Installation and operation instructions document 1241 h2xxxxxxx- hydronic boiler model f85h volume water heater model f85v sizes 500–2000 mbtu/h warning if the information in this manual is not followed exactly, a fire or explosion may result causing property damage, personal injury or loss of life....

National combustion co., inc. Page 2 table of contents section 1. General information 1.1 introduction ........................................................ 3 1.2 model identification ............................................ 3 1.3 warranty ........................................................

Fire coil 85 (500-2000) page 3 section 1. General information using this manual – because fire coil 85 boilers and water heaters are identical appliances, with the exception of materials of manufacture, labels and ultimate use application, this manual provides information for the proper installation...

National combustion co., inc. Page 4 9 fuel n = natural gas p = propane 10 altitude a = 0–10,000 feet 11 location c = indoor and outdoor 12 firing mode k = two-stage 13 revision 1 = first version of design 14 heat exchanger b = glass-lined cast iron / copper / bronze trim (std. On water heaters) c =...

Fire coil 85 (500-2000) page 5 respect to return/supply header for the best results, a pump-mounted fire coil 85 boiler should be located within 15 feet (4.6m) of the supply and return headers. The pump is sized for 30 feet (9.1m) of piping. If the appliance must be installed with longer piping runs...

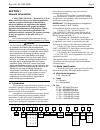

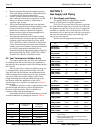

National combustion co., inc. Page 6 air vent conn. Conn. Size a b c d e f w v 500 33¾ 86 16¾ 43 6½ 17 10 25 8 20 46¼ 117 6 15 8 20 750 45¾ 116 22¾ 58 6½ 17 10 25 9½ 24 58¼ 148 6 15 10 25 1000 57¾ 147 28¾ 73 6½ 17 10 25 9½ 24 70¼ 178 8 20 10 25 1250 68¼ 173 34¼ 87 10¼ 26 10 25 9 23 80¾ 205 8 20 12 3...

Fire coil 85 (500-2000) page 7 the appliance has/have sufficient power to pull air and vent properly when the following guidelines for horizontal air and vent are followed ( see table 2 ). Note: the vent collar size is larger than the size of the vent pipe that can be used. Vent collar size and hori...

National combustion co., inc. Page 8 in addition to air needed for combustion, air shall also be supplied for ventilation, including all air required for comfort and proper working conditions for personnel. The fire coil 85 loses less than 1 percent of its input rating to the room, but other heat so...

Fire coil 85 (500-2000) page 9 route the vent pipe to the heater as directly as possible. Seal all joints and provide adequate hangers as required in the venting system manufacturer’s instal- lation instructions. Horizontal portions of the venting system must be supported to prevent sagging and may ...

National combustion co., inc. Page 10 u.S. Installations (see note 1) canadian installations (see note 2) a= clearance above grade, veranda, porch, 12 inches (30 cm) 12 inches (30 cm) deck, or balcony b= clearance to window or door that may be 4 feet (1.2 m) below or to side of opening; 36 inches (9...

Fire coil 85 (500-2000) page 11 the vent terminal ( see figure 3 ). Seek local municipalities and their codes for appropriate installation techniques. From massachusetts rules and regulations 248 cmr 5.08: (a) for all side wall horizontally vented gas fueled equipment installed in every dwelling, bu...

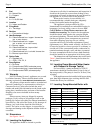

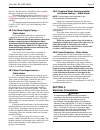

National combustion co., inc. Page 12 size distance from gas meter and or last stage regulator gas type 0-100' 100-200' 200-300' 500 natural 1½" 2" 2" 500 propane 1" 1½" 1½" 750 natural 2" 2" 2½" 750 propane 1½" 1½" 2" 1000 natural 2" 2½" 3" 1000 propane 1½" 2" 2½" 1250 natural 2½" 2½" 3" 1250 propa...

Fire coil 85 (500-2000) page 13 proceeding with the installation. 1. Verify that the appliance is fitted for the proper type of gas by checking the rating plate. Fire coil 85 appliances are equipped to operate at elevations up to 10,000 feet (3050m). Fire coil 85 appliances may be adjusted to operat...

National combustion co., inc. Page 14 combustibles for hot water pipes. Pipe the discharge of the relief valve (full size) to a drain or in a manner to prevent injury in the event of pressure relief. Install an air purger, an air vent, a diaphragm-type expansion tank, and a hydronic flow check in th...

Fire coil 85 (500-2000) page 15 this line. The line must be installed to allow complete drainage of both the valve and the line. Suggested piping diagrams are shown in figures 10 through 13 . These diagrams are meant only as a guide. Components required by local codes must be properly installed. The...

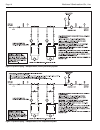

National combustion co., inc. Page 16 figure 6. Hydronic piping — multiple boilers, primary secondary system. Figure 7. Hydronic piping — multiple boilers, low temperature system..

Fire coil 85 (500-2000) page 17 figure 8. Hydronic piping — one boiler, multi-temperature system. Figure 9. Hydronic piping - primary-secondary, reverse-return..

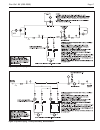

National combustion co., inc. Page 18 figure 10. Hydronic piping - primary-secondary, reverse-return, low temperature. Figure 11. Water heater piping — one heater, one tank..

Fire coil 85 (500-2000) page 19 figure 12. Water heater piping — multiple heaters, one tank. Figure 13. Water heater piping — one heater, multiple tanks..

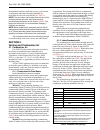

National combustion co., inc. Page 20 figure 14. Water heater piping — multiple heaters, multiple tanks. Table 9. Water flow requirements — f85v. Unit gpm ft temp rise °f lpm m temp rise °c size s n h s n h s n h s n h s n h s n h 500 45 68 90 1.8 2.3 3.5 19 13 9 170 257 341 0.5 0.7 1.1 10 7 5 750 4...

Fire coil 85 (500-2000) page 21 volt single-phase power to the terminal marked “120v (l2)” and supply the pump using the terminal marked “l2 load (ext. Pump)”. Note: this pump control is equipped with a delay on break typically set for 3 minutes, but can be adjusted between 0.1 and 10 minutes. Field...

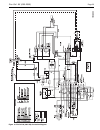

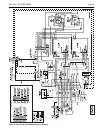

National combustion co., inc. Page 22 figure 18. Fire coil 85 (1250–2000) wiring diagram. Figure 17. Fire coil 85 (1000) wiring diagram..

Fire coil 85 (500-2000) page 23 figure 19. Fire coil 85 (500–750) connection diagram..

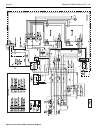

National combustion co., inc. Page 24 figure 20. Fire coil 85 (1000) connection diagram..

Fire coil 85 (500-2000) page 25 figure 21. Fire coil 85 (1250–2000) connection diagram..

National combustion co., inc. Page 26 coil 85 is available with an alarm kit. This alarm kit contains a dry contact for up to 120v which is available within the 120v field wiring panel. These terminals will be clearly labeled "alarm" and are rated up to 10 amps. 5.3 external staging control wiring w...

Fire coil 85 (500-2000) page 27 the controller to the desired operating set point. The controller has an interstage differential that can be adjusted from 3°f to 10°f. This allows the user to have some control over how stage 2 and stage 1 call for heat ( see figure 22 ). Because the fire coil 85 con...

National combustion co., inc. Page 28 note: unit sizes 1000–2000 have two ignition controls and two ignitors, which work independently of one another. If the ignition control for stage 1 fails to properly light the main burners for that stage, the second ignition control will still be active, and wi...

Fire coil 85 (500-2000) page 29 normally occurs, it should be isolated from the system and completely drained of all water. All systems connected to it should also be drained or protected from freezing. 6. Low water cutoffs, if installed, should be checked every 6 months. Float type low water cutoff...

National combustion co., inc. Page 30 combustion air. Determine the cause, and correct. Replace the burners in the reverse order 7.2.2 filter the filter used in the fire coil 85 is washable with an 83% arrestance. Since the filter is washable, it will only need replacement when unwashable, deteriora...

Fire coil 85 (500-2000) page 31 brush or fine water spray before servicing the heat exchanger. The fire coil 85 has a pre-mixed burner system. These systems provide the burners with sufficient air for complete combustion, and black carbon sooting is seldom experienced. If sooting is suspected, view ...

National combustion co., inc. Page 32 functioning properly, then burners should be inspected. There should be no distortion or perforations in the burners outside of the active burner port area. Replace if indicated. 8.3 short cycling — boiler because the fire coil 85 is a stage-fired boiler, and it...

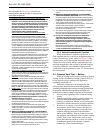

Fire coil 85 (500-2000) page 33 iitem description size size size size size size size 500 750 1000 1250 1500 1750 2000 sheet met al component s – see figure 23 1 panel, jacket, front 5f3320 7f3320 10f3320 12f3320 15f3320 17f3320 20f3320 2 a panel, jacket, side, lower left 5f3420 5f3420 5f3420 5f3420 ...

National combustion co., inc. Page 34 item description size size size size size size size 500 750 1000 1250 1500 1750 2000 32 assembly , copper t ube, heat exchanger 5c4000 7c4000 10c4000 12c4000 15c4000 17c4000 20c4000 assembly , cupro-nickel, heat exchanger 5c4020 7c4020 10c4020 12c4020 15c4020 17...

Fire coil 85 (500-2000) page 35 item description size size size size size size size 500 750 1000 1250 1500 1750 2000 manifold, 4 burner/orifice, left l2012600 l2012600 l2012600 l2012600 (2) (2) (2) (4) manifold, 4 burner/orifice, right l2012700 l2012700 l2012700 l2012700 (1) (1) (1) (2) 54 assembly ...

National combustion co., inc. Page 36 71 cover , return, glass-lined cast iron 10364300 10364300 10364300 10364300 10364300 10364300 10364300 cover , return, bronze 10364301 10364301 10364301 10364301 10364301 10364301 10364301 72 pump housing, glass-lined cast iron s2056900 s2056900 s2056900 s20569...

Fire coil 85 (500-2000) page 37 figure 23. Sheet metal components..

National combustion co., inc. Page 38 figure 24. Internal components.

Fire coil 85 (500-2000) page 39 figure 25. Heat exchanger components. Fire coil 85 hydronic boiler size pump p/n 500 a2001700 750 a2001700 1000 a2001800 1250 a2001800 1500 a2001900 1750 a2001900 2000 a2109700 fire coil 85 water heater size pump p/n soft water normal water hard water 500 a2001700 a20...

National combustion co., inc. Page 40 h2xxxxxx- figure 26. Electrical components. National combustion co. Company reserves the right to change specifications, components, features, or to discontinue products without notice. Ph: 1-888-ok-natco • fax: 718-291-6870 (customer service, applications, tech...