Nautilus Be Strong Commercial Series U916 Manual

Summary of Be Strong Commercial Series U916

Page 1

Be strong. ® 003-3376-060309a rework manual commercial series bike u916.

Page 2: Table of Contents

Table of contents products affected and requiring work………………………………………………………3 tools required………………………………………………………………………………………..3 parts………………………………………………………………………………………………………4 parts list………………………………………………………………………………....................6 hardware………………………………………………………………………………………………..7 assembly……………………...

Page 3: Tools Required

Products affected and requiring rework u916 upright bike product sku made in serial numbers domestic 380000 taiwan all domestic 380000 usa 38000070913007-38000081201012 international 380001 taiwan all international 380001 usa 38001071030004-38001081215048 global 100155 taiwan 100155acu09030001-10015...

Page 4

Item pn description qty r bike kit u bike kit 1 002-6845 shroud spacer 1 2 41375-021 d51 display firmware 1 firmware 3 002-6840 intermediate hub assembly 1 4 000-6432 belt, alternator, u/r916 1 5 000-6214 assembly, overmold, intermediate 8v pulley 1 6 sm40329 flywheel, cast, 5300 1 4.

Page 5

7 003-4716 spacer, seat, r916 4 8 902-4274 scw-ghcs m8x1.25x25 ss 1 9 902-4141 nut nl m8-1.25 g2 blkz 3 10 902-4140 nut nl m6-1.0 g2 blk z 2 11 002-6858 u916 rework sticker - blue 1 12 003-3375- 060309 r916 rework manual 13 003-3376- 060309 u916 rework manual 5.

Page 6

Parts list / box contents parts list / box contents h ref # description qty a console 1 b console mast 1 c main frame 1 d seat assembly 1 e handlebar 1 f right mast shroud 1 g left mast shroud 1 h water bottle holder 1 i hardware pack (not shown) 1 a b c d e f g 6.

Page 7

Hardware and tool list hardware bag - note: illustrations are not to scale. The hardware bag contains the following individual parts and tools. Ref #1 allen head bolt m10x25 qty. 4 ref #2 spring washer m10 qty. 4 ref #3 flat washer m10 qty. 4 ref #8 phillips head screw #10-32 x 3/4” qty. 6 ref #4 ph...

Page 8

Step 1: locate the following for this step: parts: s console mast (b) s seat assembly (d) hardware: s ref #1 allen head bolt m10x25 qty. 4 s ref #2 spring washer m10 qty. 4 s ref #3 flat washer m10 qty. 4 tools: s 8mm allen wrench 1-1 connect the attached long wire tie (l) to the main and tv cables ...

Page 9

Assembly guide step 2: locate the following for this step: parts: s handlebar (e) hardware: s ref #6 allen head bolt m8x20 qty. 4 s ref #7 spring washer m8 qty. 4 tools: s 6mm allen wrench 2-1 connect the attached long wire tie (l) to the handlebar cables (m) and use it to pull the cables out throug...

Page 10

Assembly guide step 3: locate the following for this step: parts: s display console (a) hardware: s ref #4 phillips head screw 1/4”x20 qty. 4 s ref #5 spring washer m6 qty. 4 tools: s phillips head screwdriver 3-1 plug the main console wire (q) into the large connector labeled j5 (large connector) o...

Page 11

Perform ftware upgrades on all c51/52 consoles / controllers using a fisp dongle. Ed: software upgrade programming instructions tread and non-tread c51 and c52 console/controllers – using the field in-system programmer (fisp) dongle occasionally it will be necessary to reprogram the console if there...

Page 12

With the corresponding side of the f.I.S.P. Dongle. F the ribbon ack of the c5x console/controller. Plug the f.I.S.P. Into the back of the console/controller. Note: if f ong way. Make sure it is oriented correctly. Tly. If the f.I.S.P. Led still does not turn on, replace the f.I.S.P. Programming rib...

Page 13

If the led turns red, it indicates a failed program sequence. If this happens, try the above process again. Ing cable from the console/controller. Power does not need to be turned off prior to removing the cable. . The c5x console/controller should display the machine configuration, status, and then...

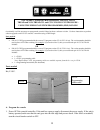

Page 14: Sheild Spacer Installation

Sheild spacer installation step 1: remove the left cover. Using a phillips head screwdriver remove the left cover. Step 2: adding spacer to standoff. Push the right side cover away from the frame, add part 002-6845 to the standoff as shown in the picture. Add a drop of ca adhesive to part 002-6845 b...

Page 15: Pulley Replacement

Intermediate hub assembly, belt and pulley replacement mediate shaft. Step 1: remove the belt and black intermediate pulley. Remove the four 902-5665 screws from the ediate shaft 5mm hex wrench, this will allow the belt to removed as well. Interm using a step 2: removing pulley from the inter remove...

Page 16: Step 3:

Step 3: removing pulley and external snap ring. Remove pulley 000-6214 from intermediate shaft with puller or pry bar. Step 4: removing intermediate shaft. Beware of sharp edges on intermediate shaft. Remove external snap ring from intermediate shaft located behind 000- 6214 pulley. Using a rubber m...

Page 17: Step 5:

Step 5: installing new intermediate shaft. Ediate shaft. Pulley. Step 8: reinstalling the belt. Step 6: reattach the snap ring to the interm start shaft into bearing housing, make sure the shaft is inserted straight or it will bind, using a rubber mallet tap the shaft through the bearings until snap...

Page 18: Step 9:

Reverse the process described in step 4 reinstall the crank drive belt. Step 9: attach new intermediate pulley and torque to 20 ft lbs. Step 10: reinstalling the belt. 000-6214 intermediate pulley, (4) 902- 5665 screws, and (4) 27579 lock washers. Hand start the screws and washers into the pulley. T...

Page 19: Step 12:

Step 12: step 11: reattach cover. When the belt is installed correctly there is a groove visible on each side of the pulley. 19.

Page 20

Document #: sm-qty-f-133 rev. Level: c release date: 7/23/08 page 1 of 2 subject: u/r916 final goods inspection check sheet check powder coat on all parts for bare metal, light coverage, etc. (per sm-qty-g-030) check pedals and cranks for scratches, damage, etc. Verify crank nuts secure verify all s...

Page 21

Document #: sm-qty-f-133 rev. Level: c release date: 7/23/08 page 2 of 2 reinstall shrouds f inal i nspection check shrouds for scratches, cracks, cleanliness, proper fit, etc. Verify shroud mounting hardware secure verify pedals secure after shrouds installed run test after shrouds installed to ens...

Page 22

Desc: final packaging quality note: remove handle bar from mast being careful in pulling the wires out of the neck. Screws are used over and new mounting screws are placed in hard ware kit. Wrap quick silver around mounting and where wires handle bar is mounted. Wrap quick silver around chr grips. 2...

Page 23

Place handle bar in xxx bag. Place wrapped handle bar in carton wrap console in bubble wrap and place in box. Close up box. Close and tape shut the carton. The carton will be put in with the bike at later time. Break screws loose. 23.

Page 24

Use dewalt to remove screws holding mast. Use care when pulling wires thru mast off. Pull wire tie back through and reattach the customer pulls the cables up the mast. Get 000-4897 bag and place over mast. 24.

Page 25

Place mast in carton. Remove seat from bike. Get 000-4897 bag and place over seat assembly. 25.

Page 26

Place seat post in carton and block with foam from the console. Wrap up cables and stuff into the mast mounting opening using care not to cut insulation on cables. Wrap quick silver on legs and pedals. 26.

Page 27

Get bag 17885 and place over bike. Get 002-0587 tube and place over bike. Place hardware bag in carton with mast and fold top down and tape. 27.

Page 28

Place battery charger in carton. Intl 21756 dom 002-0677 close carton and tape. Place handle bar and console box inside tube. 28.

Page 29

Place mast and hardware bag on top of mast and console box. Get (4) 2x4 upright supports and place in box on both ends. Get (2) cross boards and place on supports. Place seat carton inside tube. 29.

Page 30

Staple 2x4 upright supports to side of box using bostich gun 1 ½ staples gun. Close carton and staple top flap staple (4) xxx corner protectors to carton. 30

Page 31

Band box shut on both ends. Place bands where the upright supports are in box. 31.

Page 32: Appendix

Console firmware upgrade to v21 using fisp setting up the fisp for one or two device programming there are various versions of the fisp windows application in use, the earliest versions do not have as many features as the later and the first step toward successful programming the fisps will be to ac...

Page 33

The multi-build fisp load screen should look something like this: -or- 33.

Page 34

For single device loads (not recommended), it’s more versatile to do a mult-device load: at this point some important information is seen on the screen and the setup procedure follows: 1- connect the supplied usb cable to power up the device ( do not connect the fisp to the target or device to be pr...

Page 35

9- clear the data transfer window and verify the programs were loaded correctly. “click” on fisp at the top off the window (not bottom) and select verify fisp. The below screen should be seen (note the “ok” on the verifying lines): 10- clear the data transfer window and disconnect the fisp, from the...

Page 36

Be strong. ® for more information about our commercial series exercise equipment or other nautilus ® equipment for your home, visit www.Nautilus.Com. © 2008 nautilus, inc. All rights reserved. Nautilus, the nautilus logo, remote operation control, be strong are either registered trademarks or tradem...