- DL manuals

- NAMCO

- Arcade Game Machines

- Prop cycle

- Operator's Manual

NAMCO Prop cycle Operator's Manual

Summary of Prop cycle

Page 1

Operators manual i t is the responsibility of the operator to maintain customer safety at all times , and it is imperative that the details set out in this manual are followed precisely , part no. 90500089.

Page 2

No part of this publication may be reproduced by any mechanical, photographic or electronic process, or in the form of phonographic recording, nor may it be stored in a retrieval system, transmitted or otherwise copied for public or private use, without permission from namco europe limited while the...

Page 3: Safety Warning

Safety warning in order to use this machine safely, be sure to read this installation and commissioning manual carefully before installation, adjustment or use of this machine. Whenever the owner of this machine entrusts disassembly, installation, adjustment or routine maintenance to another person,...

Page 4: Contents

Contents operators manual ......................................................................................................................... 1 safety warning ...................................................................................................................... 3 1. Specificati...

Page 5

Page 5 1. Specifications power supply:- 230volts ac monitor:- thomson 52” projector monitor (rp52) coin acceptor:- mars cashflow - 1 channel dimensions:- assembled 1250(w) x 2430(d) x 2320(h) monitor cabinet 1250(w) x 645(d) x 1940(h) cycle assembly 980 (w) x 1785(d) x 1380(h) header assembly 1145(w...

Page 6

Page 6 2. How to play this is a new flight game in which the player gains points by riding a human- powered propcycle and flying freely in the sky. The player flies the propcycle and gains points by hitting and popping floating red balloons. (1) operation the game is operated by using the handlebars...

Page 7

Page 7 3. Major components.

Page 8

Page 8 4. Installation notes on installation danger never turn the power to the machine on until installation has been completed. Danger in order to avoid injury or damage to the machine due to mis- operation, ensure that the voltage of the mains supply is 230volts ac. Also, in order to prevent poss...

Page 9

Page 9 warning this machine is designed for indoor use only. The game must not be installed outdoors or under the following conditions:- a. In areas directly exposed to sunlight, high humidity, direct water contact, dust, high heat or extreme cold. B. In locations that would present an obstacle in t...

Page 10

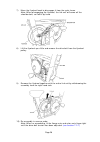

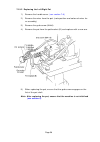

Page 10 4-2 connecting the cycle assy to the monitor cabinet 1, connect the connectors between the cycle assembly and the monitor cabinet. 2. Remove 2off hex head set screws (m8x25), spring and flat washers on each joint bracket, turn the bracket over and refit, finger tight, using the same screws a...

Page 11

Page 11 4-3 removing the shipping bracket 1. Remove the two hex head set screws (m8x16) retaining the shipping bracket to the cycle base. 2. Remove the two hex head set screws (m12x20) retaining the shipping bracket to the cycle assembly. 3. Remove the shipping bracket. (ensure that the bracket and ...

Page 12

Page 12 5. Adjustments 5-1 turning on the power after the machine has been installed, turn on the power. The power switch is located on the rear of the main cabinet. (see section 3 “major components” (page 3).) 5-2 adjustment switches the adjustment switches are located inside the coin door. 1. Serv...

Page 13

Page 13 5-3 test mode 1. Open the coin door and slide the test switch “on”. The “menu screen” will be displayed on the monitor. 2. Select the test required by moving the handle bars up or down. The colour of the selected test will change. 3. Enter the selected test by pressing the start button. Sele...

Page 14

Page 14 5-3-1 coin options a. Select item (1) “coin options” on the menu screen, to set the game cost and related settings. B. Move the handle bars up or down to select the required item then press the start button. C. Move the handle bars left or right to change the settings then press the start bu...

Page 15

Page 15 5-3-2 game options a. Select item (2) “game options” on the menu screen to set the game options. B. Move the handle bars up or down to select the required item then press the start button. C. Move the handle bars left or right to change the settings then press the start button to store the n...

Page 16

Page 16 5-3-3 i/o test a. Select item (3) “i/o test” on the menu screen. B. Move the handle bars up or down to select the required item then press the start button. C. Move the handle bars left or right to change the settings then press the start button to store the new values. D. Select “exit” and ...

Page 17

Page 17 5-3-3-1 switch test a. Select “switch” on the menu screen and press the start button. The following screen is displayed. I/o test dip 12345678 switch up / down : 0000 ................................... (a) right / left : 0000 ................................... (b) start : off ................

Page 18

Page 18 5-3-3-2 pedal test a. Select “pedal” on the menu screen and press the start button. The following screen is displayed. I/o test dip 12345678 switch pedal pedal 7fbf .................... (a) ready press start .................... (b) to exit : push start and handlebars up } (a) pedal rotation...

Page 19

Page 19 e. When the start button has been pressed, the following screen is displayed. F. If “ok” is displayed the pedals are correct. If “ng” is displayed there has been a problem in reading the pedal rotation. Press start and repeat steps c) and d) again. If “ng” is still displayed after repeating ...

Page 20

Page 20 5-3-3-4 lamp test a. Select “lamp” on the menu screen and press the start button. The following screen is displayed. B. When the start button is pressed once, ‘off’ changes to ‘on’ and the start button lamp turns on. When the start button is pressed again, ‘on’ changes to ‘off’ and the start...

Page 21

Page 21 5-3-5 sound test a. Select “sound test ” on the menu screen and press the start button. The following screen is displayed. B. Volume adjust move the handle bars up or down to select the item to be changed, and then move the handle bars left or right to change the setting of the selected item...

Page 22

Page 22 6. Initialization adjustments when replacing parts (initialization) the following adjustments should always be performed after replacing the game pc board, rom, steering assy, pedal assy, or control pots. The game will not operate correctly if these adjustments are not made. A) ensure that h...

Page 23

Page 23 7. Maintenance maintenance and repair should only be carried out by competent persons. Warning • do not make any alterations to this machine without prior approval. Doing so could cause unforeseeable danger. • only parts specified by namco europe ltd. Should be used when replacing or repairi...

Page 24

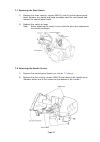

Page 24 7-1 pedal pressure adjustment this game is designed so that the pedal pressure can be adjusted. This will have an effect on the difficulty of the game. At the time of shipment, the pressure is set to a light setting. The mechanism becomes uncovered so take care not to trap hands or fingers i...

Page 25

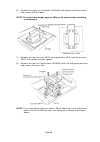

Page 25 7-2 inspecting or adjusting the drive belt the mechanism becomes uncovered so take care not to trap hands or fingers in the mechanism 1) remove the three security screws (m5x12) and remove the upper cover. 2) remove five security screws (m5x20) and four security screws (m5x12) and remove the...

Page 26

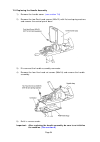

Page 26 4) to increase the tension, slacken the front nylon nuts (m6) and tighten the rear nylon nuts (m6). To decrease the tension, slacken the rear nuts and tighten the front nuts. Note: to ensure that the flywheel remains parallel within the frame, adjust each nut on both sides by the same amount...

Page 27

Page 27 4) remove the four pozi head screws (m5x12) and remove the wheel cover. 5) remove the hexagonal flange nuts (3/8”) on both sides and the four eye bolts which retain the flywheel shaft to the frame assembly. 6) move the flywheel forward to release the tension on the drive belt, and slip the d...

Page 28

Page 28 7) move the flywheel back to disengage it from the cycle frame. Note: when disengaging the flywheel, the link unit will come off the shoulder bolt, so hold it by hand. 8) lift the flywheel up a little and remove the drive belt from the flywheel pulley. 9) remove the flywheel together with th...

Page 29

Page 29 7-4 inspecting and replacing the pedal sensor sticker 1) remove the top and left side covers (see section 7-2) 2) remove the two pozi head screws (m5x10) and remove the sensor pcb. 3) look through the square cut out and make sure that the sensor sticker is not dirty or damaged. 4) if the sen...

Page 30

Page 30 7-5 replacing the fluorescent tube danger; to prevent electric shock, ensure machine is switched off before commencing work. 1) remove the ten socket button head screws (m5x12), and remove the side vac-forms. (five screws on each vac-form) 2) remove the two countersunk screws (m5x12) from th...

Page 31

Page 31 7-6 replacing the fan warning: the front base assembly weighs approx. 25kg. It should be handled by at least two people. 1) remove the four security screws (m5x30). 2) disconnect and remove the front base assembly. 3) remove the four security screws (m5x12) and remove the front cover..

Page 32

Page 32 4) remove the three countersunk screws (m5) and remove the fan box front panel. 5) remove the four m4 whizz nuts on the rear of the front base wood and remove the fan from the front..

Page 33

Page 33 7-7 replacing the start switch 1) remove the three security screws (m5x12) and lift up the control panel hood. Remove the switch and lamp assembly from the start button and remove the control panel hood. 2) replace the switch or lamp. Note : when replacing the switch ensure that the wires ar...

Page 34

Page 34 7-9 replacing the handle assembly 1) remove the handle cover. (see section 7-8) 2) remove the two pozi head screws (m5x12) with flat and spring washers and remove the control panel base. 3) dis-connect the handle assembly connector. 4) remove the four hex head set screws (m8x16) and remove t...

Page 35

Page 35 7-10 replacing the handle pots. 7-10-1 replacing the up/down pot 1) remove the four security screws (m5x12) and remove the front cover 2) remove the three wires from the pot (note position and colour of wires for re-assembly) 3) remove the grub screw (m4x8), then slide the pot bracket (a) to...

Page 36

Page 36 7-10-2 replacing the left/right pot 1) remove the handle cover. (see section 7-8) 2) remove the wires from the pot. (note position and colour of wires for re-assembly) 3) remove the grub screw (m4x8) 4) remove the pot from the pot bracket (b) and replace with a new one. 5) when replacing the...

Page 37

Page 37 7-11 replacing the pedals 1) remove the security screw (m5x12) and remove the pedal cover. 2) loosen the nylon nut (m6) on the crank pin ensuring that no threads are protruding through the nut. (if any thread is protruding , the thread may be damaged in the following step). 3) turn the pedal...

Page 38

Page 38 4) when re-fitting, the crank pin should be inserted from the front (monitor side) when the pedal is directly downward. 5) the crank arm moves 2 ~ 3mm in and out on the shaft when the crank pin is inserted. Move the crank arm to the outside and tighten the nylon nut (m6) note: if the nylon n...

Page 39

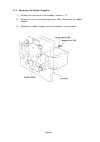

Page 39 7-12 replacing the vibration proof rubbers 1) remove the two security screws (m5x12) and remove the joint cover. 2) disconnect the connector and remove the three hex head screws (m12x25). 3) lift the cycle assembly straight up and remove from the base assembly. Note: the cycle assembly weigh...

Page 40

Page 40 6) remove the eight hex head bolts (m10x25) (with spring and flat washers) and remove the joint base. Note: the joint base weighs approx. 20kg so be careful when installing or removing it. 7) remove the four hex nuts (m12), spring washers (m12) and flat washers (m12) and remove the joint spa...

Page 41

Page 41 9) remove the two hex head bolts m10x25) (with spring and flat washers) and remove the vibration proof rubber. 10) replace the vibration proof rubber and re-assemble in reverse order. When installing the cross link, press the bearing against the positioning plate to position it in the forwar...

Page 42

Page 42 7-13 replacing the rubber stoppers 1) remove the joint base as described in section 7-12. 2) remove the hex nut and spring washer (m8) and remove the rubber stopper. 3) replace the rubber stopper and re-assemble in reverse order..

Page 43

Page 43 8. Parts list item description part no 1 thomson 52" projector monitor 84000030 2 projector cabinet side decal - lhs 40000341 projector cabinet side decal - rhs 40000369 3 prop cycle pcb assy - system s22 xpc-pcb 4 smpsu 5v/30a - astec 301-3400 83000001 5 elkay block 5way 66000014 6 fuse 1¼"...

Page 44

Page 44.

Page 45

Page 45 item description part no 3 side cover - lhs 45000977 4 side cover - rhs 45000978 5 crossbar vac-form 45000979 6 handlebar stem vac-form - front 45000980 7 handlebar stem vac-form - rear 45000981 8 pedal side vac-form - lhs 45000982 9 pedal side vac-form - rhs 45000983 10 pedal cover vac-form...

Page 46

Page 46.

Page 47

Page 47 item description part no 1 steering shaft 45000954 2 handlebars 45000955 3 steering base 45000957 4 switch support bracket 45000956 5 handlebar locating bracket 45000958 6 handlebar bearing block 45000959 7 rosta spring support bracket 'a' 45000960 8 rosta spring support bracket 'b' 45000961...

Page 48

Page 48 item description part no ------- bike mechanical assembly - complete xpc-bike 1 flywheel xpc-flywheel 2 flywheel drive pulley xpc-flywhldrvpul 3 pulley n168-r03a xpc-pulley 4 drive wheel xpc-drivewheel 5 shim washer xpc-shim 6 drive belt n168-r06 xpc-drivebelt 7 magnet holder xpc-magnetholde...

Page 49

Page 49 item description part no 1 rear barrier perspex 39000306 2 perspex fixing bracket 46000009 3 perspex fixing plate 46000010 4 rear safety barrier clamp 46000014 5 barrier pipe joint 46000012 6 barrier cushion 46000013 7 rear barrier pipe 46000011.

Page 50

Page 50

Page 51

Page 51 item description part no 1 main base metalwork 45000985 2 base step right 45000986 3 base step left 45000987 4 coin tower 45000988 5 bike base surround 45000989 6 bike base 45000990 7 bike mounting plate 45000991 8 bike rear base cover 45000992 9 bike rotational shaft 45000993 10 bearing was...

Page 52

Page 52 item description part no 1 fan cover vac-form 45000934 2 fan/speaker box wood 37100099 3 fan cover 45000935 4 top fan mesh 45000936 5 bottom fan mesh 46000042 6 speaker mesh 45000938 7 speaker mesh washer 45000939 8 fan - rotary 45000940 9 fan warning decal 40000343 10 loudspeaker 5½" full r...

Page 53

Page 53 item description part no 1 header wooden housing 37100097 2 fluorescent tube 3ft 98000016 3 header acrylic retaining bracket - upper 46000034 4 header acrylic 30000230 5 header vac-form with inset - rhs 45000932 6 header vac-form with inset - lhs 45000931 7 header vac-form decal 'namco' 4000...

Page 54

Page 54 item description part no 1 sub bass cabinet 37100100 2 sub bass cabinet grille 46000035 3 bass drive unit 6½" 62000068.

Page 55

Page 55.

Page 56

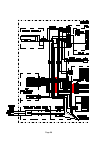

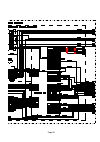

Page 56 9. Schematics.

Page 57

Page 57.

Page 58

Page 58.

Page 59

Page 59.