- DL manuals

- Nature's Comfort

- Boiler

- GT-6000

- Installation And Operating Manual

Nature's Comfort GT-6000 Installation And Operating Manual

Installation and Operating Manual For

GT-6000 Downdraft Gasification

Non-Pressurized Outdoor Wood Boiler

Manufactured by Nature’s Comfort LLC.

Made In The USA

Built Like A Tank

With Laser Precision

Full color and French manual available online at: / Couleur et manuel en français est disponible en ligne à:

www.naturescomfortllc.com

Revision 2012-1.3

Tested May 2012 to CSA-B366.1-2011 & UL 2523-2009

SAVE THESE INSTRUCTIONS!

Summary of GT-6000

Page 1

Installation and operating manual for gt-6000 downdraft gasification non-pressurized outdoor wood boiler manufactured by nature’s comfort llc. Made in the usa built like a tank with laser precision full color and french manual available online at: / couleur et manuel en français est disponible en li...

Page 2: Itroductio

Itroductio thank youand congratulations on the purchase of your new nature’s comfort gt series high efficiency downdraft gasification boiler! With the purchase of this nature’s comfort boiler, you can now appreciate the high degree of craftsmanship and reliability that are a result of every boiler b...

Page 3

Table of contents i. General information a. Terminology .....................................................................................4 b. Clearance to combustibles required ..................................4 c. Boiler dimensions & specs .........................................................

Page 4

Page 4 of 30 i. General information a. Terminology in this manual boiler: refers to the nature’s comfort gt boiler. Furnace:refers to the existing indoor gas or oil fired unit which heats the air or radiant water heat for the home. B. Clearance to combustibles required top, front, rear and sides: 36...

Page 5

Page 5 of 30 d. Safety precautions do not operate this equipment for anything other than its intended purpose or for anything other than in accordance with the instructions contained in this manual and all other instructions accompanying the boiler. It is important to observe safety precautions to p...

Page 6

Page 6 of 30 e. Controls & plumbing connections the gt boiler uses a hot water thermostat (aquastat) with a sensor that is inserted into a brass drywell for sensing the water temperature of the unit. When the temperature falls below the differential setting on the aquastat, the blower turns on and t...

Page 7

Page 7 of 30 f. Heating the home the gt series boiler saves energy and provides the most comfortable heating available. It heats the home by burning seasoned hardwood in 2 stages to heat a firebox (1 st burn stage), refractory channel (2 nd burn stage) and heat exchanger tubes surrounded by a steel ...

Page 8

Page 8 of 30 iii. Installing boiler installation is to be performed by a qualified installer and shall comply with all the requirements of the authority having jurisdiction over the installation. A. Location of boiler the gt boiler must be located to comply with the clearance requirements. Keep the ...

Page 9

Page 9 of 30 b. Chimney: a 6” stainless steel rain cap must be purchased separately for installation and can be obtained from nature’s comfort or your dealer. The person operating the unit is responsible for operating in a manner that does not create a public nuisance condition. The recommendations ...

Page 10

Page 10 of 30 d. Plumbing hook up plumbing connections should be well insulated after installation. Cover bottom access holes as well. Minimum pipe size permitted is 1”. Install the outgoing pex line on the pump flange that is already mounted to the lower end of the circulation pump. Install the ret...

Page 11: Verticle Tube Placement:

Page 11 of 30 and bounce the door/ash pan closed, then leave open to fully cure before starting a fire to get a custom, long term seal. Note! Adjust fuel door if you ever see any amount of smoke. See maintenance section. Door adjustment is done at the factory but may be required again after installa...

Page 12

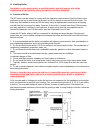

Page 12 of 30 g. Forced air systems - thermostat wiring the next example drawings are for controlling the blower on a forced air system independently of the existing heat source (i.E. Propane, electric, fuel oil, etc). Nature’s comfort can provide custom diagrams for other types of control setups as...

Page 13

Page 13 of 30 h. Adding bypass valves adding a bypass valve system (3 valves, 2 t’s and unions) at each heat exchanger is a good idea so that if there is a potential problem such as a stopped up heat exchanger, it can be diagnosed & serviced easily as well as being used for a summer bypass as explai...

Page 14

Page 14 of 30 slide the heat exchanger into the hole for a test fit. Ideally the header and tubes (f) should stick out of the plenum. While test fitting try to determine how much tape is needed around the frame of the heat exchanger to seal and keep air from flowing around it. A different amount (th...

Page 15

Page 15 of 30 crimp the sheet metal to the edge of the heat exchanger (item g) using channel-lock pliers. This not only forms a virtually airtight seal, but also supports the heat exchanger as well. K. Adjusting plenum air flow the motors on most force air furnaces have three speeds to provide vario...

Page 16

Page 16 of 30

Page 17

Page 17 of 30 m. Filling the gt boiler with water once all piping connections are complete, flush about 20 gallons of water into the float stack and drain, repeating until it comes out clean. Close drain valve and pour nature’s comfort boiler treatment in – required for warranty. Fill the boiler wit...

Page 18

Page 18 of 30 b. Heating a pool or spa please contact a local pool/spa specialist if this boiler is to be used to heat a pool or spa. A stainless steel (or 90/10 copper/nickel alloy) tube & shell water-to-water heat exchanger must be used to transfer heat from the boiler to a pool or spa since the c...

Page 19

Page 19 of 30 iv. Operation a. Wood requirements 20% moisture content or lower is required for a gt boiler to achieve proper gasification. Using unseasoned (“wet” or “green”) wood causes cooler burning temperatures preventing gasification and severely reducing efficiency, causing the boiler to plug ...

Page 20

Page 20 of 30 c. Loading wood caution! Doors, covers, coals & ashes are hot! Wear safety glasses and use heavy gloves. Caution! Never open fuel door without first turning off the boiler at the front or rear switch and allow idling for at least 10 minutes before opening or flame spillage may occur! C...

Page 21

Page 21 of 30 v. Maintenance a. Cleaning wear heavy gloves and clothing and safety glasses as metal, firebrick and ashes will be hot. Moisture combined with ash will eat through a boiler in short order and ash corrosion is not covered under warranty. Clean ash out frequently enough to prevent any “c...

Page 22

Page 22 of 30 experience on how often cleaning is necessary (varies by operation, heating demand and wood quality). Creosote occurs on a larger scale when there is too much moisture content in the wood being used (green, un-seasoned wood) or from extended idling during milder weather. D. Actuator ba...

Page 23

Page 23 of 30 installing rope on bolted covers (1” round or 1/2” round) upper covers: install 1” round rope seal with a ½” bead of high temperature caulk behind it to glue the rope in place. Make sure to push the rope to the outside of the corners to mate properly with the jamb (do not stretch the r...

Page 24

Page 24 of 30 causing oscillation (vibration). Scale buildup happens if the water has too much hardness and is something that is greatly accelerated if the water does not have the proper amount of treatment. Vibration can lead to fracturing and breaking of the shaft and is not covered under warranty...

Page 25

Page 25 of 30 going away when going away during freezing weather and no one will be keeping the boiler going, turn the backup heat system on, the rear control switch off and keep the circulation pump running. The boiler will now operate in reverse heat being kept above freezing by the backup system ...

Page 26

Page 26 of 30 trouble shooting problem cause solution boiler does not come up to temperature. Green or soft wood is being used, coals are not being pushed over holes before loading use dry, hard wood keep hot coals pushed over holes in floor the boiler is at temperature and is steaming poor water ci...

Page 27

Page 27 of 30 copy of safety labels.

Page 28

Page 28 of 30 20 year limited warranty nature's comfort llc, of shipshewana, in 46565 warrants material and labor on any defects in workmanship on the fire drum for a period of 20 years from the purchase date to the original owner only (see proration below) and on the water jacket for a period of 10...

Page 29

Page 29 of 30 customer warranty card please fill in the following information and keep for future reference. Name: ___________________________________ (first) (last) address: ___________________________________ (street) ___________________________________ (city) (state) (zip) phone: _________ ______...

Page 30

Page 30 of 30 warranty registration card - to be mailed in all fields must be filled out name: _________________________________________________________________ (first) (middle) (last) address: _________________________________________________________________ (street) _______________________________...