- DL manuals

- Natco

- Water Heater

- ANSI Z 21.10.3

- Service Manual

Natco ANSI Z 21.10.3 Service Manual

member

gama

ANSI Z 21.10.3

NATIONAL COMBUSTION CO. INC.

104-11 180

TH

STREET

JAMAICA, NY 11433

TEL.: 1-718-291-8400 and 1-888-OK-NATCO

FAX: 1-718-291-6870 (sales, cust. svc.)

......or visit our website at: www.nationalcombustion.com

© 2006, 2005, 2004 National Combustion Co., Inc.

PAGE: 1

LP-41 REV: 1/1/06

OPERATING, INSTALLATION, AND

SERVICE MANUAL FOR THE

VOYAGER

GAS FIRED WATER HEATER

SUPER HIGH EFFICIENCY GAS FIRED WATER HEATING COMBINATION APPLIANCE

Summary of ANSI Z 21.10.3

Page 1

Member gama ansi z 21.10.3 national combustion co. Inc. 104-11 180 th street jamaica, ny 11433 tel.: 1-718-291-8400 and 1-888-ok-natco fax: 1-718-291-6870 (sales, cust. Svc.) ......Or visit our website at: www.Nationalcombustion.Com © 2006, 2005, 2004 national combustion co., inc. Page: 1 lp-41 rev:...

Page 2

Page: 2.

Page 3

Limiting valves are available. Tems, the water meter has a no return or back flow device built into the system to prevent back flowing of water back into city mains. Some require back flow preventers on all incoming water supplies. Under these circumstances, you will need a hot water expansion tank ...

Page 4

Domestic water connection the domestic water connections must be installed in accordance to all local and national plumbing codes, or any applicable standard which prevails. The inlet and outlet ports of the super-e are 1" on 45 gallon models. On the 80 and 119 gallon models, the inlet and outlet po...

Page 5

Page: 5 caution a domestic hot water tempering/anti-scald valve should be installed into hot water line to prevent the maximum outlet water temperature from exceeding 119 degrees f. As per the national standard plumbing code, to prevent scald injury. Electrical connection the electrical connection f...

Page 6

Warning the gas valve is a special gas valve which has a pressure augmented regulator feature, as well as negative outlet pressure. This valve must not be replaced with a conventional valve under any circumstances. Make sure valve is in the “off”position prior to turning gas supply on. As an additio...

Page 7

12) it is recommended that you use one of the mentioned vent kits specifically for voyager installations; either kgavt0501cvt (2 in.), kgavt0601cvt (3 in.), or v1000. Cleaner / cement cement for all venting must be all purpose cement, and must conform to astm d-2235, d-2564 and f-493, and cleaner fo...

Page 8

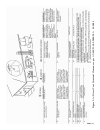

Page: 8 venting examples (note: shown as intake & exhaust pipe and fittings added together) * = minimum vent length ** = maximum vent length total equivalent grand total combined friction total vent length vent length loss friction (feet) (feet) qty. (feet) loss with fitting intake & of 90° for each...

Page 9

Warning it is extremely important to follow these instructions exactly. Failureto follow instructions exactly could result in fire, injury or death. Special venting instructions for 2" vented ssv100r, & ssv130r models only. For 3" vented models, see page 5. Venting ssv100r and ssv130r only inlet air...

Page 10

Used to determine the operating status of the appliance and provide assistance when troubleshooting any problems which may occur. All indicators are of the solid state variety and should last for the life of the appliance. The controller has sufficient built-in memory to retain the programmed temper...

Page 11

Overall appliance and control operation a normal operating sequence is as follows: 1. The control determines that the actual water temperature inside tank is 4 degrees f., with the factory set 8 degree f. Differential, below programmed temperature set point; the control performs selected system diag...

Page 12

Page: 12.

Page 13

Propane/lp gas conversion from natural gas = .250" 100,000 btu super-e’s- air orifice = 1.125" gas orifice sizes- natural gas = .280" propane/lp gas = .235" natural gas conversion from propane/lp = .285" propane/lp gas conversion from natural gas = .250" page: 13 low voltage cable assembly (710b0041...

Page 14

Page: 14 very important set-up instructions! If you have a combustion analyzer, the following ratings will be very helpful in setting up your super-e: for natural gas - co2 reading should be between 9 ½% & 10 ½% o2 reading should be between 3 ½% & 4 ½% co reading should be under 10 ppm for propane g...

Page 15

Page: 15.

Page 16

Page: 16.

Page 17

Page: 17.

Page 18

Page: 18.

Page 19

Page: 19.

Page 20

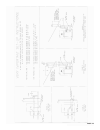

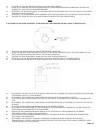

Page: 20 please note: the methods described are suggested generic methods only. Specific job site observations and sizing may require alternate installation methods. Refer to fig. 3a pg. 21 for further details. 1) never vent into a walkway or patio area, or any alley, or otherwise public area less t...

Page 21

Page: 21 fi g u re 3 -a : direc t v ent t erm inal cle a rance s per ansi z 21. 10. 3 -2 004 /c sa 4 .3 -20 04.

Page 22

Page: 22.

Page 23

Page: 23.

Page 24

Page: 24.

Page 25

Page: 25.

Page 26

Page: 26.

Page 27

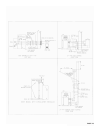

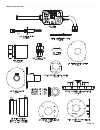

Page: 27 complete tear down procedure tools required: 5/16" nut driver ¼" flat head screwdriver 3/8" deep socket #2 phillips head screwdriver 7/16" deep socket 10" pipe wrench ½" deep socket 1 ¼" drive inch pound torque 3/8" wrench wrench (range 0-200) 7/16" wrench snap ring or needle nose pliers no...

Page 28

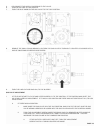

Urner mounting flange gasket with a new gasket, b prayed with permatex high tack spray-a-gasket adhe urner with the flat side of the flange facing dow lower outlet flange gasket with a new gasket. Be prayed with permatex high tack spray-a-gasket adhe on burner mounting flange. Be sure that the sight...

Page 29

Nto the end of the air inlet manifold. Apter over the end of the air inlet manifold unti ts the end of the air inlet manifold. Pter by hand, with 1/8" pipe thread facing up. Ss barb back into the trap adapter with a 7/16" d op of the split union with hole facing up, as sh page: 29 20. Re-connect the...

Page 30

Page: 30 parts illustrations.

Page 31

Lear vinyl hose that connects between the gas valve and the page: 31 6. Remove the c trap adapter. Gas valve replacement - removal 1. Shut off power to the super-e. 2. Remove the door from the super-e cabinet. 3. Shut off the gas valve by turning the blue knob on the valve to the "off" position. 4. ...

Page 32

Page: 32 4. Re-connect the clear vinyl hose to the gas valve and to the trap adapter. 8. Slide the gas valve out through the front of the voyager cabinet. Remove the gas valve wiring harness from the gas valve. Gas valve replacement - installation note: if you have two manometers available, then fol...

Page 33

Page: 33 9. Turn the line voltage back on, to the super-e. Gas valve adjustment i. Let the unit start to cycle and listed carefully to the ignition. If the ignition was quiet, the valve will need no adjustment. If it was a loud ignition or there was not ignition at all, follow these steps: a. If the...

Page 34

Page: 34 2. Put a 1/8" npt hose barb in place of the outlet pressure tap plug. No sealant is required on this fitting. 3. Re-connect the gas valve wiring to the gas valve. 4. Slide the gas valve back into position by putting the gas valve inlet pipe through the gas valve inlet hole in the left-top o...

Page 35

Page: 35 11. Turn the line voltage back on to the super-e. 10. Remove the small round brass plug from the gas valve by turning it counter-clockwise with a small punch and hammer. 7. Re-connect the supply gas piping to the valve. 8. Turn on the gas to the super-e. 9. Turn the blue knob on the gas val...

Page 36

Page: 36 20. Put the super-e cabinet door back in place. 13. If there was no ignition: a. Make sure the gas valve in the "on" position, gas is on to the unit, and the gas valve wiring harness is plugged into the gas valve and into the control board. B. Turn the adjustment screw under the brass cap y...

Page 37

Page: 37 important instructions for ssvh models how thesystem works withradiantheat both the super-e ssv and ssvh models are very efficient and powerful water heating devices. The super-e ssv and ssvh models produce larger amounts of hot water in a very small compact design, when compared with conve...

Page 38

Page: 38 note: these overall dimensions are approximate within +/– 1". Heat transfer products reserves the right to change or discontinue models without notice. Note: a bronze circulator between the domestic hot water outlet and domestic cold water inlet is required to achieve ratings below: voyager...

Page 39

Very important!!! This super-e has the new 1200 board and blower system! The additional features are listed below: 1. The board will detect proper polarity by illuminating the green led light located on the lower right corner of the board. No light means improper polarity! 2. The blower cable and th...

Page 40

Page: 40