- DL manuals

- National Mower

- Lawn Mower

- I-TRIM

- Owner's Manual

National Mower I-TRIM Owner's Manual

Summary of I-TRIM

Page 1

National mower co. 700 raymond ave., p.O. Box 14299, st. Paul, minnesota 55114-0299, u.S.A. Phone (651) 646-4079 – fax (651) 646-2887 www.Nationalmower.Com march 2006 i-trim owner's manual includes specifications, assembly, operation, maintenance & parts lists.

Page 2

2.

Page 3: Table of Contents

I-trim ® 3 table of contents table of contents ...................................................... 3 introduction ............................................................... 4 safe operating practices ...................................... 4-6 decal (transfer) identification ....................

Page 4

4 introduction read this manual carefully to learn how to operate and maintain your product properly. The information in this manual can help you and others avoid injury and product damage. The operator is responsible for operating this product properly and safely. This manual identifies potential h...

Page 5

I-trim ® 5 operation • do not operate the engine in a confined space where dangerous carbon monoxide fumes can collect. • operate only in daylight or in good artificial light. Stay alert for holes in the terrain and other hidden hazards. • before attempting to start the engine, disengage all blade a...

Page 6: Important

6 warning– california, usa residents are required by law (ca prc 4442 & ca h & sc 13005) to equip their engines with spark arresters when operating in flammable vegitation. Arresters must be obtained from your engine dealer and are not available from national mower company. • be careful during adjus...

Page 7: Decal Identification

I-trim ® 7 decal identification national has provided decals in many locations throughout the machine to aid the operator in identifying, controlling and operating the i-trim safely and correctly. It is important that all decals are clean and visable at all times. Replace decals that are damaged, mi...

Page 8

8 f g h j i.

Page 9

I-trim ® 9 item part no. Description / location a 07792 i-trim model / left and right sides of operator panels b 07794 natinal logo / top of rear hood c 07793 national name / front of steering column d 07797 diesel fuel / top of fuel tank e 07796 hydraulic fluid / top of hydraulic tank f 07778 warni...

Page 10: Introduction

10 introduction this manual has been prepared by national mower company as an aid to users for set up, operation and servicing and ordering replacement parts. Additional information will gladly be furnished by calling or writing the company. Please furnish us with the model number, serial number and...

Page 11: 1—Specifications

I-trim ® 11 1.1—engine specifications type: 3 cylinder turbocharged diesel engine model: briggs & stratton 954 dt horsepower: 34 hp cooling: water cooled 1.2—transmission traction drive: oilgear variable displacement hydrostatic pump wheel drive char lynn hydraulic motors motors: with disc-parking b...

Page 12: 2—Assembly Instructions

12 figure b 2—assembly instructions 2.1—tractor assembly handle banding material with caution. Use heavy leather gloves. Banding is sharp! The side and rear lift arms are spring-loaded up. Take care when handeling. 1. Remove crating top, front and sides from the tractor crate. Cut banding from roll-...

Page 13

I-trim ® 13 2.4—deck motors and blades the i-trim is available with standard or mulch- ing blades. The rear/right decks require a rh blade and the left deck uses a lh blade. Mulching blades rear/right -p/n 306245 (stamped 306245) left -p/n 306311 (stamped 306311) straight blades rear/right - p/n 306...

Page 14

14 1. Remove rear rh wheel to replace battery. Install battery with side mount terminals facing toward engine. See fig f. 2. Place battery hold down strap over bolts and secure with flat washers and hex nuts. Do not over-tighten. 3. Connect the red ignition wire to the positive (+) terminal of the b...

Page 15: 3—General Information

I-trim ® 15 3.2—traction drive train power from the engine is transmitted by direct drive to the variable displacement pump. The pump supplies hydraulic fluid to the hydraulic motors. 3.3—mower deck drive hydraulic power to the deck motors is actuated by electric switch mounted on the rh control pan...

Page 16: 4—Controls

16 battery charging oil pressure low water temperature water in fuel glow plug on 4.3—hour meter the hour meter (2,fig. J) indicates the number of hours the tractor has been operated. It can be used to keep track of maintenance intervals and the amount of time required to perform various tasks. The ...

Page 17

I-trim ® 17 4.4—throttle lever push throttle lever (4, fig. J) forward to increase engine speed, pull back to decrease the engine speed. Position throttle at full throttle or slightly less for optimum power and deck speed during mowing. 4.5—traction pedal the traction pedal (5, fig. J) operates the ...

Page 18: 5—Operation

18 5—operation 5.1—check list 1. Fill the fuel tank with good quality, clean, diesel with a minimum of 40 octane. Fresh fuel prevents gum from forming in the fuel system. Fill tank to 1 inch (25 mm) below filler neck. Do not overfill. 2. Check oil in the engine crankcase. It should be filled to the ...

Page 19

I-trim ® 19 5.4—mowing operation 1. Check the turf area for debris that would cause damage to the decks. Never operate the decks when they are in the up position because of the danagers of flying objects and exposed blades. 2. When cutting large areas, the most satisfactory method is to first cut th...

Page 20: 6—Adjustments

20 6.2—parking brake adjustment the parking brake should be set so that it holds the tractor securely. The parking brake must be released before the traction pedal is engaged. 1. Adjust the brake by loosening set screw in the brake knob and turning knob clockwise to tighten, or counterclockwise to l...

Page 21

I-trim ® 21 6.4—rear mower lift the rear mower lift height has been preset at the factory and normally will not need to be adjusted. The i-trim may be fitted with a needle valve on the rear lift cylinder. Turning the needle valve cw will slow the lift and lowering speed of the rear deck. Always lock...

Page 22: 7—Maintenance

22 3. When the battery is being installed or removed make sure that the positive and negative terminals do not come in contact with metal tractor parts at the same time or severe damage may result. 4. Battery connections must be kept clean and tight at all times. Loose cables will cause eventual bat...

Page 23

I-trim ® 23 7.4—charging a battery to avoid possible injury, stand away from battery when charger is turned on. A damaged battery or a battery with an internal short could explode charge battery only in a well verted location, away from sparks or open flame. 1. Remove the battery from the tractor be...

Page 24

24 1. Remove the old filter 2. Install new filter, filling filter with oil before re-installing. Apply oil to the o-ring of the filter prior to installation. Hand tighten only. 3. Run engine at idle speed with hydrostatic pump in neutral for five minutes. 4. Check hydraulic oil level and add oil if ...

Page 25

I-trim ® 25 this page is blank.

Page 26

26 1 daily dipstick / left side of engine check level 1 2 daily radiator reservoir bottle check level 1 3 daily hydraulic tank check level 1 4 daily fuel tank check level 1 5 daily* pre-air filter inspect/clean 1 6 daily* screenbox, radiator fins/ rear inspect/clean 1 7 weekly height adjustment shaf...

Page 27

I-trim ® 27 18 19 21 7 14 7 7 13 17 1 2 7 7 3 9 5 15 7 7 7 7 4 12 12 12 20 12 12 22 12 7 5 11 10 6 8 8 8 8 16 23.

Page 28: 8—Storage

28 8—storage 8.1—general instructions when you do not plan to use your vehicle for some time, it should be stored in a dry and protected place. Unnecessary exposure to the elements may deteriorate its appearance and shorten the usual service life. 8.2—engine 1. Drain the fuel from the fuel tank. 2. ...

Page 29: 9—Trouble Shooting

I-trim ® 29 9—trouble shooting engine will not start the operator must be seated. Check position of controll switch (on dash). Switch must be in the off position. Check to see that the traction pedal is in neutral. (neutral is in the center position). Check all safety switches for conductivity. See ...

Page 30

30 9. Safety interlock board (sib): the itrim is equipped with an integrated circuit board designated as the safety interlock board (sib). The sib controls the vehicle starter cranking, engine run and deck run circuits and the indicator lights. The starter motor won’t crank unless the following cond...

Page 31

I-trim ® 31 if no lights come on and fuse is good and there is power to the board: 1. Make sure sib is grounded by checking the resistance between the capacitor ground on the sib and the vehicle frame. Resistance should be 0. If sib is not grounded: 1. Check the resistance between terminal j1-7 on t...

Page 32

32 problem: starter cranks but engine won’t start check the electrical system after checking for fuel in the tank and after priming the fuel system. Using a test light with the ignition switch in the on position, check for power at the fuel pump connector on the engine. If test light comes on: make ...

Page 33

I-trim ® 33 - - - + + + + 9 5 7 3 1 8 10 ji 6 4 2 4 j3 j2 j4 relay seat gro und cap a cito r relay pedal relay blade relay run relay buzzer 3 li ght (4 ) indicat o r relay 2 1 7 5 3 1 8 6 4 5 3 1 6 1 2 3 4 j3 j2 j4 4 3 2 1 5 6 6 5 1 2 3 4 7 8 temp batt water fi lt fu el pl ug glo w pr es s j1 oil 4 ...

Page 34

34.

Page 35

I-trim ® 35.

Page 36

36 figure 1 23 4 5 3 6 7 8 9 10 11 12 13 15 16 19 20 2 1 18 21 17 22 24.

Page 37

I-trim ® 37 figure 1—screen box, guards, rops, misc item no. Q ty. Part no. D escription 1 1 306435 weldment - side cover, lh 2 1 07063 hour meter 3 5 07697 led 4 1 306341 panel - instrument, lh 5 1 203086 throttle control 6 1 306162 weldment - bumper plate 7 1 306298 cover - steering tower 8 1 3059...

Page 38

38 figure 2 7 1 5 6 8 9 10 11 6 12 15 16 1 2 9 17 18 19 20 21 22 23 24 25 26 18 27 28 2 2 30 31 29 13 23 32 32 13 6 2 3 4 4.

Page 39

I-trim ® 39 figure 2—deck lift arms and pull arms it e m n o . Q ty. P art no. D escription 1 2 07719 bushing - 1x1.5x2, boston #b1624-16 2 5 02511 thrust washer 3 1 02263 hex nut 3/8-24 nylock 4 3 02403 flat washer - 3/8 sae 5 1 07709 lift cyl - wing deck 6 10 204447 bushing - pull arm 7 1 02036 he...

Page 40

40 figure 3 27 1 2 4 6 8 10 11 12 5 13 14 16 17 18 19 20 21 22 23 24 25 9 7 3 15 28 26.

Page 41

I-trim ® 41 figure 3— seat, wheels, engine, radiator, hyd tank it e m n o . Q ty. P art no. D escription 1 1 306195 weldment - hydraulic reservoir 2 1 305497 strainer 3 1 07316 strainer 4 1 07783 cap & fill tube - hydraulic tank 5 1 b&s 820263 filter - air cleaner, cartridge 6 1 306421 hot air defle...

Page 42

42 figure 4 4 1 2 26 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 27 28 29 3 29.

Page 43

I-trim ® 43 figure 4—wheel motors, filters, hyd components it e m n o . Q ty. P art no. D escription 1 1 07688 steering filter 2 1 07690 steering valve 3 1 07689 filter element 4 1 306357 brkt - lift valve, lh 5 1 07692 lift valve, 6 1 306356 brkt - lift valve 7 1 305034 filter canister, hydraulic 8...

Page 44

44 figure 5 16 4 6 2 7 10 11 13 11 14 11 13 11 15 11 8 11 15 8 21 17 7 18 19 5 3 1 2 6 22 20 8 8 12 12 21 9.

Page 45

I-trim ® 45 figure 5—pedal assy, hyd pumps.

Page 46

46 figure 6a figure 6b.

Page 47

I-trim ® 47 figure 6a — front axle, fuel tank, and frame figure 6b - front wheel assy.

Page 48

48 23 1 2 3 4 5 6 7 9 10 13 14 18 6 22 20 12 19 11 21 8 15 16 17 24 figure 7—engine and radiator assembly figure 7 note: contact briggs & stratton for p/ns starting with b&s.

Page 49

I-trim ® 49 32 3 15 27 7 8 2 2 8 27 6 26 25 10 11 24 16 17 18 12 22 21 20 19 23 25 5 9 4 1 13 28 29 30 31 32 33 32 31 33 item no. Qty. Part no. Description 1 1 306171 weldment - deck platform rr 2 2 306064 weldment - front roller axel 3 1 306074 weldment - blade holder 4 2 306067 weldment - rear rol...

Page 50

50 34 35 22 14 15 2 32 9 29 11 7 28 26 36 25 10 8 28 3 21 29 23 1 4 13 24 18 19 20 12 23 22 25 21 28 6 5 27 16 30 31 33 36 35 34 35 item no. Qty. Part no. Description 1 1 306058 weldment - caster axel 2 1 306074 weldment - blade holder 3 1 306170 weldment - caster pivot mount rh 4 1 306169 weldment ...

Page 51

I-trim ® 51 28 7 11 30 9 18 3 5 6 22 26 23 24 12 13 25 19 20 21 2 24 23 22 26 28 30 8 10 4 27 28 29 14 34 1 15 16 32 31 36 35 33 34 35 35 36 figure 10—left hand mower assembly * item no. Qty. Part no. Description 1 1 306107 weldment - l deck platform 2 1 306108 weldment - caster pivot mount 3 1 3060...

Page 52

52 figure 1 1 39 4 7 1 27 36 10 34 14 31 8 3 28 22 6 23 11 17 11 5 24 29 19 9 37 20 15 25 30 2 18 32 24 26 24 26 12 15 11 28 15 28 32 28 28 32 26 2 33 16 35 13 13 11 21 38 13 40 12 08/22/05.

Page 53

I-trim ® 53 figure 11—hydraulic decks and oil cooler item no. Qty. Part no. Description 1 1 306195 weldment - hydraulic reservoir 2 2 305737 deck motor - r, rear decks, ccw 3 1 305736 deck motor - l deck cw 4 1 305037 base - hydraulic filter 5 1 07691 deck valve manifold assy 6 1 07692 lift valve, 7...

Page 54

54 figure 12 39 4 7 1 27 36 10 34 14 31 8 3 28 22 6 23 11 17 11 5 24 29 19 9 37 20 15 25 30 2 18 32 24 26 24 26 12 15 11 28 15 28 32 28 28 32 26 2 33 16 35 13 13 11 21 38 13 40 12 08/22/05.

Page 55

I-trim ® 55 figure 12—hydraulic wheel motors, steering.

Page 56

56 item part no. Description qty. 1 07063 hourmeter 1 2 07697 led lights on instrument 5 3 07065 keyswitch 1 4 07496 switch, deck motor 1 5 07695 relay, starter solenoid 1 6 07700 circuit breaker 1 7 b&s 820373 time delay module-glowplug preheat 1 8 07695 relay, glow plug 1 9 07716 safety interlock ...

Page 57

I-trim ® 57 1 07501 seal kit (includes all of below) 1 2 --------- o-ring, 1-1/4” 1 3 --------- wear ring, 1.5” x .38” wide 1 4 --------- washer 1 5 --------- crown seal, 1.5” 1 6 --------- o-riing 1 7 --------- o-ring 1 8 --------- wiper 1 figure 14—steering cylinder, 204382 item part no. Descripti...

Page 58

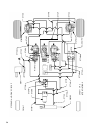

58 07742 306195 07740 07741 07737 07743 07752 07749 07739 07685 07686 07746 07691 07734 left side 204382 07735 07690 07738 07688 07736 dte 07/07/05-2 a sheet 1 of 2 07748 07693 07750 top view steering and drive circuit right side front 07693 07744.

Page 59

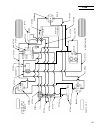

I-trim ® 59 306195 07768 07754 07753 07758 circuit 07692 07759 07755 mower drive and deck lift 07756 07709 07710 sheet 2 of 2 07760 a dte 07/07/05 3005037 07761 07757 07767 306005 07766 306004 07765 306004 top 07764 07763 07762 07691 rear bottom 07683 07769.

Page 60

60

Page 61: National Mower Company

I-trim ® 61 national mower company two year limited warranty for i-trim mowers for the period of two years from the date of purchase, or 1,500 hours, whichever occurs first (45 days if the product is used for rental purposes), national mower company will repair or replace free of charge, for the ori...

Page 62

62.