x0 y0 r0 a progr...

Page 119: Set

111 5-3. Description of basic instructions set set rst reset outline set: holds the contact (in bit) on. Rst: holds the contact (in bit) off. Program example ■ operands ■ time chart ■ explanation of example • when x0 turns on, y0 goes on and holds the contact (in bit) on. • when x1 turns on, y0 goes...

Page 120

5-3. Description of basic instructions 112 • when the set and rst instructions are used, the contents of the output changes with each step during the processing of the operation. Example: when x0, x1, and x2 are turned on the external output at the i/o update depends on the final results of the oper...

Page 121

113 5-3. Description of basic instructions outline turns on the output and maintains its condition. Program example ■ operands ■ time chart ■ explanation of example • when x0 turns on, output relay y0 goes on and maintains its condition. • y0 goes off when x1 turns on. Description • when the set tri...

Page 122: Nop

Outline no operation program example ■ explanation of example • y0 outputs when x1 turns on. Description • the nop instruction can be used to make the program easier to read when checking or correcting. • when the nop instruction is inserted, the size of the program will increase slightly, however, ...

Page 123: Tmr

Outline tmr: sets the on-delay timer for 0.01 s units (0 to 327.67 s) tmx: sets the on-delay timer for 0.1 s units (0 to 3276.7 s) tmy: sets the on-delay timer for 1 s units (0 to 32767 s) program example ■ operands ■ explanation of example ■ time chart on off x0 on off t5 on off y0 3s 3s • three se...

Page 124

116 5-3. Description of basic instructions description • the tm instruction is a down type preset timer. • if there are not enough tm instruction numbers, you can increase the number by changing the setting of system register 5. Refer to page 230, “8-5. System registers”, for details on how to chang...

Page 125

■ changing the value in the set value area (sv) all control units can change the value in the set value area (sv), even during run mode, using the high-level instruction f0 (mv) or the programming tool (fp programmer ii or npst-gr). The range of values that can be specified in the set value area (sv...

Page 126

■ application example when using two timer instructions t0 y0 x0 tmx 30 0 on off x0 on off t0 on off on off on off t1 y0 y1 3s 2s st pshs tm k pops tm k st ot st ot x x x t y t y 0 0 30 1 20 0 0 1 1 t1 y1 tmx 20 1 program example 2 t0 t1 y1 tmx 30 x0 y0 tmx 20 0 1 on off x0 on off t0 on off on off o...

Page 127

Outline subtracts the preset counter. Program example ■ operands ■ explanation of example ■ time chart on off x0 on off x1 on off c100 on off y0 • • • # # # # # # # # # # ten times • in order to reset the counter, turns reset trigger x1 on and then off. • when the leading edge of the x0 is ...

Page 128

Description • the ct instruction is a down type preset counter. • if there are not enough ct instruction numbers, you can increase the number by changing the setting of system register 5. Refer to page 230, “8-5. System registers”, for details on how to change the number of contact numbers. • when p...

Page 129

Notes: ■ changing the value in the set value area (sv) all the control units can change the value in the set value area (sv), even during run mode, using the high-level instruction f0 (mv) or the programming tool (fp programmer ii or npst-gr). The range of values that can be specified in the set val...

Page 130

5-3. Description of basic instructions 122 outline shifts one bit of 16-bit [word internal relay (wr)] data to the left. Program example ■ operands ■ explanation of example ■ time chart on off x0 on off x1 on off on off r30 on off on off on off on off x2 r31 r32 r33 r34 • if shift trigger x1 turns o...

Page 131

123 5-3. Description of basic instructions notes: description • shifts one bit of the specified data area (wr) to the left (to the higher bit position). • when programming the sr instruction, be sure to program the data input, shift and reset triggers. Data input: specifies the state of new shift-in...

Page 132: McE

5-3. Description of basic instructions 124 mc master control relay mce master control relay end availability step 2 2 all series outline executes the instructions from mc to mce when the predetermined trigger (i/o) turns on. Program example ■ explanation of example ■ time chart description • execute...

Page 133: Incorrect

Notes: x1 y0 x0 ( mc 0 )! ( mce 0 )! X2 ( mc 1 )! ( mce 1 )! X3 y1 • another master control instruction ( mc , mce ) set can be programmed between one master control instruction set as shown on the right. This construction is called “nesting”. 125 5-3. Description of basic instructions 1. When progr...

Page 134

5-3. Description of basic instructions 126 outline indicates the end of a main program. Program example ■ explanation of example • step 50 is the end of the main program area. Description • indicates the end of a main program. Notes: • place any subroutine programs and interrupt programs after the e...

Page 135: St =

Outline performs start operation by comparing two word data in the comparative conditions. The contact goes on/off depending on the result of the comparison. Program example ■ operands ■ explanation of example • compares the contents of data register dt0 with the constant k50. If dt0 = k50, the exte...

Page 136

Description • compares the word data specified by s1 with the word data specified by s2 according to the comparative conditions. The contact goes on/off depending on the result of the comparison. • the result of the comparison operation is as follows: ■ flag condition • error flag (r9007): turns on ...

Page 137: An =

Outline performs and operation by comparing two word data in the comparative conditions. The contact goes on/off depending on the result of the comparison. The contacts are connected serially. Program example ■ operands ■ explanation of example • compares the contents of data register dt0 with the c...

Page 138

Description • compares the word data specified by s1 with the word data specified by s2 according to the comparative conditions. The contact goes on/off depending on the result of the comparison. The contacts are connected serially. • the result of the comparison operation is as follows: ■ flag cond...

Page 139: Or =

Availability step 5 5 5 5 5 5 c24, c40, c56, and c72 series cpu version 2.7 or later ( ) outline performs or operation by comparing two word data in the comparative conditions. The contact goes on/off depending on the result of the comparison. The contacts are connected in parallel. Program example ...

Page 140

Description • the contact goes on/off depending on the result of the comparison. The contacts are connected in parallel. • the result of the comparison operation is as follows: ■ flag condition • error flag (r9007): turns on and keeps the on state when the area specified using the index modifier exc...

Page 141: Std =

Availability step 9 9 9 9 9 9 c24, c40, c56, and c72 series cpu version 2.7 or later ( ) outline performs start operation by comparing two double word data in the comparative conditions. The contact goes on/off depending on the result of the comparison. Program example ■ operands ■ explanation of ex...

Page 142

Description • compares the double word data specified by s1 and s1+1, with the double word data specified by s2 and s2+1, according to the comparative conditions. The contact goes on/off depending on the result of the comparison. • the result of the comparison operation is as follows: ■ flag conditi...

Page 143: And =

Availability step 9 9 9 9 9 9 c24, c40, c56, and c72 series cpu version 2.7 or later ( ) outline performs and operation by comparing two double word data in the comparative conditions. The contact goes on/off depending on the result of the comparison. The contacts are connected serially. Program exa...

Page 144

Description • compares the double word data specified by s1 and s1+1, with the double word data specified by s2 and s2+1, according to the comparative conditions. The contact goes on/off depending on the result of the comparison. The contacts are connected serially. • the result of the comparison op...

Page 145: Ord =

Availability step 9 9 9 9 9 9 c24, c40, c56, and c72 series cpu version 2.7 or later ( ) outline performs or operation by comparing two double word data in the comparative conditions. The contact goes on/off depending on the result of the comparison. The contacts are connected in parallel. Program e...

Page 146

Description • compares the double word data specified by s1 and s1+1, with the double word data specified by s2 and s2+1, according to the comparative conditions. The contact is connected in parallel depending on the results of the comparative conditions. • the result of the comparison operation is ...

Page 147

139 5-4. Hints for programming basic instructions 1. Basic circuit with basic instructions x0 y0 x1 item ladder diagram time chart and & and not operation or & or not operation self-hold circuit interlock circuit on-delay timer circuit one shot circuit x0 on off x1 on off y0 on off x0 on off x1 on o...

Page 148

140 2. Basic instructions not displayed on the keys of fp programmer ii 1) when you do not know the basic instruction codes for the fp programmer ii procedure: 1. The instruction code list is appeared on the screen when press the keys as follows. 2. Press the or to find desired instruction code. 3. ...

Page 149

141 3. Duplicated use of outputs 1) duplicated output • duplicate use of same number designation in the kp and ot instructions is prohibited. Even if the same output is used for multiple application instructions, such as the set or rst instruction, or a data transfer instruction, it is not regarded ...

Page 150

142.

Page 151: Chapter 6

Chapter 6 high-level instructions 6-1. Configuration of high-level instructions ............................144 1. Types of high-level instructions ...................................144 2. Configuration of high-level instructions ......................144 3. Operands for high-level instructions.......

Page 152

6-1. Configuration of high-level instructions 1. Types of high-level instructions • in the fp1 control unit, the following high-level instructions are available: data transfer instructions: these instructions copy or exchange the 16-bit or 32-bit data. Bin arithmetic instructions: these instructions...

Page 153

145 6-1. Configuration of high-level instructions notes: • there is no need to program the same triggers many times when two or more high-level instructions are programmed consecutively with the same trigger. In the program example shown right, the x0 for second and third instructions can be omitted...

Page 154

146 6-1. Configuration of high-level instructions 3. Operands for high-level instructions ■ registers and constants • the word relays (wx, wy, wr), timer/counter area (sv, ev), register (dt), index registers (ix, iy) and constants (k, h) consist of 1 word (16 bits) and are handled as word units. • t...

Page 155

147 6-1. Configuration of high-level instructions ■ data handled in the fp1 programmable controller • the fp1 programmable controller can handle data in 16-bit units (word) or 32-bit units (double word). 0 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 ...

Page 156

148 6-1. Configuration of high-level instructions ■ word external input relay (wx), word external output relay (wy) and word internal relay (wr) • “wx”, “wy” and “wr” express the relays (x, y and r). This word format treats the 16-bit relay groupings as one word. • the word relay addresses (wx, wy a...

Page 157

Hexadecimal constant (h constant) • the hexadecimal constant is used to represent binary numbers with fewer digits. The hexadecimal number system uses one digit to represent four binary digits (bits). The hexadecimal constant is expressed by adding the prefix “h” to the data. Example: when h18a6 (he...

Page 158

150 6-2. Table of high-level instructions 6-2. Table of high-level instructions 1. Data transfer instructions 2. Bin arithmetic instructions • a: available, n/a: not available • specification of flag operation in the above tables: [↕] the flag (special relay) available for the instruction (turns on/...

Page 159

151 6-2. Table of high-level instructions 3. Bcd arithmetic instructions • a: available, n/a: not available • specification of flag operation in the above tables: [↕] the flag (special relay) available for the instruction (turns on/off according to the condition). [ ](blank) the flag (special relay)...

Page 160

152 6-2. Table of high-level instructions 4. Data comparison instructions • a: available, n/a: not available • specification of flag operation in the above tables: [↕] the flag (special relay) available for the instruction (turns on/off according to the condition). [ ](blank) the flag (special relay...

Page 161

153 6-2. Table of high-level instructions 5. Logic operation instructions 6. Data conversion instructions • a: available, n/a: not available • specification of flag operation in the above tables: [↕] the flag (special relay) available for the instruction (turns on/off according to the condition). [ ...

Page 162

154 6-2. Table of high-level instructions 7. Data shift instructions • a: available, n/a: not available • specification of flag operation in the above tables: [↕] the flag (special relay) available for the instruction (turns on/off according to the condition). [ ](blank) the flag (special relay) not...

Page 163

155 6-2. Table of high-level instructions 8. Up/down counter and left/right shift register instructions 9. Data rotate instructions 10. Bit manipulation instructions 11. Auxiliary timer instruction • a: available, n/a: not available • specification of flag operation in the above tables: [↕] the flag...

Page 164

156 6-2. Table of high-level instructions 12. Special instructions 13. High-speed counter special instructions • a: available, n/a: not available • specification of flag operation in the above tables: [↕] the flag (special relay) available for the instruction (turns on/off according to the condition...

Page 165

6-3. Description of high-level instructions high-level instruction reference 6-3. Description of high-level instructions 157 instruction number ladder diagram on the screen using npst-gr software available operands for instruction explanation of program example, details of instruction, and flag cond...

Page 166: (Mv)

158 6-3. Description of high-level instructions outline copies the 16-bit data to the specified 16-bit area. Program example ■ operands ■ explanation of example • the contents of word external input relay wx0 are copied to word internal relay wr0 when trigger x0 turns on. Bit position wx0 1 0 1 0 1 ...

Page 167

159 6-3. Description of high-level instructions description • the 16-bit data or 16-bit equivalent constant specified by s is copied to the area specified by d when the trigger turns on. ■ flag condition • error flag (r9007): turns on and keeps the on state when the area specified using the index mo...

Page 168: (Dmv)

160 6-3. Description of high-level instructions outline copies the 32-bit data to the specified 32-bit area. Program example ■ operands ■ explanation of example • the contents of word internal input relays wr1 and wr0 are copied to data registers dt1 and dt0 when trigger x0 turns on. Note: • when pr...

Page 169

161 6-3. Description of high-level instructions description • the 32-bit data or the 32-bit equivalent constant specified by s is copied to the 32-bit area specified by d when the trigger turns on. ■ flag condition • error flag (r9007): turns on and keeps the on state when the area specified using t...

Page 170: (Dgt)

6-3. Description of high-level instructions outline copies the hexadecimal digits in one 16-bit area to the specified digit in another 16-bit area. Program example ■ operands ■ explanation of example • the hexadecimal digit 0 of the data register dt100 is copied to hexadecimal digit 0 of word extern...

Page 171

163 6-3. Description of high-level instructions description • the hexadecimal digits in the 16-bit data or in the 16-bit equivalent constant specified by s are copied to the 16-bit area specified by d according to content specified by n when the trigger turns on. ■ how to specify the n • the hexadec...

Page 172

164 6-3. Description of high-level instructions ■ examples of hexadecimal digit copy s d (1) when hexadecimal digit 1 of the source is copied to hexadecimal digit 1 of the destination: n: h 1 0 1 s d (2) when hexadecimal digit 3 of the source is copied to hexadecimal digit 0 of the destination: n: h...

Page 173: F22

165 f22 (+) 16-bit data [s1 + s2 → d] availability step 7 all series 6-3. Description of high-level instructions outline adds two 16-bit data and stores the result in the specified area. Program example ■ operands ■ explanation of example • the contents of data registers dt0 and dt1 are added when t...

Page 174

166 description • the 16-bit data or 16-bit equivalent constant specified by s1 and s2 are added together when the trigger turns on. The added result is stored in d. ■ flag condition • error flag (r9007): turns on and keeps the on state when the area specified using the index modifier exceeds the li...

Page 175: F23

167 outline adds two 32-bit data and stores the result in the specified area. Program example ■ operands ■ explanation of example • the contents of data registers dt1 and dt0 and the contents of data registers dt101 and dt100 are added when trigger x0 turns on. The added result is stored in data reg...

Page 176

168 note: description • the 32-bit data or 32-bit equivalent constant specified by s1 and s2 are added together when the trigger turns on. The added result is stored in d+1 and d. ■ flag condition • error flag (r9007): turns on and keeps the on state when the area specified using the index modifier ...

Page 177: –

169 outline subtracts the 16-bit data from the minuend and stores the result in the specified area. Program example ■ operands ■ explanation of example • subtracts the contents of data register dt2 from the contents of data register dt0 when trigger x0 turns on. The subtracted result is stored in wo...

Page 178

170 description • subtracts the 16-bit data or 16-bit equivalent constant specified by s2 from the 16-bit data or 16-bit equivalent constant specified by s1 when the trigger turns on. The subtracted result is stored in d. ■ flag condition • error flag (r9007): turns on and keeps the on state when th...

Page 179: –

171 outline subtracts the 32-bit data from the minuend and stores the result in the specified area. Program example ■ operands ■ explanation of example • subtracts the contents of data registers dt201 and dt200 from the contents of data registers dt101 and dt100 when trigger x0 turns on. The subtrac...

Page 180

172 note: description • subtracts the 32-bit data or 32-bit equivalent constant specified by s2 from the 32-bit data or 32-bit equivalent constant specified by s1 when the trigger turns on. The subtracted result is stored in d+1 and d. ■ flag condition • error flag (r9007): turns on and keeps the on...

Page 181: F30

173 outline multiplies two 16-bit data and stores the result in the specified 32-bit area. Program example ■ operands ■ explanation of example • multiplies the contents of word external input relay wx0 and decimal constant k100 when trigger x0 turns on. The multiplied result is stored in data regist...

Page 182

174 note: description • multiplies the 16-bit data or 16-bit equivalent constant specified by s1 and the 16-bit data or 16-bit equivalent constant specified by s2 when the trigger turns on. The multiplied result is stored in d+1 and d (32-bit area). ■ flag condition • error flag (r9007): turns on an...

Page 183: F31

Outline multiplies two 32-bit data and stores the result in the specified 64-bit area. Program example ■ operands ■ explanation of example • multiplies the contents of data registers dt1 and dt0 and the contents of data registers dt101 and dt100 when trigger x0 turns on. The multiplied result is sto...

Page 184

176 notes: description • multiplies the 32-bit data or 32-bit equivalent constant specified by s1 and the one specified by s2 when the trigger turns on. The multiplied result is stored in d+3, d+2, d+1, and d (64-bit area). ■ flag condition • error flag (r9007): turns on and keeps the on state when ...

Page 185: –

177 outline divides the 16-bit data by the divisor and stores the result in the specified area and the remainder in special data register dt9015. Program example ■ operands ■ explanation of example • divides the contents of data register dt100 by decimal constant k10 when trigger x0 turns on. The qu...

Page 186

178 description • the 16-bit data or 16-bit equivalent constant specified by s1 is divided by the 16-bit data or 16- bit equivalent constant specified by s2 when the trigger turns on. The quotient is stored in d and the remainder is stored in the special data register dt9015. ■ flag condition • erro...

Page 187: –

Outline divides the 32-bit data by the divisor and stores the result in the specified area and the remainder in special data registers dt9016 and dt9015. Program example ■ operands ■ explanation of example • divides the contents of data registers dt201 and dt200 by the contents of data registers dt1...

Page 188

180 note: description • the 32-bit data or 32-bit equivalent constant specified by s1 is divided by the 32-bit data or 32- bit equivalent constant specified by s2 when the trigger turns on. The quotient is stored in d+1 and d and the remainder is stored in the special data registers dt9016 and dt901...

Page 189: F60

181 outline compares one 16-bit data with another. Program example ■ operands ■ explanation of example • compares decimal constant k100 with the contents of data register dt0 when trigger x0 turns on. The compared result is stored in special internal relays r900a, r900b, and r900c. When dt0 > k100, ...

Page 190

182 description • compares the 16-bit data specified by s1 with one specified by s2 when the trigger turns on. The compared result is stored in special internal relays r9009, and r900a to r900c. ■ flag condition • error flag (r9007): turns on and keeps the on state when the area specified using the ...

Page 191

183 notes: 6-3. Description of high-level instructions • if you program the f60 (cmp) instruction using special internal relay r9010 (on all the time), the same trigger as the instruction need not be programmed. • the comparison instruction flags r900a to r900c are updated with each execution of the...

Page 192: F61

184 outline compares one 32-bit data with another. Program example ■ operands ■ explanation of example • compares the content of data registers dt101 and dt100 with the content of data registers dt1 and dt0 when trigger x0 turns on. The compared result is stored in special internal relays r900a, r90...

Page 193

185 description • compares the 32-bit data or 32-bit equivalent constant specified by s1 with one specified by s2 when the trigger turns on. The compared result is stored in special internal relays r9009, and r900a to r900c. ■ flag condition • error flag (r9007): turns on and keeps the on state when...

Page 194

186 notes: 6-3. Description of high-level instructions • if you program the f61 (dcmp) instruction using special internal relay r9010 (on all the time), the same trigger as the instruction need not be programmed. • the comparison instruction flags r900a to r900c are updated with each execution of th...

Page 195: F80

187 outline converts 16-bit binary data to bcd code that expresses 4-digit decimals. Program example ■ operands ■ explanation of example • converts the contents of timer/counter elapsed value area ev0 to bcd code that expresses 4-digit decimals when trigger x0 turns on. The converted data is stored ...

Page 196

188 description • converts the 16-bit binary data specified by s to the bcd code that expresses 4-digit decimal when the trigger turns on. The converted data is stored in d. • the binary data that can be converted to bcd code are in the range of k0 (h0) to k9,999 (h270f). ■ flag condition • error fl...

Page 197: F81

189 outline converts bcd code that expresses 4-digit decimals to 16-bit binary data. Program example ■ operands * the k constant available here is in the range of k0 to k9999. ** the h data specified here should be in the form of bcd code that express 4-digit decimal ranging from h0 (bcd) to h9999 (...

Page 198

190 description • converts the bcd code that expresses 4-digit decimals specified by s to 16-bit binary data when the trigger turns on. The converted data is stored in d. ■ flag condition • error flag (r9007): turns on and keeps the on state, - when the area specified using the index modifier exceed...

Page 199: Instructions

191 6-4. Hints for programming high-level instructions 6-4. Hints for programming high-level instructions 1. How to use bcd data 1) bcd data bcd stands for binary coded decimal and is one of the codes represented in binary. It was introduced as convenient way to handle numbers which had to be input ...

Page 200

192 6-4. Hints for programming high-level instructions 2) processing bcd data in the programmable controllers • since the data in the programmable controllers are basically processed in standard binary, it is recommended that data in the programmable controllers be proceeded by the binary form using...

Page 201

193 6-4. Hints for programming high-level instructions 2. How to use index registers (ix, iy) 1) index registers (ix, iy) • each fp1 has two index registers available (ix and iy). • the functions of index registers are classified into two types as follows: - modifier of other operands - memory area ...

Page 202

194 6-4. Hints for programming high-level instructions 2) application examples of index registers (ix, iy) ■ saving/outputting data in the same order that it is received/stored example 1: when saving the data in the same order in which it is received • the data input from wx1 is transferred to the d...

Page 203

195 6-4. Hints for programming high-level instructions ■ setting/displaying data according to digital switch input example 1: when setting the timer set (preset) values input from the digital switch • the selection of the timer instruction number is performed using the input from the digital switche...

Page 204

196 6-4. Hints for programming high-level instructions 3. Operation errors 1) operation errors • an operation error is one of the errors in the programmable controllers. These errors occur when an instcruction [one of high-level/some basic (e.G., st =) instructions] is executed abnormally. • when an...

Page 205

197 6-4. Hints for programming high-level instructions 4) steps to take when an operation error occurs ■ searching the errors • first, confirm that k45 (h2d) is stored in the special data register dt9000 by using the npst-gr software or fp programmer ii. This means that an operation error occurred. ...

Page 206

198 6-4. Hints for programming high-level instructions 4. Overflow and underflow 1) overflow and underflow • when performing some instructions, the operation result may exceed the maximum overflow or go below the minimum underflow in the range of 16-bit or 32-bit data. When an overflow or underflow ...

Page 207

199 6-4. Hints for programming high-level instructions 3) overflow and underflow in bcd operations (4-digit or 8-digit) in bcd data, only positive numbers can be handled in the fp1. ■ 4-digit bcd operation ■ 8-digit bcd operation example: • overflow when dt0 = h9999 and dt1 = h1 (bcd), h0 (bcd) is s...

Page 208

200

Page 209: Chapter 7

Chapter 7 troubleshooting 7-1. Self-diagnostic function .....................................................202 1. Operation monitor leds when an error occurs...........202 2. Operation status when an error occurs ........................203 1) duplicated output error (total-check error) ......203 ...

Page 210

202 7-1. Self-diagnostic function 7-1. Self-diagnostic function fp1 programmable controllers use the self-diagnostic function when something goes wrong with the fp1. The abnormalities detected by the self-diagnostic function are divided into three categories: • self-diagnostic error this type of err...

Page 211

203 7-1. Self-diagnostic function 2. Operation status when an error occurs when an error occurs, the fp1 usually stops operating. However, regarding duplicated output errors, a backup battery abnormality, and operation errors, you can continue operation by changing the system register settings. 1) d...

Page 212: 7-2. Troubleshooting

204 7-2. Troubleshooting 7-2. Troubleshooting 1. Points to be checked when an error occurs when an abnormality is detected, check the following points. • if the err. Led is turned on, refer to page 205, ■ when an err. Led is on. • if the alarm led is turned on, refer to page 209, ■ when an alarm led...

Page 213

205 7-2. Troubleshooting ■ when an err. Led is on set the mode selector of the programmable controller from run to prog. Is err. Led on the programmable controller turned off? Probably a total-check error. Check the program using the programming tool. Yes (err. Led off) no (err. Led on) • using npst...

Page 214

206 7-2. Troubleshooting total-check error code correct the program according to the following table. Error code e1 e2 e3 e4 e5 e8 name of error syntax error (syntax) duplicated output error (dup use) not paired error (pair) system register parameter error (mismatch) program area error (prg area) op...

Page 215

207 7-2. Troubleshooting probably a self-diagnostic error. Check the program using the programming tool. • using npst-gr software ver. 3.1 open [npst menu] by pressing esc , and then select “monitor” to skip to the [monitor] subwindow. In the [monitor] subwindow, select “7. Status display”. At the b...

Page 216

208 7-2. Troubleshooting notes: • the error cancellation function of the programming tool is available for fp1s with cpu ver. 2.7 or later. (all fp1s with the suffix “b” on the part number have this function.) • to perform this function, use “op 112” of the fp programmer ii or [status display] of np...

Page 217

■ when an alarm led is on • if the alarm led is turned on again, there is probably an abnormality in the fp1. Please contact your dealer. • if the err. Led is turned on, go to page 205, ■ when an err. Led is on. • if the alarm led is turned on, the program execution time is too long. Check the progr...

Page 218

■ when all leds are off • be sure to check the fluctuation in the power supply. • if the leds on the programmable controller turn on at this moment, the capacity of the built-in dc power supply is not enough to control the load. • prepare another power supply to control the input devices. • if the l...

Page 219

■ diagnosing output malfunction 1 1 output condition: the output indicators are on • if the power is properly supplied to the load, there is probably an abnormality in the load. Check the load again. • if the power is not supplied to the load, there is probably an abnormality in the fp1’s output. Pl...

Page 220

• using npst-gr software ver. 3.1 • using fp programmer ii 3 3 input condition: the input indicators are on how to monitor the inputs: • using npst-gr software ver. 3.1 • using the fp programmer ii if the input monitored is off, there is probably an abnormality with the fp1’s input. Please contact y...

Page 221

4 4 input condition: the input indicators are off • if the power is properly supplied to the input terminal, there is probably an abnormality in the fp1’s internal circuit. Please contact your dealer. • if the power is not properly supplied to the input terminal, there is probably an abnormality in ...

Page 222

■ when “plc = comm. Err” is displayed on the npst-gr screen • npst-gr baud rate setting in this window, you can find the baud rate as shown below: trns rate (bps) [19200 / 9600 / 4800 / 2400 / 1200 / 600 / 300 ] select a baud rate (19200 or 9600), press the key and select “save disk ? Yes” to regist...

Page 223

■ when “protect error” is displayed 1 1 when memory unit (eprom) or master memory unit (eeprom) is installed in the programmable controller if memory unit (eprom) or master memory unit (eeprom) is installed on the programmable controller, the program cannot be modified. Proceed with program modifica...

Page 224: 7-3. Maintenance

216 7-3. Maintenance 7-3. Maintenance although programmable controllers have been designed in such a way to minimize maintenance and offer trouble- free operation, several maintenance aspects should be taken into consideration. If preventive maintenance is performed periodically, you will minimize t...

Page 225

2) how to replace backup battery • replace the battery within three minutes, after applying the power to the programmable controller more than one minute. Procedure 3. Removable terminal • removable terminal construction is used for c24, c40, c56, and c72 series control units. This makes wiring of t...

Page 226

218.

Page 227: Chapter 8

Chapter 8 appendix 8-1. Fp1 i/o allocation table ....................................................220 8-2. Table of memory areas.......................................................221 8-3. Table of special internal relays..........................................223 8-4. Table of special data ...

Page 228

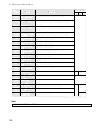

220 8-1. Fp1 i/o allocation table 8-1. Fp1 i/o allocation table the i/o addresses for the fp1 control unit, primary and secondary expansion units, and intelligent units (fp1 i/o link unit, fp1 a/d converter unit, and fp1 d/a converter unit) are assigned as follows. Notes: • x50 to x67 and y50 to y5f...

Page 229: 8-2. Table of Memory Areas

221 8-2. Table of memory areas 8-2. Table of memory areas notes: • timer/counter contacts are represented in decimal. • word addresses are represented in decimal. • the addresses for relay bits (x, y, and r) are represented by a combination of word addresses (decimal) and hexadecimals. The least sig...

Page 230

222 c14/c16 data area index modifier constant item name and function numbering c24/c40 c56/c72 symbol 256 words dt0 to dt255 70 words (dt9000 to dt9069) one word each (no numbering system) 16-bit constant (word): k-32,768 to k32,767 32-bit constant (double word): k-2,147,483,648 to k2,147,483,647 16...

Page 231

223 8-3. Table of special internal relays 8-3. Table of special internal relays the special internal relays are used for special purposes in the fp1 programmable controller. These special internal relays cannot output. Use special internal relays only as contacts. Notes: • special data registers dt9...

Page 232

Note: • c24c, c40c, c56c, and c72c types only. Address r9012 r9013 r9014 r9015 r9018 r9019 r901a r901b r901c r901d r901e r9020 r9026 r9027 r9029 r902a r902b r9032 name scan pulse relay initial on relay initial off relay step ladder initial on relay 0.01 s clock pulse relay 0.02 s clock pulse relay 0...

Page 233

Note: • c24c, c40c, c56c, and c72c types only. Address r9033 r9036 r9037 r9038 r9039 r903a r903b name print-out flag i/o link error flag rs232c error flag rs232c receive flag (f144) rs232c send flag (f144) high-speed counter control flag cam control flag description on while a f147 (pr) instruction ...

Page 234

226 8-4. Table of special data registers 8-4. Table of special data registers each special data register is prepared for the specific application. Note: • * special data registers dt9017 and dt9018 are available only for fp1s with cpu version 2.7 or later. (all fp1s with a suffix “b” on the part num...

Page 235

227 8-4. Table of special data registers a: available, n/a: not available address dt9025 dt9027 dt9030 dt9031 dt9032 dt9033 dt9034 dt9035 dt9037 dt9038 dt9040 dt9041 dt9042 dt9043 name interrupt enabled status register time interrupt interval register message 0 register message 1 register message 2 ...

Page 236

228 8-4. Table of special data registers note: • c24c, c40c, c56c, and c72c types only. A a: available, n/a: not available n/a a (see note.) lower 16-bit of high-speed counter elapsed value is stored in dt9044. Higher 16-bit of high-speed counter elapsed value is stored in dt9045. Lower 16-bit of hi...

Page 237

229 8-4. Table of special data registers note: • c24c, c40c, c56c, and c72c types only. A: available, n/a: not available address name description availability c14/ c16 c24/ c40 c56/ c72 dt9058 dt9059 dt9060 dt9061 dt9062 dt9063 dt9064 dt9065 dt9066 dt9067 clock/calendar adjustment register communica...

Page 238: 8-5. System Registers

230 8-5. System registers 8-5. System registers 1. What are system registers • the fp series programmable controller is configured by setting certain parameters. The parameters, which configure the system and special functions, are called system registers. • like other registers in the fp1, each sys...

Page 239

231 8-5. System registers ■ how to set system registers the system registers can be set by a programming tool. • using npst-gr software ver. 3.1 1 set the mode of the programmable controller to prog. 2 open the [system register] window using the following procedure: set the mode of the npst-gr softw...

Page 240

232 8-5. System registers 2. Table of system registers note: • * this function is available for c24, c40, c56, and c72 series with cpu version 2.7 or later. (all c24, c40, c56, and c72 series with a suffix “b” on the part number have this function.) address 0 4 5 6 name of system register program ca...

Page 241

233 8-5. System registers address 7 8 14 20 26 31 name of system register hold area starting address settings for internal relays hold area starting address settings for data registers hold/non-hold setting for step ladder operation settings for duplicated use of output operation settings when an op...

Page 242

234 8-5. System registers note: • * when system registers 400, 402, 403, and 404 are set at the same time, their priorities are: -1st 400 (high-speed counter mode settings) -2nd 402 (pulse catch input function settings) -3rd 403 (interrupt trigger settings) -last 404 (input time filtering settings) ...

Page 243

235 8-5. System registers address 402 403 name of system register pulse catch input function settings pulse of 500 µs or more duration interrupt trigger settings default value h0 h0 description this register specifies the pulse catch inputting function availabilities for x0 to x7. • settings 0: stan...

Page 244

236 8-5. System registers address 404 name of system register input time filtering setting (x0 to x1f) default value h1111 (all 2 ms) description sets the input filtering time in 8-input units. • settings set value h0 h1 h2 h3 h4 h5 h6 h7 input filtering time 1 ms 2 ms 4 ms 8 ms 16 ms 32 ms 64 ms 12...

Page 245

237 8-5. System registers note: • * the modem communication settings (system register 411 msb) are available only for c24, c40, c56, and c72 series fp1s with cpu ver. 2.7 or later. (all c24, c40, c56, and c72 series fp1s with a suffix “b” on the part number have this function.) address 410 411 412 n...

Page 246

238 8-5. System registers note: • * the settings for the header and the terminator in system register 413 become effective when system register 412 is set to k2 (general). If you select k1 (comptr lnk) or k0 (unused), the settings are discarded. Address 413 name of system register communication form...

Page 247

239 8-5. System registers note: • * the system register 416 setting is available only for c24c, c40c, c56c, and c72c type fp1s with cpu ver. 2.7 or later. (all c24c, c40c, c56c, and c72c type fp1s with a suffix “b” on the part number have this function.) to specify system register 416, npst-gr softw...

Page 248

240 8-5. System registers address 418 name of system register buffer capacity setting for data received from rs232c serial port default value k1660 description this register specifies the number of words to be used as a buffer. (refer to system register 417 on page 239 for details about the starting...

Page 249

8-6. Versions of programming tools 1. Differences between npst-gr ver. 2.4 and 3.1 npst-gr software ver. 3.1 is designed to support all the functions of the fp1 programmable controllers described in this manual. However, compared with previous npst-gr software, version 3.1 requires an additional sys...

Page 250