- DL manuals

- NAMCO

- Game

- PAC-MAN SMASH

- Operation Manuals

NAMCO PAC-MAN SMASH Operation Manuals

M259_Intro_EN.indd 2

2/5/2013 7:39:59 AM

PAC-MAN SMASH

Operation Manual

To ensure safe operation of the machine, be sure to read this Operation Manual before use.

Keep this Operation Manual in a safe place for quick access whenever needed.

The actual product may differ slightly from the illustrations in this Operation Manual.

NAMCO BANDAI Games Inc.

Summary of PAC-MAN SMASH

Page 1

M259_intro_en.Indd 2 2/5/2013 7:39:59 am pac-man smash operation manual to ensure safe operation of the machine, be sure to read this operation manual before use. Keep this operation manual in a safe place for quick access whenever needed. The actual product may differ slightly from the illustration...

Page 2: Introduction

Introduction thank you very much for purchasing pac-man smash (referred to as “the machine” in this manual). This operation manual describes: • how to safely install, move, transport, operate, service and dispose of the machine. • how to make full use of the machine’s functions and operate it correc...

Page 3: Safety Precautions

Test mode troubleshooting 1 levels of risk / de fi nition of “t echnician” 1. Safety precautions -be sure to read to ensure safe operation- instructions to the owner if you delegate the work for installing, moving, transporting, operating, servicing or disposing the machine to other people, ensure t...

Page 4

1. Safety precautions -be sure to read to ensure safe operation- 2 1-3 critical safety precautions z should an abnormality occur, turn off the power switch immediately to stop operations. Then, be sure to disconnect the power cord plug from the outlet. Operating the machine while the abnormality per...

Page 5: 1-4

1. Safety precautions -be sure to read to ensure safe operation- test mode troubleshooting 3 critical safety precautions / machine w arning labels 1-4 machine warning labels z the warning labels attached to the machine contain important information for ensuring safety. Be sure to observe the followi...

Page 6

1. Safety precautions -be sure to read to ensure safe operation- 4 caution sticker do not approach net part no.: 461-771 warning sticker service b (exp) part no.: 461-539 warning sticker service b (exp) part no.: 461-539 m259_01_en.Indd 4 m259_01_en.Indd 4 2/5/2013 7:41:26 am 2/5/2013 7:41:26 am.

Page 7

1. Safety precautions -be sure to read to ensure safe operation- test mode troubleshooting 5 machine w arning labels (when transporting the side tower cabinet) warning sticker installation and transport part no.: 461-770 warning sticker installation and transport part no.: 461-770 m259_01_en.Indd 5 ...

Page 8: Table of Contents

6 table of contents introduction 1. Safety precautions -be sure to read to ensure safe operation- .........................................................................................1 1-1 levels of risk ...............................................................................................

Page 9

Table of contents 7 test mode troubleshooting 7-9-2 number of coins per game .............................................................................................................................53 7-9-3 number of plays per game ...................................................................

Page 10

Table of contents 8 8a-5-4 opening and closing the service door ........................................................................................................108 8b. Service - must be performed by a technician -..................................................................................

Page 11

Table of contents 9 test mode troubleshooting 8b-4-5 hopper assembly .........................................................................................................................................150 (1) replacing the l hopper motor ............................................................

Page 12: Specifi Cations

10 2. Specifi cations (1) rated power supply ac 120 ±10 v (50/60 hz), ac 220 ±10 v (50/60 hz) (2) rated power consumption 310 w (3) maximum current consumption 3 a (4) cashbox capacity approx. 200,000 yen (2,000 100 yen coins) (5) dimensions 1) when installed width (w) 2,030 x depth (d) 2,570 x heig...

Page 13

2. Specifi cations test mode troubleshooting 11 speci fi cations 1,530 mm 2,080 mm 120 mm 1,490 mm 840 mm 1,240 mm 1,530 mm 1,240 mm 840 mm table top assembly width (w) 1,490 x depth (d) 2,080 x height (h) 120 [mm] cabinet (l) assembly width (w) 1,530 x depth (d) 1,240 x height (h) 840 [mm] cabinet ...

Page 14

2. Specifi cations 12 side tower assembly width (w) 960 x depth (d) 1,030 x height (h) 2,050 [mm] (when the signboard is removed) width (w) 960 x depth (d) 1,030 x height (h) 1,700 [mm] 880 mm 960 mm 1,030 mm 520 mm 530 mm 2,050 mm 1,700 mm 920 mm 2,050 mm 620 mm hopper assembly width (w) 880 x dept...

Page 15: Package Contents

Test mode troubleshooting 13 speci fi cations / package contents 3. Package contents the following items are included when this machine is shipped. (1) side tower cabinet width (w) 920 x depth (d) 620 x height (h) 1,710 [mm] weight 85 kg (2) cabinet (l) assembly width (w) 1,540 x depth (d) 1,240 x h...

Page 16

3. Package contents 14 (1) side tower cabinet no. 1 to 3 z package contents no. Name specifi cation qty. 1 operation manual (this manual) 1 2 service key 2 3 torx wrench t25, for m5 1 m259_03_en.Indd 14 m259_03_en.Indd 14 2/5/2013 7:46:01 am 2/5/2013 7:46:01 am.

Page 17

3. Package contents test mode troubleshooting 15 package contents (2) cabinet (l) assembly 8 to 11 3, 4, 6, 7 2 1 5 z package contents no. Name specifi cation qty. 1 service key 2 2 goal (r) assembly 1 3 rail (l) assembly 1 4 rail (r) assembly 1 5 signboard 1 6 goal cover (red) 1 7 goal cover (blue)...

Page 18

3. Package contents 16 (3) cabinet (r) assembly 4, 12, 13 16, 17, 18 1, 5, 15 2, 6 to 11, 14 3 z package contents no. Name specifi cation qty. 1 service key 2 2 screws see “z list of screws” on page 20. 1 set 3 goal (l) assembly 1 4 blower fan 1 5 cash box key 2 6 side wall 2 7 side tower bracket (l...

Page 19

3. Package contents test mode troubleshooting 17 package contents no. Name specifi cation qty. 10 center guard bracket (b) 1 11 triangle bracket 1 12 blower bracket (l) 1 13 blower bracket (r) 1 14 hopper wall 1 15 selector door key 2 16 cashflow selector option cable 1 17 cashflow counter option ca...

Page 20

3. Package contents 18 (5) hopper assembly 1 z package contents no. Name specifi cation qty. 1 hopper assembly 1 (6) center guard 1 z package contents no. Name specifi cation qty. 1 center guard unit 1 m259_03_en.Indd 18 m259_03_en.Indd 18 2/5/2013 7:46:04 am 2/5/2013 7:46:04 am.

Page 21

3. Package contents test mode troubleshooting 19 package contents (7) side net no. 1 to 4 z package contents no. Name specifi cation qty. 1 net l frame (l) 1 2 net l frame (r) 1 3 net s frame (l) 1 4 net s frame (r) 1 (8) light assembly no. 1 to 4 z package contents no. Name specifi cation qty. 1 li...

Page 22

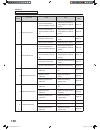

3. Package contents 20 z list of screws (included with the cabinet (l) assembly) no. Name specifi cation qty. B1 phillips hexagon socket head bolt (with fl at and spring washers) m8×35 10 b2 button head bolt m5×16 5 b3 button head bolt m5×35 4 b4 button head bolt m6×16 3 b5 button head bolt m6×25 12...

Page 23

3. Package contents test mode troubleshooting 21 package contents no. Name specifi cation qty. B15 torx bolt m5×16 12 b16 hex nut with fl ange m5 3 b17 torx bolt m5×20 4 b18 countersunk cap bolt m5×35 2 b19 square washer m8 10 b20 spring washer m6 6 b21 flat washer m5 13 b22 flat washer ø24 for m5 4...

Page 24

22 4. Overall structure (part names) overall blower fan caster level adjuster circle led goal cover mallet speaker mini puck (s puck) big puck (l puck) coin box door selector door front door table table top assembly cabinet (r) assembly cabinet (l) assembly playing fi eld corner cover goal net l net...

Page 25

4. Overall structure (part names) test mode troubleshooting 23 overall structure (part names) overall (back and interior) l escalator assembly s escalator assembly corner rail (r) rear panel rail (r) assembly service door r service door l service door cord box assembly and power switch goal (r) asse...

Page 26: Installation

24 5. Installation z install the machine according to the instructions in this operation manual. Failure to follow these instructions may result in a fi re, electric shock, injury or malfunction. (see “8a installation and assembly” on page 74.) z install the machine securely by using the level adjus...

Page 27

5. Installation test mode troubleshooting 25 installation conditions 5-1-2 play zone for the installed machine z create a play zone around the machine so that players do not bump into bystanders or passersby. Z leave a space of 100 cm or more between the machine and the wall or other machines so tha...

Page 28: As Doors and Corridors)

5. Installation 26 5-2 required dimensions for the delivery route (such as doors and corridors) entranceways and the delivery route must be larger than the dimensions noted below. Z table width (w) 2,570 x depth (d) 1,690 x height (h) 1,350 [mm] weight 280 kg in addition, the table can be disassembl...

Page 29

Test mode troubleshooting 27 required dimensions for the delivery route (such as doors and corridors) / moving (on the same floor) 6. Moving and transporting z do not leave the machine on a slope. It may fall over or result in an accident. 6-1 moving (on the same floor) z move the machine carefully ...

Page 30: 6-2 Transporting

6. Moving and transporting 28 6-2 transporting 6-2-1 transporting manually (such as carrying on stairs) z before transporting the machine manually, be sure to disassemble it into the table and side tower assembly, and disassemble the hopper assembly from the side tower assembly for easier carrying. ...

Page 31

Test mode troubleshooting 29 transporting 6. Moving and transporting z when transporting the machine by hand, be sure to use the following number of people. Straining yourself may result in an accident or injury. [when the table is disassembled] • table top assembly (95 kg): 4 people or more • goal ...

Page 32

30 6. Moving and transporting 6-2-2 loading and unloading to and from a vehicle z when using a forklift to transport the machine, observe the following. Failure to observe the following instructions may result in an accident, such as the machine falling over. • be sure to insert the fork into the sp...

Page 33

Test mode troubleshooting 31 transporting 6. Moving and transporting 6-2-3 transporting on a vehicle z when transporting the machine on a vehicle, secure the machine fi rmly so that it does not move during vehicle transport. Failure to secure the machine may result in an accident. Z do not subject t...

Page 34: Operation

32 7. Operation z should an abnormality occur, turn off the power switch immediately to stop operations. Then, be sure to disconnect the power cord plug from the outlet. Operating the machine while the abnormality persists may result in a fi re or accident. Z dust accumulating on the power cord plug...

Page 35

Test mode troubleshooting 33 people who should avoid playing / safety precautions for playing 7. Operation 7-1 people who should avoid playing z to ensure the safety of players, be careful not to let the following types of people play. Otherwise, this may result in an accident. • people who disregar...

Page 36: Safety

34 7. Operation 7-3 important parts for ensuring player and bystander safety z this machine includes important parts used to ensure the safety of players and bystanders. Operating the machine while these “important parts for ensuring player and bystander safety” are broken, damaged or deteriorated, ...

Page 37: 7-4

Test mode troubleshooting 35 important parts for ensuring player and bystander safety / pre-operation inspection 7. Operation 7-4 pre-operation inspection check the items below before starting machine operations. If there is an abnormality, resolve it by referring to “8b-3 troubleshooting” on page 1...

Page 38

36 7. Operation 7-4-2 function inspection items (after power on) (1) check the lights. (do the score led, time led and circle led light up?) (see “7-8-2 score led, time led and circle led test” on page 42.) (2) check the switch inputs. (see “7-8-3 switch input test” on page 43.) (3) check the blower...

Page 39

Test mode troubleshooting 37 opening and closing doors 7. Operation 7-5 opening and closing doors 7-5-1 opening and closing the selector door use the supplied selector door key to open the selector door. Selector door to close the door, perform the procedure in reverse. 7-5-2 opening and closing the...

Page 40

38 7. Operation 7-5-3 opening and closing the goal (l) and (r) assemblies the description below explains how to open and close the (l) side. Follow the same procedure to open and close the (r) side. Use the supplied service key to unlock the lock (①) on the left side of the goal (l) assembly, and th...

Page 41: Switches

Test mode troubleshooting 39 explanation of the power switch and adjustment switches 7. Operation 7-6 explanation of the power switch and adjustment switches 7-6-1 turning the power switch on power switch on off z after completing the installation work, turn on the power switch. Z when turning the p...

Page 42: 7-7 Playing The Game

40 7. Operation 7-7 playing the game this machine is an air hockey game where players use mallets to hit pucks supplied automatically during the set time into the opponent’s goal to score points. (1) the start sound is output, then a big puck is supplied to the playing fi eld. At the same time, the ...

Page 43: 7-8

Test mode troubleshooting playing the game / t est mode 41 7. Operation 7-8 test mode the machine displays the test contents on the signboard that displays the score and timer. 7-8-1 test item selection mode use the supplied service key to open the selector door and set the test switch to on (slide ...

Page 44

42 7. Operation 7-8-2 score led, time led and circle led test score led model version time led test item selection display (score led, time led and circle led test) in this test item selection mode, “led” is displayed in the left side score led. The “model (1-digit number)” and “version (one alphabe...

Page 45

Test mode troubleshooting test mode 43 7. Operation 7-8-3 switch input test score led time led test item selection display (switch input test) in this test item selection mode, “sin” is displayed in the left side score led. M259_07_enin6.Indd 43 m259_07_enin6.Indd 43 2/5/2013 8:06:53 am 2/5/2013 8:0...

Page 46

44 7. Operation press the enter button (green). The following test display appears. Score led time led switch input test display z the coin switch counter value (two digits) is displayed in the left side score led. The right side displays the bill counter input count (two digits). (1) the value coun...

Page 47

Test mode troubleshooting test mode 45 7. Operation 7-8-4 blower fan on/off test and sensor check score led time led test item selection display (blower fan on/off test) in this test item selection mode, “fan” is displayed in the left side score led. The time led displays the sensor states as follow...

Page 48

46 7. Operation 7-8-5 solenoid on/off test and sensor check score led time led test item selection display (solenoid on/off test) in this test item selection mode, “sol” is displayed in the left side score led. The time led displays the sensor states as follows. (on: lighted, off: off) led no. Senso...

Page 49

Test mode troubleshooting test mode 47 7. Operation 7-8-6 l hopper motor on/off test and sensor check score led time led test item selection display (l hopper motor on/off test) in this test item selection mode, “lhop” is displayed in the left side score led. The time led displays the sensor states ...

Page 50

48 7. Operation 7-8-7 s hopper motor on/off test and sensor check score led time led test item selection display (s hopper motor on/off test) in this test item selection mode, “shop” is displayed in the left side score led. The time led displays the sensor states as follows. (on: lighted, off: off) ...

Page 51

Test mode troubleshooting test mode 49 7. Operation 7-8-8 sound test score led time led test item selection display (sound test) in this test item selection mode, “snd” is displayed in the left side score led. Press the act button (yellow) to play the speaker test sound from only the l side speaker,...

Page 52

50 7. Operation 7-8-9 ticket dispenser test * this item is displayed only when the ticket dispenser use setting is “on”. (see “7-9-11 ticket dispenser use setting” on page 63.) score led time led test item selection display (ticket dispenser test) in this test item selection mode, “dis” is displayed...

Page 53: 7-9

Test mode troubleshooting 51 setting mode 7. Operation 7-9 setting mode the machine displays the setting contents on the signboard that displays the score and timer. 7-9-1 setting item selection mode use the supplied service key to open the selector door, and set the test switch to on (slide the swi...

Page 54

52 7. Operation item order item name (display in setting item selection mode) item reference page 1 number of coins per game page 53 2 number of plays per game page 54 3 big bang mode play time page 55 4 normal hockey mode play time page 56 5 mini puck supply frequency more/less setting for big bang...

Page 55

Test mode troubleshooting 53 setting mode 7. Operation 7-9-2 number of coins per game score led time led setting item selection display (number of coins per game) in this setting item selection mode, “coin” is displayed in the left side score led and the number of coins is displayed in the right sid...

Page 56

54 7. Operation 7-9-3 number of plays per game score led time led setting item selection display (number of plays per game) in this setting item selection mode, “play” is displayed in the left side score led and the number of plays is displayed in the right side score led. Press the enter button (gr...

Page 57

Test mode troubleshooting 55 setting mode 7. Operation 7-9-4 big bang mode play time score led time led setting item selection display (big bang mode play time) in this setting item selection mode, “b-pl” is displayed in the left side score led and the play time (seconds) is displayed in the right s...

Page 58

56 7. Operation 7-9-5 normal hockey mode play time score led time led setting item selection display (normal hockey mode play time) in this setting item selection mode, “n-pl” is displayed in the left side score led and the play time (seconds) is displayed in the right side score led. Press the ente...

Page 59

Test mode troubleshooting 57 setting mode 7. Operation 7-9-6 mini puck supply frequency more/less setting for big bang mode score led time led setting item selection display (mini puck supply frequency more/less setting for big bang mode) in this setting item selection mode, “b-pc” is displayed in t...

Page 60

58 7. Operation 7-9-7 3-puck setting for normal hockey mode score led time led setting item selection display (3-puck setting for normal hockey mode) in this setting item selection mode, “n-pc” is displayed in the left side score led and “off” or “on” is displayed in the right side score led. Press ...

Page 61

Test mode troubleshooting 59 setting mode 7. Operation 7-9-8 attract bgm on/off score led time led setting item selection display (attract bgm on/off) in this setting item selection mode, “asnd” is displayed in the left side score led and “on” or “off” is displayed in the right side score led. Press...

Page 62

60 7. Operation 7-9-9 mini puck low warning on/off this function informs when the number of mini pucks has decreased. * when the number of mini pucks decreases by 50 pucks or more during game operation due to loss or other reasons, the 4-digit score in the left side score led blinks while the machin...

Page 63

Test mode troubleshooting 61 setting mode 7. Operation 7-9-10 error log (1) number of errors saved in error log display mode score led time led setting item selection display (error log) in this setting item selection mode, “errl” is displayed in the left side score led and the number of errors save...

Page 64

62 7. Operation (2) error log contents display mode score led time led setting item selection display (error log contents display mode) “er00” to “er19” is displayed in the left side score led, and the corresponding error code saved in the error log is displayed in the right side score led. Z an err...

Page 65

Test mode troubleshooting 63 setting mode 7. Operation 7-9-11 ticket dispenser use setting score led time led setting item selection display (ticket dispenser use setting) in this setting item selection mode, “tdis” is displayed in the left side score led, and “on” or “off” is displayed in the right...

Page 66

64 7. Operation 7-9-12 number of tickets paid to winner * this item is displayed only when the ticket dispenser use setting is “on”. (see “7-9-11 ticket dispenser use setting” on page 63.) score led time led setting item selection display (number of tickets paid to winner) in this setting item selec...

Page 67

Test mode troubleshooting 65 setting mode 7. Operation 7-9-13 number of tickets paid to loser * this item is displayed only when the ticket dispenser use setting is “on”. (see “7-9-11 ticket dispenser use setting” on page 63.) score led time led setting item selection display (number of tickets paid...

Page 68

66 7. Operation 7-9-14 number of tickets paid in case of a tie * this item is displayed only when the ticket dispenser use setting is “on”. (see “7-9-11 ticket dispenser use setting” on page 63.) score led time led setting item selection display (number of tickets paid in case of a tie) in this sett...

Page 69

Test mode troubleshooting 67 setting mode 7. Operation 7-9-15 game mode setting score led time led setting item selection display (game mode setting) in this setting item selection mode, “lony” is displayed in the left side score led and “on” or “off” is displayed in the right side score led. Press ...

Page 70

68 7. Operation 7-9-16 return all settings to default settings (factory settings) score led time led setting item selection display (return all settings to default settings (factory settings)) in this setting item selection mode, “adef” is displayed in the left side score led and a value indicating ...

Page 71

Test mode troubleshooting 69 mini puck low w arning and adding mini pucks 7. Operation 7-10 mini puck low warning and adding mini pucks 7-10-1 mini puck low warning when the mini puck low warning on/off setting mode is set to on and the number of mini pucks decreases by 50 or more, the 4-digit score...

Page 72: 7-11 Daily

70 7. Operation 7-11 daily cleaning 7-11-1 cleaning the playing field z be careful not to scratch the playing fi eld when cleaning. Z do not use thinner, benzene, gasoline, alcohol or other organic solvents. This may degrade the materials. Z do not use wax or other substances that may block the air ...

Page 73

Test mode troubleshooting 71 daily cleaning 7. Operation 7-11-2 cleaning the goal covers and corner covers z do not use thinner, benzene, gasoline, alcohol or other organic solvents. This may degrade the materials. Wipe away any dirt using a soft cloth moistened with water or a neutral cleanser dilu...

Page 74

72 7. Operation 7-11-4 cleaning the signboard and cover panel z do not use thinner, benzene, gasoline, alcohol or other organic solvents. This may degrade the materials. Wipe away any dirt using a soft cloth moistened with water or a neutral cleanser diluted with water and then fi rmly wrung out. Si...

Page 75

Test mode troubleshooting 73 daily cleaning 7. Operation 7-11-5 cleaning the sloped areas z do not use thinner, benzene, gasoline, alcohol or other organic solvents. This may degrade the materials. Wipe away any dirt using a soft cloth moistened with water or a neutral cleanser diluted with water an...

Page 76: 8. Technician’S Manual

74 8. Technician’s manual - must be performed by a technician - 8a. Installation and assembly 8a-1 number of workers, work time and work space 8a-1-1 number of workers and work time (1) number of workers the work should be performed by four technicians. (2) work time the estimated work time for four...

Page 77: 8A-2 Assembly

Test mode troubleshooting 75 number of w orkers, w ork t ime and w ork space/ assembly 8a. Installation and assembly - must be performed by a technician - 8a-2 assembly 8a-2-1 assembling the table (1) assembling the table, goals and corner covers join the cabinet (l) and (r) assemblies with 10 phill...

Page 78

76 8a. Installation and assembly - must be performed by a technician - attach the harness released in step with the six coating clips as shown in the fi gure. Harness coating clip open the goal (l) assembly. (see “7-5-3 opening and closing the goal (l) and (r) assemblies” on page 38.) lead out the t...

Page 79

Test mode troubleshooting 77 assembly 8a. Installation and assembly - must be performed by a technician - remove the two fl ange socket bolts (m5 x 16). Flange socket bolt (m5 x 16) close the goal (l) assembly. (see “7-5-3 opening and closing the goal (l) and (r) assemblies” on page 38.) lift the go...

Page 80

78 8a. Installation and assembly - must be performed by a technician - attach the blower brackets (l) and (r) to the table top assembly with thee fl ange socket bolts (m5 x 16) each. Flange socket bolt (m5 x 16) blower bracket (l) table top assembly blower bracket (r) z do not place the table top as...

Page 81

Test mode troubleshooting 79 assembly 8a. Installation and assembly - must be performed by a technician - z when attaching the table top assembly, be careful where you place your hands to avoid trapping your hands. Hand positions hand positions lift up the table top assembly with four people as show...

Page 82

80 8a. Installation and assembly - must be performed by a technician - attach the table top assembly to the cabinet with six button head bolts (m6 x 40) and six spring washers (m6). Z it may be diffi cult to attach the screws if the fl oor surface is not level. In this case, adjust the level adjuste...

Page 83

Test mode troubleshooting 81 assembly 8a. Installation and assembly - must be performed by a technician - lead out and connect the two connectors through the holes, and secure them with the coating clips. Z store the excess harness length below the holes so that there is no slack in the connected co...

Page 84

82 8a. Installation and assembly - must be performed by a technician - set the corner covers (red • l, red • r, blue • l and blue • r) on the respective corners of the cabinet, and secure them with two button head bolts (m6 x 40), one button head bolt (m6 x 25) and three fl at washers (m6) each. Cor...

Page 85

Test mode troubleshooting 83 assembly 8a. Installation and assembly - must be performed by a technician - connect the connector, and place the goal cover (red) on the goal (l) assembly. Goal cover (red) connector goal (l) assembly attach the goal cover (red) with two torx bolts (m5 x 16) and two fl ...

Page 86

84 8a. Installation and assembly - must be performed by a technician - secure the goal cover (red) with two torx bolts (m5 x 8). Goal cover (red) torx bolt (m5 x 8) follow the same procedure as steps to to install the goal (r) assembly and goal cover (blue). Close the goal (l) and (r) assemblies. (s...

Page 87

Test mode troubleshooting 85 assembly 8a. Installation and assembly - must be performed by a technician - [if the goal (l) and (r) assembly locks are stiff, cannot be locked, or are loose, perform the procedure below.] remove the goal cover of the goal to be adjusted by reversing the procedure in st...

Page 88

86 8a. Installation and assembly - must be performed by a technician - (2) installing the nets attach the center guard bracket (a) with four button head bolts (m6 x 25) and four fl at washers (m6). Z install the center guard bracket (a) in a level manner so that it is not tilted. Button head bolt (m...

Page 89

Test mode troubleshooting 87 assembly 8a. Installation and assembly - must be performed by a technician - insert the center guard into the center guard brackets (a) and (b), and then secure it with three button head bolts (m6 x 16) and three fl at washers (m6). * install the center guard so that the...

Page 90

88 8a. Installation and assembly - must be performed by a technician - follow the same procedure in step to attach the net s frame (r) to the cabinet (r) assembly. Insert the hooks of the net l frame (l) into the cabinet (l) assembly, and then secure it with three button head bolts (m6 x 50), three ...

Page 91

Test mode troubleshooting 89 assembly 8a. Installation and assembly - must be performed by a technician - follow the same procedure in step to attach the net l frame (r) to the cabinet (r) assembly. Attach the triangle bracket with fi ve button head bolts (m5 x 16) and fi ve fl at washers (m5). Tria...

Page 92

90 8a. Installation and assembly - must be performed by a technician - 8a-2-2 level adjuster adjustment z adjust the level adjusters so that the table casters are at a height of approximately 5 mm from the fl oor. (the casters should be able to turn freely.) if the machine is unstable, it may move d...

Page 93

Test mode troubleshooting 91 assembly 8a. Installation and assembly - must be performed by a technician - 8a-2-3 assembling the side tower assembly attach the signboard with eight torx bolts (m5 x 12). Signboard torx bolt (m5 x 12) remove the wing bolt (m4 x 6), slide the s bucket and s hopper cover...

Page 94

92 8a. Installation and assembly - must be performed by a technician - z do not move the side tower cabinet in the condition with the caster brackets (f) removed. Doing so may cause the side tower cabinet to fall over. Remove the four phillips hexagon socket head bolts (with fl at and spring washers...

Page 95

Test mode troubleshooting 93 assembly 8a. Installation and assembly - must be performed by a technician - attach the hopper wall with four phillips pan head screws (with fl at and spring washers) (m4 x 10). Hopper wall phillips pan head screw (with fl at and spring washers) (m4 x 10) remove the two ...

Page 96

94 8a. Installation and assembly - must be performed by a technician - 8a-2-4 installing the light assembly z the light assembly is installed while standing in a high location. Use a stool or similar platform. Working in an unnatural body posture may cause an injury or machine damage. Lead the conne...

Page 97

Test mode troubleshooting 95 assembly 8a. Installation and assembly - must be performed by a technician - connect the connectors. Attach the connector cover with a phillips pan head screw (with fl at and spring washers) (m4 x 10). Connector cover connector phillips pan head screw (with fl at and spr...

Page 98

96 8a. Installation and assembly - must be performed by a technician - 8a-2-5 installing the side tower assembly lead out the fi ve connectors from the right and left holes in the front of the side tower cabinet. Connector side tower assembly remove the torx bolt (m5 x 25). Torx bolt (m5 x 25) side ...

Page 99

Test mode troubleshooting 97 assembly 8a. Installation and assembly - must be performed by a technician - secure the harness clamp of the harness led out in step with the torx bolt (m5 x 25) removed in step . Harness clamp torx bolt (m5 x 25) harness attach the side tower bracket (l) and side tower ...

Page 100

98 8a. Installation and assembly - must be performed by a technician - while lifting up the sloped area of the side tower assembly, insert the hopper assembly into the opening in the side surface of the table until the front of the side tower assembly touches the side surface of the table. Side towe...

Page 101

Test mode troubleshooting 99 assembly 8a. Installation and assembly - must be performed by a technician - attach the side tower assembly with 2 countersunk cap bolts (m5 x 35), 4 button head bolts (m5 x 35). [if the bolt holes are not aligned during procedure, go to step .] button head bolt (m5 x 35...

Page 102: 100

100 8a. Installation and assembly - must be performed by a technician - insert the tip of the rail (l) assembly into the square hole in the back side of the hopper assembly, and hook the hook on the opposite side of the rail (l) assembly onto the corner rail (l). Z attach the rail so that the plate ...

Page 103: 101

Test mode troubleshooting 101 assembly 8a. Installation and assembly - must be performed by a technician - remove the service door r. (see “8a-5-2 opening and closing the service doors l and r” on page 107.) connect the three connectors inside the cabinet (r) assembly. Connector cabinet (r) assembly...

Page 104: 102

8a. Installation and assembly 102 - must be performed by a technician - connect the connector. Connector reattach the service door r. (see “8a-5-2 opening and closing the service doors l and r” on page 107.) attach the two side walls with four torx bolts (m5 x 16) each. Torx bolt (m5 x 16) side wall...

Page 105: 103

8a. Installation and assembly test mode troubleshooting 103 assembly - must be performed by a technician - remove the four phillips hexagon socket head bolts (with fl at and spring washers) (m6 x 16), and remove the two caster brackets (r). Caster bracket (r) hexagon socket head bolt (with fl at and...

Page 106: 104

8a. Installation and assembly 104 8a. Installation and assembly - must be performed by a technician - attach the side tower assembly with 2 countersunk cap bolts (m5 x 35), 4 button head bolts (m5 x 35). Button head bolt (m5 x 35) button head bolt (m5 x 35) button head bolt (m5 x 35) countersunk cap...

Page 107: 105

8a. Installation and assembly test mode troubleshooting 105 assembly - must be performed by a technician - 8a-2-6 preparing the pucks and mallets place the mallets on the corner covers. Corner cover mallet put 50 of each of the big pucks and mini pucks (green, pink, orange) into the goal (l). Goal (...

Page 108: 106

8a. Installation and assembly 106 - must be performed by a technician - 8a-3 connecting the power cord and ground z be sure to install the ground wire. Failure to install the ground wire may result in electric shock in the event of electrical leakage. Insert the socket side of the power cord into th...

Page 109: 107

Test mode troubleshooting 107 connecting the power cord and ground / checks after installation /opening and closing doors 8a. Installation and assembly - must be performed by a technician - 8a-5 opening and closing doors 8a-5-1 opening and closing the front doors remove the two torx bolts (m5 x 35),...

Page 110: 108

8a. Installation and assembly 108 - must be performed by a technician - 8a-5-3 opening and closing the rear panel remove the four torx bolts (m5 x 25). Use the supplied service key to unlock, and remove the rear panel. Torx bolt (m5 x 25) rear panel to install, perform the procedure in reverse. 8a-5...

Page 111: 109

109 test mode opening and closing doors / inspection and service troubleshooting 8b. Service - must be performed by a technician - 8b. Service - must be performed by a technician - z to avoid electric shock, accidents or injuries to yourself or other people, or damage to the electronic circuits, be ...

Page 112: 110

110 8b. Service - must be performed by a technician - 8b-1-2 cleaning the puck paths (1) cleaning the insides of the goal (l) and (r) assemblies the description below explains how to clean the (l) side. Follow the same procedure to clean the (r) side. Z to avoid electric shock, accidents or injuries...

Page 113: 111

111 test mode inspection and service troubleshooting 8b. Service - must be performed by a technician - (2) cleaning the rail (l) and (r) assemblies the description below explains how to clean the (l) side. Follow the same procedure to clean the (r) side. Z to avoid electric shock, accidents or injur...

Page 114: 112

112 8b. Service - must be performed by a technician - (3) cleaning the insides of the l and s buckets (hopper assembly) z to avoid electric shock, accidents or injuries to yourself or other people, or damage to the electronic circuits, be sure to turn off the power switch before starting work. Z do ...

Page 115: 113

113 test mode inspection and service troubleshooting 8b. Service - must be performed by a technician - (4) cleaning the hopper disks and hopper bottoms (hopper assembly) the description below explains how to clean the s hopper disk. Follow the same procedure to clean the l hopper disk. Z to avoid el...

Page 116: 114

114 8b. Service - must be performed by a technician - remove the cord clip and disconnect the two connectors. Loosen the four pan head screws (with fl at and spring washers) (m4 x 10), and remove the s hopper motor bracket. Phillips pan head screw (with fl at and spring washers) (m4 x 10) (loosen) c...

Page 117: 115

115 test mode inspection and service troubleshooting 8b. Service - must be performed by a technician - remove the two pan head screws (with fl at and spring washers) (m4 x 10), and remove the disk retainer bracket. (perform this step only for the s hopper disk.) pan head screw (with fl at and spring...

Page 118: 116

116 8b. Service - must be performed by a technician - (5) cleaning the s slider assembly z to avoid electric shock, accidents or injuries to yourself or other people, or damage to the electronic circuits, be sure to turn off the power switch before starting work. Z do not use thinner, benzene, gasol...

Page 119: 117

117 test mode inspection and service troubleshooting 8b. Service - must be performed by a technician - remove the two torx bolts (m5 x 12), and remove the cover panel. Torx bolt (m5 x 12) cover panel wipe away any dirt from the puck paths using a soft cloth moistened with water or a neutral cleanser...

Page 120: 118

118 8b. Service - must be performed by a technician - 8b-1-3 removing jammed pucks z check that pucks are not damaged or deformed before putting them back into the machine. Otherwise, the pucks may jam again. (1) inside the goal (l) or (r) assembly the description below explains how to remove jammed...

Page 121: 119

119 test mode inspection and service troubleshooting 8b. Service - must be performed by a technician - (3) inside the corner rail (l) or (r) the description below explains how to remove jammed pucks from the (l) side. Follow the same procedure to remove jammed pucks from the (r) side. Z to avoid ele...

Page 122: 120

120 8b. Service - must be performed by a technician - (4) inside the l or s bucket (hopper assembly) z to avoid electric shock, accidents or injuries to yourself or other people, or damage to the electronic circuits, be sure to turn off the power switch before starting work. Turn off the power switc...

Page 123: 121

121 test mode inspection and service troubleshooting 8b. Service - must be performed by a technician - (6) in case of s escalator assembly the description below explains how to remove jammed pucks from the l side. Follow the same procedure to remove jammed pucks from the r side. Z to avoid electric ...

Page 124: 122

122 8b. Service - must be performed by a technician - (7) in case of l escalator assembly z to avoid electric shock, accidents or injuries to yourself or other people, or damage to the electronic circuits, be sure to turn off the power switch before starting work. Turn off the power switch. (see “7-...

Page 125: 123

123 test mode inspection and service troubleshooting 8b. Service - must be performed by a technician - (8) in case of the slider assembly z to avoid electric shock, accidents or injuries to yourself or other people, or damage to the electronic circuits, be sure to turn off the power switch before st...

Page 126: 124

124 8b. Service - must be performed by a technician - 8b-1-4 adding big pucks z to avoid electric shock, accidents or injuries to yourself or other people, or damage to the electronic circuits, be sure to turn off the power switch before starting work. Turn off the power switch. (see “7-6-1 turning ...

Page 127: 125

125 test mode troubleshooting error display (for t echnicians) 8b. Service - must be performed by a technician - 8b-2 error display (for technicians) 8b-2-1 display when an error occurs when an error occurs, “err” is displayed in the left side score led, and the error number is displayed in the righ...

Page 128: 126

126 8b. Service - must be performed by a technician - error number error name cause action reference page 6 goal (l) sensor error • a puck or foreign object is jammed inside the l side goal. • remove the jammed puck or foreign object from inside the goal (l). Page 118 • a puck or foreign object is j...

Page 129: 127

127 test mode troubleshooting error display (for t echnicians) 8b. Service - must be performed by a technician - error number error name cause action reference page 11 s hopper motor error • a mini puck is jammed inside the hopper. • remove the jammed puck. Page 120 • a foreign object other than a m...

Page 130: 128

128 8b. Service - must be performed by a technician - error number error name cause action reference page 15 rail (l) jamming error • a puck is jammed inside the rail (l). • remove the jammed puck. Page 118 16 rail (r) jamming error • a puck is jammed inside the rail (r). 17 s divider (l) outlet sen...

Page 131: 129

129 test mode troubleshooting error display (for t echnicians) 8b. Service - must be performed by a technician - error number error name cause action reference page 25 ticket dispenser (l) error • the dispenser has run out of tickets. • a ticket dispenser (l) malfunction. • add tickets. • replace th...

Page 132: 130

130 8b. Service - must be performed by a technician - 8b-3 troubleshooting z to avoid electric shock, accidents or injuries to yourself or other people, or damage to the electronic circuits, be sure to turn off the power switch before starting work. Z if the problem is not described in “8b-3 trouble...

Page 133: 131

131 test mode troubleshooting 8b. Service troubleshooting - must be performed by a technician - 8b-3-1 overall symptom main cause action reference page the machine does not start even when the power switch is turned on. The power cord is disconnected from the outlet or the machine, or is not connect...

Page 134: 132

132 8b. Service - must be performed by a technician - 8b-3-3 goal (l) and (r) assemblies symptom main cause action reference page pucks jam frequently. One or both of the goal coin locks are not closed. Use the service key and close the goal. Page 38 a deformed puck is being used. Replace the deform...

Page 135: 133

133 test mode troubleshooting 8b. Service troubleshooting - must be performed by a technician - 8b-3-6 hopper assembly symptom main cause action reference page the hopper disk does not operate. A foreign object has entered the hopper. Remove the side tower assembly, and remove the foreign object fro...

Page 136: 134

134 8b. Service - must be performed by a technician - 8b-3-7 slider assembly symptom main cause action reference page mini pucks are not supplied during game play. Normal hockey mode was selected at the start of the game. Select big bang mode at the start of the game. Page 40 the machine is set to o...

Page 137: 135

135 test mode troubleshooting 8b. Service troubleshooting - must be performed by a technician - 8b-3-10 signboard assembly symptom main cause action reference page the time led pc board does not light. A time led pc board malfunction. Replace the time led pc board. Page 168 main pc board malfunction...

Page 138: 136

136 8b. Service - must be performed by a technician - 8b-4 removing, installing and replacing assemblies and parts 8b-4-1 table (1) removing and installing the goal (l) and (r) assemblies the description below explains how to remove and install the l side. Follow the same procedure to remove and ins...

Page 139: 137

137 test mode troubleshooting removing, installing and replacing assemblies and parts 8b. Service - must be performed by a technician - disconnect the two connectors. Connector goal (l) assembly remove the four fl ange socket bolts (m5 x 10) and two fl ange socket bolts (m5 x 16) from the right and ...

Page 140: 138

138 8b. Service - must be performed by a technician - to install, perform the procedure in reverse. (2) removing and installing the rail (l) and (r) assemblies z to avoid electric shock, accidents or injuries to yourself or other people, or damage to the electronic circuits, be sure to turn off the ...

Page 141: 139

139 test mode troubleshooting removing, installing and replacing assemblies and parts 8b. Service - must be performed by a technician - (3) replacing the blower fan z to avoid electric shock, accidents or injuries to yourself or other people, or damage to the electronic circuits, be sure to turn off...

Page 142: 140

140 8b. Service - must be performed by a technician - remove the four fl ange socket bolt (m5 x 16), the four flat washer(ø24 for m5), and remove the blower fan from the blower fan mounting plate. Flat washer (ø24 for m5) flange socket bolt (m5 x 16) blower fan blower mounting plate to install, perf...

Page 143: 141

141 test mode troubleshooting removing, installing and replacing assemblies and parts 8b. Service - must be performed by a technician - 8b-4-2 goal (l) and (r) assemblies (1) replacing the goal (l) and (r) sensors (photosensor side) and (photo-emitter side) the description below explains how to repl...

Page 144: 142

142 8b. Service - must be performed by a technician - 8b-4-3 rail (l) and (r) assemblies (1) replacing the rail (l) and (r) sensors (upper) and (middle) the description below explains how to replace the (l) side. Follow the same procedure for replacement of the (r) side. Z to avoid electric shock, a...

Page 145: 143

143 test mode troubleshooting removing, installing and replacing assemblies and parts 8b. Service - must be performed by a technician - remove the two pan head screws (m3 x 6), and remove the rail (l) sensors (upper) and (middle). Rail (l) sensor (upper) [refl ective type photo-interrupter] phillips...

Page 146: 144

144 8b. Service - must be performed by a technician - (2) replacing the rail (l) and (r) sensors (lower) the description below explains how to replace the (l) side. Follow the same procedure for replacement of the (r) side. Z to avoid electric shock, accidents or injuries to yourself or other people...

Page 147: 145

145 test mode troubleshooting removing, installing and replacing assemblies and parts 8b. Service - must be performed by a technician - 8b-4-4 side tower assembly (1) removing and installing the side tower assembly z to avoid electric shock, accidents or injuries to yourself or other people, or dama...

Page 148: 146

146 8b. Service - must be performed by a technician - (2) replacing the main pc board z to avoid electric shock, accidents or injuries to yourself or other people, or damage to the electronic circuits, be sure to turn off the power switch before starting work. Z pc boards are sensitive to static ele...

Page 149: 147

147 test mode troubleshooting removing, installing and replacing assemblies and parts 8b. Service - must be performed by a technician - unlock the 7 spacer locks, and replace the main pc board. Spacer main pc board to install, perform the procedure in reverse. M259_08b_enin6.Indd 147 m259_08b_enin6....

Page 150: 148

148 8b. Service - must be performed by a technician - (3) replacing the switching regulator z to avoid electric shock, accidents or injuries to yourself or other people, or damage to the electronic circuits, be sure to turn off the power switch before starting work. Z pc boards are sensitive to stat...

Page 151: 149

149 test mode troubleshooting removing, installing and replacing assemblies and parts 8b. Service - must be performed by a technician - (4) replacing the ssr z to avoid electric shock, accidents or injuries to yourself or other people, or damage to the electronic circuits, be sure to turn off the po...

Page 152: 150

150 8b. Service - must be performed by a technician - 8b-4-5 hopper assembly (1) replacing the l hopper motor z to avoid electric shock, accidents or injuries to yourself or other people, or damage to the electronic circuits, be sure to turn off the power switch before starting work. Turn off the po...

Page 153: 151

151 test mode troubleshooting removing, installing and replacing assemblies and parts 8b. Service - must be performed by a technician - loosen the four pan head screws (with fl at and spring washers) (m4 x 10), and remove the l hopper motor bracket. L hopper motor bracket phillips pan head screw (wi...

Page 154: 152

152 8b. Service - must be performed by a technician - remove the four phillips pan head screws (with fl at and spring washers) (m5 x 40), and replace the l hopper motor. L hopper motor phillips pan head screw (with fl at and spring washers) (m5 x 40) to install, perform the procedure in reverse. Z w...

Page 155: 153

153 test mode troubleshooting removing, installing and replacing assemblies and parts 8b. Service - must be performed by a technician - m259_08b_enin6.Indd 153 m259_08b_enin6.Indd 153 2/5/2013 8:12:08 am 2/5/2013 8:12:08 am.

Page 156: 154

154 8b. Service - must be performed by a technician - (2) replacing the l hopper motor sensor z to avoid electric shock, accidents or injuries to yourself or other people, or damage to the electronic circuits, be sure to turn off the power switch before starting work. Turn off the power switch. (see...

Page 157: 155

155 test mode troubleshooting removing, installing and replacing assemblies and parts 8b. Service - must be performed by a technician - (3) replacing the s hopper motor z to avoid electric shock, accidents or injuries to yourself or other people, or damage to the electronic circuits, be sure to turn...

Page 158: 156

156 8b. Service - must be performed by a technician - remove the encoder bracket. (see the step of “8b-4-5 (4) replacing the s hopper motor sensor” on page 158.) remove the two set screws (m4 x 10), and remove the s hopper gear. Set screws (m4 x 10) s hopper gear remove the four phillips pan head sc...

Page 159: 157

157 test mode troubleshooting removing, installing and replacing assemblies and parts 8b. Service - must be performed by a technician - to install, perform the procedure in reverse. Z when installing, align the bottom surface of the hopper gear with the tip of the motor shaft. Hopper gear bottom sur...

Page 160: 158

158 8b. Service - must be performed by a technician - (4) replacing the s hopper motor sensor z to avoid electric shock, accidents or injuries to yourself or other people, or damage to the electronic circuits, be sure to turn off the power switch before starting work. Turn off the power switch. (see...

Page 161: 159

159 test mode troubleshooting removing, installing and replacing assemblies and parts 8b. Service - must be performed by a technician - (5) replacing the s hopper motor driver pc board z to avoid electric shock, accidents or injuries to yourself or other people, or damage to the electronic circuits,...

Page 162: 160

160 8b. Service - must be performed by a technician - disconnect the four connectors, remove the four phillips pan head screws (with fl at and spring washers) (m4 x 25), and replace the s hopper motor driver pc board. Connector connector s hopper motor driver pc board phillips pan head screw (with f...

Page 163: 161

161 test mode troubleshooting removing, installing and replacing assemblies and parts 8b. Service - must be performed by a technician - 8b-4-6 slider assembly (1) replacing the stopper solenoids (l) and (r) the description below explains how to replace the (l) side. Follow the same procedure for rep...

Page 164: 162

162 8b. Service - must be performed by a technician - disconnect the two connectors, remove the two hex nuts with fl ange (m4), and remove the stopper base l. Connector connector stopper base l hex nut with fl ange (m4) remove the four phillips pan head screw (with fl at and spring washers) (m3 x 6)...

Page 165: 163

163 test mode troubleshooting removing, installing and replacing assemblies and parts 8b. Service - must be performed by a technician - (2) replacing the stopper (l) and (r) sensors the description below explains how to replace the (l) side. Follow the same procedure for replacement of the (r) side....

Page 166: 164

164 8b. Service - must be performed by a technician - 8b-4-7 s escalator assembly (1) replacing the s divider (l) and (r) outlet sensors the description below explains how to replace the (l) side. Follow the same procedure for replacement of the (r) side. Z to avoid electric shock, accidents or inju...

Page 167: 165

165 test mode troubleshooting removing, installing and replacing assemblies and parts 8b. Service - must be performed by a technician - 8b-4-8 l escalator assembly (1) replacing the l divider solenoid z to avoid electric shock, accidents or injuries to yourself or other people, or damage to the elec...

Page 168: 166

166 8b. Service - must be performed by a technician - (2) replacing the l divider sensor z to avoid electric shock, accidents or injuries to yourself or other people, or damage to the electronic circuits, be sure to turn off the power switch before starting work. Turn off the power switch. (see “7-6...

Page 169: 167

167 test mode troubleshooting removing, installing and replacing assemblies and parts 8b. Service - must be performed by a technician - (3) replacing the l divider (l) and (r) outlet sensors the description below explains how to replace the (l) side. Follow the same procedure for replacement of the ...

Page 170: 168

168 8b. Service - must be performed by a technician - 8b-4-9 signboard assembly (1) replacing the time led (time led pc board) z to avoid electric shock, accidents or injuries to yourself or other people, or damage to the electronic circuits, be sure to turn off the power switch before starting work...

Page 171: 169

169 test mode troubleshooting removing, installing and replacing assemblies and parts 8b. Service - must be performed by a technician - to install, perform the procedure in reverse. (2) replacing the score led (score led pc board) z to avoid electric shock, accidents or injuries to yourself or other...

Page 172: 170

170 8b. Service - must be performed by a technician - 8b-4-10 illuminator assembly (1) replacing the circle led the description below explains how to replace the l side. Follow the same procedure for replacement of the r side. Z to avoid electric shock, accidents or injuries to yourself or other peo...

Page 173: 171

171 test mode troubleshooting removing, installing and replacing assemblies and parts 8b. Service - must be performed by a technician - disconnect the connector, and remove the phillips pan head screw (with fl at and spring washers) (m4 x 10). Connector s escalator assembly phillips pan head screw (...

Page 174: 172

172 8b. Service - must be performed by a technician - remove the four phillips countersunk wood screws (3.1 x 8), and remove the illumination base plate. Illumination base plate (l) phillips countersunk wood screw (3.1 x 8) disconnect the connector, and remove the circle led. Circle led connector to...

Page 175: 173

173 test mode troubleshooting removing, installing and replacing assemblies and parts 8b. Service - must be performed by a technician - 8b-4-11 replacing the led fluorescent light remove the side tower assembly. (see the side tower assembly installation procedure.) remove the light frame unit. (see ...

Page 176: 174

174 9. Disposal z when disposing of the machine, follow the applicable regulations for collection, transportation and disposal. Z when delegating the collection, transportation and disposal of the machine, be sure to delegate to specialists in each fi eld. M259_09_en.Indd 174 m259_09_en.Indd 174 2/5...

Page 177: 175

Test mode troubleshooting 175 disposal m259_09_en.Indd 175 m259_09_en.Indd 175 2/5/2013 8:14:10 am 2/5/2013 8:14:10 am.

Page 178: 176

176 10. Parts list 10-1 overall 26 23 30 31 25 26 23 25 24 18 14 9 9 17 9 19 16 15 20 9 32 33 27 11 2 1 back side 26 23 (opposite side ) z (back) x x 10 13 29 12 side tower assembly back side 25 23 z (back) m259_10_enin6.Indd 176 m259_10_enin6.Indd 176 2/5/2013 8:14:57 am 2/5/2013 8:14:57 am.

Page 179: 177

10. Parts list test mode troubleshooting 177 overall 28 8 3 4 5 6 7 (view with the side tower assembly removed) 34 35 36 no. Name qty. Type and rating part no. 1 side tower bracket (l) 1 pm10-15513-00 2 side tower bracket (r) 1 pm10-15514-00 3 mallet 4 pm90-15505-00 4 big puck 100 (1 set: 10 pucks) ...

Page 180: 178

10. Parts list 178 10-2 table top assembly 3 5 6 7 8 9 4 1 2 10 12 11 (back side) m259_10_enin6.Indd 178 m259_10_enin6.Indd 178 2/5/2013 8:15:18 am 2/5/2013 8:15:18 am.

Page 181: 179

10. Parts list test mode troubleshooting 179 table top assembly no. Name qty. Type and rating part no. 1 air chamber 1 pm63-15730-13 2 blower mounting plate 1 pm63-15730-14 3 field (pac) 1 pm40-15703-00 4 goal bumper (l) 2 pm10-15639-00 5 goal bumper (r) 2 pm10-15640-00 6 bumper s (l) 2 pm10-15641-0...

Page 182: 180

10. Parts list 180 10-3 cabinet (l) assembly 17 18 b b 1 2 14 6 13 22 21 10 19 16 23 24 3 15 21 a a c c c – c b – b 11 12 20 4 8 a – a 9 5 7 6 (detailed view of part ) corner rail part ( ) 25 25 25 6 5 27 26 m259_10_enin6.Indd 180 m259_10_enin6.Indd 180 2/5/2013 8:15:18 am 2/5/2013 8:15:18 am.

Page 183: 181

10. Parts list test mode troubleshooting 181 cabinet (l) assembly no. Name qty. Type and rating part no. 1 table cabinet (l) exp 1 pm63-15730-00 2 front door 1 pm63-15730-01 3 service door l 1 pm63-15730-02 4 goal set bracket 1 pm10-15647-00 5 corner inner r (l) 1 pm10-15649-00 6 corner outer r (l) ...

Page 184: 182

10. Parts list 182 10-4 goal (l) assembly 12 13 25 23 13 24 12 2 3 5 14 z 22 15 16 17 18 12 ( rear view) 12 ( z-direction view) m259_10_enin6.Indd 182 m259_10_enin6.Indd 182 2/5/2013 8:15:22 am 2/5/2013 8:15:22 am.

Page 185: 183

10. Parts list test mode troubleshooting 183 goal (l) assembly a 1 4 6 11 19 a 21 20 a – a 8 10 9 13 5 7 26 12 (view with removed) (view with removed) (opposite side ) no. Name qty. Type and rating part no. 1 goal inner r (l) 1 pm10-15528-00 2 goal outer lower (l) 1 pm10-15529-00 3 slope 1 pm10-1548...

Page 186: 184

10. Parts list 184 10-5 rail (l) assembly z z 1 9 2 3 6 5 4 7 8 no. Name qty. Type and rating part no. 1 rail l (a) 1 pm10-15542-00 2 pendulum 3 pm10-15543-00 3 rail sensor bracket a 1 pm10-15544-00 4 refl ective-type photo-interrupter 3 gp2a25j00004 pm79-15470-00 5 rail sensor bracket b 1 pm10-1554...

Page 187: 185

10. Parts list test mode troubleshooting 185 rail (l) assembly / cabinet (r) assembly 10-6 cabinet (r) assembly d d 16 17 b b 1 33 13 32 c c 14 20 a a 12 21 15 22 9 18 23 2 24 24 24 5 4 5 25 26 (detailed view of part ) corner rail part ( ) e e 4 5 6 8 a – a b – b 3 7 c – c 11 19 10 m259_10_enin6.Ind...

Page 188: 186

10. Parts list 186 d – d 28 27 29 30 detailed view of service panel ex 38 39 40 41 37 36 35 34 42 no. Name qty. Type and rating part no. 1 table cabinet (r) exp 1 pm63-15730-03 2 service door r 1 pm63-15730-04 3 goal set bracket 1 pm10-15647-00 4 corner inner (r) 1 pm10-15665-00 5 corner outner (r) ...

Page 189: 187

10. Parts list test mode troubleshooting 187 cabinet (r) assembly / goal (r) assembly 10-7 goal (r) assembly 12 23 21 24 22 12 13 2 3 18 z 11 (view with removed) m259_10_enin6.Indd 187 m259_10_enin6.Indd 187 2/5/2013 8:15:30 am 2/5/2013 8:15:30 am.

Page 190: 188

10. Parts list 188 a a a – a 14 19 20 11 1 10 15 4 17 16 9 35 35 6 7 8 12 3 (view with removed) 21 25 ( z-direction view) (view with removed) 21 5 (opposite side ) m259_10_enin6.Indd 188 m259_10_enin6.Indd 188 2/5/2013 8:15:31 am 2/5/2013 8:15:31 am.

Page 191: 189

10. Parts list test mode troubleshooting 189 goal (r) assembly no. Name qty. Type and rating part no. 1 goal inner r (r) 1 pm10-15539-00 2 slope 1 pm10-15486-00 3 goal back plate 1 pm10-15531-00 4 goal outer r 1 pm10-15532-00 5 stopper (l) 1 pm10-15487-00 6 stopper (r) 1 pm10-15487-01 7 clasp 2 pm10...

Page 192: 190

10. Parts list 190 10-8 rail (r) assembly z 1 3 2 8 6 7 view with and removed (z direction) 8 1 4 5 no. Name qty. Type and rating part no. 1 rail r (a) 1 pm10-15550-00 2 rail sensor bracket a 1 pm10-15544-00 3 rail sensor bracket b 1 pm10-15545-00 4 refl ective-type photo-interrupter 3 gp2a25j00004 ...

Page 193: 191

10. Parts list test mode troubleshooting 191 rail (r) assembly / side tower assembly 10-9 side tower assembly a a b b a – a 17 1 11 9 13 11 11 8 7 9 13 11 m259_10_enin6.Indd 191 m259_10_enin6.Indd 191 2/5/2013 8:15:33 am 2/5/2013 8:15:33 am.

Page 194: 192

10. Parts list 192 lower front side during transport 16 16 15 2 3 2 15 6 4 5 27 23 24 22 14 25 26 6 10 10 18 14 2 main pc board detailed view of 4 b – b 1 lower back side during transport 1 21 19 11 21 20 12 21 19 11 21 20 12 detailed view of open close cross-sectional diagram 2 3 view with and remo...

Page 195: 193

10. Parts list test mode troubleshooting 193 side tower assembly no. Name qty. Type and rating part no. 1 side tower cabinet (exp) 1 pm63-15730-05 2 rear panel 1 pm63-15730-06 3 service door 1 pm63-15730-07 4 pcb base exp 1 pm63-15730-08 5 rack rail l 1 pm10-15554-00 6 rack rail u 1 pm10-15555-00 7 ...

Page 196: 194

10. Parts list 194 10-10 hopper assembly 40 27 35 25 a a c b b c 18 1 19 54 18 44 17 16 31 45 38 32 31 24 19 16 23 17 27 26 35 b-b d d cross-sectional diagram a-a cross-sectional diagram 54 4 5 54 m259_10_enin6.Indd 194 m259_10_enin6.Indd 194 2/5/2013 8:15:45 am 2/5/2013 8:15:45 am.

Page 197: 195

10. Parts list test mode troubleshooting 195 hopper assembly 7 3 2 w y z 6 x 52 47 47 33 33 46 46 34 9 8 30 39 29 46 5 6 d-d cross-sectional diagram view with removed view with and removed 27 c-c cross-sectional diagram (condition with removed) x w , 26 , 25 , 6 , 5 , m259_10_enin6.Indd 195 m259_10_...

Page 198: 196

10. Parts list 196 21 36 48 49 52 22 12 52 21 13 14 22 10 28 22 11 43 42 15 28 41 50 20 37 z 41 detailed view of part y detailed view of part x detailed view of part w detailed view of part no. Name qty. Type and rating part no. 1 hopper base 1 pm10-15562-00 2 l hopper bottom 1 pm10-15563-00 3 s hop...

Page 199: 197

10. Parts list test mode troubleshooting 197 hopper assembly no. Name qty. Type and rating part no. 12 l hopper motor bracket exp 1 pm10-15688-00 13 s hopper motor bracket 1 pm10-15569-00 14 l hopper latch 1 pm10-15570-00 15 s hopper latch 1 pm10-15571-00 16 l bucket base a 2 pm10-15572-00 17 l buck...

Page 200: 198

10. Parts list 198 10-11 slider assembly (opposite side ) (opposite side ) (opposite side ) (opposite side ) (opposite side ) detailed view of and (the figure shows .) 14 7 29 9 4 20 2 10 28 8 12 16 1 6 18 19 8 17 30 15 13 27 22 2 2 3 21 26 9 11 23 24 25 (opposite side ) 5 detailed view of and (the ...

Page 201: 199

10. Parts list test mode troubleshooting 199 slider assembly no. Name qty. Type and rating part no. 1 slider base 1 pm10-15588-00 2 s slope l 1 pm10-15589-00 3 s slope r 1 pm10-15590-00 4 l slope l 1 pm10-15591-00 5 l slope r 1 pm10-15592-00 6 cover panel (pac) 1 pm40-15708-00 7 cover panel retainer...

Page 202: 200

10. Parts list 200 10-12 s escalator assembly 8 3 4 5 7 16 9 9 12 12 11 11 1 10 13 14 1 4 3 2 15 6 a a a-a 3 cross-sectional diagram detailed view of 1 detailed view of m259_10_enin6.Indd 200 m259_10_enin6.Indd 200 2/5/2013 8:15:52 am 2/5/2013 8:15:52 am.

Page 203: 201

10. Parts list test mode troubleshooting 201 s escalator assembly no. Name qty. Type and rating part no. 1 s rail (r) 1 pm10-15607-00 2 s rail (l) 1 pm10-15608-00 3 s divider base 1 pm10-15609-00 4 s divider cover 1 pm10-15610-00 5 s divider 1 pm90-15498-00 6 s divider spring 1 pm22-15691-00 7 joint...

Page 204: 202

10. Parts list 202 10-13 l escalator assembly 15 11 22 12 11 12 22 10 19 20 4 1 5 13 17 16 17 6 2 7 3 m259_10_enin6.Indd 202 m259_10_enin6.Indd 202 2/5/2013 8:15:53 am 2/5/2013 8:15:53 am.

Page 205: 203

10. Parts list test mode troubleshooting 203 l escalator assembly 8 12 18 21 14 9 3 detailed view of no. Name qty. Type and rating part no. 1 l rail (r) 1 pm10-15620-00 2 l rail (v) 1 pm10-15621-00 3 l rail (h) 1 pm10-15622-00 4 l rail (h) cover 1 pm10-15623-00 5 l slope top l 1 pm10-15624-00 6 l sl...

Page 206: 204

10. Parts list 204 10-14 signboard assembly 3 1 2 4 5 6 no. Name qty. Type and rating part no. 1 signboard base 1 pm10-15634-00 2 divider hook 1 pm10-15635-00 3 signboard (pac) 1 pm40-15709-00 4 signboard cushion 16 731-588 5 score led pc board 1 pm15-15475-00 6 time led pc board 1 pm15-15474-00 10-...

Page 207: 205

10. Parts list test mode troubleshooting 205 signboard assembly / cord box assembly / illuminator assembly 10-16 illuminator assembly 10 5 6 9 9 3 1 2 4 7 8 no. Name qty. Type and rating part no. 1 illumination base (l) 1 pm63-15730-11 2 illumination base (r) 1 pm63-15730-12 3 illumination base plat...

Page 208: 206

10. Parts list 206 10-17 light assembly 10 11 5 6 9 3 8 1 2 4 7 no. Name qty. Type and rating part no. 1 light frame 1 pm10-15674-00 2 light cover 1 pm40-15718-00 3 ballast bracket 1 pm10-15675-00 4 light arm l 1 pm10-15676-00 5 light arm r 1 pm10-15677-00 6 light connector cover 1 pm10-15678-00 7 l...

Page 209: 11. Wiring Diagram

213 test mode troubleshooting w iring diagram 11. Wiring diagram g f e d c b a g f e d c b a 10 9 8 7 6 5 4 3 2 1 10 9 8 7 6 5 4 3 2 1 awg16 awg18 awgxx awg24 awgxx narrow line wide line awg line explanatory remarks gn/ye other color awgxx all color awgxx black brown red orange yellow green blue vio...

Page 210

11. Wiring diagram test mode troubleshooting 214 w iring diagram g f e d c b a g f e d c b a 10 9 8 7 6 5 4 3 2 1 10 9 8 7 6 5 4 3 2 1 awg16 awg18 awgxx awg24 awgxx narrow line wide line awg line explanatory remarks gn/ye other color awgxx all color awgxx black brown red orange yellow green blue vio...

Page 211

11. Wiring diagram test mode troubleshooting 215 w iring diagram g f e d c b a g f e d c b a 10 9 8 7 6 5 4 3 2 1 10 9 8 7 6 5 4 3 2 1 awg16 awg18 awgxx awg24 awgxx narrow line wide line awg line explanatory remarks gn/ye other color awgxx all color awgxx black brown red orange yellow green blue vio...

Page 212

11. Wiring diagram test mode troubleshooting 216 w iring diagram g f e d c b a g f e d c b a 10 9 8 7 6 5 4 3 2 1 10 9 8 7 6 5 4 3 2 1 awg16 awg18 awgxx awg24 awgxx narrow line wide line awg line explanatory remarks gn/ye other color awgxx all color awgxx black brown red orange yellow green blue vio...

Page 213

11. Wiring diagram test mode troubleshooting 217 w iring diagram g f e d c b a g f e d c b a 10 9 8 7 6 5 4 3 2 1 10 9 8 7 6 5 4 3 2 1 awg16 awg18 awgxx awg24 awgxx narrow line wide line awg line explanatory remarks gn/ye other color awgxx all color awgxx black brown red orange yellow green blue vio...

Page 214

The machine specifications or the information in this operation manual may be changed without prior notice. This machine uses some recycled materials. 1715002300 part no.: 731-695 first edition issued december 2012.