Warning if the information in this manual is not followed exactly, a fire or explosion may result causing property damage, personal injury or loss of life. Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance. What to do if you smell gas •...

National combustion co., inc. Page 2 section 1. General information 1.1 introduction ...................................................... 3 1.2 model identifi cation .......................................... 4 1.3 warranty .......................................................... 4 1.4 dimension...

Fire coil 85 (200, 300, 400) page 3 section 1. General information using this manual – because the fire coil 85 boilers and fire coil 85 water heaters are identical appliances, with the exception of materials of manufacture, labels and ultimate use application, this manual provides information for t...

National combustion co., inc. Page 4 all installations must be made in accordance with: 1) in the u.S., the " national fuel gas code "ansi z223.1/nfpa54, latest edition and all applicable local codes as required by the authorities having jurisdiction (ahj), or 2) in canada, the "natural gas and prop...

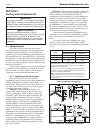

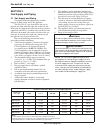

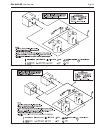

Fire coil 85 (200, 300, 400) page 5 figure 1a. Dimensional data - non pump mounted. *air and vent connections may be on top or back of the fire coil 85, and are fi eld convertible. Model a combustion air connection b* vent connection c* horizontal (cat iii) vent pipe size in. Cm in. Cm in. Cm in. Cm...

National combustion co., inc. Page 6 figure 1b. Dimensional data - pump mounted. *air and vent connections may be on top or back of the fire coil 85, and are fi eld convertible. Model a combustion air connection b* vent connection c* horizontal (cat iii) vent pipe size in. Cm in. Cm in. Cm in. Cm 20...

Fire coil 85 (200, 300, 400) page 7 the dimensions and requirements that are shown in table 2 should be met when choosing the locations for the appliance. 1.6 locating pump-mounted water heater with respect to storage tank(s) for best results, a pump-mounted fire coil 85 water heater should be locat...

National combustion co., inc. Page 8 section 2. Venting and combustion air warning for indoor installations, as an additional measure of safety, natco strongly recommends installation of suitable carbon monoxide detectors in the vicinity of this appliance and in any adjacent occupied spaces. Avertis...

Fire coil 85 (200, 300, 400) page 9 2.1.2 intake combustion air the combustion air can be taken through the wall, or through the roof. When taken from the wall, it must be taken from out-of-doors by means of the natco horizontal wall terminal (see table 1). When taken from the roof, a fi eld-supplie...

National combustion co., inc. Page 10 avertissement le fonctionnement d’appareils connectés à un évent commun bouché peut provoquer de sérieuses blessures corporelles ou la mort. Des dispositifs de sécurité doivent être mis en place pour empêcher que les appareils soient utilisés avec un évent commu...

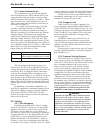

Fire coil 85 (200, 300, 400) page 11 u.S. Installations (see note 1) canadian installations (see note 2) a= clearance above grade, veranda, porch, 12 inches (30 cm) 12 inches (30 cm) deck, or balcony b= clearance to window or door that may direct vent only: 12 inches (30 cm) be opened other than dir...

National combustion co., inc. Page 12 6. If the boiler or water heater uses ducted combustion air from an intake terminal located on the same wall, locate the vent terminal at least 3 feet (0.9m) horizontally from the combustion air terminal, and locate the vent terminal at least 1 foot (0.3m) above...

Fire coil 85 (200, 300, 400) page 13 1. Detailed instructions for the installation of the venting system design or the venting system components; and 2. A complete parts list for the venting system design or venting system. (d) manufacturer requirements – gas equipment venting system not provided. W...

National combustion co., inc. Page 14 above, return doors, windows, exhaust fans, fi replace dampers and any other gas burning appliance to their previous conditions of use. 7. Any improper operation of the common venting system should be corrected so that the installation conforms with the national...

Fire coil 85 (200, 300, 400) page 15 section 3. Gas supply and piping 3.1 gas supply and piping gas piping should be supported by suitable hangers or fl oor stands, not by the appliance. The fire coil 85’s gas train allows the user to pipe the gas from either the right side or the left side of the u...

National combustion co., inc. Page 16 section 4a. Water connections — fire coil 85 boiler 4a.1 heating system piping: hot supply connections — boiler note: this appliance must be installed in a closed pressure system with a minimum of 12 psig (82.7 kpa) static pressure at the boiler. Hot water pipin...

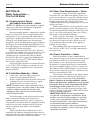

Fire coil 85 (200, 300, 400) page 17 model (size) 20°f 25°f 30°f 35°f flow gpm h/l feet flow gpm h/l feet flow gpm h/l feet flow gpm h/l feet 200 17 1.6 14 1.0 11 0.7 10 0.5 300 26 3.5 20 2.3 17 1.6 15 1.2 400 34 6.3 27 4.0 23 2.8 19 2.1 metric equivalent model (size) 11°c 14°c 17°c 19°c fl ow lpm h...

National combustion co., inc. Page 18 figure 5. Hydronic piping — multiple boilers, low temperature system. Figure 6. Hydronic piping — one boiler, multi-temperature system..

Fire coil 85 (200, 300, 400) page 19 figure 7. Hydronic piping — primary-secondary, reverse-return. Figure 8. Hydronic piping — primary-secondary, reverse-return, low temperature..

National combustion co., inc. Page 20 section 4b. Water connections — fire coil 85 water heater 4b.1 water system piping — water heater hot water piping should be supported by suitable hangers or fl oor stands. Do not support piping with this appliance. Due to expansion and contraction of copper pip...

Fire coil 85 (200, 300, 400) page 21 temperatures higher than required for other uses, an anti-scald mixing or tempering valve shall be installed to temper the water for those uses in order to reduce scald hazard potential. 4b.5 freeze protection — water heater although fire coil 85 water heaters ar...

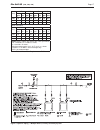

National combustion co., inc. Page 22 figure 9. Water heater piping — one heater, one tank. Figure 10. Water heater piping — multiple heaters, one tank..

Fire coil 85 (200, 300, 400) page 23 figure 11. Water heater piping — one heater, multiple tanks. Figure 12. Water heater piping — multiple heaters, multiple tanks..

National combustion co., inc. Page 24 section 5. Electrical connections warning the appliance must be electrically grounded in accordance with the requirements of the authority having jurisdiction or, in the absence of such requirements, with the latest edition of the national electrical code, ansi/...

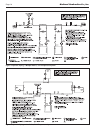

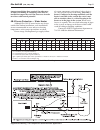

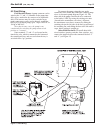

Fire coil 85 (200, 300, 400) page 25 figure 14. Field wiring. 5.2 field wiring field installed pump: a pump contactor can be wired to the “2” and “4” terminals on the pump time delay relay, attached to dry contacts of an adjustable delay. The contacts may be used to switch a larger pump contactor or...

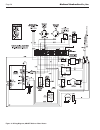

National combustion co., inc. Page 26 figure 15. Wiring diagram, on/off boiler or water heater..

Fire coil 85 (200, 300, 400) page 27 figure 16. Wiring diagram, 2-stage boiler or water heater.

National combustion co., inc. Page 28 figure 18. Logic diagram, 2-stage boiler or water heater. Figure 17. Logic diagram, on/off boiler or water heater..

Fire coil 85 (200, 300, 400) page 29 section 6. Operating instructions 6.1 filling the boiler system 1. Ensure the system is fully connected. Close all bleeding devices and open make-up water valve. Allow system to fi ll slowly. 2. If make-up water pump is employed, adjust pressure switch on pumping...

National combustion co., inc. Page 30 strip labeled "input stage 1." the input for stage 2 is initiated by closing the circuit between the 2 terminals on the terminal strip labeled "input stage 2." 6.4 sequence of operation the pump time delay relay will receive a signal to initiate. If the unit is ...

Fire coil 85 (200, 300, 400) page 31 6.6 operating the burner and set-up 6.6.1 set-up for 0 to 2500 feet altitude the setup must be checked before the unit is put in operation. Problems such as failure to start, rough ignition, strong exhaust odors, etc. Can be due to improper setup. Damage to the f...

National combustion co., inc. Page 32 6.8 to restart the fire coil 85 if drained, follow section 6.1 in this manual for proper fi lling and purging. 1. Switch off the main electrical disconnect switch. 2. Close all manual gas valves. 3. Wait five (5) minutes. 4. Set the aquastat or thermostat to its...

Fire coil 85 (200, 300, 400) page 33 a qualifi ed service technician inspect the basic items listed below every year. A. Ignition control b. Ignitor c. Water temperature control d. Automatic gas valve e. Pressure switches and tubing f. Blower g. High limit h. Pump (if required) i. Relays j. Flow swi...

National combustion co., inc. Page 34 wires, remove the mounting screws and remove the transformer. Replace transformer in the reverse order. 7.2.8 flow switch the fire coil 85 uses a paddle-type fl ow switch to ensure that the unit has water fl ow before ignition is allowed. To replace the fl ow sw...

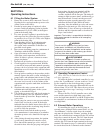

Fire coil 85 (200, 300, 400) page 35 section 8. Trouble shooting 8.1 resolving lockouts there are many causes of lockouts. The three most common causes are: (1) inadequate gas supply, (2) poor combustion, (3) ignitor failure. 1. Inadequate gas supply: before proceeding, ensure that the gas supply ha...

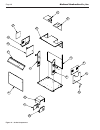

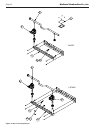

National combustion co., inc. Page 36 item description model 200 model 300 model 400 combustion chamber components see figure 20 1 base assembly 2c1000 3c1000 4c1000 2 support, tile notch 2c2019 3c2019 4c2019 3 chamber, refractory, heat exchanger t2108802 t2108803 t2108804 4 assembly, front panel, c...

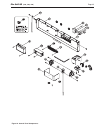

Fire coil 85 (200, 300, 400) page 37 jacket components see figure 21 40 panel, front, jacket r2c3320 r3c3320 r4c3320 41 panel, rear, jacket 2c3220 3c3220 4c3220 42 panel, top, jacket 2c3021 3c3021 4c3021 43 panel, jacket, control access 2f3019 3f3019 4f3019 44 panel, hx side access, jacket 2c3620 2c...

National combustion co., inc. Page 38 85 spacer, gas orifi ce f2022400 f2022400 f2022400 86 gas valve, combination, nat. (dsi) 3/4" npt x 3/4" npt v0079400 v0079400 v0079400 gas valve, combination, lp (dsi) 3/4" npt x 3/4" npt v0079500 v0079500 v0079500 87 cover, gas inlet, air box 2c2018 2c2018 2c2...

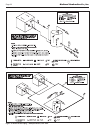

Fire coil 85 (200, 300, 400) page 39 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 22 23 24 25 26 27 28 29 30 31 31 31 31 31 32 20 21 19 figure 20. Combustion chamber components..

National combustion co., inc. Page 40 figure 21. Jacket components. 40 41 42 48 51 43 44 45 46 47 49 50 52 53 54 54 55.

Fire coil 85 (200, 300, 400) page 41 60 61 62 63 63 64 64 65 65 66 66 73 67 68 69 70 71 72 figure 22. Heat exchanger components..

National combustion co., inc. Page 42 80 81 85 84 84 86 87 on/off 80 82 83 85 86 86 2 stage figure 23. Gas train components..

Fire coil 85 (200, 300, 400) page 43 figure 24. Control panel components..

H2341 100- dimensions and specifications subject to change without notice in accordance with our policy of continuous product improvement. Ph: 1-888-ok-natco • fax: 718-291-6870 (customer service, applications, technical service) 104-11 180th street, jamaica, ny 11433 • 718-291-6870 email: sales@nat...