- DL manuals

- NAMCO

- Video Gaming Accessories

- TIME CRISIS 2

- Operation Manual

NAMCO TIME CRISIS 2 Operation Manual

Summary of TIME CRISIS 2

Page 2: Introduction

Introduction thank you very much for purchasing namco’s time crisis 2 (“this machine”). This operation manual describes: how run, install, move, maintain, and scrap this machine safely how to run this machine correctly while making full use of its functions how to ensure safety for players and obser...

Page 3: Safety Precautions

Safety precautions safety precautions be sure to read these instructions to ensure safe use instructions to the owner: if you wish to commission another party to install, transport. Maintain, or scrap this ma- chine, please instruct that party to read and observe all instructions for the particular ...

Page 4

1. L-3 top-priority safety precautions warning should any trouble occur, turn off the power and stop operating this machine immediately. Then do not forget to unplug the power cord. Running this machine trouble unsolved may cause a fire or other accident. L some parts in the monitor retain high heat...

Page 5

1. Safety precautions l-4 description of the “warning label” attached to this machine warning . The “warning label” describes important safety precautions. Observe the following: l as the “warning label” attached to this machine should be read easily, take care to decide the place to install this ma...

Page 6

Contents contents 1 . Safety precautions .................................................................................................................... 1 l-1 magnitudes o f risk.. .....................................................................................................................

Page 7

Contents 7-2-2 modes ................................................................................................................................ 7-2-3 r u l e s ................................................................................................................................. 28 7...

Page 8

Contents 9. Discard . . . 73 10. Parts list ........................................................................................................................................ Cabinet assy .............................................................................................................

Page 9: Specifications

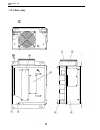

Specifications (3) rated power supply : ac or ac hz) maximum power : (for ac power supply) 440w (for 220v ac power supply) maximum current consumption : (for ac power supply) (for 220v ac power supply) cash box capacity : approx. 300,000 yen (3.000 coins) c r t : 29” color monitor x 2 units dimensio...

Page 10

Tower assy 1 . 1 0 0 720 signboard assy 1 , 4 6 0 t-----l pedal assy (7) wright a s cabinet assy : t o w e r : assy : pedal assy :.

Page 11

3. Checking package contents 3. Checking the package contents when packed and shipped, this machine consists of the following: . Be sure to check that you have received all packages indicated below. . It you find any component missing. Contact your dealer. L body assy: 1 unit tower assy: 1 unit l bo...

Page 12: 4 .

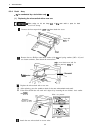

4. Overall construction 4 . Overall construction (components and their names) signboard assy gun coin assy pedal assy . . Warning sticker (high warning sticker (inside) power switch rack assy 10

Page 13: 5. Installation

Installation 5. Installation . Install the components according to the descriptions and specified procedures in operation manual (see p-11. 5. Installation). Failure to follow any procedure might result in a fire, shock. Injury, or breakdown. . The power plug into the service outlet securely all the...

Page 14

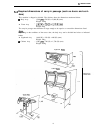

5. Zone as installed warning . Set a play zone as illustrated in the below to prevent customers leaving this machine from getting into contact with observers and passers-by. Machine must be from the . Allow for a clearance of at least between the rear of this machine the hand and the nearby wall and...

Page 15

Installation required dimensions of carry-in passage (such as doors and corri- dors) this machine is shipped as divided. The divisions have the dimensions mentioned below. Body assy : 1,500 x 790 (d) x 2,090 (h) (mm) weight: 229kg l tower assy : weight: 42kg the carry-in passage must therefore be la...

Page 16

5. Installation 5-2-l dividing the signboard assy and cabinet assy -to be conducted by a technician only this task need not be conducted if the ceiling above the passage and the opening of the access door are high enough. Remove the two torque bolts x 12) from the back of the signboard assy and deta...

Page 17

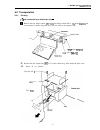

5. Installation 5-3 assembly 5-3-l connecting the cabinet assy to the tower assy -to be conducted by a technician only l install this machine at a position where the monitor does not reflect the incandescent lamp. Such reflection might prevent the gun sensor from functioning. (a fluorescent lamp is ...

Page 18

5 . Q fix the cower assy with four flange sockets x 20) furnished with this machine. Q pull out harness from the tower assy. Then connect the two connectors to the cabinet harness nge socket (mb 20) q with four torque bolts x 12). Attach the joint removed in step q when follow reverse order. 1 6.

Page 19

5. Installation 5-3-2 installing the pedal assy -to be conducted by a technician only q tack four pedal brackets furnished with this machine to the right and left under-pipes of the tower assy with eight flange sockets x 12). Flange socket 12) pedal bracket (put through the round holes) he round hol...

Page 20

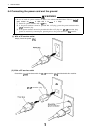

5. Installation 5-4 connecting the power cord and the ground warning l be sure to install the ground conductor in either of the methods described below. Failure to a ground conductor may an electric shock in the of a leakage. (1) ground the ground conductor with a plug. (2) (if the ground conductor ...

Page 21

(3) if the 2p service outlet available has no ground terminal ground the ground conductor by linking it to the ground terminal at the rear of the cabinet (no ground conductor is furnished with this machine.) ground terminal l install the ground conductor as illustrated below. Toothed washer (m4) cup...

Page 22: 6. Moving and Transporting

6. Moving and transporting 6. Moving and transporting w a r n i n g - , do not leave this machine on a slope. Leaving it on a slope may result i n causing an unexpected accident. L the tower is not designed to be carried with a do not use a for moving and i a . , . __ . . . Accident. 6-1 moving (on ...

Page 23

6. Moving and 6-2 transportation 6-2-l dividing be conducted by a technician only remove the four flange sockets x four flange sockets (m6 x pedal and one connector to detach the pedal assy. (do the same at the opposite side.) pedal bracket socket e socket q remove the four torque bolts x 12) of the...

Page 24

6. Moving and transporting q remove the four flange sockets x 20) from the tower assy. Detach the tower assy from the cabinet assy. After the detachment, house the portion of the harness that sticks out of the tower assy. Tower harness 20) q fix the joint cover with four torque bolts (ms x 12). If t...

Page 25

6. Movingand transporting 6-2-2 manual carrying (up or down the stairs, for example) warning . Be sure to divide this machine into the cabinet assy, signboard tower and pedal transporting any combination of assemblies without dividing them may result in an accident or injury. 5-2-i ‘dividing the sig...

Page 26

6. Moving and transporting 6-2-3 loading and unloading a vehicle or something similar warning l sure to divide this machine into the body tower and pedal assy. (see p-21, ‘dividing:) note the fork stickers when moving and transporting the body with a forklift. The tower assy is not designed to be tr...

Page 27

6. Moving and transporting 6-2-4 trucking . When transporting this machine on a vehicle, fasten the machine firmly so that it will not start moving due to or slowdown. Failure to fasten it might cause an accident. When lowering any equipment from a higher level, do not let it get shocked. L in ropin...

Page 28: Operating This Machine

7. Operating machine operating this machine warning . If any trouble should occur, off the power switch immediately and stop operating this machine. Then be sure to unplug the power cord. Operating this machine with its trouble unsolved may cause a fire or accident. . Dust accumulated on the power p...

Page 29

7. Operating machine pre-service check before beginning your service, check the items described below. If any trouble is found, take appropri- ate actions according to ‘troubleshooting.” 7-l-l appearance check warning . Check the points listed below before operating machine. These checks are require...

Page 30

The mach/ne 7-2 how to play this machine provides gun g games where players use a pedal to hide behind an object avoid an enemy attack, then get out from behind the object with their own timing to attack the enemy. 7-2-l how to control step on the pedal = attack position: at this position, you can s...

Page 31

7. Machine 7-3 adjustment 7-3-l turn on the power switch. When you are through p- “installation,” on the power switch at the bottom left of the rear of body assy. O n s w i t c h 7-3-2 adjustment switches the service door of the coin assy, and you will find adjustment switches. Switch: (a) service s...

Page 32

7. Operating machine (a) service switch (red) press this switch to increase the credit count without activating the coin counter. (b) test switch turn this switch on to enter the test mode. In the test mode, you can change game fees and other parameters and conduct various tests. (see p-31, 7-4 ‘“te...

Page 33

7. Operating this machine 7-4 test mode description of the menu screen unlock the coin door with a key furnished with this machine to open the door, then mm on test switch. The screen displays menu. Coin options i / o test ads data link malfunction 1 2 difficulty l/r:not the same -- the internal bat...

Page 34

Operating this machine (c) low-battery display l when the level is low, a message appears. You must have battery on the (1) game pc board replaced wirh a new one. Contact your dealer. Setting a game fee and free play (coin options) here you set a game fee and free play parameters. Q while on the men...

Page 35

7. 7-4-3 setting the type of game (game options) here you set the type of game. Q while on the menu screen, select game options and press the enter switch. The game options screen will then appear. Game options [default in green] player’s life 4 difficulty s o o n d o n h i - s c o r e n o yes enter...

Page 36

7. Operating this machine tests for switches test) conduct tests on the switches. Q while on the menu screen, select i/o test and press the the test screen will then appear. Dip 4 12345678 [on/off] link on 2 i/o pcb initialize solenoid test enter test screen . Q with the select switch, choose an opt...

Page 37

7. Machin e (c) pcb check this function displays a screen for checking the board i/o test dip 4 12345678 [on/off] link on 2 i/o pcb check master tx 3536 ltd. Time crisis 2; i/o pcb connect ok ltd. Exit select enter check screen press the enter switch to go back to the test screen. (d) gun initialize...

Page 38

Operating (e) switch test this function tests the various switches. I/o test dip 4 12345678 link on 2 switch test coin 0 service o f f test o n off select off enter off trigger off foot up select sw + enter switch test screen q the switch test screen displays the status of the switches. Q operating ...

Page 39

7. This machine solenoid test this function the blow-back mechanism of the gun. I/o test dip 4 12345678 [on/off] link on 2 solenoid test pull gun trigger to action m i t select enter solenoid test screen q pull the trigger to activate the gun’s blow-back mechanism. Q press the enter switch to go bac...

Page 40

7. Operating machine monitor test the monitor test performs various adjustments on the monitor. (see p-55, 8-3-l (3) “adjusting the monitor.“) while on the menu screen, select monitor test and press the enter switch. The tor test screen will then appear. Monitor test pattern crosshatch (crt) pattern...

Page 41

7. Operating machine 7-4-6 sound test the sound test function adjusts the sound volume and performs a stereo check and related operations. Q while on the menu screen. Select sound test and press the enter switch. The test screen will then appear. Sound test g r e w ] volume front l sp (o-64) 40 (o-6...

Page 42

7. Operating this machine displaying and initializing game (ads data) this function displays various game data. While on the menu screen, select ads data and press the enter switch. The ads data will then appear. Power-off does not cause data to be lost, unless you execute ads initialize or backup m...

Page 43

7. Operating machine 748 others this function initializes backup memory and conducts related operations. Q while on the menu screen, choose others and press the enter switch. The others screen will then appear. Others mon (a) rom2 fri clock --- --:--:-- - - backup initialize no yes exit select enter...

Page 44

7. Operating machine 7-5 setting the gun aiming (gun initialize) this function sets the gun aiming. While on the test screen, select gun and press the enter switch. (or on the test switch while holding down the service switch.) the gun initialize screen (fig, 1) will then appear. Gun initialize menu...

Page 45

7. Operating this machine gun initialize (crt) this function sets the gun aiming (fig. 2-i). Gun initialize (crt) shoot at screen to check gun accuracy push enter gun up select sw + fig. 2-1 gun initialize (crt) screen 1 q the screen indicated in fig. 2-1 allows you to check if the gun has the corre...

Page 46: 8. Maintenance

8. Maintenance 8. Maintenance warning . Before performing maintenance (such as troubleshooting and repairs), always off the power switch to prevent service people and other persons around them from getting an electric shock, accident, or injury. . Some parts in the projector retain high heat and vol...

Page 47

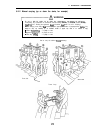

8. Maintenance 8-l-l greasing the plunger of the pedal assy -to be conducted by a technician only l grease the plunger every six months. Q loosen the four flange sockets (m6 x 20) on the cabinet body side. Remove the four flange sockets x 12) on the pedal assy, then remove the connector. Then remove...

Page 48

8. Maintenance remove the two dished-end washer nuts (m4) and remove the q remove the four dished-end nuts from the holder, then pull up the holder while pulling the plunger. Q wipe off the grease from the pedal plate. Q grease the plate and the spherical portion of the plunger. L specified grease b...

Page 49

8. 8-l-2 checking the plunger of the pedal assy for wear and tear q remove the four torque bolts 12). Then detach the cover. Torque q press the pedal with a hand and make a visual check to see if the plunger is pressing the rnicroswitch. Q if the plunger is worn and not the microswitch, replace the ...

Page 50

8. Maintenance 8-2 troubleshooting warning l before carrying out this task, always off the power switch to prevent workers and people around from getting an electric accident. Or injury and to protect the electric circuit from damage. . The case of trouble, first check that all connectors are firmly...

Page 51

Maintenance 8-2-3 signboard assy be conducted by a technician only symptom the fluorescent lamp does not light up. See page page 14 replace the glow lamp with a new one. 8-2-4 tower assy -to be conducted by a technician only symptom c a u s e action s e e e-2-5 pedal assy -to be conducted by a techn...

Page 52

8. Maintenance 8-3 disassembling, reassembling and replacing the assys and parts 8-3-i cabinet assy -to be conducted by a technician only (1) detaching and reattaching the rear cover . Before carrying out this task always off the power to prevent workers and people around them from getting an electr...

Page 53

8. Maintenance ( 2 ) replacing the monitor with a new one represents something that must not be touched. Before carrying out this task, always off the power switch to prevent workers and people around them from getting an electric shock, accident. Or and protect the electric circuit from damage. . S...

Page 54

8. Maintenance remove the pedal assy and tower assy. (see p-2 1 “dividing” to be conducted by a technician only.“) q of the torque bolts 12) at the back of the cabinet assy, loosen the and detach the top four, thus removing the maintenance panel. Torque bolt (m5 12) \ rear panel loosen emove the two...

Page 55

8. Maintenance monitor q remove the eight torque bolts (m.5 x then detach the monitor mask. Torque bolt (m5 20) 53.

Page 56

8. Maintenance q remove the four phillips hexagon bolts (with flat and spring washers) (m8 x 25) and four washers. W a r n i n g - , l the about 40kg. Work must be conducted by least workers. Q tilt the top of the monitor forwards slowly, then detach the monitor. I i phillips hexagon bolt (with flat...

Page 57

8. Maintenance (3) adjusting the monitor represents something that must not be touched. D a n g e r l the monitor is adjusted while powered on. This may therefore give you an electric shock, accident, or injury. Do not touch anything other than the parts specified in the adjustment procedure. . Some...

Page 58

8. Maintenance n e e d e d . The monitor is factory-configured to its best condition. No readjustment is detach the maintenance panel. (see p-51.8-3-1 “replacing the monitor with a new one.“) q this machine may come with a monitor having a differently-shaped frame depending on the time of production...

Page 59

8. Maintenance (a) adjustment function the adjustment boards for nanao-made monitors are as below. F i g . 1 a d j u s t m e n t board for uanao-made monitor fig. 2 adjustment board for monitor contrast (cont.) (contrast) bright (luminance adjustment) (horizontal size adjustment) (horizontal positio...

Page 60

8. Maintenance (b) getting ready for adjustment l the display position and size on the monitor varies according to the direction of this machine. Perform all adjustments with machine actually installed, whenever possible. If you have to move this machine for adjustment, adjust it with the machine or...

Page 61

8. Non-signal area white margin adjust so that the narrowest white margin may be wide or less respectively in the top. Left and right at the center border of screen screen outer frame of the green window outer frame of the black crosshatch fig. 3 adjustment of screen size and position contrast can b...

Page 62

8. Maintenance (4) detaching and reattaching the rack l before out task, always turn off the power to prevent workers and people around them from getting an electric shock, accident, or injury and to protect the electric circuit from damage. Q detach the rear cover. (see p-50.8-3-1 (1) “detaching an...

Page 63

Maintenance (5) replacing the game pc board with a new one l before out task, always off the to prevent workers and people around them from getting an electric shock, accident, or and to protect the electric circuit from damage. Q detach the rear cover. (see p-50.8-3-1 (1) “detaching and reattaching...

Page 64

8. Maintenance q remove the four phillips round head screws (with flat and spring washers) (m3 x 6) from the top board and the four studs the phillips round head screws (with flat and spring washers) x 6) from the bottom board. Detach the two game pc boards. Phillips round head screw (with flat and ...

Page 65

8. Maintenance signboard assy -to be conducted by a technician only (1) replacing the fluorescent lamp and glow lamp with new ones workers and people around them from getting an electric accident, or injury to protect the electric circuit from damage. . The fluorescent lamp can heat up to a high tem...

Page 66

8. Maintenance g-3-3 tower assy be conducted by a technician only (1) replacing the pc board with a new one before out this task, always off the power switch to protect the electric circuit from damage. L when the connectors from the pc board, always hold the p c board. . When connecting the connect...

Page 67

8. Maintenance q disconnect the four connectors of the pc board. Q remove the four cup screws (m) (m3 x then detach the pc board. Pc board c o n n e c t o r s q attach a new board in reverse order. Cup (m3 65.

Page 68

8. Maintenance 8-3-4 pedal assy be conducted by a technician only (1) replacing the microswitch with a new one before carrying out this task. Always off power switch to protect the electric circuit from damage. Remove the four torque bolts x then detach the cover. Torque bolt 12) . Q q remove the tw...

Page 69

8 . (2) replacing the plunger with a new one l before carrying out this task, always off the power switch to protect the electric circuit from damage. Detach the holder. (see “greasing the plunger of the pedal pull the plunger out of the holder, then replace it with a new one. At that time, grease t...

Page 70

8. Maintenance 8-3-5 g u n a s s y -to be conducted by a technician only (1) replacing the gun assy with a new one before carrying out this task, always off power switch to protect the circuit from damage. Remove the six torque bolts x 12) and detach the holder cover. Disconnect the two connectors. ...

Page 71

8. Maintenance (2) how to open the gun slide l before out this task, always, off the power switch to protect the circuit from damage. Remove the four cap bolts (m3 x 10). One button bolt (m4 x 25). And one box nut (m4). Then detach the gun slides (l) and gun slide button 25) gun slide (r) cap bolt h...

Page 72

8. Maintenance (3) how to open the gun cover l before carrying out this task. Always off the power switch to protect the electric circuit from damage. Remove the gun slides (l) and (r). (see p-69, 8-3-5 (2) “how to open the gun slide.“) q place the gun cover face-down, and remove the four button bol...

Page 73

8 . (4) replacing the solenoid with a new one before carrying out this task, always off the power switch to protect the electric circuit from damage. Detach the gun cover and gun slide. (see p-69.8-3-5 (2) “how to open the gun slide” and p-70.8-3-5 (3) “how to open the g u n c o v e r . “ ) disconne...

Page 74

8. Maintenance (5) replacing the microswitch with a new one l before carrying out this task, always off the power switch to protect the circuit from damage. Q detach the gun cover(r) and gun slide (r). (see p-69.8-3-5 (2) “how to open the gun slide” and p-70.8-3-5 (3) “how to open the gun cover.“) r...

Page 75

9. Discard 9. Discard warning . Before discarding this machine, collect, and dispose of its components according to relevant laws. . If you wish to entrust a third party to collect, transport. End dispose of this machine to discard, employ agents specializing in respective works. 7 3.

Page 76: 10. Parts List

Parts 10. Parts list 1 o-l cabinet assy.

Page 77

10. Parts l/st n o . Model and rating part 1 cabinet 1 671-113 sticker (inside) i i 461-376 3 rope hook i i 671-120 4 signboard hook i i 5 monitor mask 1 671-125 6 monitor mask(r) 1 7 monitor 2 (nanao) woofer 2 006-115 9 i lo242 (l 1 0 woofer cover 2 671-115 bracket i 4 4 1 3 caster 5 102-013 1 4 i ...

Page 78

1 o-2 signboard assy 7 6.

Page 79

No. Part i model and i 1 box i i i 671-211 2 stay 2 671-214 3 sianboard i 1 i l a m p i i fluorescent lamp fixture i i 6 speaker cover 1 671-215 7 mask 4 671-217 speaker i 4 i 9 signbcard side sticker(r) 1 671-263 1 0 sionboard side sticker 1 i 671-213 1 1 connector cover 1 671-216.

Page 80

10. Parts list 1 o-3 control base assy.

Page 81

7 9.

Page 82

Parts list 1 o-4 rack assy.

Page 83

P a r t s n o . Q ’ t y model and rating bracket (l) 1 461-050 2 i 1 3 i cover i i 461-716 4 5 f panel (1) 6 fan motor 7 finger guard 8 switching regulator 9 1 0 stud i i 461-717 8 1.

Page 84

10. Parts ust cord box assy.

Page 85

10. Parts list n o . Part model and rating part 1 cord box 1 671-411 2 noise filter 1 3 power switch 1.

Page 86

10. Parts list tower assy 8 4.

Page 87

10. Parts l/st no. Part 1 coin 2 beam (b) 3 main tower 1 671-611 4 back cover 671-616 5 i caster 2 i 102.064 6 cover 1 671-617 7 pipe cover 2 671-619 i pedal bracket 4 631-115 9 1 0 coin assy 1 1 gun base 1 2 holder cover 1 671-673 1 3 beam (a) 1 4 pop slicker 1 5 sticker set of pop and description ...

Page 88

10. Parts list 10-7 pedal assy 6 6.

Page 89

Parts l/st when is of the hexagon socket head button bolt [hexagon socket head button no. 1 pedal part 1 model and rating part 631-215 2 pedal 3 pedal base 1 637-211 4 1 5 spring cover 1 631-218 6 rubber plug cushion 2 tm-96, article 3 7 rubber stopper 1 631-217 8 1 631-219 9 holder 1 631-213 631-22...

Page 90

Parts list o-8 gun assy.

Page 91

Parts list gun assy (r) (red) n o . Part i model and ratina i 1 gun cover (l-r) 1 296461 2 trigger spring 1 296421 3 trigger(r) 4 solenoid i 5 tube bracket (a) 6 gun cord harness assy 7 tube bracket 8 296-424 9 gun cover (r-r) 1 1 0 g u n slide (r-r) i 1 i i 296-464 11 slide rail i i 296-425 1 2 e-t...

Page 92

10. Parts 1 o-9 coin assy 90

Page 93

10. Parts l/st n o . Front plate assy 2 coin lock 3 cover i 461-036 4 i service door(c) i i 461-713 coin door 1 6 electronics lock 1 i i 101-034 7 counter 2 003-033 6 coin 1 464-022 9 1 10 cash box(k) i 461-040 1 1 service plate (a-2p) 1 4 6 1 - 7 1 4 1 2 2 1 3 ( i c e 2 (red) i 1 4 service sticker ...

Page 94

10. Parts 92.

Page 95

I i ! I.- !.

Page 96

11. Wiring i t o w e r 1.