- DL manuals

- Nanni

- Engine

- N2.10

- Operator's Manual

Nanni N2.10 Operator's Manual

Summary of N2.10

Page 1

Nanni marine engine operator’s manual engines n2.10 n2.14 n3.21.

Page 2: English

English you can download a copy of this manual in english on nannidiesel.Com. Français vous pouvez télécharger ce manuel en français sur notre site web à l’adresse www.Nannidiesel.Com. Italiano scarica una copia del manuale in lingua italiano sul nannidiesel.Com. Deutsch sie können eine kopie dieses...

Page 3: Ontents

C ontents 1 introduction ............................. 1 about this manual .........................2 safety ........................................ 3 emergency kit ..............................3 safety alert symbols .....................3 safety icons ..................................4 safety pr...

Page 4: Ntroduction

Thank you for choosing a nanni product! Contact a nanni authorized dealer for the servicing of your product. A list of dealers can be found on our web site: www.Nannidiesel.Com nanni engines are the product of many years of experience in the deve- lopment of marine engines and equipment designed for...

Page 5: About This Manual

About this manual this operator’s manual contains important information, tips, sugges- tions and warnings. We urge you to read it carefully and familiarize yourself with the engine before starting. For your own safety and longer service life of the engine, follow the instructions and warnings contai...

Page 6: Emergency Kit

Read this chapter carefully as it concerns your safety. Most acci- dents are caused by failing to follow basic safety rules. Be aware of the possible risks involved in handling the engine and make sure to take the necessary precautions to pro- tect yourself, those around you and the equipment. Read ...

Page 7: Safety Icons

Safety icons several stickers are fixed directly on the engine. They are intended to help you to quickly identify the location of certain components and avoid possible hazards when working on the engine. Ensure these stickers are always visible and change them if neces- sary. Refers to important inf...

Page 8: Safety

Safety precautions exhaust gas exhaust gases contain carbon monoxide. This colourless and odourless gas is extremely har- mful and could lead to poisoning which could result in loss of consciousness or death. The first symptoms of carbon monoxide intoxication are as follows: • dizziness • nausea • h...

Page 9: Explosion

Immediately clean up any liquids spilled and keep the engine com- partment clean and accessible so as to minimise the risk of fire. Be careful as fuel can burn. Damaged pipes can lead to fire. Explosion explosions caused by fuel vapour can cause serious injury! Carefully follow the safety rules when...

Page 10: Battery Acid

Special attention must be brought on boat with metallic hull, especially concerning the protection of the persons against electrical shock and the protection against galvanic and electrolytic corrosion. Battery acid the acid in batteries can cause serious injury and even death! When servicing the ba...

Page 11: Accidental Starting

Accidental starting accidental starting can cause se- rious injury and even death! Disconnect the battery before wor- king on the engine. Ensure no one is alongside the engine or working on before starting it. A rotating propeller can cause serious injury or death. Ensure all the protection mechanis...

Page 12: About The Engine

About the engine engine identification both the engine and the transmis- sion has an identification plate that contain several informations. Keep these plates accessible and in good condition. Record and keep the engine and transmission serial number and designation. These numbers should always be q...

Page 13: Remote Control

Remote control the remote control is an optional extra not in the scope of supply of the engine. The remote control installed on the boat can be diffe- rent than the ones shown in this document. On most boats, the control lever controls both the engine rpm and the gear shift (ahead / astern). Howeve...

Page 14: Operation In Cold

Operation in cold weather conditions nanni engines are designed to ope- rate effectively in cold weather. However, for effective starting and cold weather operation, extra care are necessary. Contact your nanni dealer for additional infor- mation and local availability of cold weather aids. Winter g...

Page 15: Engine Homologation

Engine homologation the engine type can be exhaust emission certified. It means that nanni guarantees that all engines of the same type that are manufac- tured are approved and certified by the authorities in accordance with different exhaust emissions stan- dards. However, for the engine to be in a...

Page 16: Warranty

Warranty this manual is supplemented by a warranty information booklet. We recommend that you read this publication thoroughly. Pay special attention to the appli- cable duty cycle and to the limita- tions that result. Failure to comply with the warranty conditions will void the warranty. The validi...

Page 17: About The

About the propeller the propeller is a critical compo- nent of the propulsion system. It converts the engine power in thrust. To be efficient, the propeller must be perfectly adapted to the boat and to its use. In all cases, the propeller should allow the engine to reach its rated rpm with the maxim...

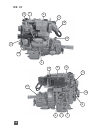

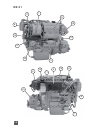

Page 18: Engine Main Components

Engine main components notice: the engine may not be exactly as represented here. Some com- ponents may not be part of the engine ordered. P/n components 1 alternator 2 alternator belt 3 starter 4 fuses box 5 air filter 6 fuel filter 7 fuel feed pump 8 fuel injection pump 9 heat exchanger 10 coolant...

Page 19: N2.10

N2.10 16 1 5 2 3 11 13 14 15 12 16 18 7 17 8 9 10 4 6 19.

Page 20: N2.14

N2.14 17 1 5 2 3 6 11 13 14 15 12 16 18 7 17 19 8 9 10 4.

Page 21: N3.21

N3.21 18 1 5 2 3 6 15 18 7 8 9 10 4 11 12 13 14 16 17 19.

Page 22: Standard Panel

I warning read the starting and stopping instructions before operating the engine. The instrument panel provides you with important informations about the engine. Notice: this chapter only des- cribes instruments and panels that come standard on nanni engines. Contact your dealer if the boat is fit-...

Page 23: Instrumentation

Instrumentation tachometer & warning lamps the analog tachometer displays the engine speed. Multiply the indicated value by 100 to get the revolutions per minute of the engine. The function of the warning lamps is explained in the following pages. Rpm x 100 hourmeter & voltmeter the display at the b...

Page 24: Engine Oil Pressure

Engine oil pressure indicator notice: this indicator does not show the engine oil level. This indicator shows the oil pressure in bar and psi. If the oil pressure in the lubrication circuit is too low, the acoustic alarm sounds and the corresponding war- ning lamp comes on. Coolant temperature indic...

Page 25: Warning Lamps

Warning lamps coolant temperature this warning lamp comes on and the alarm sounds when the coolant temperature is too high. I danger never open the coolant filler cap or any plug of the cooling system when the engine is warm. Steam or hot fluid can spray out. I caution if this alarm comes on while...

Page 26

Preheating this lamp comes on when the glow plugs (if fitted) are activated. Engine oil pressure this warning lamp lights up and the alarm sounds when the engine oil pressure is too low. I caution if this alarm comes on while operating the engine, stop the engine, except in extreme emer- gencies, ...

Page 27: Note

Note 24.

Page 28: Before Starting

Before starting i warning put all the protective covers back before starting the engine. I caution open the sea cock (if equipped) before starting the engine. The raw water pump impeller will be damaged if it runs dry even for few seconds, and may lead to engine overheating. Perform all of the follo...

Page 29: Starting The

Starting the engine i danger the propeller can cause se- rious injury when rotating. Check that nobody is in the water near the propeller before starting. never use a start spray or any other equivalent product these products are highly flammable. I caution always preheat the engine. Never rac...

Page 30: Panel With Key

Panel with key 1. Move the control lever to the neutral position. 2. Push the manual stop control (if fitted). 3. Insert the key in the on/stop starter switch. 4. Turn the key a quarter-turn to the right. All the warning lamps come on and the acoustic alarm sounds. After a few seconds, only the engi...

Page 31: During Operation

During operation i caution never press the start button when the engine is running. Check the instruments and warning lamps after starting, and regularly when cruising. Cruising speed a recommended engine speed is given in the chapter technical data to help you to set your crui- sing speed. Notice: ...

Page 32: Sailing With The Engine

Sailing with the engine stopped if the engine is fitted with a sail drive transmission model sp60, when cruising under sail with the engine stopped: if the blades of the propeller are foldable: • put the throttle lever astern (in reverse). The blades are closed when the boat moves forward. Hydrodyna...

Page 33: Stopping The

Stopping the engine i caution never stop the engine by using the main switch. This could da- mage the electrical system. Before stopping the engine, let it run at idle in neutral for few mi- nutes, especially if the engine has been operated at high speed and load. This will allow the coolant to cool...

Page 34: Anchoring

Anchoring when the boat is at anchor or in port for extended period, vegetation may develop on the hull, the keel, the drive, the rudder, the propel- ler, etc. It will significantly affect the behaviour of the boat and the performance of the engine if the vegetation is not removed before the next ti...

Page 35: Aintenance

I warning as far as possible, perform maintenance operations with the engine stopped, remove the key from the panel and turn off the power supply. read this whole chapter and all safety precautions before starting any maintenance work. Make sure you understand how to perform every operation. Thi...

Page 36: Service Schedule

Service schedule notice: an operation requiring service every day requires service after 100 hours or every year, and so on. Some components may not be part of the engine ordered. Operations marked with should be done in a nanni workshop. * operations to perform after 20 operating hours or 45 days...

Page 37

Every 200 operating hours / at least every year. change the engine and transmission oil *. change the oil filters *. change the fuel filters *. check the raw water pump impeller. Change if needed. check the engine flexible mountings. Adjust as necessary *. clean the turbo wastegate. cl...

Page 38: General

General inspection i caution do not let oil, fuel or grease deposits build up around the engine as they may increase the risk of fire in the engine compart- ment. Make a habit of visually checking the engine and its compartment each time you operate the boat, before starting the engine: check for fu...

Page 39: Exhaust System

Exhaust system inspect all exhaust system com- ponents (hoses, clamps, mixing elbow, manifold, etc.) check for cracks, leaks and corrosion. Tight or change them if necessary. Check for carbon or soot residue on exhaust components as it indicates an exhaust leak. If any defect appears on compo- nent ...

Page 40: Fuel System

Fuel system i danger stop the engine and let it cool down before refuelling or carrying out any operation on the fuel system. I warning fuel is flammable and can be dangerous. Fuel spilled on hot surface or near spark can burn. do not step on the injection pipes. Always make sure they are not ...

Page 41: Fuel Requirements

Fuel requirements only use grade of fuels indicated in the chapter technical data. Other grades of fuel can increase fuel consumption and cause opera- ting problems, resulting in a shorter engine service life. Use of fuel additives can result in poor performance or engine damage. Before starting the...

Page 42: Replacing The Fuel Filter

Replacing the fuel filter notice: do not fill the new filter with fuel before assembly. Engine model n2.10: n2.10 1. Close the fuel cock. Clean the filter bracket. 2. To avoid fuel leakage, clamp off the fuel supply line near the filter. 3. Disconnect the hoses. Clean-it. 4. Remove the fuel filter ....

Page 43: Air Bleeding

Air bleeding bleeding the air in the fuel system is necessary : • after a maintenance operation on the fuel system. • if the fuel tank has been emp- tied. • the engine has not been started for a long time. To bleed the fuel system if it is not fitted with an electric pump: 1. Fill totally the fuel t...

Page 44: Lubrication

Lubrication system i danger carry out these operations with the engine stopped and cold. Remove the key and switch off the main switch to prevent acci- dental starting. Hot oil and hot surfaces can burn. I caution never operate the engine if the oil crankcase has been over- filled. Drain the oil i...

Page 45: Draining The Engine Oil

Draining the engine oil 1. Start the engine and let it warm few minutes so that oil suction is easier. 2. Stop the engine and remove the key from the panel. 3. Connect a disposal hose to the drain pump and place a container under the disposal hose. Notice: on the engine model n2.10, the oil pump has...

Page 46: Cooling System

Cooling system overview the cooling system cools the en- gine in order to maintain a proper operating temperature and prevent overheating. On some engines, the cooling system also cools the fuel, the oil or the intake air. The cooling system is made of two circuits: • the coolant circuit which is th...

Page 47: Coolant

Coolant i caution always use coolant made of 50% antifreeze with anticorro- sion additive and 50% of clean water. The antifreeze protects the engine against internal cor- rosion. this mix must be used all year around, even if there is no risk of frost. never use water alone to completely fill ...

Page 48: Coolant Level

Coolant level i danger never open the coolant filler cap or any plug of the cooling system when the engine is operating or warm. Steam or hot fluid can spray out. Always check the coolant level before starting the engine. 1. Stop the engine and remove the key from the panel. 2. Turn the coolant fill...

Page 49: Coolant - Filling

Coolant - filling mix the anti-freeze with water in a clean container before filling the heat exchanger. The coolant must be totally free from dust. Fill the exchanger slowly not to introduce air into the coolant system. Refer to the chapter technical data to know the coolant capacity of the heat ex...

Page 50: Raw Water System

Raw water system i danger when the boat is in the water, water can flow into the boat via components located below the waterline. Close the raw water cock (if fitted) or prevent water discharge before working on this raw water system. The raw water system allows to cool the engine coolant and the ex...

Page 51: Raw Water Pump Impel-

Raw water pump impel- ler i caution if the engine has been run wi- thout supply of raw water, check the raw water pump impeller. Change it if needed. The raw water pump impeller is an essential component of the engine. It should be changed regularly along with the seal. A worn impeller could crack a...

Page 52: Cleaning The Raw Water

Cleaning the raw water filter a raw water filter must be fitted between the raw water intake and the raw water pump of the engine. The model of prefilter can vary according the boat as the raw water filter is an optional extra not in the scope of supply of the engine. These instructions are given as...

Page 53: Raw Water System -

Raw water system - cleaning and inhibiting the raw water system must be flushed with fresh water to prevent the buildup of deposits and salt crystals in the circuit. It must also be protected against corrosion and frost when performing long-term storage. 1. Stop the engine and close the sea cock. 2....

Page 54: Electrical System

Electrical system i danger stop the engine and switch off the main switches to break the current before working on the electrical system. Isolate shore current to any accessories mounted on the engine. I caution the main switch should always be switched on when the engine is operating. Never disconn...

Page 55: Battery

Battery i danger never touch the battery electrolyte. The diluted sulphu- ric acid solution burns skin and make holes in clothing. Should this occur, immediately wash it off with plenty of clean water and obtain medical assistance without delay. disconnect the battery leads before carrying out a...

Page 56: Alternator Belt

Alternator belt i danger stop the engine and remove the key before servicing the alterna- tor belt. Always keep a replacement belt on-board. The alternator belt drives both the coolant pump and the alternator. Additional belt can also be fitted. A loosen or damaged belt can result in overheats or in...

Page 57: Corrosion

Corrosion protection the engine and all metal item in the boat that are exposed to water or damp can be damaged by corro- sion. There are two main categories of corrosion, which can be cumulative: galvanic corrosion and electrolytic corrosion. Both corrosion pro- cesses are a result of electric cur-...

Page 58: Electrolytic Corrosion

Electrolytic corrosion electrolytic corrosion is caused by externally generated dc electrical currents that pass through a metal item to another in an electrolyte such as raw water. Electrolytic corrosion is especially due to circuit leakage currents, shore power sys- tems or dc ground faults. The c...

Page 59: Engine Anode

Engine anode in order to protect the engine and its raw water system from corro- sion, the engine is fitted with a zinc anode. Intervals given in the service sche- dule are recommendations. Depen- ding upon operating conditions and raw water properties, it might be necessary to check and/or change t...

Page 60: Long Term

Long term storage a set of operations must be per- formed to prepare and protect the engine for a long-term storage. Refer to the corresponding chapter in the maintenance section to perform some of these operations. We recommend that you have all these operations carried out by a nanni authorized wo...

Page 61: Restarting The Engine

I caution do not point a high pressure water jet toward seals, hoses, grommets, etc. 13. Clean the hull, the hold and the drive (if fitted). 14. Check all control cables. Use grease and rust inhibitor to pro- tect the cables. 15. Disconnect battery leads. Ad- just electrolyte level if necessary. Cha...

Page 62: Roubleshooting

If the engine does not function properly, use the following chart to identify the cause. If the cause of trouble can not be found, contact a nanni autho- rized workshop. Notice: some components may not be part of the engine ordered. This list is not exhaustive and is only an assistance in case of em...

Page 63

1. Lack of fuel 2. Air in fuel system 3. Fuel filter fouled or clogged 4. Fuel do not meet specified standard 5. Water/contaminants in fuel 6. Valve clearance is wrong * 7. Low compression * 8. Insufficient battery charge / defective battery 9. Faulty electrical cables contact 10. Faulty starter or ...

Page 64: Echnical

61 model n2.10 n2.14 n3.21 engine characteristics type 4 strokes diesel max. Power - kw (hp)* 7.36 - 10 10.3 - 14 15.4 - 21 number of cylinders / arrangement 2 in line 2 in line 3 in line displacement (cm 3 ) 479 479 719 bore and stroke (mm) 67 - 68 air intake natural compression ratio 23.5:1 idle s...

Page 65

62 model n2.10 n2.14 n3.21 electrical system recommended starter battery capa- city (ah) 35 ~ 50 starter (kw) 0.8 1.0 standard alternator (v-a) 12 - 40 12 - 70 12 - 70 fuel system injection system indirect (e-tvcs) injection timing before tdc (°) 21 fuel injection pressure (bar) 137.3 specific fuel ...

Page 66: Note

63 note.

Page 68: Www.Nannidiesel.Com

Nanni industries sas 11,avenue mariotte-zone industrielle 33260 la teste france tel: + 33 (0)5 56 22 30 60 fax: +33 (0)5 56 22 30 79 email: contact@nannidiesel.Com www.Nannidiesel.Com p/n 970316081 082013.Inda.